Question 24 3AE01 - Third Assistant Engineer

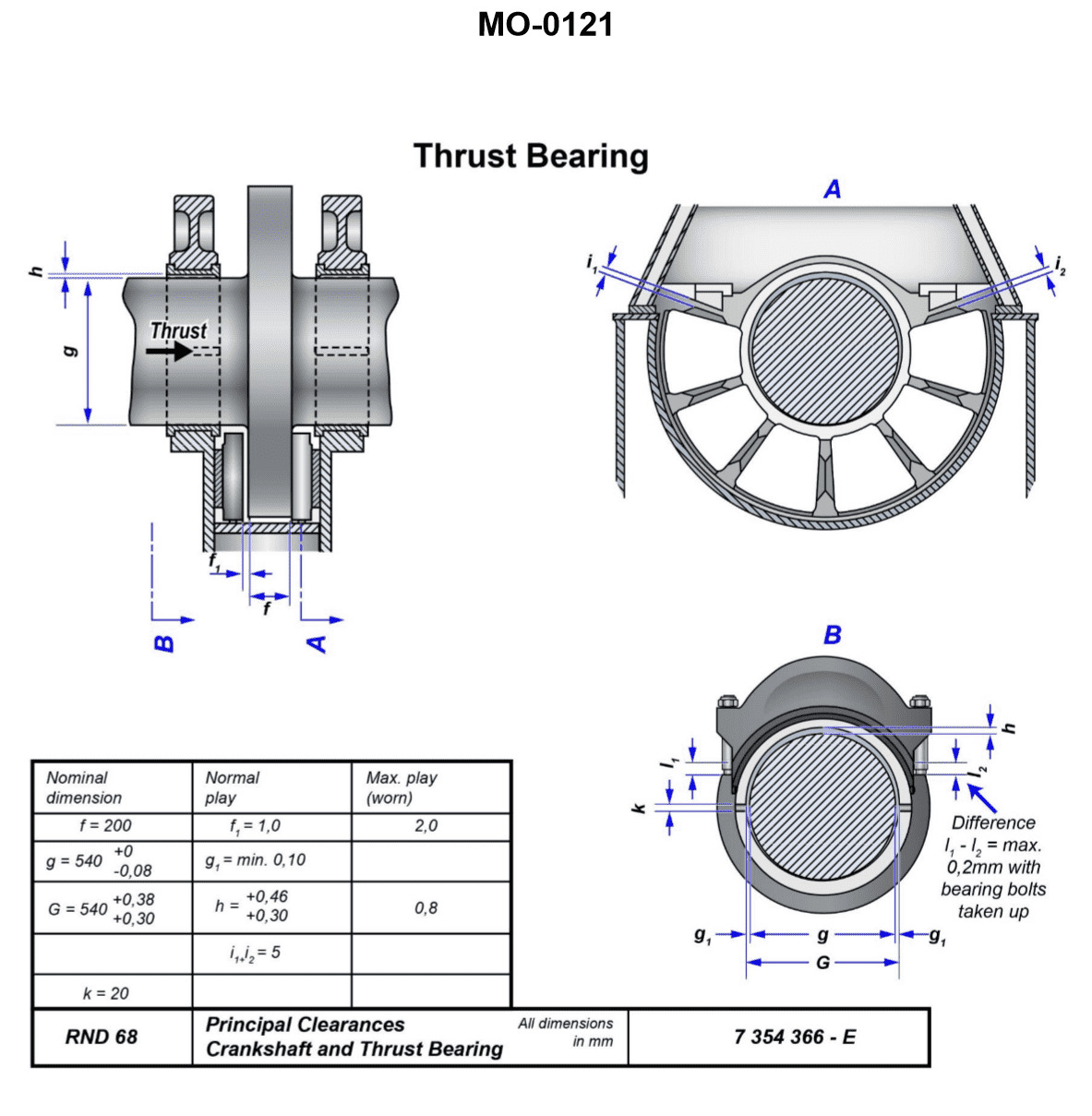

The thrust bearing shown in the illustration has over eight years of ahead running time. Measurements show "i1" is 4 mm and "i2" is 1 mm. Which of the following conditions is indicated and what steps should be taken, if any? Illustration MO-0121

The Correct Answer is A ### Explanation for Option A Option A is correct because the measurements indicate minimal and acceptable wear on the thrust bearing components over the extended running period. 1. **Interpretation of Measurements:** In typical thrust bearing arrangements (such as Kingsbury or Michell designs), $i1$ (4 mm) represents the total axial float or design clearance allowed for the shaft. $i2$ (1 mm) represents the measured movement of the shaft (wear) from its new/zero position toward the ahead stop. 2. **Wear Assessment:** The bearing has run for over eight years, and the total measured wear is only 1 mm against a total design clearance of 4 mm. 3. **Rate of Wear:** The average wear rate is $1 \text{ mm} / 8 \text{ years} = 0.125 \text{ mm}$ per year. This rate is far below typical alarm or excessive limits. Since the wear is minor and the bearing still has 3 mm of allowable movement remaining, the wear is considered non-appreciable. 4. **Conclusion:** Since the wear is minimal and well within operational limits, no extraordinary corrective actions are necessary. The standard prescribed maintenance and monitoring schedule should be continued. ### Explanation of Why Other Options Are Incorrect **B) A wear rate of 1.6 mm per year occurred. Although not excessive, this condition may require more frequent monitoring.** This option is incorrect because the calculated wear rate is based on an incorrect calculation. If the wear is 1 mm over 8 years, the rate is $0.125 \text{ mm}$ per year, not 1.6 mm per year. A rate of 1.6 mm per year would result in 12.8 mm of wear over eight years, which contradicts the actual measurement of 1 mm. **C) The stops in which the thrust bearing block rides are worn, and it is necessary to return these to their original specifications.** The primary indicator of thrust bearing wear is the change in the axial position ($i2$), which measures the actual wear of the thrust pads/shoes. While the stops may eventually wear, the reading of 1 mm indicates general, acceptable pad wear. If the stops themselves were severely worn, it would likely alter the total float measurement ($i1$) or require a much higher $i2$ reading to be considered critical. **D) A wear rate of 1.6 mm per year is excessive and requires immediate assistance from the manufacturer's field support.** This option fails for the same reason as Option B: the calculation of 1.6 mm per year is incorrect. The actual wear rate ($0.125 \text{ mm}$/year) is very low and does not require urgent attention or manufacturer assistance.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app