Question 6 DDE04 - Designated Duty Engineer - 1000-4000 HP

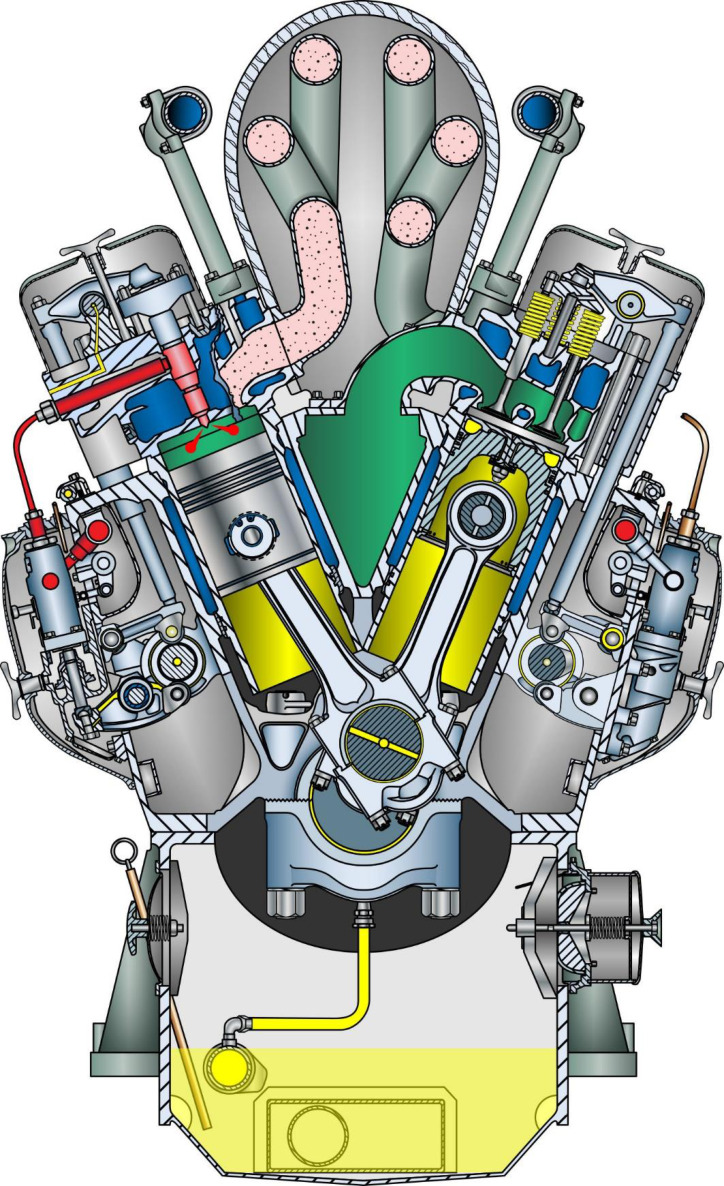

The ship-docking tug to which you are assigned is fitted with main propulsion diesel engines of the type shown in the illustration. In terms of valve operating gear, cylinder liner type, and connecting rod type, what statement is true? Illustration MO-0192

The Correct Answer is D ### Explanation of Why Option D is Correct Option D states: "This is a pushrod operated overhead valve engine, with wet cylinder liners and conventional connecting rods." This combination describes the most common and robust design features found in medium to high-speed, heavy-duty marine diesel engines typically used for tug propulsion (e.g., many models from Caterpillar, Cummins, or older Alco/Pielstick designs). 1. **Pushrod Operated Overhead Valve (OHV) Engine:** For reliable and heavy-duty service, the pushrod system is historically favored over overhead camshafts (OHC) in many medium-speed marine applications because it offers simplicity, durability, and easier maintenance access to the valve train components within the engine block. 2. **Wet Cylinder Liners:** Almost all medium- and high-speed diesels utilize wet cylinder liners. These liners are surrounded directly by the engine coolant (water jacket). This design provides excellent cooling efficiency and allows for quick and cost-effective replacement of the liner when wear occurs, without requiring replacement of the entire engine block. 3. **Conventional Connecting Rods:** This term describes a standard connecting rod setup where one rod services one piston, unlike articulated (master/slave) rods. Conventional rods are the standard for most in-line and many V-configuration engines in the tug's power class. ### Explanation of Why the Other Options Are Incorrect **A) This is an overhead cam engine, with wet cylinder liners and conventional connecting rods.** * While wet liners and conventional rods are standard, an overhead cam (OHC) engine design is less common than the robust pushrod operated overhead valve (OHV) system (Option D) in traditional heavy-duty medium-speed marine applications. The pushrod design is usually the default for this service unless the engine is a newer, high-speed, light-duty type. **B) This is a pushrod operated overhead valve engine, with jacketed cylinder liners and articulated connecting rods.** * "Jacketed cylinder liners" is vague but usually refers to the system containing wet liners. However, the term **articulated connecting rods** is incorrect. Articulated (master and slave) rods are a specialized design used primarily in certain high-output V-configuration engines (like EMD 645/710 series or older locomotive/marine designs) where two pistons share a single crankpin using a hinged connection. This design is highly specific, and the use of conventional rods (Option D) is far more common across the full range of marine diesels. **C) This is an overhead cam engine, with jacketed cylinder liners and marine-type connecting rods.** * This option incorrectly identifies the valve gear as OHC (see explanation for A). Furthermore, while any large connecting rod in a marine engine could be called "marine-type," this term often refers specifically to the large, heavy, built-up rods found in very large, slow-speed two-stroke engines (which are not used in tugs) rather than the conventional rods used in medium-speed engines.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app