Question 31 QMED05 - Machinist-Pump Technician

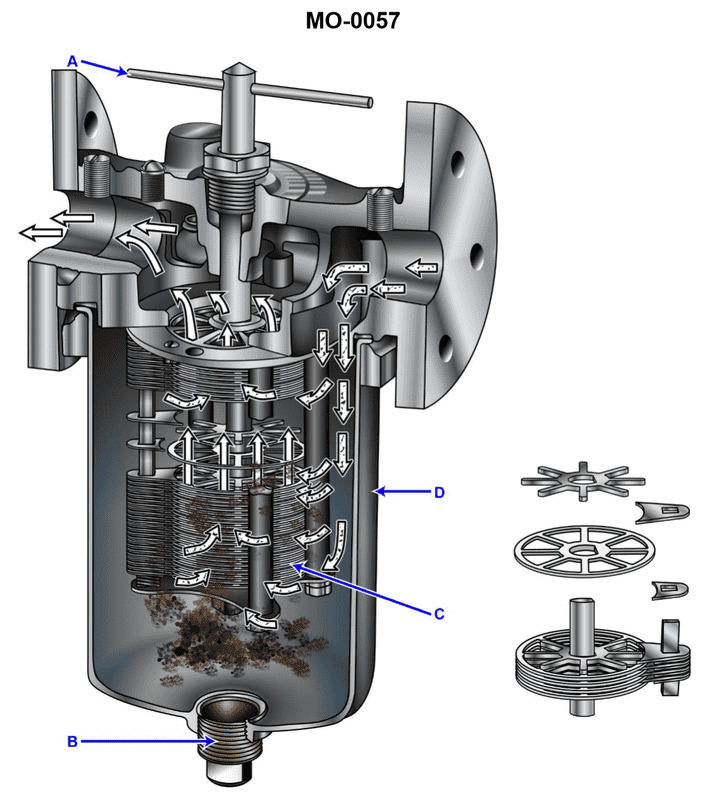

The lube oil strainer shown in the illustration is used on the reduction gear of a mid-size diesel engine. The strainer elements consist of __________. Illustration MO-0057

The Correct Answer is C **Explanation of Option C (metal disks):** The lube oil strainer referenced (often a duplex filter/strainer system used on engine reduction gears and sometimes on the main engine lube oil system itself) is typically designed to handle high flow rates of hot, relatively viscous oil while providing a reliable level of filtration without excessive pressure drop. A common type of self-cleaning strainer used in marine and power generation diesel applications is the **metal disk** type (sometimes called edge-type or stacked-disk strainers). These strainers consist of numerous metal disks separated by spacers, creating very precise, uniform gaps (typically 0.003 to 0.006 inches). When oil flows through these gaps, particulate matter is trapped on the edge of the disks. They are favored in critical systems because: 1. **Durability and Reliability:** They are robust, made of metal, and are not consumable items like paper or fine mesh. 2. **Cleanability:** They are easily cleaned (often automatically or manually) by rotating the element relative to a scraper blade, shearing off the accumulated dirt. This "backwash" or self-cleaning capability is essential for continuous operation. 3. **High Flow Rate/Low Pressure Drop:** The design allows for high flow capacity relative to the housing size. **Explanation of Incorrect Options:** **A) wire mesh:** Wire mesh is often used for coarse strainers (suction strainers or basket strainers) and sometimes for fine filtration (sintered metal mesh), but typical engine reduction gear strainers, particularly those designed for continuous operation and back-flushing, utilize the stacked metal disk design for rigidity, precise gap control, and easy cleaning, which is superior to fine wire mesh bags or baskets in this specific application. **B) pleated paper:** Pleated paper elements are used extensively in modern diesel engine *full-flow* and *bypass* filters. While they offer very high efficiency (often filtering down to 10 microns or finer), they are **consumable elements**. They cannot be cleaned or back-flushed and must be replaced regularly. The reduction gear strainer typically acts as a *primary* or *safety* strainer and is designed to be permanent and self-cleaning, making disposable paper unsuitable. **D) fibrous braid:** Fibrous braids or yarn-wound elements (depth filtration cartridges) are used in some industrial applications, but they are not standard for the high-volume, high-temperature, primary lube oil straining application on a mid-size marine reduction gear. Like paper, they are consumable depth filters that cannot be cleaned effectively, making them impractical for a permanent self-cleaning strainer application.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app