Question 58 3AE02 - Third Assistant Engineer (Alt)

How would you prevent the rudder from moving while a repair is made on the steering system using the illustrated actuator? Illustration GS-0116

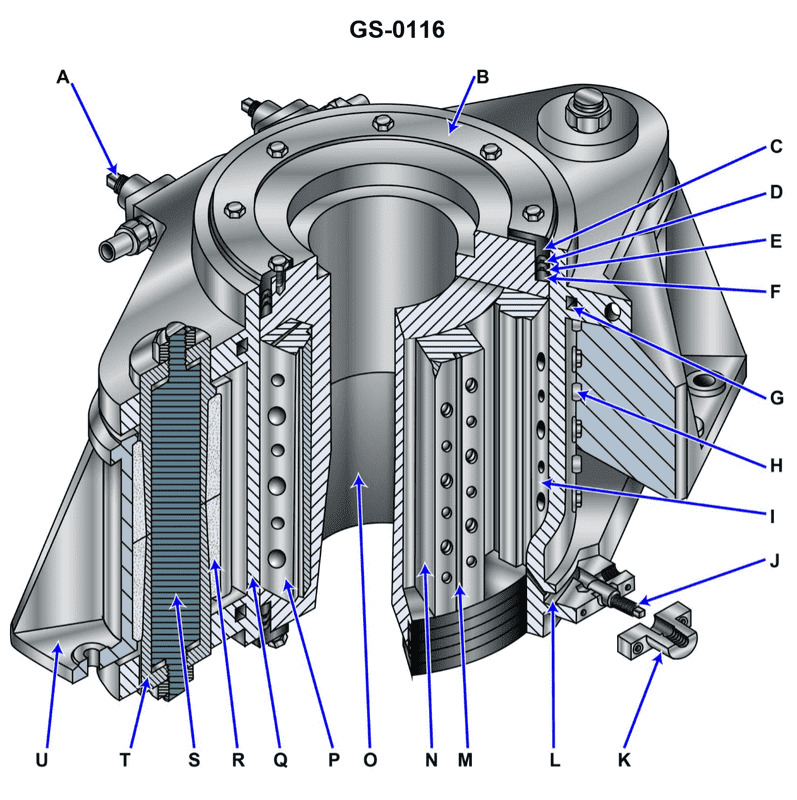

The Correct Answer is C ### Explanation of Why Option C is Correct The rudder is moved by the hydraulic pressure acting on the piston within the actuator (ram). When a repair is being made on the steering system (especially the pumps, control units, or piping), the main hydraulic lines may be depressurized or opened. If the hydraulic fluid can escape or move freely, the sea forces acting on the rudder blade will cause the rudder to swing uncontrollably, posing a severe danger. **Option C, "secure the valves in the supply and return lines,"** refers to isolating the main hydraulic cylinder (actuator) by closing and securing (locking/tagging out) the primary stop valves (king valves) leading into the ram cylinders. By closing these isolation valves, the hydraulic fluid is trapped and locked within the ram cylinders. Since liquids (like hydraulic oil) are virtually incompressible, this trapped volume of fluid acts as a solid restraint, mechanically locking the rudder firmly in its current position and preventing movement due to external sea forces. This procedure is the standard and safest way to secure a hydraulic steering gear before maintenance on the power unit. *** ### Explanation of Why Other Options are Incorrect **A) tighten the locking pins, item "H" at each position of item "I" to keep the rudder from swinging:** Items H and I usually represent the mechanical hard-over stops, which limit the maximum swing angle of the rudder. They are designed to prevent structural damage from over-travel, not to secure the rudder against sea forces for maintenance. Furthermore, using stops only prevents the rudder from exceeding a certain angle; it does not secure it firmly in the repair position. **B) tighten the locking screws in item "S":** Without the specific illustration, item "S" is abstract, but locking screws generally refer to securing linkage components or controls (like follow-up linkages or pump settings). These components control the flow of fluid; tightening them does not hydraulically or mechanically lock the main actuator cylinder against sea forces. **D) screw in the locking pin, item "J":** Item J often refers to a screw mechanism related to the bypass valve. While ensuring the bypass valve is fully closed is necessary, simply closing the bypass valve is insufficient if the main supply and return lines are still open to the hydraulic reservoir or pump system. Full isolation (Option C) traps the fluid throughout the entire ram cylinder, which is the comprehensive security measure required.

Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app