Question 4 DDE04 - Designated Duty Engineer - 1000-4000 HP

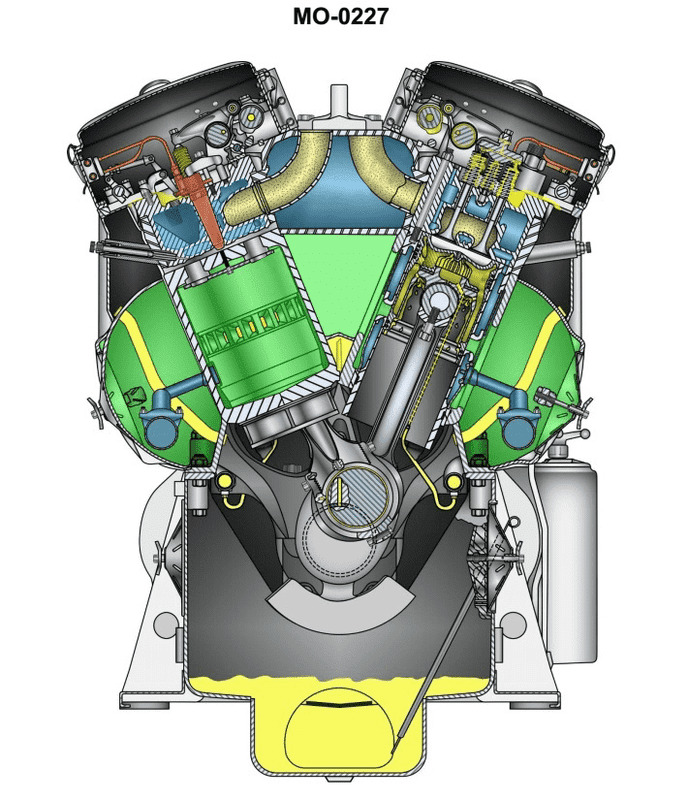

You are serving as a designated duty engineer onboard a harbor tug equipped with main propulsion diesel engines of the type shown in the illustration. What scavenging flow pattern is used in this engine type? Illustration MO-0227

The Correct Answer is C ### Why Option C ("Uniflow") is Correct The illustration MO-0227 typically depicts a large, modern, low-speed two-stroke marine diesel engine, such as those manufactured by MAN B&W or Wärtsilä-Sulzer, which are common for main propulsion in harbor tugs (though often scaled down for tugs, the basic design remains the same). These engines operate on the two-stroke cycle and use the **Uniflow** scavenging pattern. In this pattern, the scavenging air enters through ports located near the bottom of the cylinder liner and exits through exhaust valves located in the cylinder head. This arrangement ensures that the scavenging air flows predominantly in one direction (from bottom to top), creating a highly efficient process that completely sweeps the combustion gases out of the cylinder with minimal mixing. Uniflow scavenging is characterized by its high thermal efficiency and ability to support high Mean Effective Pressures (MEP), making it ideal for large propulsion units. ### Why the Other Options are Incorrect **A) Return-flow:** Return-flow scavenging (or Reverse-flow scavenging) is a general term often associated with older two-stroke designs where the flow might reverse direction, but it is not the standard technical term used for the primary flow mechanism in modern large marine diesels. **B) Cross-flow:** Cross-flow scavenging involves the scavenging air entering through ports on one side of the cylinder and exiting through exhaust ports located directly opposite on the other side. The flow travels across the piston crown. This method is generally considered inefficient due to significant mixing of fresh air and exhaust gases, and it is rarely, if ever, used in modern large marine propulsion diesels. **D) Loop:** Loop scavenging (e.g., Schnürle scavenging) involves both the inlet and exhaust ports being located near the bottom of the cylinder. The incoming air is directed upwards toward the cylinder head, loops back down, and pushes the exhaust gases out through the exhaust ports. While efficient for smaller, high-speed engines (like some auxiliary engines or small gasoline engines), it is less efficient than uniflow scavenging for the large, slow-speed main propulsion engines shown in the illustration, as it inherently involves greater mixing and incomplete gas exchange.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app