Question 49 OSE01 - Chief Engineer - OSV

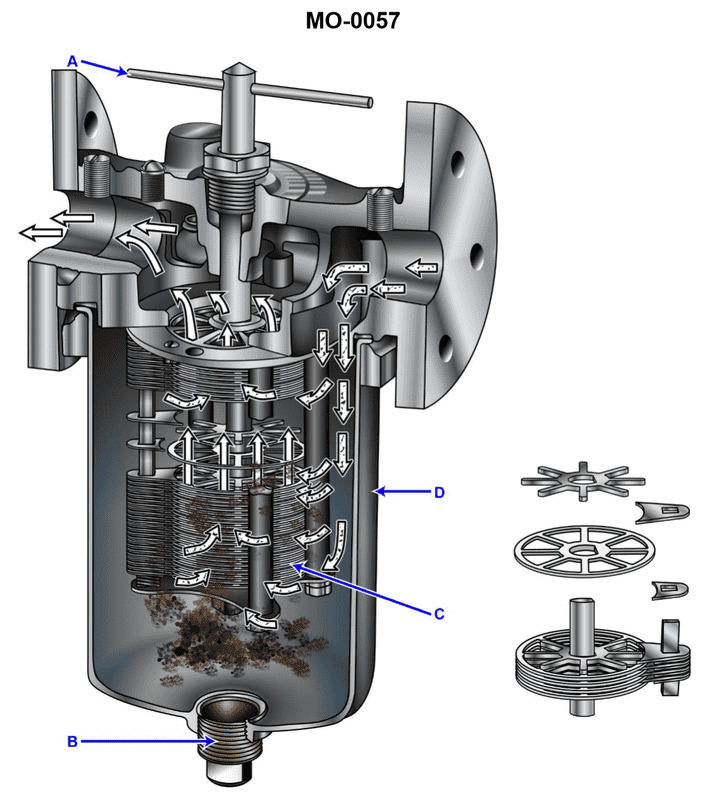

A diesel generator set on your anchor-handling supply vessel has a simplex lube oil strainer of the type shown in the illustration, situated on the discharge side of the lube oil pump. At a specified engine rpm and lube oil temperature, you notice that the inlet pressure is increasing and the outlet pressure is decreasing, resulting in an unacceptable pressure drop. What should be done? Illustration MO-0057

The Correct Answer is A **Explanation for A (Correct Option):** The scenario describes an increasing pressure drop across the strainer (inlet pressure rising, outlet pressure falling) while operating at specified conditions. This is the classic indication that the filter element (disk stack C) is becoming clogged with contaminants. The illustration depicts a simplex self-cleaning strainer (often a metal edge or disk-type filter). These strainers are designed to be cleaned *on the fly* (while the engine is running) by rotating a cleaning handle (A). This rotation scrapes or dislodges the accumulated dirt from the filter elements, which then falls into the sump below. Rotating the handle one or more full turns ensures that the entire surface of the disk stack (C) is cleaned, restoring the flow and reducing the pressure drop to an acceptable level. **Explanation of Incorrect Options:** * **B) While the engine is running, the drain plug (B) should be carefully loosened to drain the sludge from the strainer sump.** While draining the sludge (which collects the dirt removed by the self-cleaning action) is a necessary maintenance task, it does not solve the immediate problem of a clogged disk stack causing the pressure drop. Furthermore, completely loosening the drain plug (B) while the engine is running and the system is under pressure would result in a potentially dangerous high-velocity discharge of hot oil, depressurizing the lubrication system. * **C) The drain plug (B) is removed to drain the sludge from the strainer sump, but the engine must be stopped to perform this operation.** This describes the correct procedure for emptying the sump (B) safely, which is maintenance, not the immediate procedure to clean a clogged filter element (C) causing an unacceptable pressure drop. The primary requirement here is to clean the element using the handle (A). * **D) While the engine is running, the cleaning handle (A) should be rotated one-half turn to remove the accumulated dirt from the disk stack (C).** While this action addresses the problem, rotating the handle only one-half turn may not fully clean the entire filtering surface of the disk stack, depending on the strainer design. The standard procedure for continuous/edge-type self-cleaning filters is to rotate the handle one or more full turns (360 degrees) to ensure complete removal of debris from all filter slots, making option A the more comprehensive and correct operational instruction.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app