Question 46 MODE01 - Chief MODU Engineer

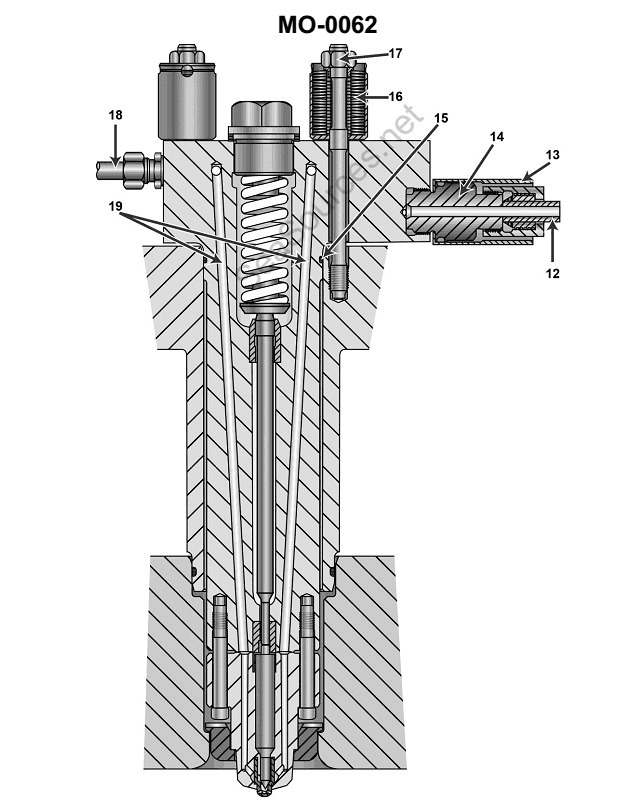

The item labeled #16 in the illustration is a stack of spring washers. Their function is to __________. Illustration MO-0062

The Correct Answer is C ### Explanation of Why Option C is Correct Option C states that the function of the stack of spring washers (often called Belleville washers or disc springs) is to **"maintain the same hold-down force on the injector regardless of varying engine operating temperatures."** When an engine operates, it generates significant heat, causing various components (like the cylinder head and the injector body) to expand and contract at different rates due to varying thermal expansion coefficients. If a standard rigid bolt were used to hold the injector, this differential thermal expansion would either increase the clamping force excessively (potentially damaging the bolt or the component) or decrease it significantly (allowing leaks or movement). Spring washers, particularly stacked disc springs, act like a strong, stiff spring. They are designed to operate over a very small deflection range while maintaining a high, relatively constant load. By deflecting slightly as the components thermally expand or contract, they absorb the dimensional change, thus ensuring that the crucial hold-down (clamping) force on the injector remains consistent across the full range of engine operating temperatures. This consistency prevents combustion gas leakage and ensures proper injector seating and alignment. ### Explanation of Why Other Options Are Incorrect **A) absorb the high-pressure pulses developed during the fuel injection process** This is incorrect. The mechanical mounting components, like the washers and bolts, are designed to handle static clamping loads and thermal expansion. The internal structure of the injector itself, and to some extent the cylinder head material, manages the high-pressure hydraulic and combustion forces. Spring washers do not function as hydraulic or mechanical dampeners for internal injection pulses. **B) prevent bolt failure by allowing limited movement of the injector when excessively high cylinder pressures are developed** This is incorrect. The goal of injector hold-down is precisely to **prevent** movement. If the injector moved under high cylinder pressure, gas leakage would occur, rapidly eroding the cylinder head and injector seat (a condition known as "blow-by"). The washers are designed to maintain a high, rigid clamping force, not to allow movement in response to pressure spikes. **D) permit accurate stretch gauge measurement of bolt elongation during installation** This is incorrect. Bolt stretch measurement (used for torque-to-yield or angle-tightening processes) is a property of the bolt itself, related to its material and design, and is measured using specialized tools (stretch gauges or micrometers). While the washer is part of the final assembly, it does not facilitate or permit the measurement of the bolt's elongation; its function is purely related to maintaining the clamping load dynamically during operation.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app