Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app

UFIV01 - Chief Engineer - UFIV

49 images

Question 1

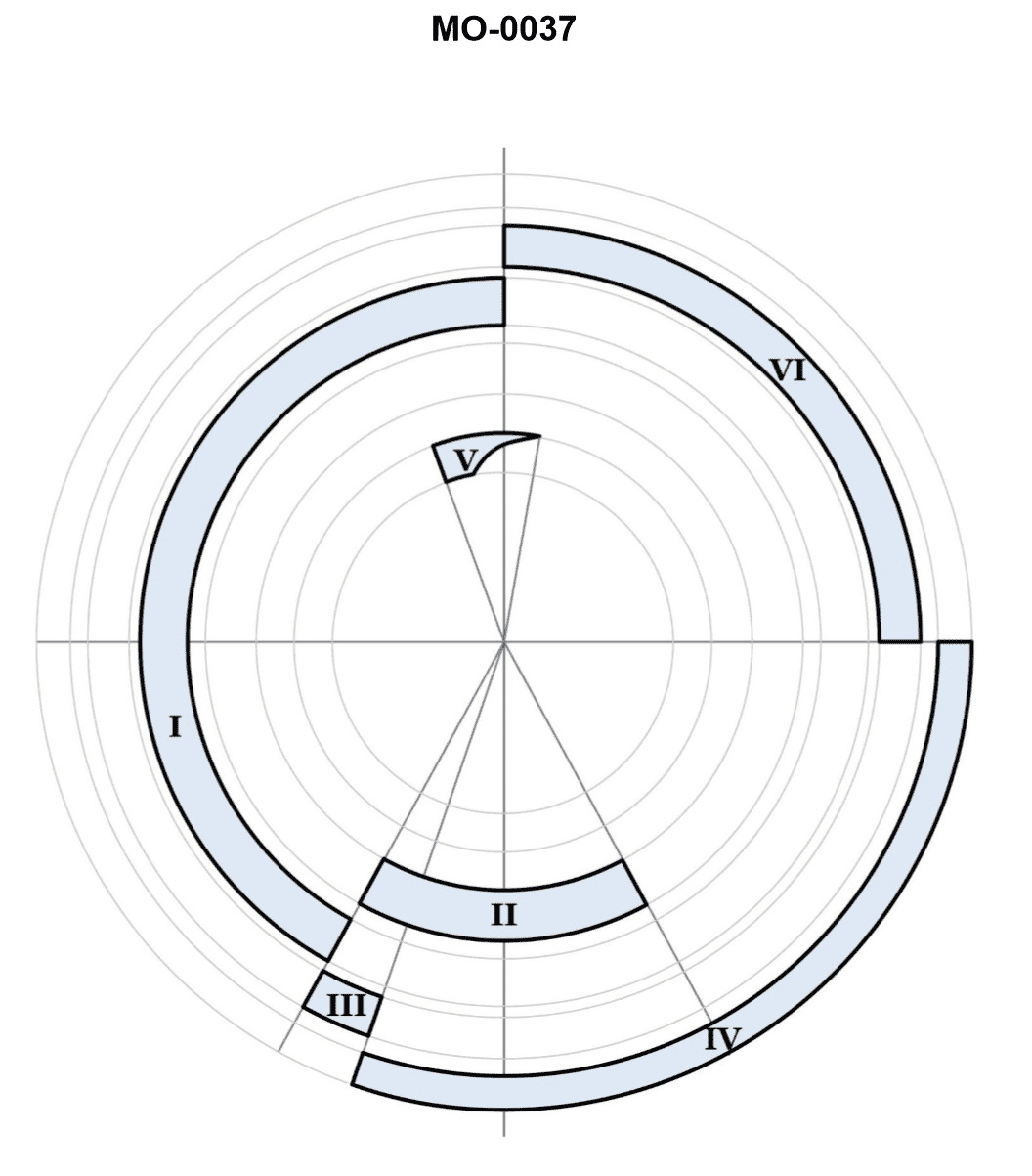

Question: You are assigned to an uninspected fishing industry line vessel fitted with main propulsion diesel engines operating on the cycle represented in the polar timing diagram shown in the illustration. What events or effects are represented by "II", "III", and "IV" respectively? Illustration MO-0037

A. "II" represents the exhaust period where the exhaust valves are held open. "III" represents a pressure loss effect where the cylinder pressure is lowered by exhaust blowdown. "IV" represents the scavenging period where the scavenging-air ports are uncovered.

B. "II" represents the exhaust period where the exhaust valves are held open. "III" represents a supercharging effect where the cylinder pressure is boosted with the scavenging air blower. "IV" represents the scavenging period where the scavenging-air ports are uncovered.

C. "II" represents the scavenging period where the scavenging-air ports are uncovered. "III" represents a pressure loss effect where the cylinder pressure is lowered by exhaust blowdown. "IV" represents the exhaust period where the exhaust valves are held open.

D. "II" represents the scavenging period where the scavenging-air ports are uncovered. "III" represents a supercharging effect where the cylinder pressure is boosted with the scavenging air blower. "IV" represents the exhaust period where the exhaust valves are held open.

The Correct Answer is D 1. **Explanation for Option D being Correct:** * **Context:** The illustration MO-0037 depicts a polar timing diagram (or valve/port timing diagram) for a large, slow-speed, uninspected fishing industry line vessel operating with main propulsion diesel engines. These diagrams typically represent two-stroke cycle engines, which utilize scavenging and have timed port/valve openings relative to the crankshaft angle (TDC/BDC). * **"II" represents the scavenging period where the scavenging-air ports are uncovered:** In a two-stroke engine, scavenging air is introduced to push residual exhaust gases out. On the timing diagram, the scavenging ports typically open slightly before the exhaust closes, allowing pressurized air to enter the cylinder. "II" represents the initial period of flow controlled by the uncovering of the ports. * **"III" represents a supercharging effect where the cylinder pressure is boosted with the scavenging air blower:** After the scavenging process is complete (residual gases removed), the pressure of the inlet air (supplied by the blower/turbocharger) often remains higher than the atmospheric pressure or the pressure required for simple scavenging. This final boost, achieved by delaying the closure of the inlet ports/valves, is known as a supercharging effect (sometimes called 'packing'), which increases the density and amount of air trapped for combustion. "III" usually represents this overlap/boosting phase just before compression begins. * **"IV" represents the exhaust period where the exhaust valves are held open:** The exhaust process must begin before BDC (Blowdown) and continue through BDC while the piston moves upward. "IV" represents the main duration where the exhaust gases are expelled from the cylinder, controlled by the opening of the exhaust valve(s) (in uniflow scavenged engines) or the exhaust ports. 2. **Why other options are incorrect:** * **Option A is incorrect:** * It incorrectly identifies "II" as the exhaust period and "IV" as the scavenging period. The scavenging period typically precedes the compression stroke immediately and the exhaust period is much longer, starting well before BDC. Furthermore, while "III" describes a pressure loss (exhaust blowdown), the diagram typically uses "III" to indicate the boosting/supercharging effect achieved by the scavenging system after the main exhaust period is completed and the ports are still open. * **Option B is incorrect:** * It incorrectly identifies "II" as the exhaust period. "II" is situated where the scavenging ports are uncovered just before the compression stroke officially starts. While it correctly identifies "III" as supercharging and "IV" as scavenging, the labeling of "II" and "IV" is reversed compared to the standard representation of the scavenging and exhaust events on the diagram. * **Option C is incorrect:** * It incorrectly identifies "II" as the scavenging period and "IV" as the exhaust period (consistent with D), but it incorrectly identifies "III" as a pressure loss effect due to exhaust blowdown. "III" occurs *after* the blowdown (which happens much earlier, when the exhaust valve first opens) and is specifically the period where the inlet pressure is maintained or boosted to maximize the trapped air charge (supercharging).

