Question 28 OSE02 - Assistant Engineer - OSV

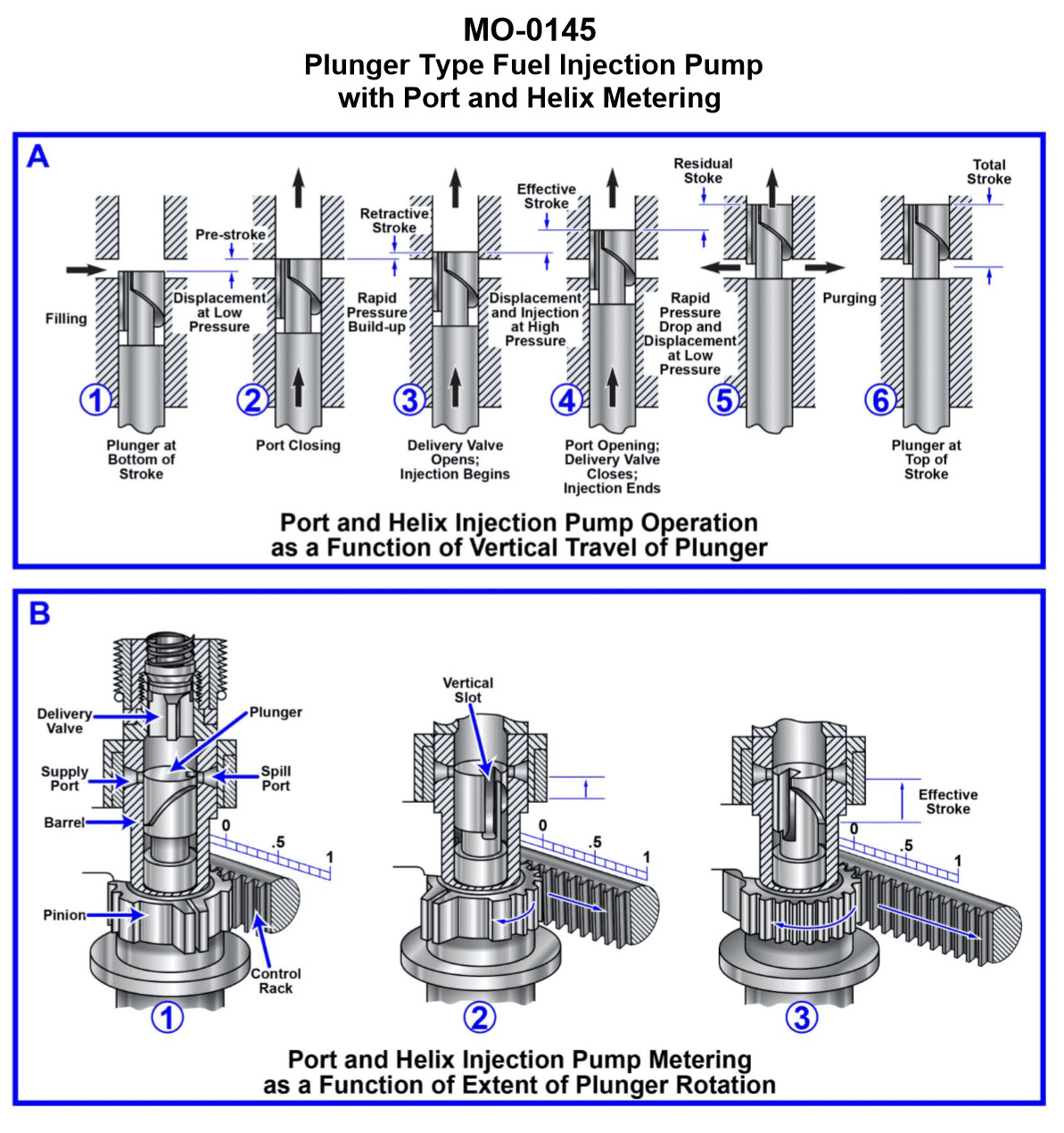

The oil spill response vessel to which you are assigned has diesel generators fitted with multi-plunger pumps with the metering principle as shown in the illustration. What statement is true concerning this injection pump type? Illustration MO-0145

The Correct Answer is C ### 1. Explanation for Option C (Correct Answer) Option C states: "As the load changes, the beginning of injection is constant, and the ending of injection is variable." This statement accurately describes the operational principle of a conventional multi-plunger jerk pump (also known as an inline or A-type pump), which is commonly used in diesel generators and marine vessels, and is typical of the type referenced by Illustration MO-0145. * **Beginning of Injection (Constant):** In this type of pump, the beginning of injection is determined by the point at which the plunger's top edge covers the intake port (spill port) on its upward stroke. This position is fixed relative to the camshaft rotation and the plunger's motion. Therefore, regardless of how much fuel is being delivered (i.e., regardless of the engine load), the beginning of the compression/delivery phase remains constant. * **Ending of Injection (Variable):** Fuel metering (and thus load control) is achieved by rotating the plunger via the rack and pinion mechanism. The plunger has a helix (or helical groove) machined into its body. When the plunger is rotated, the effective length of the stroke changes because the helix aligns with the spill port at different times. The injection ends when the helix uncovers the spill port, allowing the high-pressure fuel to spill back into the pump gallery. By rotating the plunger, the timing of this spill event is varied, thus changing the duration of injection and the volume of fuel delivered. Since the duration changes, the ending time of the injection is variable. ### 2. Explanation of Incorrect Options **A) As the load changes, the beginning of injection is variable, and the ending of injection is constant.** This is incorrect. As explained above, the beginning of injection is fixed (constant) by the design geometry (when the plunger covers the intake port), while the ending of injection is varied by the control rack (helix alignment). **B) As the load changes, the beginning of injection is variable, and the ending of injection is variable.** This is incorrect. While the ending of injection is variable (to control fuel quantity), the beginning of injection in this standard pump design is constant. Pumps that vary both beginning and ending timings are usually equipped with additional timing advance mechanisms, but the fundamental metering principle of the multi-plunger jerk pump only varies the end point. **D) As the load changes, the beginning of injection is constant, and the ending of injection is constant.** This is incorrect. If both the beginning and ending of injection were constant, the pump would deliver a constant volume of fuel, meaning there would be no way to change the engine load. The pump must vary the duration of injection (i.e., the end point) to meter the fuel quantity required for different loads.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app