Question 61 UFIV01 - Chief Engineer - UFIV

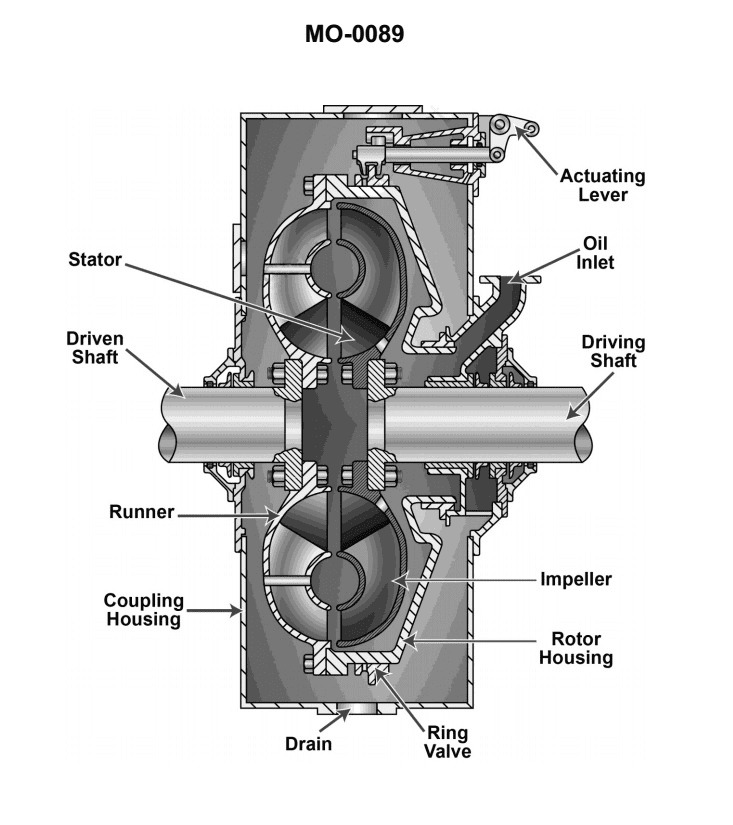

The fishing trawler to which you are assigned is fitted with hydraulic clutches similar to that shown in the illustration. If the time required for the clutch to disengage is unacceptably long, which of the following conditions would most likely be responsible for this? Illustration MO-0089

The Correct Answer is D **Explanation for D (Solid contaminants are present in the hydraulic fluid):** A hydraulic clutch system relies on the precise movement of fluid and components (like valves, pistons, and restricted orifices) to engage and disengage the clutch. If solid contaminants (dirt, metal shavings, degraded seal particles) are present in the hydraulic fluid, they can cause several problems that delay disengagement: 1. **Sticking Valves:** Contaminants can prevent spool valves or directional control valves (which control the flow of fluid to engage or release the clutch pressure) from moving freely or seating properly. 2. **Clogged Orifices/Lines:** Hydraulic clutches often use restricted orifices or narrow passages to control the rate of fluid release (damping). Contaminants can partially or fully clog these areas, preventing the pressurized fluid from draining quickly, thus slowing the disengagement process. 3. **Piston Drag/Sticking:** Contaminants can interfere with the smooth movement of the actuating piston, causing it to stick or move sluggishly, delaying the release of pressure on the clutch plates. Therefore, solid contaminants are the most likely cause of an unacceptably long disengagement time (sluggish release). **Explanation for Incorrect Options:** **A) Fluid clutch sump level maintained at too high a level:** While maintaining the fluid level too high can cause issues like foaming, aeration, or excessive drag/heat generation, it generally does not directly cause a mechanical delay in the *disengagement* speed of the clutch itself, as the speed is governed by the rate of pressure release through the control valves and lines. **B) Clutch operating fluid is maintained at too low a temperature:** Low temperatures increase the viscosity of the hydraulic fluid. High viscosity would generally make the fluid move slower through the system, potentially slowing down both engagement and disengagement. However, compared to mechanical interference from solid contaminants, this effect is usually less severe and is often compensated for by system design or warmup procedures. It is a potential cause, but solid contaminants are a more common and severe culprit for "unacceptably long" delays. **C) Clutch operating fluid is maintained at too high a temperature:** High temperatures decrease the viscosity of the hydraulic fluid (making it thinner). Low viscosity fluid flows faster. While excessively high temperatures can damage seals and lead to premature failure, making the fluid thinner would tend to *speed up* (not slow down) the flow rate, potentially leading to faster, harsher engagement/disengagement, or slippage—the opposite of a sluggish disengagement time.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app