Question 2

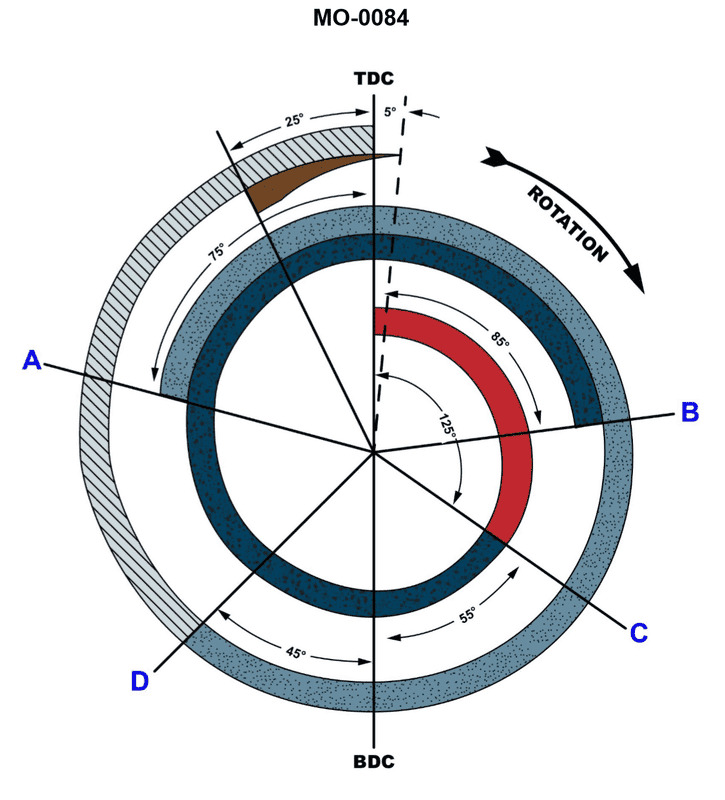

Question: You are assigned to a fishery research vessel fitted with main propulsion diesel engines operating on the cycle represented in the polar timing diagram shown in the illustration. When do the intake valves open and close respectively? Illustration MO-0084

A. The intake valves open at 45o after bottom dead center on the compression stroke. The intake valves close at 75o before top dead center on the exhaust.

B. The intake valves open at top dead center at the beginning of the intake stroke. The intake valves close at bottom dead center at the end of the intake stroke.

C. The intake valves open at bottom dead center at the end of the intake stroke. The intake valves close at top dead center at the beginning of the intake stroke.

D. The intake valves open at 75o before top dead center on the exhaust stroke. The intake valves close at 45o after bottom dead center on the compression stroke.

The Correct Answer is D **Explanation for why Option D is correct:** 1. **Context:** The illustration MO-0084 (a typical polar timing diagram for a four-stroke diesel engine) depicts the timing events of the valves relative to the crankshaft position. The cycle starts (TDC) with the power stroke, followed by exhaust, intake, and compression. 2. **Intake Valve Opening (IVO):** To maximize the scavenging (clearing of residual exhaust gases) and volumetric efficiency, the intake valve typically opens early, well before the piston reaches Top Dead Center (TDC) at the end of the exhaust stroke. This timing, known as valve overlap, allows the incoming fresh air to help push out the remaining exhaust gases. In standard timing diagrams for four-stroke engines, the intake valve usually opens around $75^{\circ}$ to $20^{\circ}$ before TDC (on the exhaust stroke). Option D states $75^{\circ}$ before top dead center (BTDC) on the exhaust stroke, which is a typical advanced opening timing. 3. **Intake Valve Closing (IVC):** To maximize the amount of air drawn into the cylinder (ram effect/inertia supercharging), the intake valve remains open after the piston has passed Bottom Dead Center (BDC) and has started moving upward on the compression stroke. This is called intake lag. Standard timing for intake valve closing is typically $20^{\circ}$ to $60^{\circ}$ after BDC (ABDC). Option D states $45^{\circ}$ after bottom dead center (ABDC) on the compression stroke, which is a common delayed closing timing for maximizing air charge. **Explanation for why other options are incorrect:** * **A) The intake valves open at $45^{\circ}$ after bottom dead center on the compression stroke. The intake valves close at $75^{\circ}$ before top dead center on the exhaust.** * This swaps the opening and closing events and places them incorrectly. Opening $45^{\circ}$ ABDC would severely restrict air intake. Closing $75^{\circ}$ BTDC would mean the valve closes near the beginning of the compression stroke, losing most of the air charge. * **B) The intake valves open at top dead center at the beginning of the intake stroke. The intake valves close at bottom dead center at the end of the intake stroke.** * This describes theoretical, idealized timing where the valves open and close exactly at TDC and BDC, respectively. Real engines use advanced opening (IVO before TDC) and retarded closing (IVC after BDC) to improve gas flow, scavenging, and volumetric efficiency. * **C) The intake valves open at bottom dead center at the end of the intake stroke. The intake valves close at top dead center at the beginning of the intake stroke.** * This completely reverses the function of the valve timing. The intake valve must be open during the intake stroke (TDC to BDC), not closed during it.

Question 2

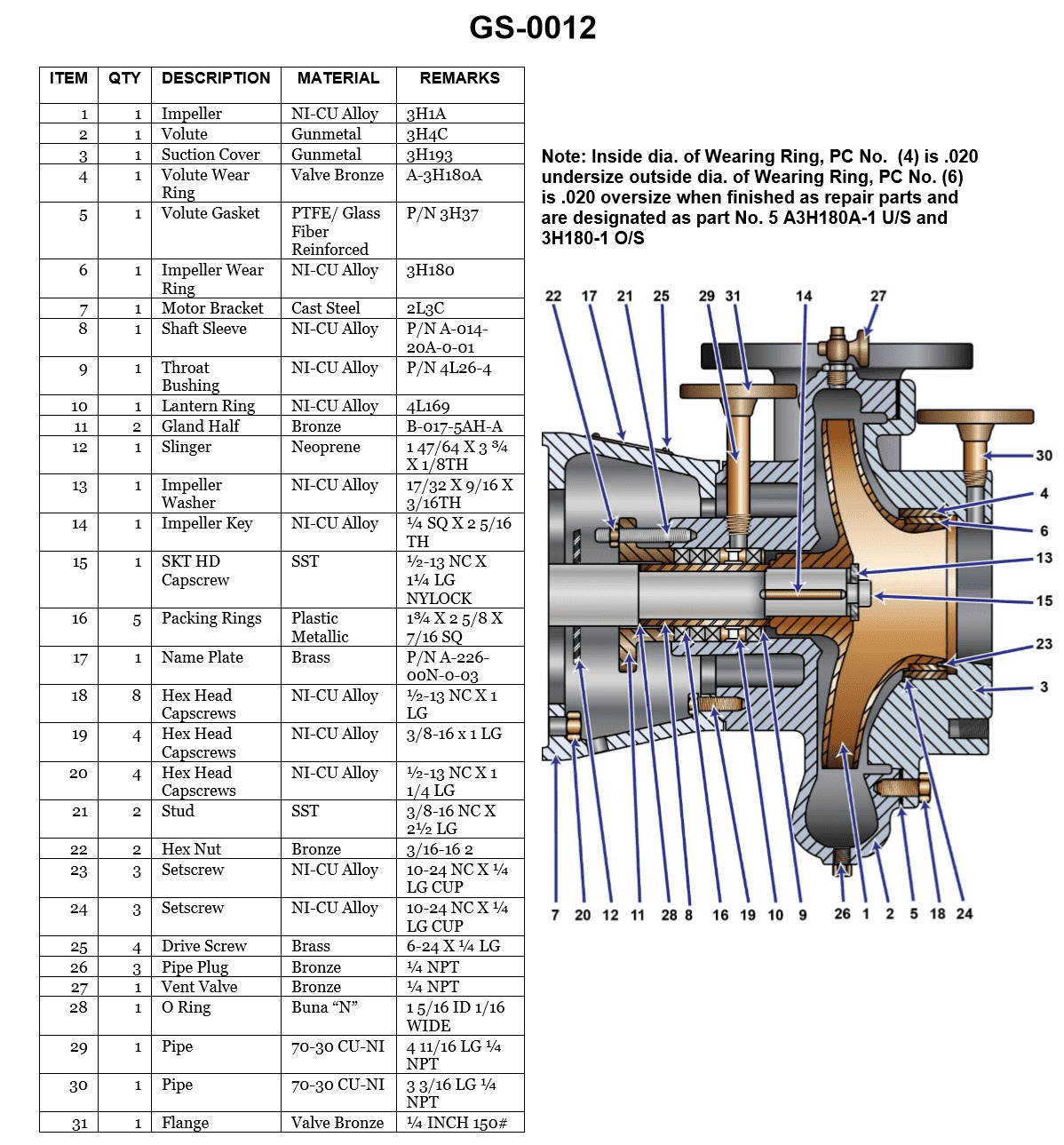

Question: In the illustration shown, an efficient seal is maintained between the suction cover and the volute by __________. Illustration GS-0012

