Question 4 QMED01 - Junior Engineer

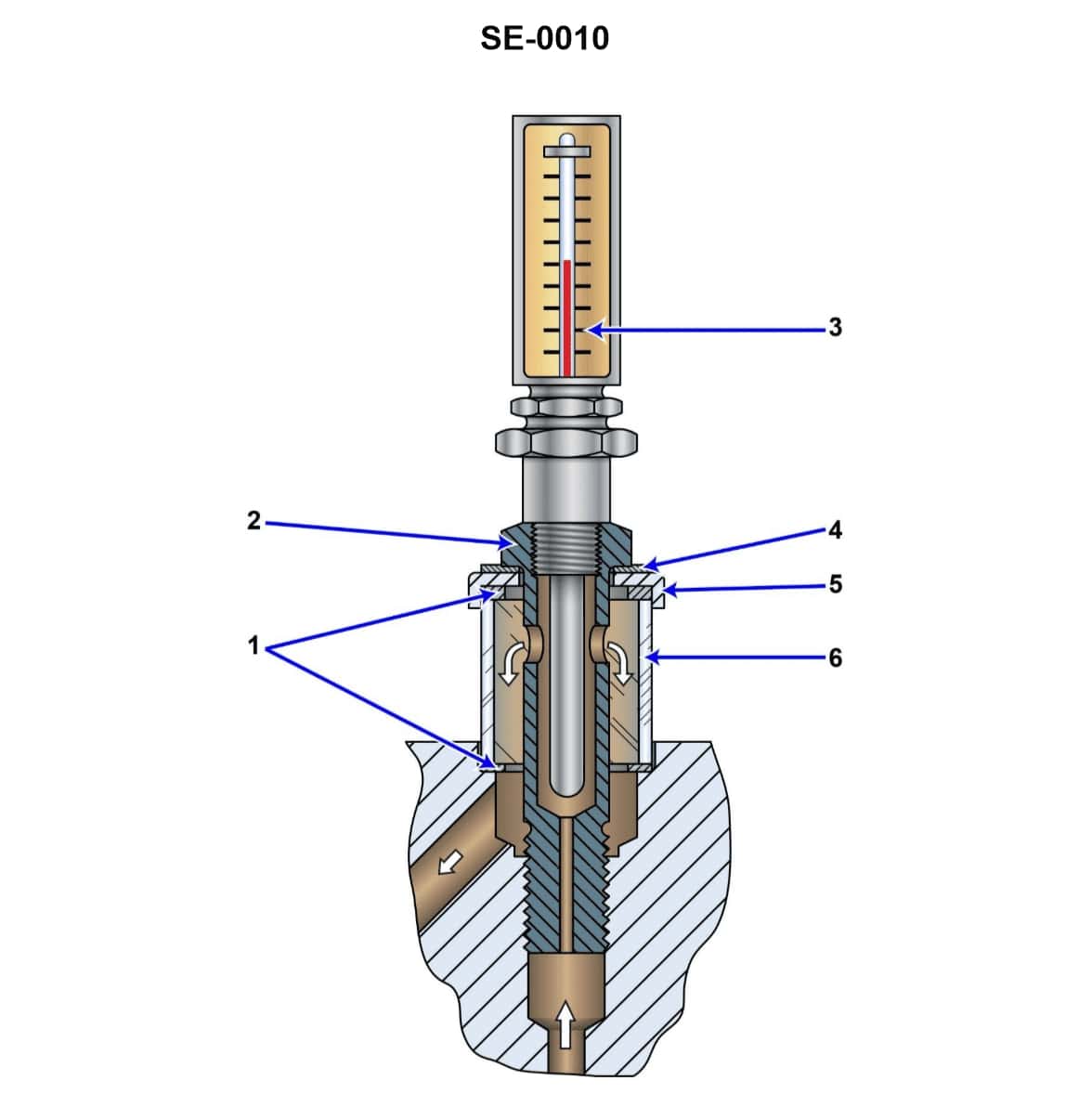

What statement is true concerning the illustrated steam turbine bearing lubricating oil flow and temperature indicating device? Illustration SE-0010

The Correct Answer is A. **Explanation of Correctness (Option A):** In standard engineering practice for pressurized lubrication systems (like those found on steam turbine bearings), the primary purpose of the local indicating devices is to monitor the condition and function of the bearing itself. 1. **Thermometer (Temperature Indication):** The most critical temperature to monitor is the temperature of the oil **after** it has passed through the bearing (the oil drain or return line). This oil has absorbed the heat generated by friction within the bearing. A sudden or elevated temperature rise in the exit oil directly indicates a problem (e.g., inadequate cooling, excessive load, or bearing wear). The temperature of the oil entering the bearing (supply oil) is typically controlled and monitored centrally, but the bearing exit temperature is the crucial local safety indicator. 2. **Sight Glass (Flow Indication):** The sight glass is generally placed on the oil return line (drain line) to visually confirm that the oil is indeed exiting the bearing and returning to the reservoir. While the flow rate is measured, the critical function of the sight glass is to provide immediate visual confirmation of oil movement **leaving** the bearing, ensuring that the bearing is not being starved of oil and the drain is not clogged. Therefore, both indicators are typically positioned on the oil drain path *leaving* the bearing. **Explanation of Incorrect Options:** * **B) The thermometer indicates the temperature of the oil entering the bearing and the sight glass indicates the flow of the oil leaving the bearing.** This is incorrect because monitoring the temperature of the oil *leaving* the bearing is the essential safety function, not the oil entering. * **C) The thermometer indicates the temperature of the oil entering the bearing and the sight glass indicates the flow of the oil entering the bearing as well.** This is incorrect. Monitoring supply conditions (flow and temperature) is less critical locally than monitoring exit conditions (heat absorption and confirmation of drainage/flow). Supply pressure is often monitored instead of or in addition to supply flow. * **D) The thermometer indicates the temperature of the oil leaving the bearing and the sight glass indicates the flow of the oil entering the bearing.** This is incorrect. While the thermometer is correctly identified as measuring the oil leaving, the sight glass is almost always placed on the drain line to confirm that the used oil is flowing out, rather than confirming the high-pressure supply flow going in.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app