Question 31 OSE01 - Chief Engineer - OSV

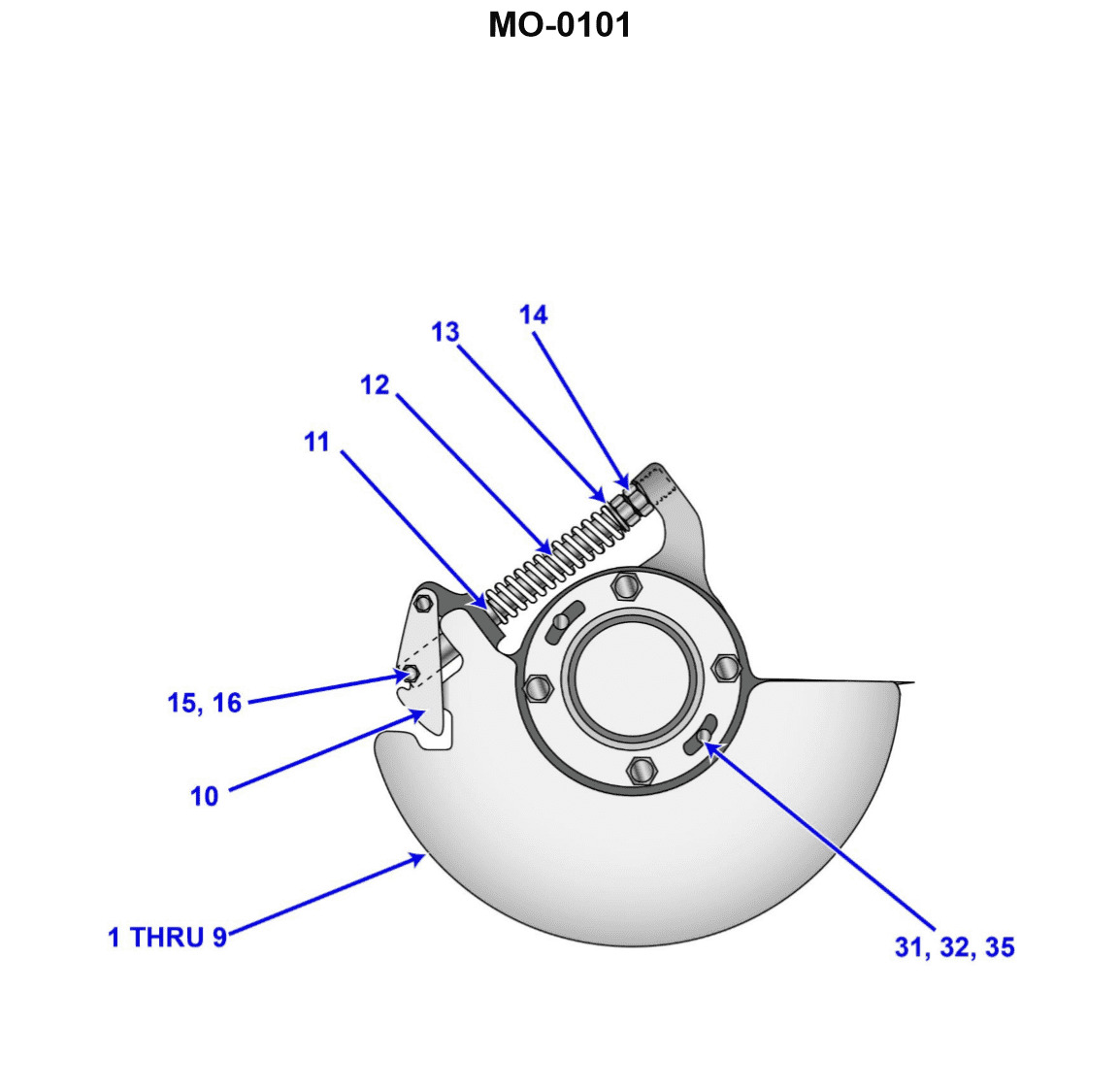

The rated speed of the main propulsion diesel engines on your offshore supply vessel is 900 rpm. The installed centrifugal overspeed trip device similar to the one shown in the illustration is designed to shut down the engine at 110% of rated speed. Upon testing the overspeed trip device, you determine that the actual shutdown occurs at 945 rpm. Which of the following would account for this? Illustration MO-0101

The Correct Answer is D **Explanation for Correct Option (D):** The engine's rated speed is 900 rpm. The design trip speed is 110% of rated speed, which is $900 \times 1.10 = 990$ rpm. The actual trip speed measured is significantly lower at 945 rpm. The overspeed trip setting is primarily controlled by the tension on the compression spring (item \#12), which is adjusted using the adjusting nut (item \#13). To increase the trip speed (make it trip later), the spring tension must be increased (i.e., the adjusting nut \#13 must be turned inward, compressing the spring more). Conversely, to decrease the trip speed (make it trip earlier), the spring tension must be decreased (i.e., the adjusting nut \#13 must be turned outward, decompressing the spring). If the jam nut (item \#14) was not properly tightened against the adjusting nut (item \#13) when the trip was last set (presumably at the correct 990 rpm), vibration during engine operation could cause the adjusting nut (\#13) to back off (loosen). Backing off the adjusting nut relieves the compression on the spring (\#12), requiring less centrifugal force (and therefore lower speed) to overcome the reduced spring force and trigger the shutdown. Since the actual trip speed (945 rpm) is lower than the intended trip speed (990 rpm), a loss of spring tension due to a loose adjusting nut/jam nut assembly is the most likely operational cause. **Explanation for Incorrect Options:** * **A) The throw-out weight (item \#10) pivot bolt (not labeled) is binding within the counterweight (item 1 through 9) drilling.** Binding or friction in the mechanism would inhibit the outward movement of the weights. This would require *more* centrifugal force (a *higher* engine speed) to overcome the friction before the device throws out and trips the engine. Since the engine is tripping too *early* (at 945 rpm instead of 990 rpm), this option is incorrect. * **B) The throw-out weight (item \#10) link bolt (item \#15 & \#16) is binding within the spring guide (item \#11) drilling.** Similar to option A, binding introduces friction. Friction would resist the movement necessary to trip the engine, causing the actual trip speed to be *higher* than the set point. Therefore, this option is incorrect. * **C) The compression spring (item \#12) was excessively compressed when the overspeed trip was last set.** Excessive compression means the spring tension is too high. High spring tension requires *more* centrifugal force (a *higher* engine speed) to overcome the force and cause the trip. If the spring was excessively compressed, the engine would trip *above* 990 rpm, not below it. Therefore, this option is incorrect.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app