A. good metal-to-metal contact

B. sealant between the two parts

C. an ptfe/glass fiber reinforced gasket

D. compressing the packing rings

The Correct Answer is C ### Why Option C is Correct: An efficient, pressure-tight seal between two major, rigid components like the suction cover and the volute casing of a centrifugal pump is standardly achieved using a **gasket**. The gasket fills microscopic irregularities and conforms to the surfaces when compressed, creating a reliable seal. An **PTFE (Teflon)/glass fiber reinforced gasket** is a common, high-performance material choice for industrial pumps because PTFE offers excellent chemical resistance and low friction, while the glass fibers provide necessary mechanical strength and dimensional stability to withstand the sealing forces and internal pressures. ### Why the Other Options are Incorrect: * **A) good metal-to-metal contact:** While machined surfaces are used, relying solely on metal-to-metal contact (a process known as lapping) to maintain a seal under varying pressures and temperatures between large pump components is generally unreliable and extremely expensive to achieve perfectly. A gasket is required to ensure a leak-proof connection. * **B) sealant between the two parts:** Sealants (like RTV silicone or threadlocker) are flexible compounds that cure in place. While sometimes used in conjunction with gaskets or in low-pressure applications, they are typically not robust enough to be the primary method for sealing the high-pressure, major casing joint between the suction cover and the volute in industrial pumps. A formed gasket is the standard engineering practice. * **D) compressing the packing rings:** Packing rings (or mechanical seals) are used to seal the area where the rotating pump shaft penetrates the casing (the stuffing box). They prevent leakage along the shaft, but they have no function in sealing the static joint between the suction cover and the volute casing.

Question 3

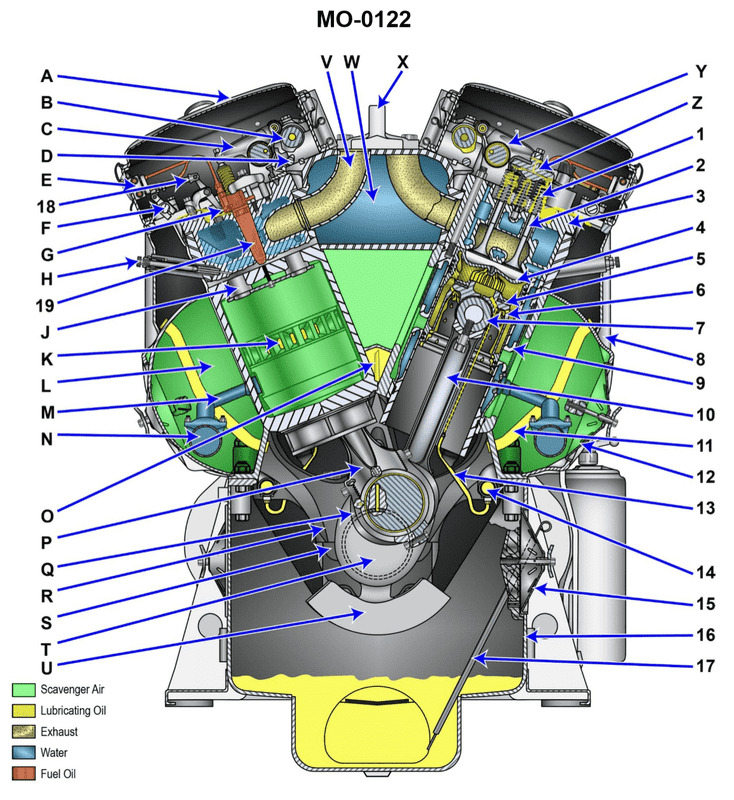

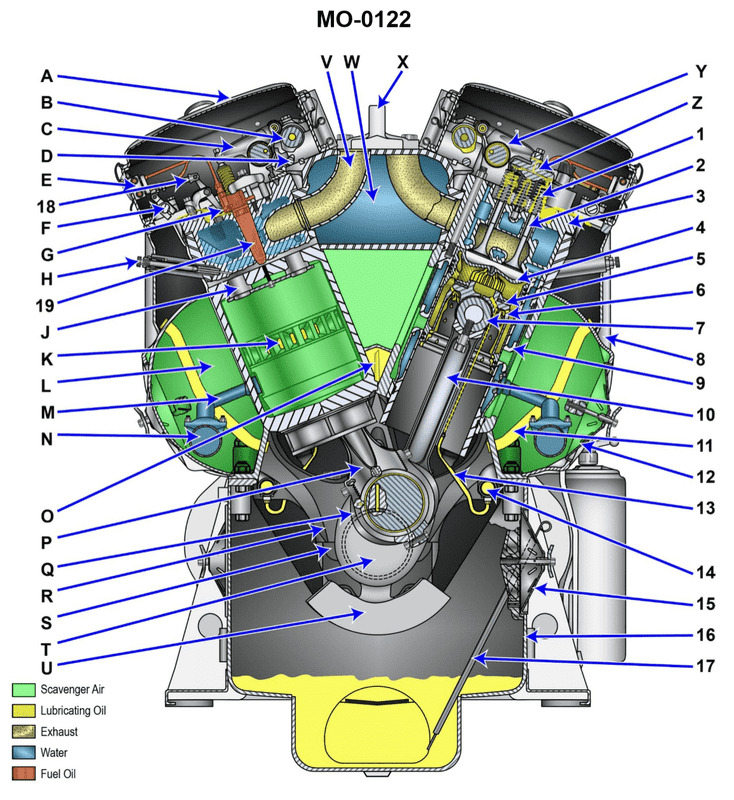

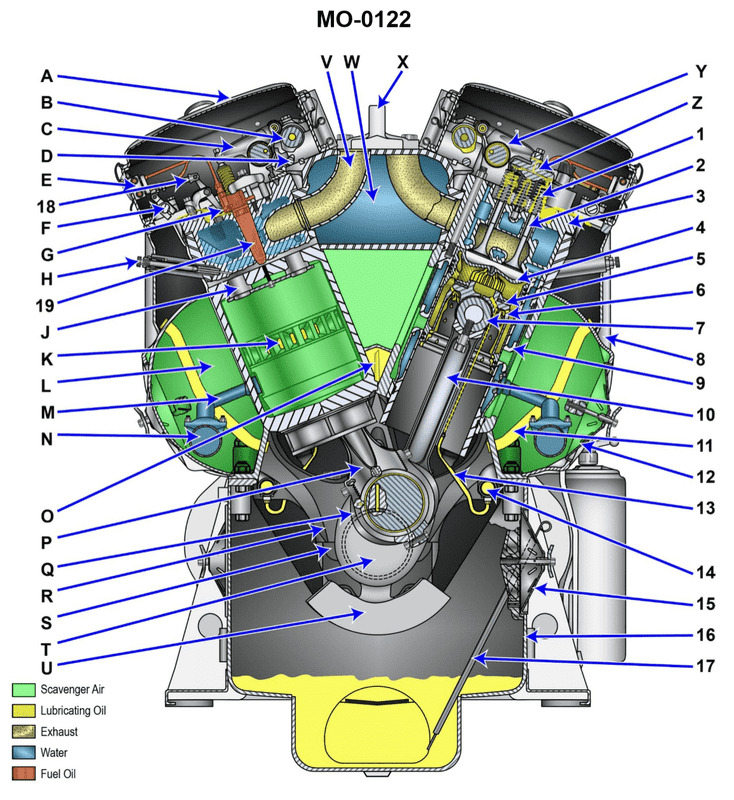

Question: You are assigned as an engineer on a fishing industry factory ship using main propulsion engines of the type shown in the illustration. Assuming that the piston is properly positioned, what statement represents the procedure for inspection of the compression rings while in place inside the engine? Illustration MO-0122

A. The inspection takes place by removing the appropriate cylinder head valve cover and viewing through the resulting opening.

B. The inspection takes place by removing the appropriate oil pan cover and viewing through the resulting opening.

C. It is not possible to inspect the compression rings while in place inside the engine.

D. The inspection takes place by removing the appropriate air box handhole cover and viewing through the resulting opening.

