Question 45 DDE01 - Designated Duty Engineer - Unlimited HP

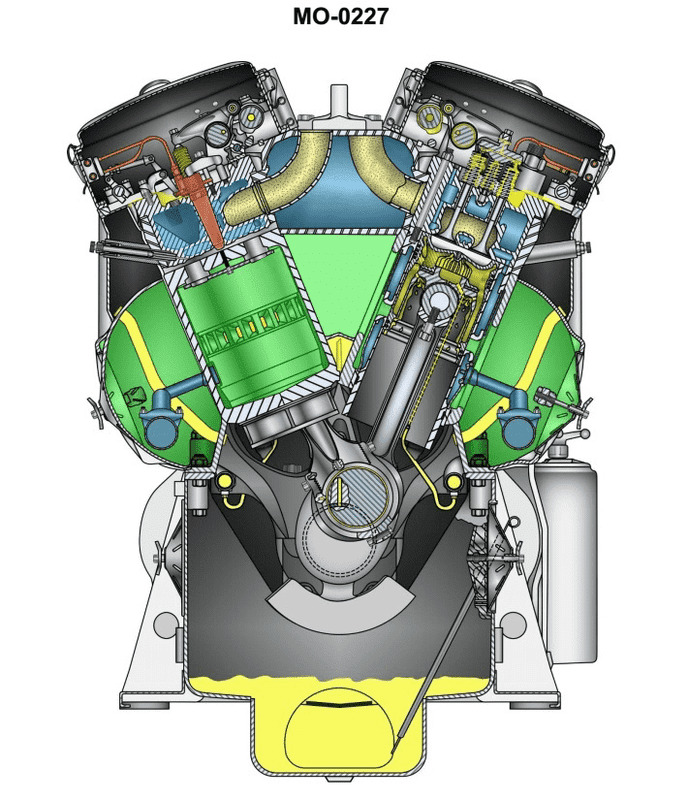

You are serving as a designated duty engineer onboard a harbor tug equipped with main propulsion diesel engines of the type shown in the illustration. What scavenging flow pattern is used in this engine type? Illustration MO-0227

The Correct Answer is C ### Explanation of Correct Option (C) **C) Uniflow** The illustration MO-0227 is a standard representation of a large, slow-speed, two-stroke marine propulsion diesel engine (typically an M.A.N. or Sulzer/Wärtsilä design). These engines are characterized by: 1. **Piston-controlled exhaust ports at the bottom of the cylinder liner (or exhaust valves at the bottom, depending on the specific older design, though the modern standard is uniflow with exhaust valves at the top).** *Correction based on standard modern practice for these engines:* The defining feature is the **intake ports located near the bottom of the liner** (controlled by the piston) and **a large single or multiple exhaust valve(s) located in the cylinder head (at the top).** 2. **Scavenging Air Flow:** Air enters through the peripheral ports at the bottom and flows straight up the cylinder, pushing the combustion products out through the exhaust valve(s) at the top. 3. **Pattern:** Because the air flows in one direction only (bottom to top) without reversing or looping back, this flow pattern is called **Uniflow**. This design maximizes scavenging efficiency and is essential for the high performance and low fuel consumption of large modern two-stroke engines. ### Explanation of Incorrect Options **A) Loop** Loop scavenging involves both the intake and exhaust ports being located at the bottom of the cylinder liner. The incoming air flows up one side, loops over near the cylinder head, and flows down the other side to exit through the exhaust ports. This pattern is generally associated with smaller, less efficient two-stroke engines (like certain older auxiliary or automotive diesels) and is not used in modern, large, crosshead marine propulsion engines. **B) Return-flow** Return-flow scavenging is essentially synonymous with Loop scavenging (where the flow returns toward the ports of entry), or sometimes used specifically to describe older Kadenacy-effect scavenging designs. It relies on the air flow reversing direction within the cylinder and is fundamentally different from the straight-through uniflow concept utilized in the illustrated engine type. **D) Cross-flow** Cross-flow scavenging is an older, generally inefficient method where the intake ports and exhaust ports are situated opposite each other (on different sides of the liner) at the bottom. The incoming air aims across the piston crown directly toward the exhaust ports. While simple, it leads to significant mixing of fresh air and exhaust gas, and poor scavenging effectiveness. This pattern is not used in large, high-efficiency marine propulsion diesel engines.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app