Question 49 1AE01 - First Assistant Engineer

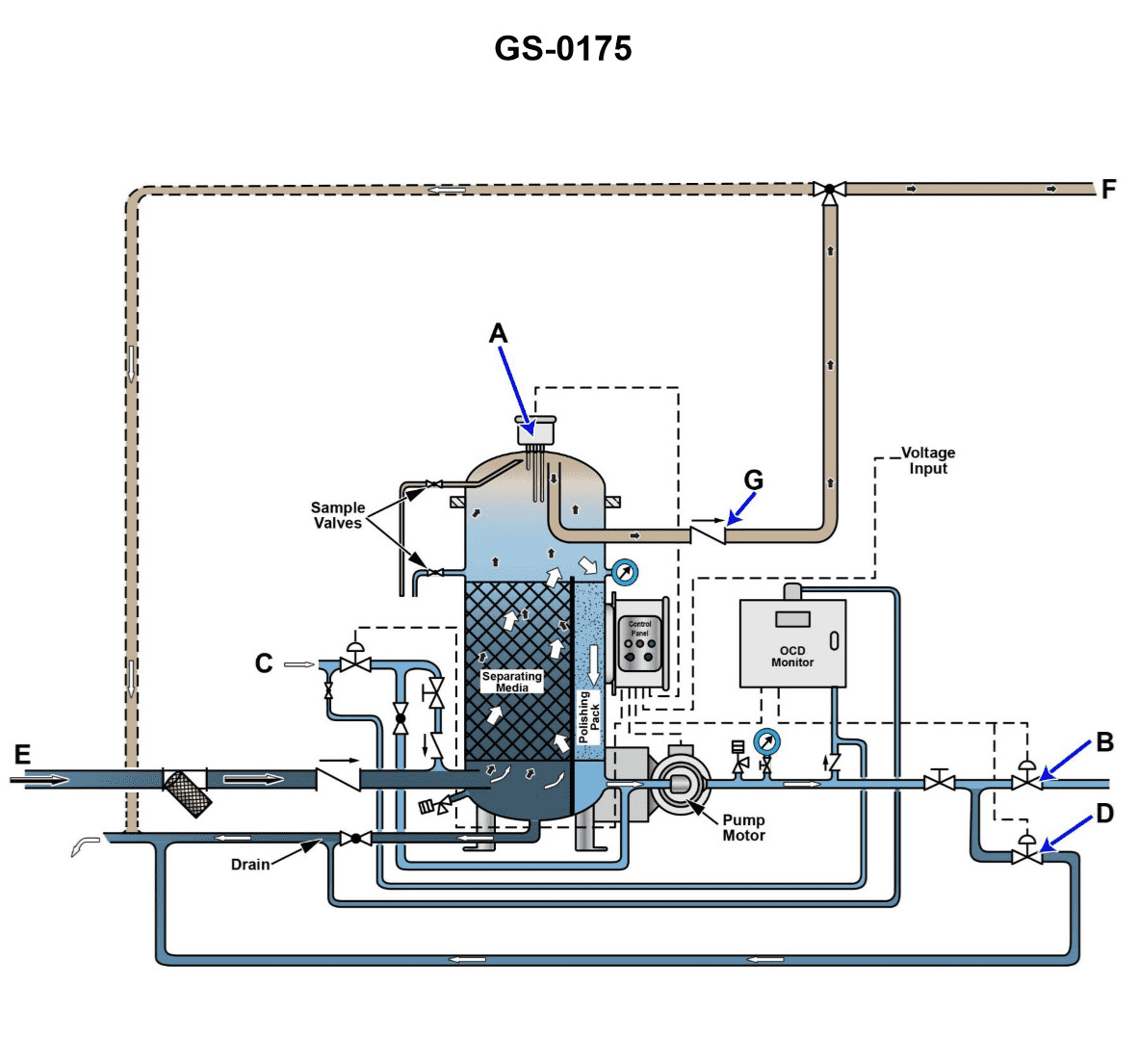

Referring to the illustration, suppose after initiating the oil discharge mode, the oily-water separator fails to come out of the oil discharge mode in a timely fashion. Cracking open the upper sampling valve reveals the presence of oil exiting under positive pressure. What is most likely the cause? Illustration GS-0175

The Correct Answer is A ### Explanation for Option A (Correct Answer) The scenario describes two key observations: 1. **The system is stuck in the oil discharge mode** (fails to exit timely). 2. **Oil is present and exiting under positive pressure** when the upper sampling valve is cracked open. The separator attempts to discharge oil by introducing clean water below the oil layer (or by other means of displacement), which pushes the oil up and out through the oil discharge line. If the system is stuck in discharge mode, it means the termination condition (usually sensing clean water at the oil discharge point or a timed cycle) is never met. If the **oil discharge check valve fails to open**, the separated oil cannot exit the separator chamber. As the internal system pressure (provided by the clean water supply or internal pump) builds up to push the oil out, the oil is trapped inside the unit, accumulating pressure. When the upper sampling valve is opened, the trapped, pressurized oil is released, matching the observation (oil exiting under positive pressure). Furthermore, since no oil is actually discharged, the sensing probes or timers will never register the successful completion of the discharge, causing the system to remain stuck in the discharge cycle. ### Why Other Options Are Incorrect **B) The upper oil/water interface detection probe fails to end the oil discharge mode.** If the upper probe fails to signal the end of the discharge, the system would remain in discharge mode (matching the first observation). However, the failure of the *probe* itself doesn't explain the presence of trapped, pressurized oil at the upper sampling valve. If the discharge check valve *was* open, the oil would be escaping, and the internal pressure should drop relative to the trapped condition described in the scenario. A failure to end the mode might be a *result* of the blockage (Option A), but it is not the *root cause* explaining the highly pressurized, trapped oil. **C) The clean water supply solenoid fails to open, and as a result provides no discharge pressure.** If the clean water supply fails to open, there would be no pressure to push the oil out. This would prevent oil discharge, but it would also prevent the buildup of positive pressure observed at the sampling valve. The absence of discharge pressure contradicts the observation that oil is exiting under positive pressure. **D) The lower oil/water interface detection probe fails to initiate the oil discharge mode.** If the lower probe failed to initiate the mode, the system would never enter the oil discharge cycle in the first place, contradicting the premise that the system "fails to come out of the oil discharge mode."

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app