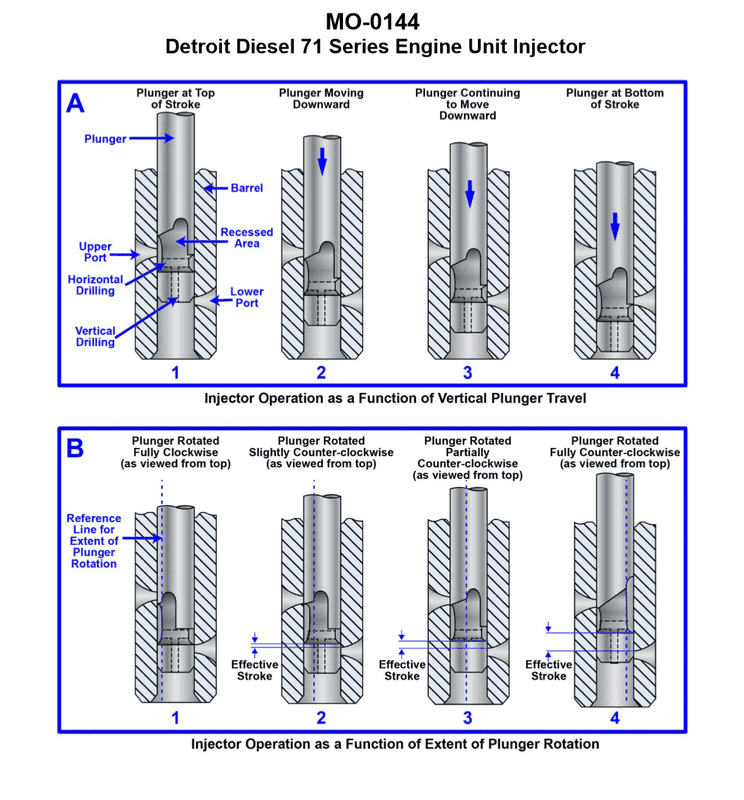

The Correct Answer is D **Explanation for Option D (Correct):** The illustration MO-0122 typically depicts a large, slow-speed, two-stroke diesel engine (common for main propulsion on factory ships). A critical design feature of these engines is the "air box" (or scavenging air manifold) which surrounds the lower part of the cylinder liner. The air box is where compressed scavenging air enters the cylinder through ports cut into the liner wall (when the piston is near bottom dead center). To facilitate maintenance and inspection, these air boxes are equipped with removable covers known as "air box handhole covers." When the piston is correctly positioned (above the scavenging ports), removing these covers allows a direct visual inspection of the piston rings (both compression and oil control rings) via the liner's scavenging ports. This is the standard, practical, and non-invasive procedure for inspecting the rings in this type of engine. **Explanation of Incorrect Options:** * **A) The inspection takes place by removing the appropriate cylinder head valve cover and viewing through the resulting opening.** This is incorrect. The valve cover (or cylinder head inspection cover) allows access to the valve gear (rockers, springs, etc.) on the top of the cylinder. It does not provide any view down the cylinder wall to the piston rings, which are much further down. * **B) The inspection takes place by removing the appropriate oil pan cover and viewing through the resulting opening.** This is incorrect. The oil pan cover (or crankcase inspection door) provides access to the running gear (crankshaft, connecting rod bearings, crosshead). While it allows viewing the underside of the piston skirt and connecting rod, the piston rings are housed high up in the piston grooves and are obscured by the cylinder liner and piston structure from this angle. * **C) It is not possible to inspect the compression rings while in place inside the engine.** This is incorrect. As detailed in the explanation for D, visual inspection of the rings while the engine is assembled is entirely possible and standard procedure by using the air box handhole covers.

Question 3

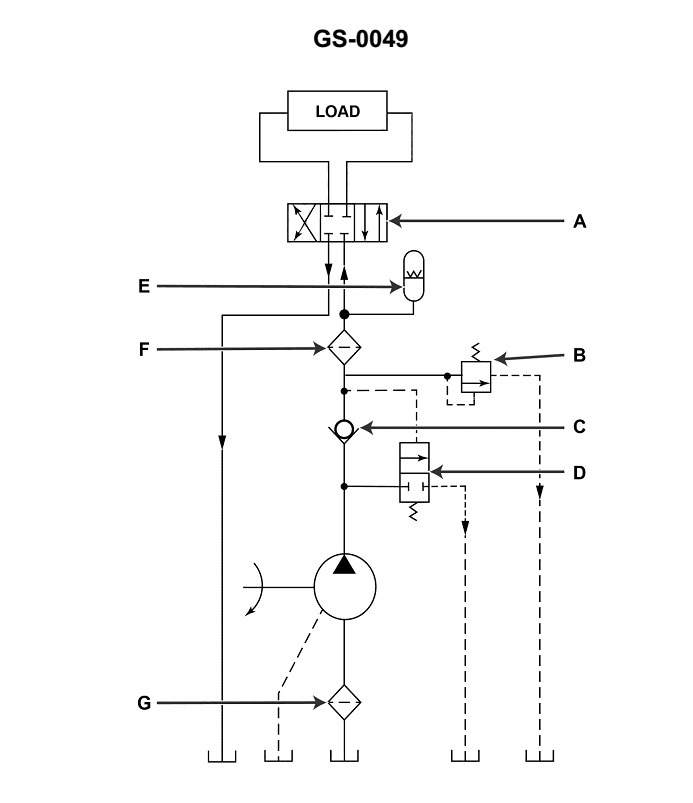

Question: Assuming valve "A" is correctly aligned in the no-flow position as shown with the system in operation, which of the following statements is true? Illustration GS-0049

A. The fixed delivery pump would be stopped automatically by a pressure switch.

B. Valve "D" would normally open before valve "B".

C. Valve "B" would be open before valve "D".

D. Valve "C" would be closed.

The Correct Answer is B **Explanation of Correct Option (B):** The illustration (GS-0049, which depicts a typical hydraulic pressure relief system using a fixed displacement pump) shows a main relief valve system (RV) controlling system pressure. This system consists of a main relief valve (RV) which is remotely piloted by a smaller pilot relief valve (RV-P). * **Valve D** represents the pilot relief valve (RV-P). * **Valve B** represents the main relief valve (RV). In a two-stage relief valve system (pilot-operated relief valve), the pilot valve (D) is a small, spring-loaded valve set to the desired system pressure. When system pressure exceeds this setting, the pilot valve (D) opens first. The opening of the pilot valve (D) allows fluid to flow, creating a pressure imbalance across the main relief valve (B) spool. This pressure imbalance forces the main relief valve (B) to open, dumping the pump's flow back to the tank, thus relieving the system pressure. Therefore, the pilot valve **D** must open to initiate the relief process before the main valve **B** opens completely to handle the high flow. **Valve "D" would normally open before valve "B" is true.** **Explanation of Incorrect Options:** * **A) The fixed delivery pump would be stopped automatically by a pressure switch.** * This is incorrect. The primary function of the relief valve system in a fixed delivery (fixed displacement) pump circuit is to manage excess pressure by dumping flow back to the tank, allowing the pump to continue running without exceeding the maximum system pressure. While some circuits might use pressure switches to shut down the pump for safety/emergency stops, it is not the **normal** function or consequence of the relief valve operation shown when flow is blocked. * **C) Valve "B" would be open before valve "D".** * This is incorrect. As explained above, this system is a pilot-operated relief valve. The pilot valve (D) must open first to actuate the main valve (B). * **D) Valve "C" would be closed.** * This is incorrect. Valve "C" is an isolation or shutoff valve located between the main system line and the pilot relief valve circuit. Assuming the relief valve system is active and correctly installed (as implied by the question), Valve "C" must be open (or removed, if it's a test point) to transmit system pressure to the relief valve circuit (D and B). If Valve "C" were closed, the relief valve system would be isolated and unable to relieve system pressure, potentially leading to catastrophic failure.

Question 4

Question: You are assigned as an engineer on a fishing research vessel using main propulsion engines of the type shown in the illustration. What statement represents the procedure for inspection of the upper cylinder liner bore while in place inside the engine? Illustration MO-0122

A. With the particular piston positioned at BDC and the corresponding oil pan handhole cover removed, inspect the upper liner bore through the scavenging-air ports.

B. With the particular piston positioned at TDC and the corresponding oil pan handhole cover removed, inspect the upper liner bore through the scavenging-air ports.

C. With the particular piston positioned at BDC and the corresponding air box handhole cover removed, inspect the upper liner bore through the scavenging-air ports.

