Question 62 UFIV01 - Chief Engineer - UFIV

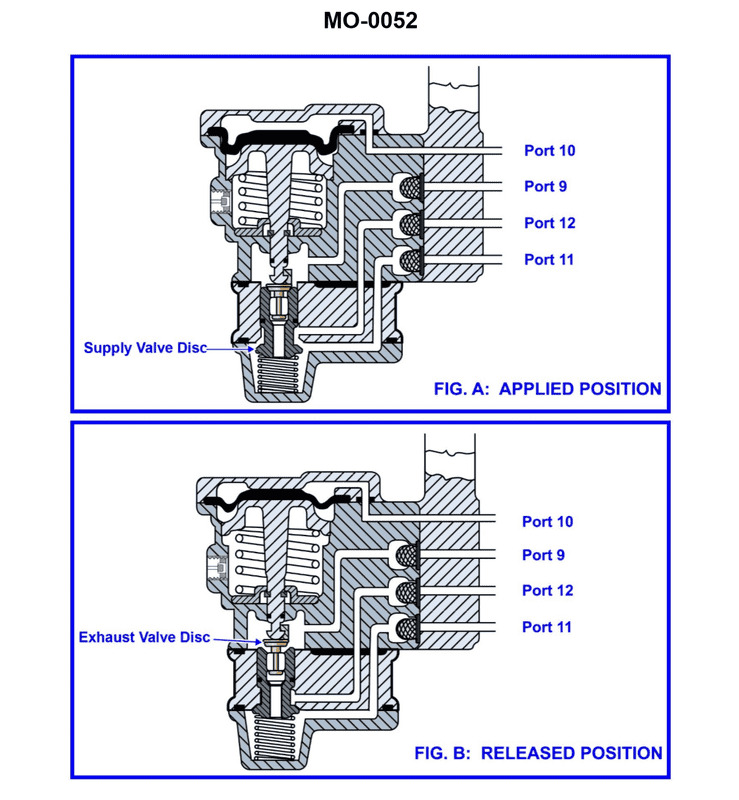

The pneumatic propulsion control system used on your fishing factory ship uses a diaphragm-operated relay valve as shown in the illustration. Periodically, the valve is to be disassembled for cleaning and inspection. What statement best describes the proper technique? Illustration MO-0052

The Correct Answer is D ### Explanation of Why Option D is Correct Option D states: "Rubber parts such as the diaphragm should be washed with soap and water, and metal parts such as the valve discs and seats should be cleaned with non-flammable solvent." This technique is the standard and safest procedure for maintaining pneumatic control components because it respects the chemical compatibility requirements of the different materials: 1. **Rubber Diaphragms:** Diaphragms are precision components, often made of synthetic rubber or specific elastomers. Exposure to harsh chemical solvents (even non-flammable ones like mineral spirits, acetone, or heavy degreasers) can cause the rubber to swell, harden, soften, or leach out plasticizers. This damage leads to operational failure, compromised sealing, or changes in the diaphragm's flexibility, resulting in improper valve actuation. Mild soap and water (detergent solution) is the recommended gentle cleaner for removing dust, grime, and environmental contaminants without affecting the material’s integrity. 2. **Metal Valve Discs and Seats:** These metal surfaces accumulate hardened deposits, oil residue (from compressor lubricant carryover), and fine particulate matter. Soap and water are often insufficient to remove petroleum-based contaminants or light corrosion. A non-flammable solvent is required to thoroughly dissolve these residues, ensuring the critical seating surfaces are perfectly clean before reassembly, which is vital for leak-free operation. ### Explanation of Why Other Options Are Incorrect * **A) Rubber parts such as the diaphragm and metal parts such as the valve discs and seats should all be washed with soap and water.** * **Incorrect:** While safe for the rubber, soap and water may be inadequate for properly cleaning oil, grease, and stubborn deposits from the precision metal valve discs and seats, leading to operational sluggishness or leakage upon reassembly. * **B) Rubber parts such as the diaphragm should be cleaned with non-flammable solvent, and metal parts such as the valve discs and seats should be washed with soap and water.** * **Incorrect:** This reverses the appropriate procedures. Using a solvent on the rubber diaphragm risks irreversible chemical damage (swelling, softening, degradation). Using only soap and water on the metal seating surfaces is often insufficient for proper decontamination. * **C) Rubber parts such as the diaphragm and metal parts such as the valve discs and seats should all be cleaned with non-flammable solvent.** * **Incorrect:** This is the most damaging option for the diaphragm. Solvents are highly likely to degrade or swell the rubber components, compromising the valve’s function and necessitating immediate component replacement.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app