Question 38 DDE04 - Designated Duty Engineer - 1000-4000 HP

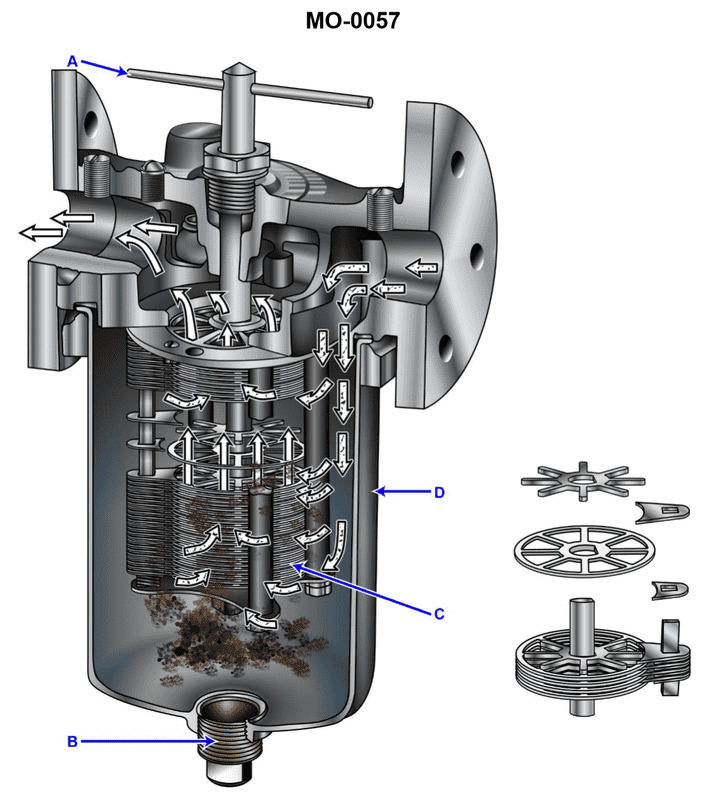

The lubricating oil system supporting the main propulsion reduction gear on the ship-docking tug to which you are assigned is fitted with a lube oil strainer as shown in the illustration. What strainer attribute will dictate the degree of filtration in terms of the particle size capable of being filtered? Illustration MO-0057

The Correct Answer is B **Explanation for B (Correct Answer):** The illustration described (MO-0057, typically depicting a common type of edge-type or stacked-disc strainer/filter) shows a straining element composed of numerous thin metal discs pressed tightly together. Filtration occurs as the oil flows radially inward or outward through the small gaps between the adjacent discs. The **vertical spacing between the metal discs** directly defines the size of the narrow opening (the slit or gap) through which the oil must pass. This gap is the determining factor for the largest particle size that can pass through the strainer. In this specific design, this critical spacing is precisely set by the thickness of the small separator pieces, often integrated into or defined by the thickness of the **cleaner blades** (or spacer ribs) positioned between the main filtering discs. Therefore, the thickness of these spacers dictates the minimum particle size the filter can block, which is the definition of the degree of filtration. **Explanation of Incorrect Options:** * **A) The length of the oil sump enclosing the straining element:** The length of the sump (reservoir) relates to the total volume of oil being held, not the filtering capacity or the size of the pores in the element itself. * **C) The number of discs in the disc-stack making up the straining element:** The number of discs determines the total effective surface area available for filtration. A higher number increases the flow rate capacity and the amount of dirt the strainer can hold before requiring cleaning, but it does not change the particle size that a single gap can block. * **D) The dimensions of the triangular oil passages in each disc conveying the strained oil upward:** These passages (often called "star" or "spoke" passages) are large channels designed to collect the already strained oil and convey it out of the element. They are downstream of the actual straining point (the gaps between the discs) and are far too large to dictate the degree of filtration.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app