D. With the particular piston positioned at TDC and the corresponding air box handhole cover removed, inspect the upper liner bore through the scavenging-air ports.

The Correct Answer is C ### Explanation of Correct Option (C) Option C is correct because it describes the standard procedure for visually inspecting the upper cylinder liner bore through the scavenging-air ports in a two-stroke engine (the type typically used for main propulsion and often featuring scavenging ports, as implied by the inspection method). 1. **Positioning the Piston at BDC (Bottom Dead Center):** To inspect the upper liner bore, the piston must be moved down to BDC. When the piston is at BDC, the scavenging-air ports are fully uncovered, allowing visual access to the critical wear area of the liner (the upper portion where the rings primarily operate during combustion). 2. **Removing the Air Box Handhole Cover:** The scavenging-air ports are located in the cylinder liner wall and communicate with the surrounding air box (also known as the scavenging belt or receiver). To gain access to the ports for inspection, the handhole covers on the air box must be removed. 3. **Inspecting Through Scavenging-Air Ports:** This is the specific pathway used for visual inspection of the liner condition (e.g., scoring, pitting, wear step) without dismantling the cylinder head or pulling the piston. ### Explanation of Incorrect Options **A) With the particular piston positioned at BDC and the corresponding oil pan handhole cover removed, inspect the upper liner bore through the scavenging-air ports.** * **Incorrect Element:** Removing the **oil pan** handhole cover provides access to the crankcase, connecting rod, and piston skirt from below, but it does not provide access to the **scavenging-air ports**, which are located on the cylinder liner wall, separate from the crankcase. **B) With the particular piston positioned at TDC and the corresponding oil pan handhole cover removed, inspect the upper liner bore through the scavenging-air ports.** * **Incorrect Elements:** * **Piston Position:** When the piston is at **TDC (Top Dead Center)**, it covers the scavenging-air ports, making inspection impossible. The piston must be at BDC. * **Handhole Cover:** Access requires removal of the **air box** cover, not the oil pan cover. **D) With the particular piston positioned at TDC and the corresponding air box handhole cover removed, inspect the upper liner bore through the scavenging-air ports.** * **Incorrect Element:** The piston must be positioned at **BDC (Bottom Dead Center)** to fully expose the scavenging-air ports and the critical upper section of the liner for inspection. Positioning it at TDC blocks the ports.

