Question 53 OSE01 - Chief Engineer - OSV

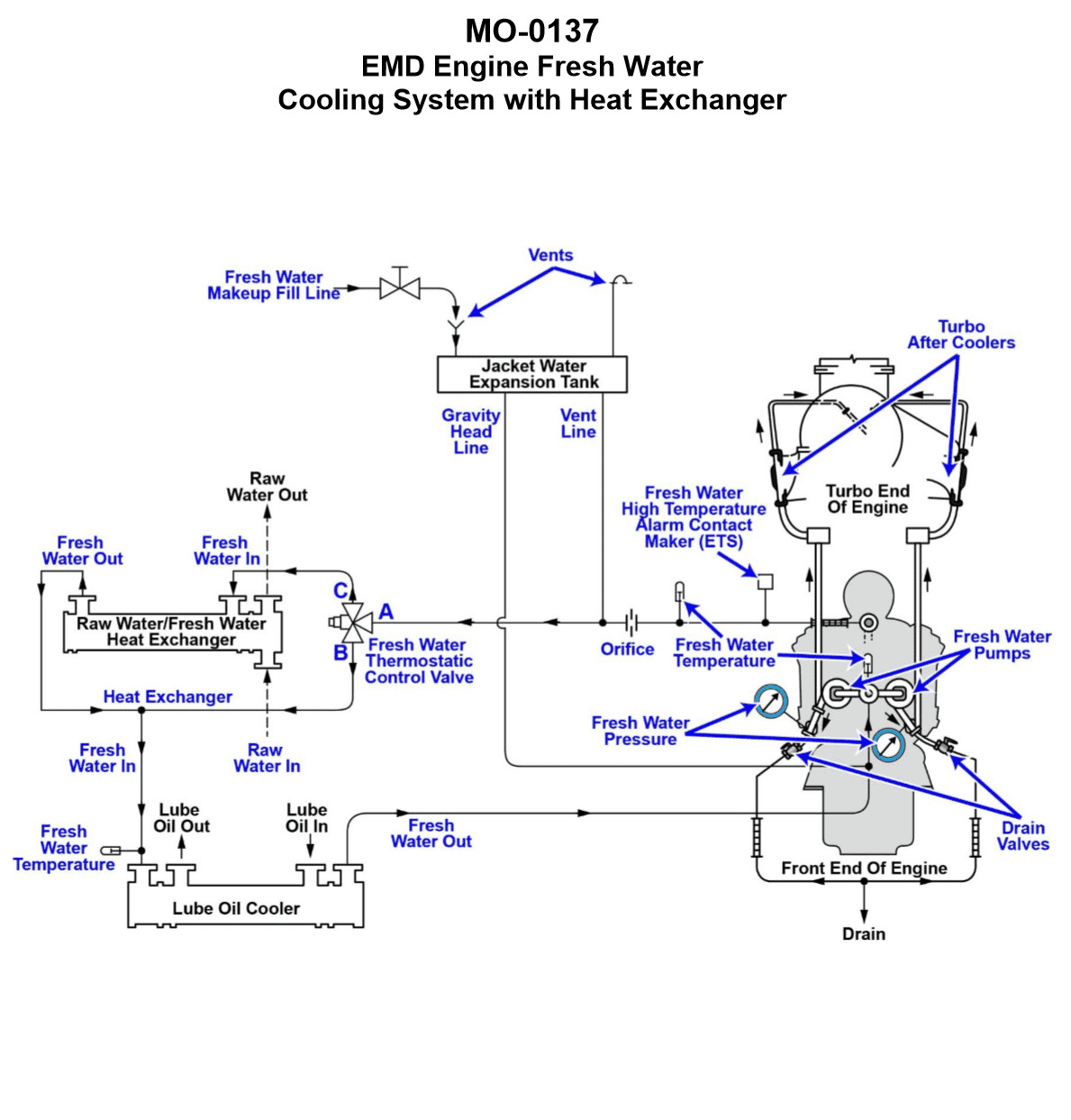

Your platform supply vessel is fitted with cooling water systems serving the main propulsion diesel engines as shown in the illustration. Which heat exchanger/cooler application and aspect would most likely require periodic mechanical cleaning with a specially designed brush? Illustration MO-0137

The Correct Answer is C ### **Why Option C is Correct** Option C, "The inside of the tubes of the RW/FW heat exchanger" (Raw Water/Fresh Water heat exchanger), is the most likely location requiring periodic mechanical cleaning with a specially designed brush. 1. **Raw Water (Seawater) Path:** In a marine cooling system, the raw water (RW), which is typically unfiltered or minimally filtered seawater, flows through the inside (tube side) of this primary heat exchanger. 2. **Fouling Source:** Seawater is the primary source of fouling in the system. It contains abrasive silt, sand, mud, biological growth (mussels, barnacles, slime), and dissolved salts that precipitate (scale) due to heat. 3. **Cleaning Necessity:** This fouling accumulates directly on the tube surfaces exposed to the seawater, forming an insulating layer that severely reduces heat transfer efficiency. Mechanical cleaning (brushing, rod cleaning) is the standard procedure to physically remove this scale and bio-fouling from the inside surfaces of the tubes. ### **Why the Other Options are Incorrect** **A) The outside of the tubes of the RW/FW heat exchanger:** * **Fluid:** The outside (shell side) of the tubes in the RW/FW heat exchanger carries the engine's closed-loop cooling medium, which is treated Fresh Water (FW). * **Fouling Risk:** Because this FW is treated, filtered, and continuously circulated in a closed loop, the risk of significant deposition or hard scaling requiring mechanical brushing is very low. Chemical treatment prevents corrosion and scaling. **B) The outside of the tubes of the lube oil cooler:** * **Fluid:** The outside (shell side) of the lube oil cooler typically carries the clean, treated Fresh Water (FW) from the engine's closed-loop system. * **Fouling Risk:** Similar to option A, the shell side is protected by clean, treated fresh water, making mechanical fouling unlikely. **D) The inside of the tubes of the lube oil cooler:** * **Fluid:** The inside (tube side) of the lube oil cooler carries the engine's lubricating oil. * **Fouling Risk:** While lube oil can suffer from thermal degradation (coking) or sludge formation, cleaning this residue is typically done using chemical solvents (circulation cleaning) because mechanical brushing is often ineffective against sticky hydrocarbon residues and carries the risk of damaging the softer brass or copper-nickel tubes. Furthermore, the primary heat exchanger (RW/FW) is the absolute highest priority for mechanical cleaning due to the severity of raw water fouling.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app