Question 5 CEL01 - Chief Engineer - Limited

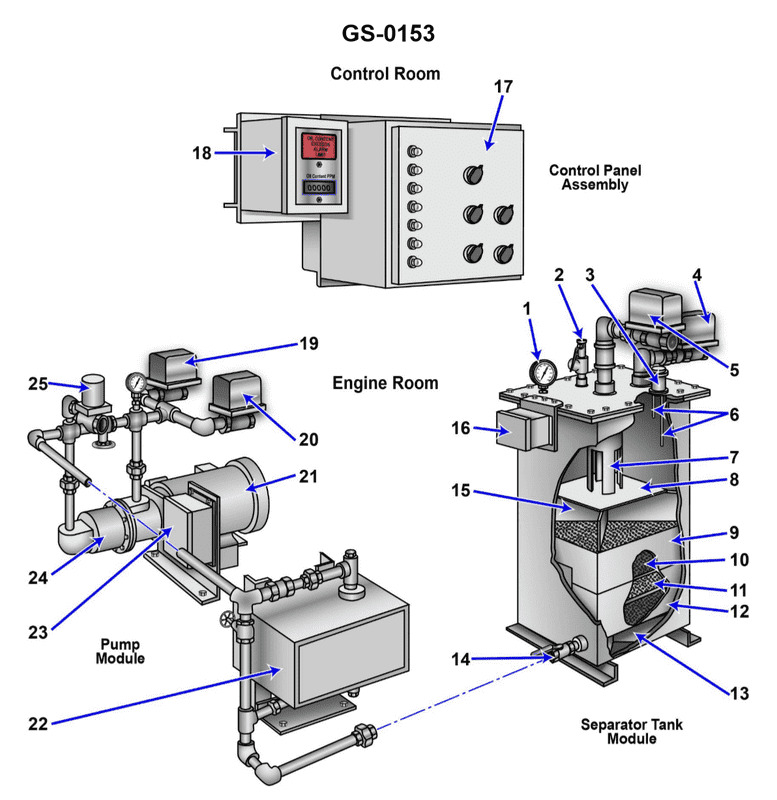

When the oily-water separator, shown in the illustration, is in operation and processing clear bilge water, what should be the internal water level? Illustration GS-0153

The Correct Answer is C ### Why Option C is Correct: In a typical marine oily-water separator (OWS), especially those utilizing gravity separation and coalescing elements (like the one implied by the reference to coalescer bed "9" and standard OWS operation), the primary goal is to separate oil (which floats) from water (which sinks). For the separator to operate efficiently and produce legally clear bilge water (meaning, water with an oil content below 15 ppm) and ensure a continuous flow of separated oil out of the top, the separation chamber must be kept full. Maintaining the water level in the **upper section of the tank** (or near the top outlet) ensures: 1. **Maximum Retention Time:** A high water level maximizes the volume of water held in the tank, increasing the residence time for gravity separation to occur. 2. **Effective Oil Skimming:** It allows the separated oil layer to accumulate at the very top, where it can be continuously skimmed off through an oil outlet (often controlled by an automatic oil discharge valve or sensor). 3. **Full Utilization of Coalescers:** It ensures that the entire coalescer matrix ("9") is submerged and functioning optimally to break emulsions and capture fine oil droplets. 4. **Hydrostatic Pressure Control:** The level is typically controlled by an interface detector or a weighted oil discharge valve/loop that maintains a constant hydrostatic head, pushing the clean water out of the bottom or middle and the oil out of the top. ### Why Other Options Are Incorrect: **A) The water level in the tank should be slightly above the upper coalescer bed "9".** This statement is often true in practice, but Option C is a more general and accurate description of the operational state. If the level is only *slightly* above the coalescer, any fluctuation in flow or movement might expose the top of the coalescer, reducing efficiency. Option C ("located in the upper section") encompasses the correct operational state (full tank) without being overly specific or potentially restrictive like "slightly above." **B) The water level should be located in the lower section of the tank as controlled by flow control valve "14".** Maintaining the water level in the lower section would drastically reduce the effective separation volume and retention time. It would also leave the upper coalescing elements dry and unable to function, resulting in poor separation and potentially discharging oily water overboard. **D) No water level is maintained in the tank.** This is incorrect. The OWS is a pressure vessel (or a system relying on hydrostatic head) designed to separate two immiscible liquids. To function continuously, the vessel must be kept full of liquid (oil and water) and the level (or interface) meticulously controlled to allow for proper discharge of both separated phases.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app