Question 12 DDE01 - Designated Duty Engineer - Unlimited HP

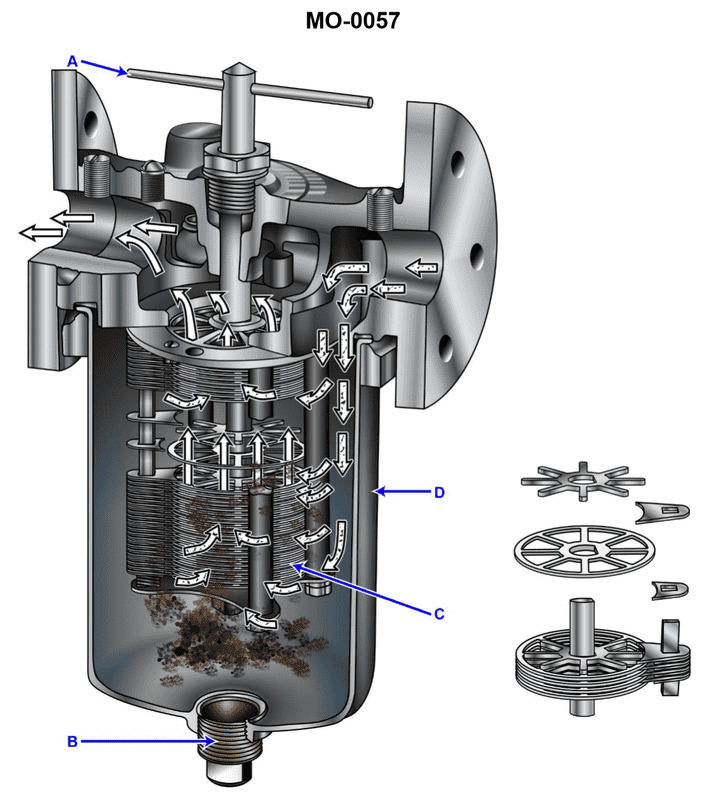

A diesel generator set on your salvage tug has a simplex lube oil strainer of the type shown in the illustration, situated on the discharge side of the lube oil pump. At a specified engine rpm and lube oil temperature, you notice that the pressure drop becomes unacceptably high. When you rotate the cleaning handle you notice that it is extremely difficult to rotate. What should be done? Illustration MO-0057

The Correct Answer is D **Explanation for Option D (Correct):** Option D is correct because the described symptoms—unacceptably high pressure drop and extreme difficulty rotating the cleaning handle—indicate a severe blockage of the strainer element (disk stack C). 1. **High Pressure Drop:** This is the primary indicator that the strainer element is heavily contaminated and restricting flow. 2. **Difficult Rotation:** The cleaning handle (A) rotates a scraper blade against the strainer disks (C) to remove light deposits during operation. If rotation is extremely difficult, it means the collected sludge and dirt (especially if hardened by heat or contamination) have heavily compacted around the disks, making the scraping mechanism ineffective or physically stuck. 3. **Necessary Action:** When the buildup is so severe that normal cleaning (rotation) is ineffective or impossible, the engine must be stopped (to prevent unfiltered oil flow or pump damage) and the strainer must be physically opened. The element (C) must be withdrawn and thoroughly cleaned, often by soaking it in a suitable solvent to dissolve the heavy, compacted deposits, restoring the required clearance and flow capacity. **Explanation of Why Other Options Are Incorrect:** **A) The cleaning handle (A) should be forced to rotate, even if it requires an extender handle to produce greater rotating torque.** * **Incorrect.** Forcing the handle is extremely dangerous. It indicates a severe mechanical blockage, and excessive torque could bend the scraper blades, damage the internal linkage, or potentially rupture the fine wire mesh or disks of the strainer element. This would necessitate a major repair and could introduce damaged metallic debris into the lubricating system. **B) No special consideration need be taken as long as the cleaning handle (A) rotates, even if it rotates with great difficulty.** * **Incorrect.** The high pressure drop is already an indicator that special consideration *must* be taken. Ignoring the difficulty of rotation and the high pressure drop risks starving engine components of lube oil (leading to catastrophic failure) or causing damage to the strainer mechanism itself. **C) After stopping the engine, the drain plug (B) should be removed to drain the accumulated sludge from the strainer sump.** * **Incorrect (Insufficient).** Draining the sump via plug (B) will remove loose sludge that has settled in the bottom of the housing. While this is good practice, it will *not* address the primary problem: the severe, compacted fouling that is stuck directly onto the filter disks (C), causing the restriction and making rotation difficult. The core issue requires removing and cleaning the element itself.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app