Question 9

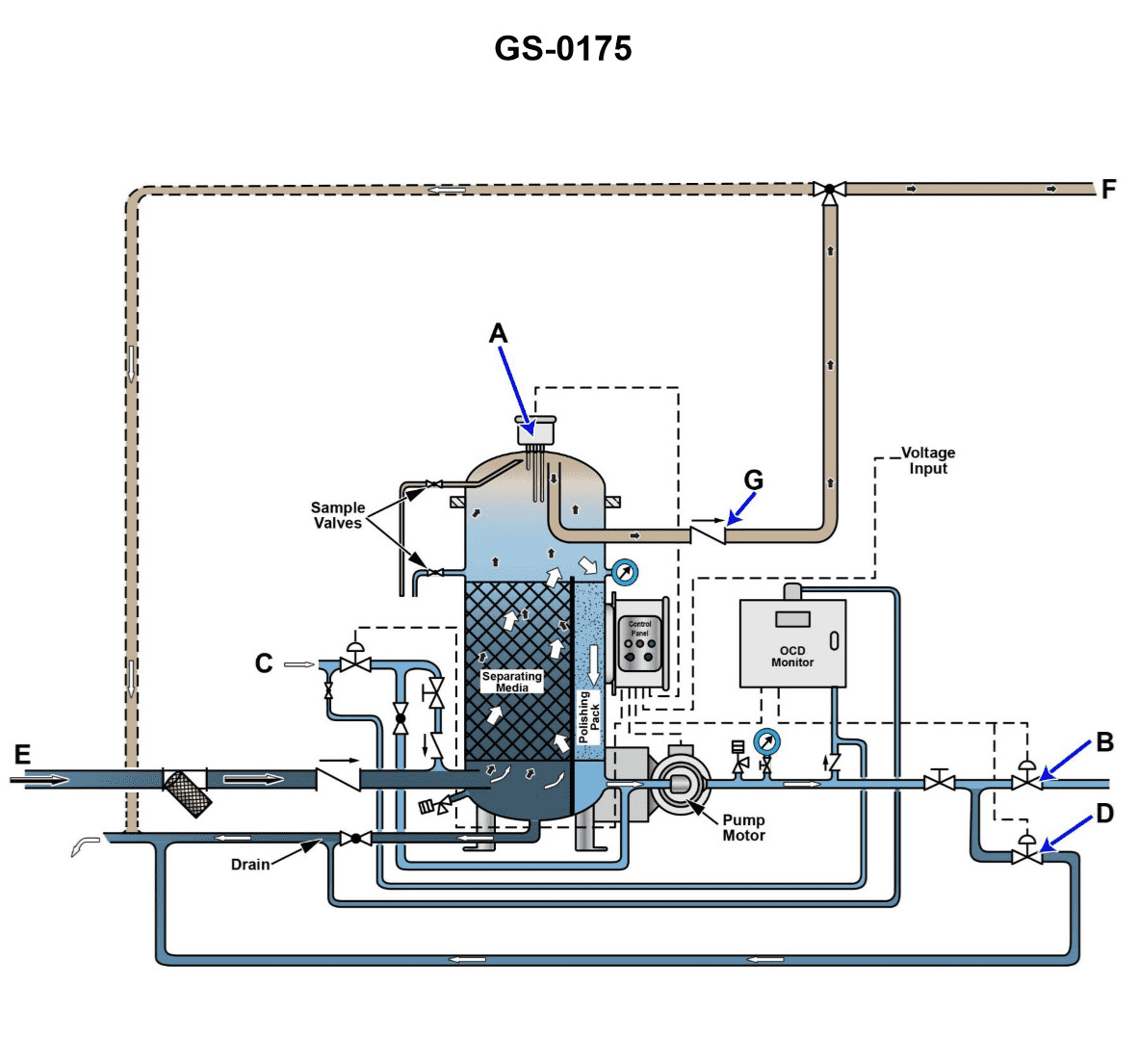

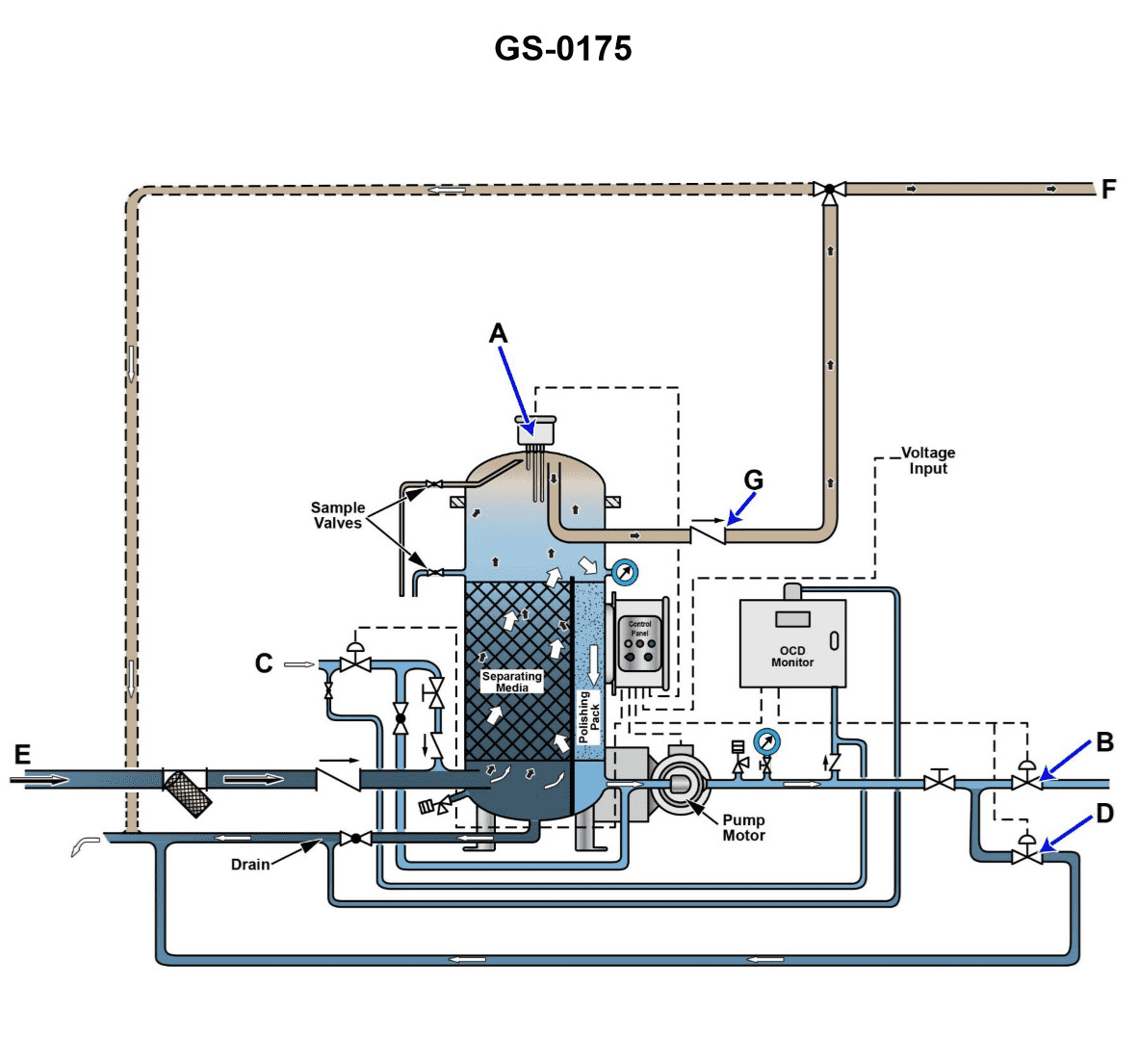

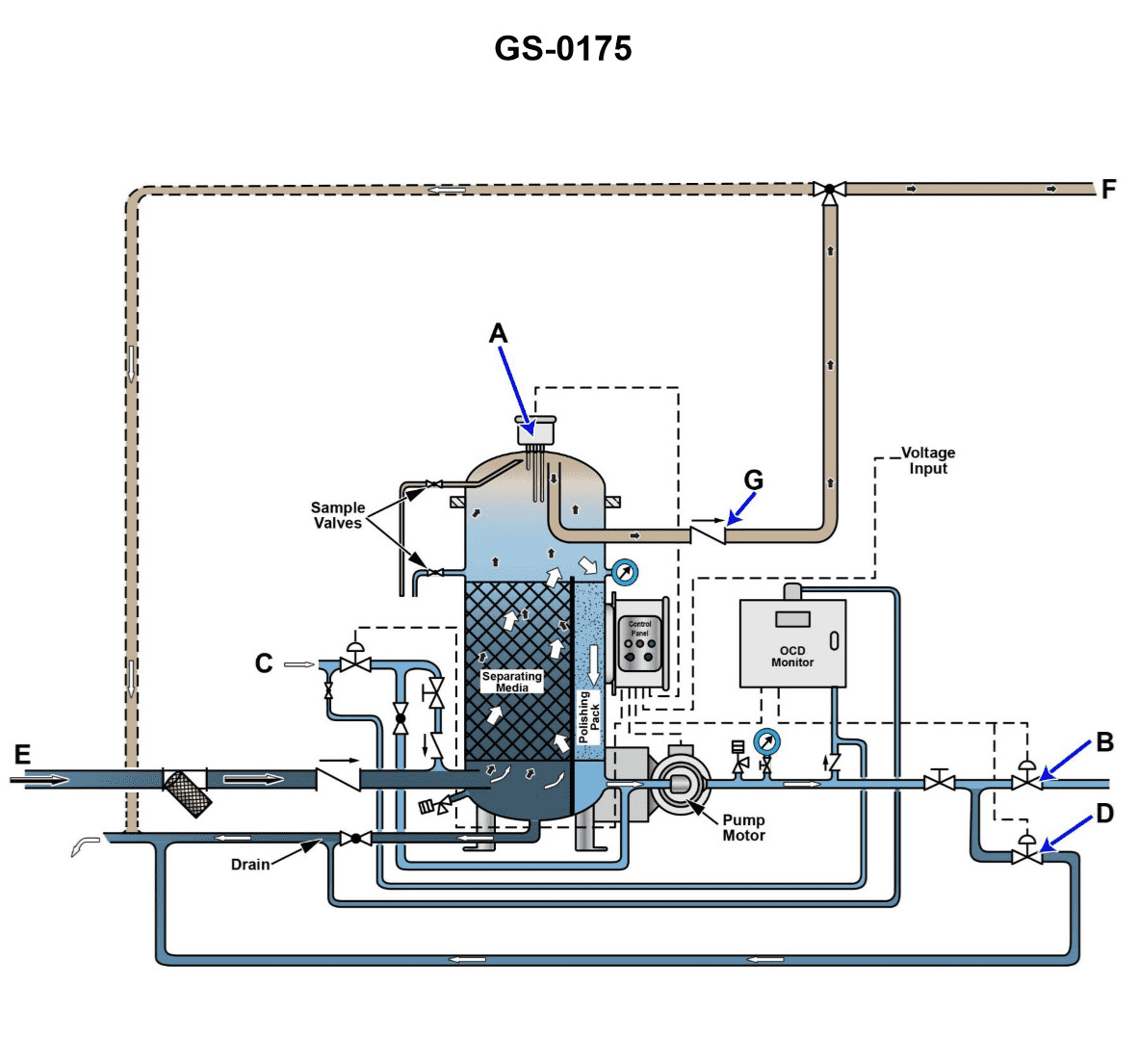

Question: The line labeled "E", as shown in the illustration, would be identified as the ______. Illustration GS-0175

A. clean water inlet line

B. waste oil outlet line

C. oily bilge water inlet line

D. processed water outlet line

The Correct Answer is C **Explanation for Option C (oily bilge water inlet line):** In systems related to treating oily water (such as an Oily Water Separator or Bilge Water Treatment Unit, which Illustration GS-0175 likely depicts), the line labeled "E" typically represents the path through which the source material—the contaminated water requiring processing—is introduced into the system. Bilge water is the water that collects in the lowest parts of a ship, and it frequently contains oil, grease, cleaning agents, and suspended solids, making it "oily bilge water." Therefore, Line E would be the **oily bilge water inlet line** bringing the untreated mixture into the separation unit. **Explanation for Why Other Options Are Incorrect:** * **A) clean water inlet line:** This is incorrect. While clean water may sometimes be used in these systems (e.g., for flushing or cleaning), the primary and most prominent inlet line is for the contaminated fluid (the bilge water). If it were a clean water inlet, it would typically be labeled for service or utility water, not the main process flow labeled "E" in this context. * **B) waste oil outlet line:** This is incorrect. The waste oil (the separated contaminant) would be an *outlet* line, typically located high on the separator unit, leading away from the system to a sludge tank or waste holding tank. An inlet line is where the mixture enters the system. * **D) processed water outlet line:** This is incorrect. The processed (treated and cleaned) water would be an *outlet* line leading away from the separator, usually discharged overboard (if compliant) or sent to a holding tank. It would not be an inlet line like "E".

