Question 70 DDE01 - Designated Duty Engineer - Unlimited HP

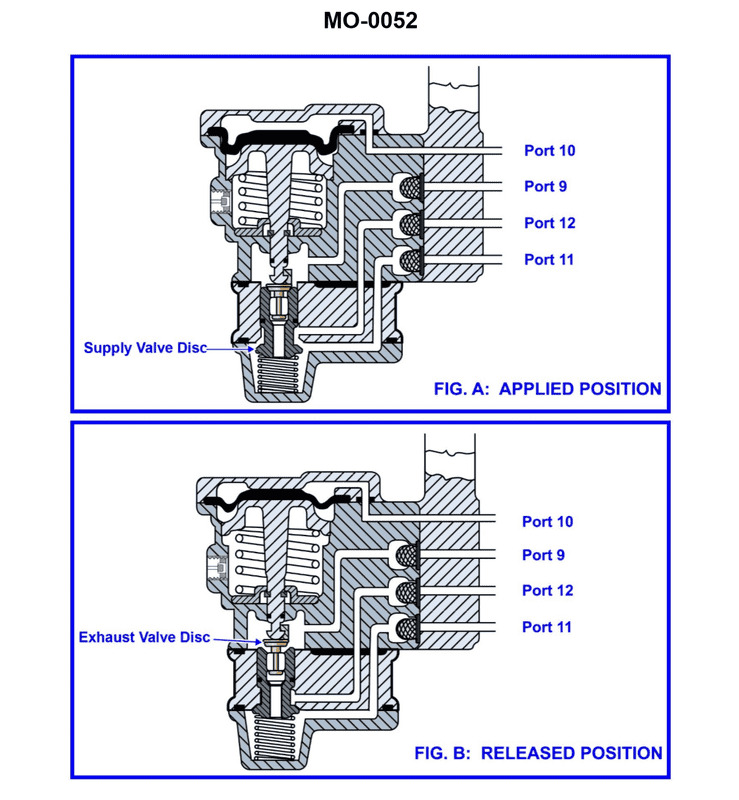

The pneumatic propulsion control system used on your river pushboat uses a diaphragm-operated relay valve as shown in the illustration. Periodically, the valve is to be disassembled for cleaning and inspection. What statement best describes the proper technique? Illustration MO-0052

The Correct Answer is B **Explanation for Option B (Correct Answer):** Option B is correct because it follows standard maintenance procedures for pneumatic control systems, especially those utilizing rubber or synthetic diaphragms and metal components. 1. **Rubber/Diaphragm Parts (Washing with Soap and Water):** Diaphragms and O-rings are often made of specialized synthetic rubber or elastomers designed to be flexible and chemically resistant to the pressurized air medium. However, harsh chemical solvents (even "non-flammable" ones, which are often petrochemical-based) can degrade, swell, harden, or compromise the long-term elasticity and sealing properties of these rubber components. Therefore, the safest and most recommended cleaning method for diaphragms is simple washing with mild soap (detergent) and warm water, followed by thorough drying. 2. **Metal Parts (Cleaning with Non-Flammable Solvent):** Metal parts, such as valve discs, seats, springs, and valve bodies, are prone to accumulating oil, varnish, and sticky residues (often introduced by compressor oil carryover in the air supply). Soap and water are generally ineffective at removing these heavy oil-based contaminants and may leave behind moisture leading to rust. Non-flammable solvents (e.g., specific commercial degreasers or kerosene-based cleaners) are required to dissolve and remove these petroleum-based contaminants from the metal surfaces, ensuring proper seating and operation of the valves. **Explanation of Incorrect Options:** * **A) Rubber parts such as the diaphragm should be cleaned with non-flammable solvent, and metal parts such as the valve discs and seats should be washed with soap and water.** This is the reverse of the proper procedure. Using solvent on rubber risks degradation, and washing heavily oiled metal parts with only soap and water is ineffective for degreasing. * **C) Rubber parts such as the diaphragm and metal parts such as the valve discs and seats should all be cleaned with non-flammable solvent.** While solvents are necessary for the metal parts, using solvent on the rubber diaphragm is highly discouraged as it will likely damage the material, leading to premature failure (cracking, swelling, or loss of flexibility). * **D) Rubber parts such as the diaphragm and metal parts such as the valve discs and seats should all be washed with soap and water.** Washing all components with soap and water is safe for the rubber, but it is insufficient for effectively cleaning and removing the inevitable oil, grease, and varnish deposits that accumulate on the critical metal seating surfaces of pneumatic valves.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app