Question 56 OSE01 - Chief Engineer - OSV

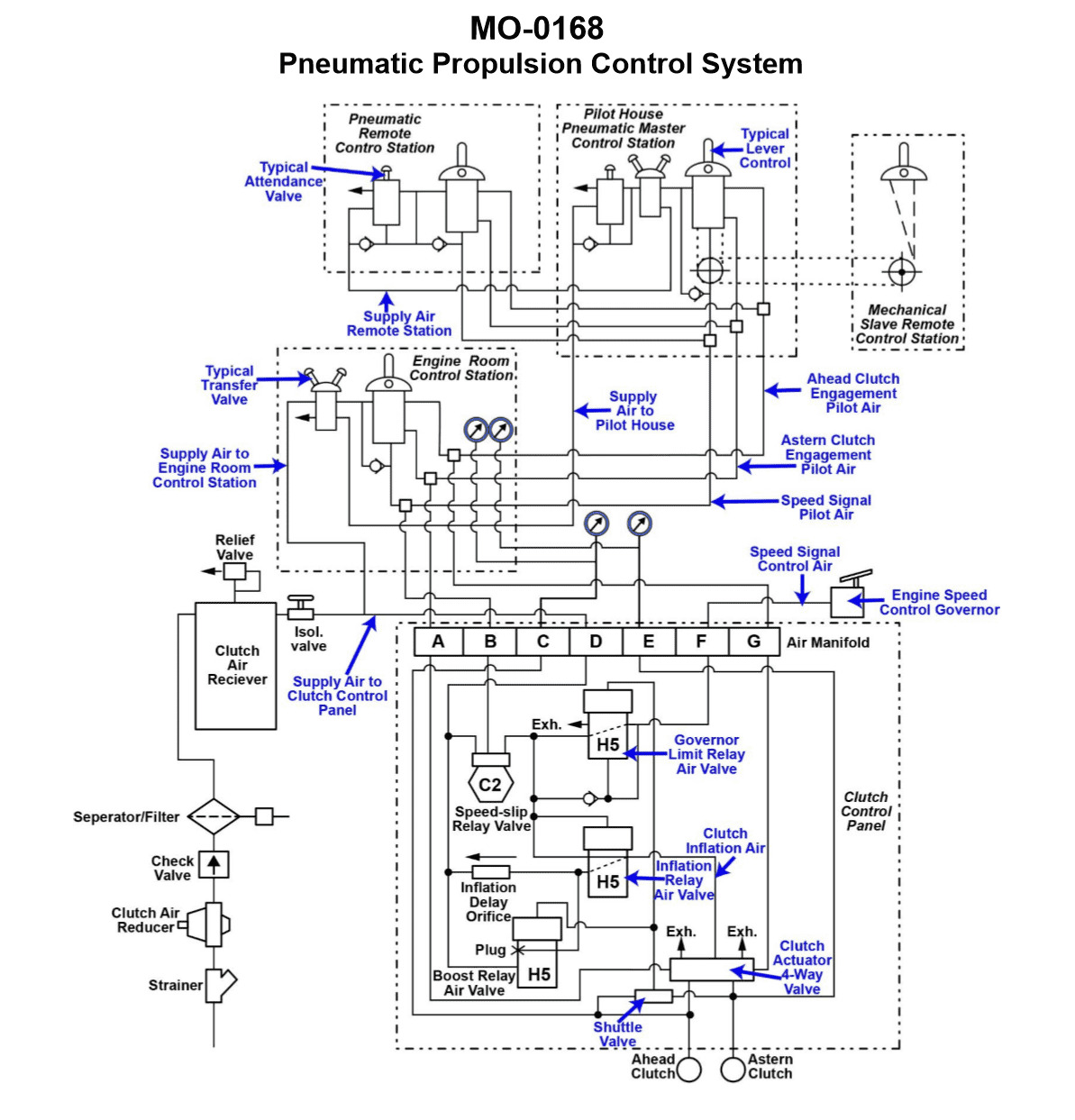

The pneumatic propulsion control system used on your offshore supply vessel is configured as shown in the illustration. In terms of clutch air system maintenance, what statement best represents operational requirements? Illustration MO-0168

The Correct Answer is D **Explanation of why Option D is correct:** Pneumatic (air-operated) propulsion control systems, especially those managing clutches (like those used on offshore supply vessels for engine-gearbox coupling or reversing gear), rely on compressed air to operate actuators and valves. For reliable and long-lasting operation, the air used in these critical systems must meet stringent quality standards regarding pressure, dryness, and cleanliness: 1. **Pressure:** The air pressure must be maintained within the specified operating range to ensure the clutch actuators have enough force to engage or disengage the clutch firmly and reliably. Insufficient pressure leads to slippage and damage; excessive pressure can damage seals and components. 2. **Dryness:** Moisture in compressed air systems is highly detrimental. It causes corrosion of internal components, washes away lubrication, and, in cold conditions, can freeze, leading to valve blockage and complete system failure. Dry air prevents these issues, ensuring smooth operation and component longevity. 3. **Cleanliness:** Airborne particulates (dirt, rust, pipe scale, oil residue) must be filtered out. These contaminants cause wear on moving parts, clog small orifices in control valves (pneumatic logic circuits), and degrade seals, leading to leaks and erratic operation. Because failure in the clutch air system directly impacts the vessel's ability to maneuver and transmit power—a critical operational necessity—all three factors (pressure, dryness, and cleanliness) are equally crucial for successful and reliable control operations. **Explanation of why the other options are incorrect:** * **A) Whereas the cleanliness of clutch air is critical, the dryness and pressure are clutch air are of secondary concern.** This is incorrect. While cleanliness is vital, insufficient pressure or moisture presence (lack of dryness) will cause immediate and catastrophic functional failures (slippage, corrosion, freezing, or inability to engage/disengage). Dryness and pressure are primary concerns, not secondary. * **B) Whereas the clutch air pressure is critical, the dryness and cleanliness of the clutch air are of secondary concern.** This is incorrect. Focusing solely on pressure ignores the long-term damage and operational failures caused by dirty or wet air. Cleanliness prevents component wear and blockages, and dryness prevents corrosion and freezing; both are critical alongside pressure. * **C) Whereas the dryness of clutch air is critical, the pressure and cleanliness of the clutch air are of secondary concern.** This is incorrect. While dryness is vital for component longevity, lack of correct pressure means the system cannot perform its basic function, and lack of cleanliness leads to immediate valve failure and component erosion. All three elements are equally critical.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app