Question 10

Question: Referring to the illustration, suppose after initiating the oil discharge mode, the oily-water separator fails to come out of the oil discharge mode in a timely fashion. Cracking open the upper sampling valve reveals the presence of oil exiting under positive pressure. What is most likely the cause? Illustration GS-0175

A. The lower oil/water interface detection probe fails to initiate the oil discharge mode.

B. The upper oil/water interface detection probe fails to end the oil discharge mode.

C. The oil discharge check valve fails to open, and as a result no oil actually discharges.

D. The clean water supply solenoid fails to open, and as a result provides no discharge pressure.

The Correct Answer is C. ### Why Option C is Correct The scenario describes a situation where the oily-water separator (OWS) is stuck in the oil discharge mode ("fails to come out of the oil discharge mode in a timely fashion"). Crucially, cracking open the upper sampling valve reveals oil exiting under positive pressure. When the OWS enters the oil discharge phase, the separated oil should be discharged from the top of the separator unit. If the **oil discharge check valve fails to open**, the separated oil has nowhere to go. This blockage prevents the oil layer from being removed. Since the separator continues to operate and separate oil (or perhaps is still pressurizing the unit), the pressure will build up, and the oil level will rise and remain high, keeping the system in the oil discharge state. The presence of oil exiting the upper sampling valve under positive pressure confirms that the system is pressurized and that oil has accumulated and is trapped inside the separation chamber (i.e., it is not discharging). Therefore, the failure of the oil discharge check valve to open is the most likely mechanical reason for the system being stuck in discharge mode with pressurized oil present. ### Why Other Options Are Incorrect **A) The lower oil/water interface detection probe fails to initiate the oil discharge mode.** If the lower probe failed to initiate the mode, the OWS would never enter the oil discharge cycle in the first place. The scenario explicitly states that the OWS *after initiating* the oil discharge mode, fails to come out of it. This indicates the initiation was successful, making option A incorrect. **B) The upper oil/water interface detection probe fails to end the oil discharge mode.** The function of the upper probe is indeed to signal the end of the oil discharge mode (usually indicating that the oil layer has been depleted and water has reached the upper probe). If the probe failed electronically (e.g., stuck "on"), the system might fail to switch out of discharge mode. However, the scenario also includes the physical evidence: oil exiting the upper sampling valve under positive pressure. If the upper probe failed electronically, but the oil was actually discharging, the pressure and oil accumulation described would not be present. The most fundamental reason for the failure to end the discharge mode while pressurized oil is present is a failure of the discharge path (C). **D) The clean water supply solenoid fails to open, and as a result provides no discharge pressure.** Clean water is often used to flush the unit or provide motive pressure for discharge in certain OWS designs. If the clean water supply failed to open, there might be insufficient pressure to push the oil out. However, the scenario states that oil is exiting the sampling valve *under positive pressure*. This indicates that sufficient pressure *is* present within the unit, whether it's operating pressure or residual pressure, contradicting the premise that the failure is due to a lack of pressure. The problem is not the lack of pressure, but the blockage preventing discharge despite the pressure.

Question 11

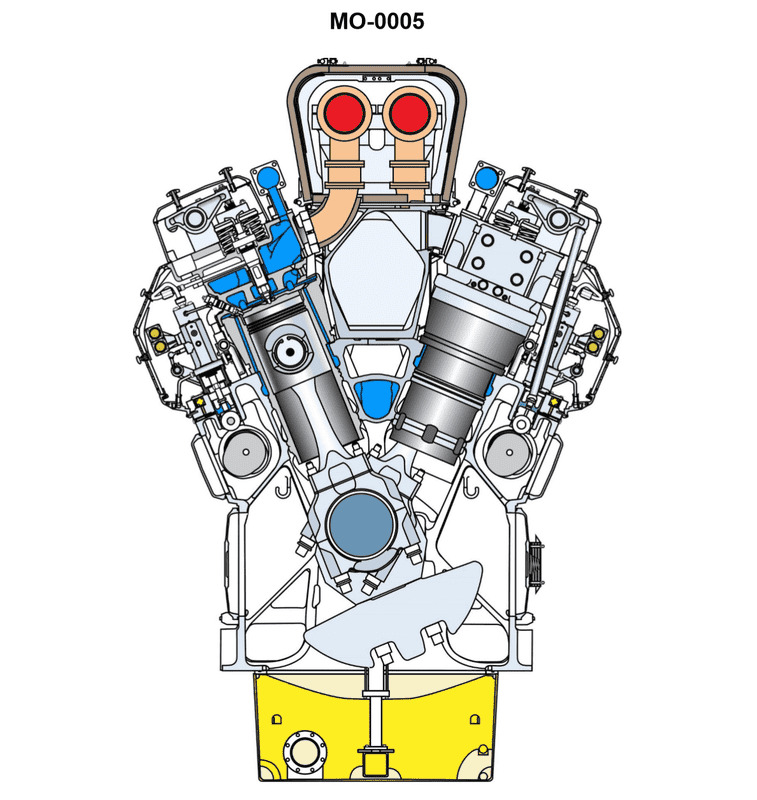

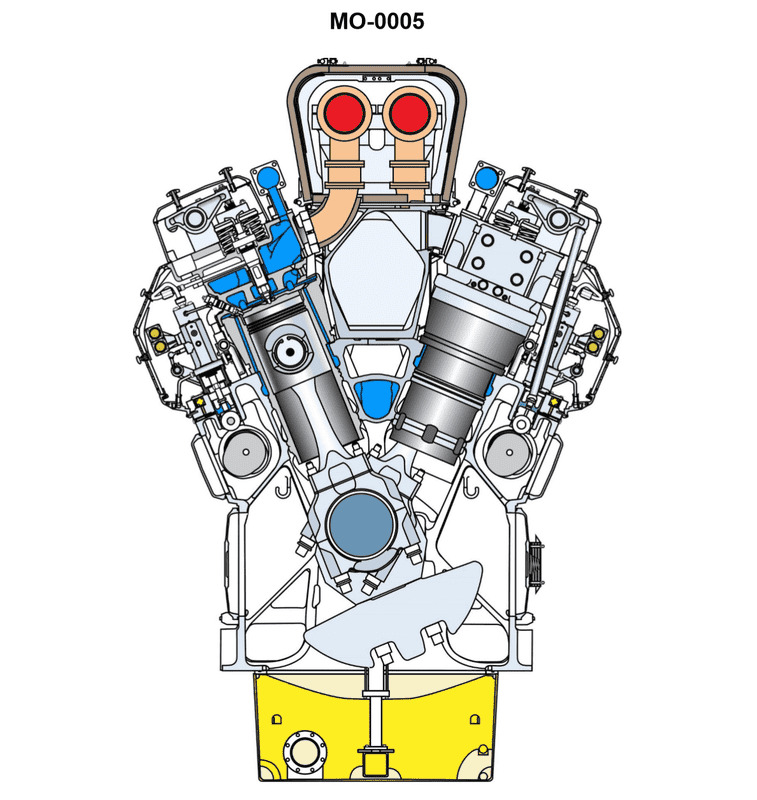

Question: The uninspected fishing trawler to which you are assigned is fitted with main propulsion diesel engines of the type shown in the illustration. In terms of valve operating gear, cylinder liner type, and connecting rod type, what statement is true? Illustration MO-0005

A. This is a pushrod operated overhead valve engine, with jacketed cylinder liners and articulated connecting rods.

B. This is a pushrod operated overhead valve engine, with wet cylinder liners and conventional connecting rods.

C. This is an overhead cam engine, with wet cylinder liners and conventional connecting rods.

D. This is an overhead cam engine, with jacketed cylinder liners and marine-type connecting rods.

The Correct Answer is B **Explanation for Option B (Correct):** Option B states that the engine is a pushrod operated overhead valve engine, with wet cylinder liners and conventional connecting rods. This description is characteristic of common medium-speed, heavy-duty marine propulsion diesel engines often found in fishing trawlers (like the one implied by Illustration MO-0005, which typically depicts a standard four-stroke marine diesel). 1. **Pushrod Operated Overhead Valve Engine:** Most engines of this size and type utilize a camshaft located lower in the engine block (often near the crankshaft), using pushrods and rocker arms to operate the valves in the cylinder head. This configuration is simpler and more robust for medium-speed applications than complex overhead camshaft (OHC) designs (Options C and D). 2. **Wet Cylinder Liners:** Wet liners are surrounded directly by the engine coolant. This design allows for better heat transfer and easier replacement during major overhauls, making them standard for large, continuously rated marine diesels. 3. **Conventional Connecting Rods:** Conventional connecting rods (typically single-piece forged steel rods with bolted big-end caps) are standard for medium-speed, trunk-piston engines where the rod connects the piston directly to the crankshaft journal. They are contrasted with articulated or marine-type connecting rods, which are used in much larger crosshead engines or specialized V-engines. Since the engine depicted is a standard trunk-piston diesel suitable for a trawler, conventional rods are used. **Explanation for Incorrect Options:** **A) This is a pushrod operated overhead valve engine, with jacketed cylinder liners and articulated connecting rods.** * **Incorrect Feature: Jacketed Cylinder Liners:** Jacketed liners are typically synonymous with "dry liners," which are pressed into the block and cooled indirectly. Wet liners are standard for this application. * **Incorrect Feature: Articulated Connecting Rods:** Articulated rods are a specific design used primarily in V-type engines or some large engines where a master rod connects the piston and a slave rod pivots off the master rod. Conventional connecting rods are standard for in-line engines of this type. **C) This is an overhead cam engine, with wet cylinder liners and conventional connecting rods.** * **Incorrect Feature: Overhead Cam (OHC):** While OHC engines exist in marine applications, pushrod designs are generally more common, robust, and cost-effective for medium-speed marine trunk-piston diesels of this size. OHC is characteristic of higher-speed or smaller engines. **D) This is an overhead cam engine, with jacketed cylinder liners and marine-type connecting rods.** * **Incorrect Feature: Overhead Cam (OHC):** As explained for C, pushrod operation is more likely. * **Incorrect Feature: Jacketed Cylinder Liners:** Wet liners are standard. * **Incorrect Feature: Marine-type Connecting Rods:** "Marine-type" connecting rods (also called crosshead connecting rods) are specific to very large, slow-speed two-stroke engines that utilize a crosshead mechanism to separate the piston side loads from the connecting rod. The engine described (suitable for a fishing trawler) is a medium-speed trunk-piston engine, which uses conventional rods.

