Question 37 OSE02 - Assistant Engineer - OSV

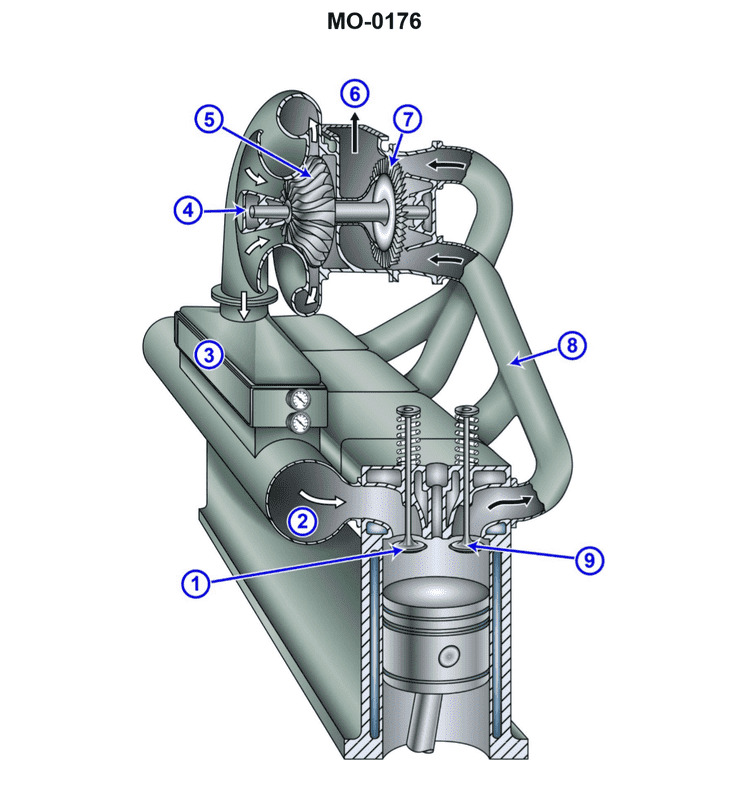

The anchor handling supply vessel to which you are assigned has diesel generator engines fitted with intake and exhaust systems as shown in the illustration. What type of turbo-charging configuration is used? Illustration MO-0176

The Correct Answer is D **Explanation for Option D (Pulse turbocharging):** The defining characteristic of pulse turbocharging (or pressure-pulse turbocharging) is that the exhaust manifold is divided into sections, with pipes leading from groups of cylinders (typically 2 or 3) to separate nozzles within the turbocharger turbine housing. This design is used to utilize the kinetic energy (pressure pulse) created when the exhaust valve opens. By preventing the pressure pulse from one cylinder from interfering with the scavenging process (exhaust gas removal) of another cylinder that might have its exhaust valve open concurrently, it ensures that the maximum available energy from the exhaust gas is delivered directly to the turbine wheel. If the illustration shows a manifold system with pipes grouped according to firing order and leading into separate entries (usually twin or quadruple entry) on the turbocharger casing, it indicates a pulse-turbocharging system. This configuration is very common on medium-speed diesel engines used in auxiliary power applications like those found on Anchor Handling Supply Vessels (AHTS). **Explanation of Incorrect Options:** * **A) Boost-controlled turbocharging:** This term usually refers to a method of regulating the compressor output (boost pressure) using a wastegate or variable geometry turbine (VGT) rather than describing the fundamental exhaust energy utilization strategy (pulse vs. constant pressure). It is a control mechanism, not the basic system configuration shown by the manifold type. * **B) Constant pressure turbocharging:** In this configuration, all exhaust gases from the cylinders are collected in a single, large manifold (a receiver) before entering the turbocharger. The pressure remains relatively constant, and energy is extracted primarily from the thermal (enthalpy) energy of the gas, sacrificing the kinetic energy of the pressure pulse. This requires a very different, un-divided manifold compared to the pulse system. * **C) 2-stage turbocharging:** This configuration uses two separate turbochargers operating in series (one high-pressure, one low-pressure) to achieve a very high overall pressure ratio. While modern AHTS vessels might use complex systems, the illustration typically focuses on the manifold-to-turbine connection (pulse vs. constant pressure), not the number of sequential compression stages. If the illustration shows only a single turbocharger unit connected to a divided manifold, it is not a 2-stage system.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app