Question 51 AEL01 - Assistant Engineer - Limited

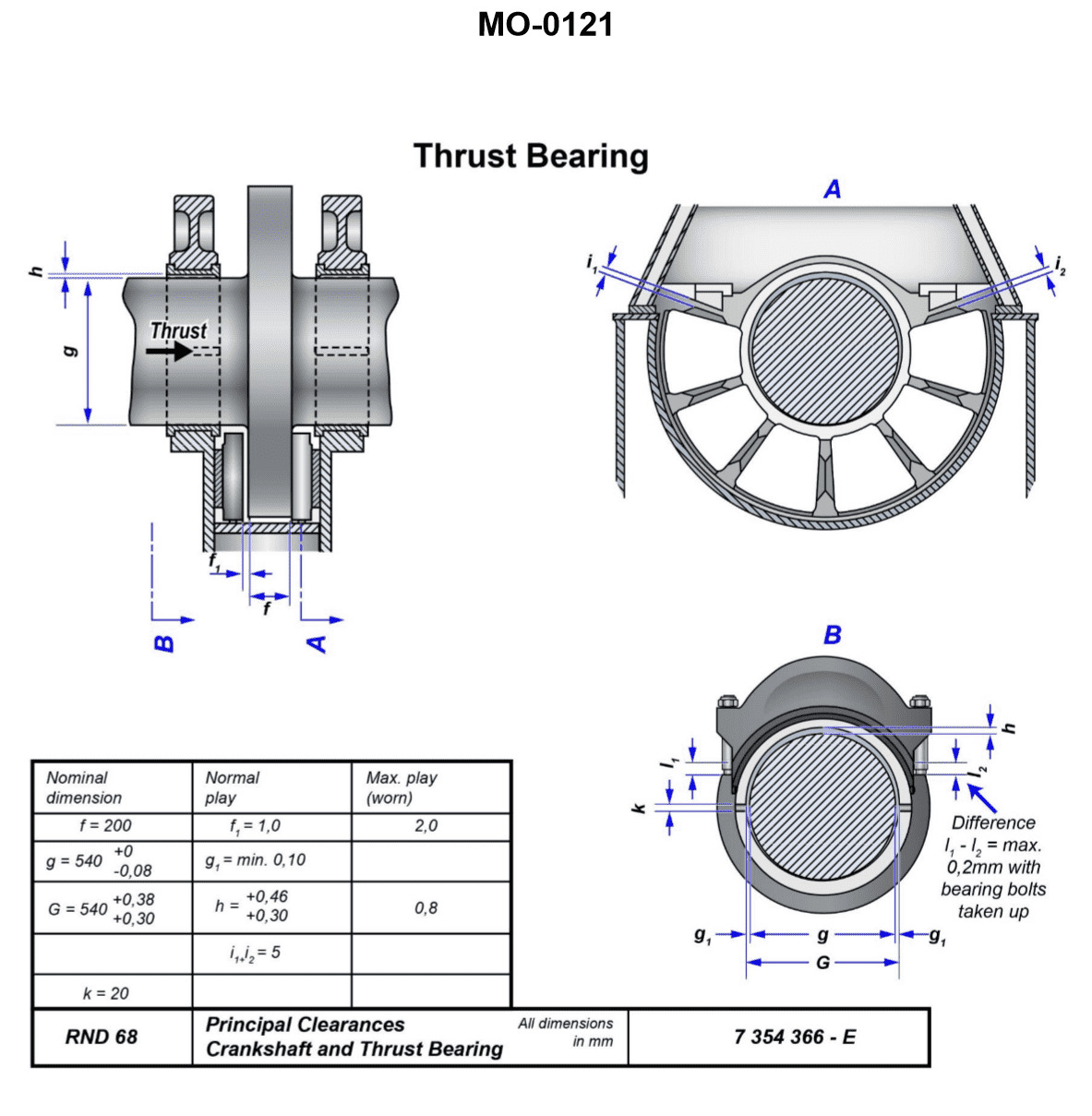

When installing the bearing cap on the device shown in the illustration, which of the precautions listed must be observed? Illustration MO-0121

The Correct Answer is B ### Explanation of Correct Option (B) **B) Once the bearing cap is properly torqued, measure the end gap dimensions to ascertain even tightening of the cap.** This is a critical quality assurance step when installing bearing caps (such as main bearing caps or connecting rod caps). Precision components like bearing caps must be torqued evenly to maintain the perfect circularity (roundness) of the housing bore. If the cap is torqued unevenly or improperly seated, the bore will become oval (distorted). By measuring the resulting bore dimensions, or in some contexts, measuring the slight gap or distortion at the split line ("end gap dimensions"), the technician verifies that the torquing process was successful and that the bore is ready to accept the bearing with the correct clearance. Failure to check this can lead to rapid bearing failure due to bore distortion. ### Explanation of Incorrect Options **A) Prior to installing the cap, position the thrust shoes in their proper locations.** While thrust shoes (washers) must be installed correctly, they relate to axial movement control, typically on a specific main bearing. This step is part of the assembly process, but it is not the primary *precaution* needed to confirm the proper installation and roundness of the *cap itself* after torquing, which is the focus of the question. **C) If the device is covered with abrasive material or contaminates, the unit may be reassembled, provided an abnormal method of reassembly is followed.** This is fundamentally incorrect and violates all principles of precision assembly. Contaminants (dirt, metal shavings, abrasives) must be completely removed before reassembly. Reassembling a contaminated unit, regardless of the method, guarantees catastrophic failure of the bearing surfaces. **D) After applying anti-seize to the external threads, torque one side at a time to the appropriate values using a quality torque wrench.** This procedure involves two serious errors: 1. **Anti-seize:** Anti-seize drastically alters the friction coefficient of the threads, causing the resulting clamping force to be much higher than intended for the specified torque value. Engineers specify precise lubrication (often clean engine oil or dry threads) to achieve the correct bolt stretch. 2. **Torque Method:** Critical fasteners like bearing cap bolts must be torqued in stages (e.g., 50%, 100%) and in an alternating pattern (cross-pattern) to ensure the cap seats evenly. Torquing "one side at a time" to the full value will severely warp the cap and distort the bearing bore.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app