Question 19 DDE04 - Designated Duty Engineer - 1000-4000 HP

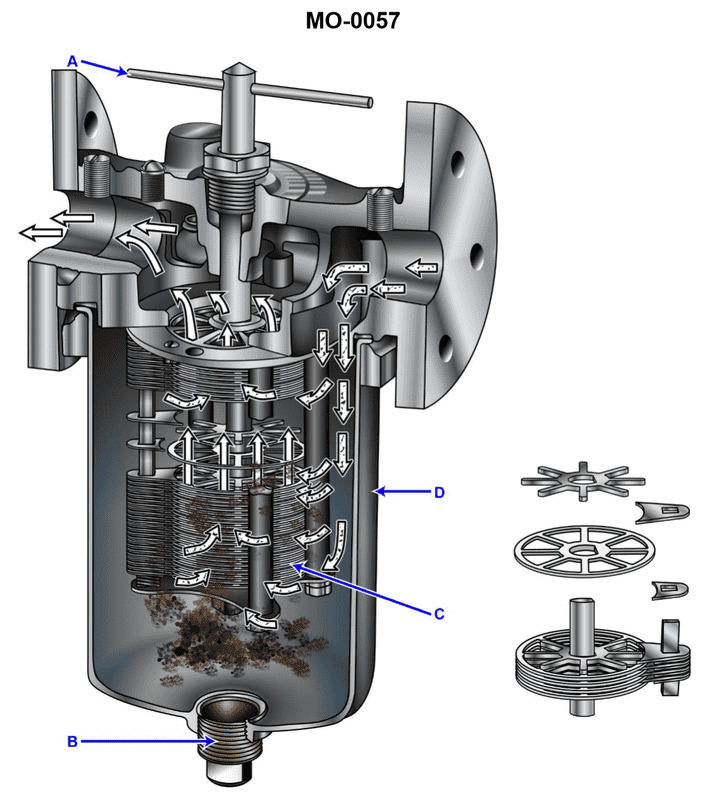

A diesel generator set on your salvage tug has a simplex lube oil strainer of the type shown in the illustration, situated on the discharge side of the lube oil pump. At a specified engine rpm and lube oil temperature, you notice that the pressure drop becomes unacceptably high. When you rotate the cleaning handle you notice that it is extremely difficult to rotate. What should be done? Illustration MO-0057

The Correct Answer is A **Explanation for Option A (Correct):** The problem describes a situation where the pressure drop across the lube oil strainer is unacceptably high, and the cleaning handle is extremely difficult to rotate. This specific type of simplex strainer (often a metal edge or plate-type strainer like the one typically implied by Illustration MO-0057) is cleaned by rotating the handle (A), which causes scrapers or combs to clean the disk stack (C). If the handle is extremely difficult to rotate, it indicates that the disk stack (C) is severely and densely clogged with hard, tenacious sludge, carbon, or heavy residues that the internal scrapers cannot easily dislodge or break up. Since the simple scraping action is failing, the only effective remedy is a thorough manual cleaning. To do this safely and effectively, the engine must be stopped, the element must be removed (withdrawn), and the severe deposits must be broken down by soaking the element in a suitable solvent before physical cleaning. This restores the required flow area and reduces the pressure drop to an acceptable level. **Explanation of Incorrect Options:** * **B) The cleaning handle (A) should be forced to rotate, even if it requires an extender handle to produce greater rotating torque.** Forcing the handle could damage the delicate internal scraping mechanism, warp the strainer disks, or potentially shear the shaft or handle mechanism. Strainer assemblies are precision components and should not be subjected to excessive, non-designed torque. Furthermore, even if forced, the severely impacted debris may only be partially scraped off, leading to rapid re-clogging and further damage. * **C) After stopping the engine, the drain plug (B) should be removed to drain the accumulated sludge from the strainer sump.** While draining the sump via plug (B) is a necessary routine maintenance step to remove accumulated sludge that has fallen off the disks, it addresses the sludge *after* it has been removed from the stack. The primary problem here is the *clogging* of the disk stack (C) which is causing the high differential pressure and preventing the handle from turning easily. Draining the sump will not clear the tenacious deposits stuck firmly between the strainer disks. * **D) No special consideration need be taken as long as the cleaning handle (A) rotates, even if it rotates with great difficulty.** The fact that the pressure drop is "unacceptably high" is itself a special consideration. High differential pressure compromises lubrication flow, potentially leading to lube starvation or bypass activation (if equipped), which can cause catastrophic engine damage. The difficulty in rotation signals a dangerous level of clogging that requires immediate attention, not neglect.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app