Question 11

Question: Referring to the illustration, suppose while in the oil separation processing mode, the oil content detector display screen shows 17.9 ppm and the oily-water separator is discharging back to the bilge water holding tank for recirculation. What is most likely the cause? Illustration GS-0175

A. The bilge water holding tank level is excessively high resulting in a high-level alarm.

B. The oily-water separator bilge suction strainer is excessively clogged.

C. The bilge water holding tank contents is excessively contaminated with oil.

D. The oily-water separator service pump is excessively worn.

The Correct Answer is C **Explanation for Option C (Correct Answer):** The scenario states two critical pieces of information: 1. The oil content detector (OCD) display screen shows **17.9 ppm** (parts per million). 2. The oily-water separator (OWS) is discharging back to the bilge water holding tank for **recirculation**. Regulations (like IMO MEPC 107(49)) typically require that processed water discharged overboard must not exceed 15 ppm. If the detector reads above the set threshold (which is usually set at or slightly below 15 ppm, or potentially a higher internal alarm limit depending on the system design, but certainly indicating high contamination), the system automatically triggers an alarm and diverts the discharge flow away from the overboard line and back into the bilge holding tank (recirculation mode) to prevent illegal discharge. A reading of 17.9 ppm is too high for legal discharge. This high reading directly indicates that the water entering or leaving the final stage of the separator is still heavily contaminated with oil. The most direct and likely cause for the final effluent to be heavily contaminated is that the **input source (the bilge water holding tank contents) is excessively contaminated with oil**, overwhelming the separation capabilities of the OWS system. **Explanation for Other Options (Incorrect):** * **A) The bilge water holding tank level is excessively high resulting in a high-level alarm.** While a high-level alarm may stop the transfer pump, it does not directly cause the final effluent to register 17.9 ppm. The 17.9 ppm reading is a quality (contamination) issue, not a quantity (level) issue. * **B) The oily-water separator bilge suction strainer is excessively clogged.** A clogged strainer would restrict flow (reduce throughput), potentially reducing the efficiency of the pump or causing the separator to trip on low flow/pressure, but it would not inherently increase the PPM reading of the processed water. If anything, reduced flow might slightly aid separation time, although the primary symptom of clogging is reduced flow volume. The high PPM reading is a failure of separation quality, not flow rate. * **D) The oily-water separator service pump is excessively worn.** A worn pump would primarily result in reduced flow or reduced pressure to the separator, which might make the separation process less effective if the flow falls outside the optimal range. However, this is a less direct cause than the input contamination being too high. Typically, if the OWS is functioning, the most critical factor determining the failure to meet the 15 ppm standard is the volume and concentration of oil presented to the system (i.e., the state of the bilge water holding tank contents). If the OWS is operating but failing the quality check, the primary source of the problem is usually the input load exceeding capacity.

Question 12

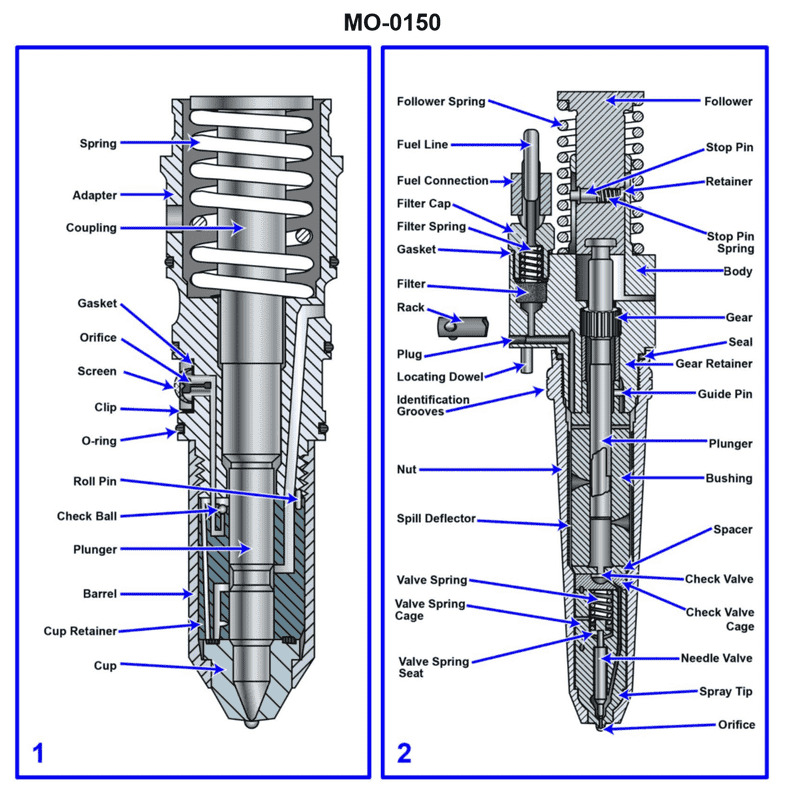

Question: The fishing industry line vessel to which you are assigned is fitted with main propulsion diesel engines of the type shown in the illustration. In terms of valve operating gear, cylinder liner type, and connecting rod type, what statement is true? Illustration MO-0122

A. This is an overhead cam engine, with wet cylinder liners, and marine-type connecting rods.

B. This is an overhead cam engine, with jacketed cylinder liners and hinged-strap, fork-and-blade connecting rods.

C. This is a pushrod operated overhead valve engine, with jacketed cylinder liners and conventional connecting rods.

D. This is a pushrod operated overhead valve engine, with wet cylinder liners and hinged-strap, fork-and- blade connecting rods.

The Correct Answer is B ### Explanation of Why Option B is Correct Option B states: "This is an overhead cam engine, with jacketed cylinder liners and hinged-strap, fork-and-blade connecting rods." This combination accurately describes the design features of many high-speed or medium-speed V-type diesel engines commonly used for main propulsion in fishing vessels (which the referenced illustration, MO-0122, is designed to represent). 1. **Overhead Cam Engine (OHC):** Medium-speed V-configuration engines often utilize an overhead camshaft (or very short cam-to-valve linkage) to improve valve timing and reduce inertia inherent in long pushrod systems, allowing for higher engine RPM. 2. **Jacketed Cylinder Liners:** This term refers to cylinder liners that are supported within a structure where the cooling water circulates around the outer structure (the cylinder block/jacket), making them "dry liners." This is typical for high-output, compact V-engines, as opposed to "wet liners" where the cooling water is in direct contact with the liner exterior. 3. **Hinged-Strap, Fork-and-Blade Connecting Rods:** This is the definitive characteristic of many large V-type engines. This complex assembly allows two connecting rods (one from each bank of the V) to share a single, narrow crankpin journal. The "fork" rod straddles the journal, while the "blade" rod (which often uses a hinged strap to facilitate assembly) fits precisely within the gap of the fork rod. This arrangement ensures proper geometric balance and shared journal loading in V-engines. ### Why Other Options Are Incorrect **A) This is an overhead cam engine, with wet cylinder liners, and marine-type connecting rods.** * **Incorrect Feature:** The engine type depicted, utilizing the highly specific fork-and-blade rod design, typically employs dry (jacketed) liners, not wet liners. Furthermore, "marine-type connecting rods" is too vague and does not specify the required fork-and-blade geometry. **C) This is a pushrod operated overhead valve engine, with jacketed cylinder liners and conventional connecting rods.** * **Incorrect Feature:** If the engine uses the specialized V-configuration requiring hinged-strap/fork-and-blade rods, it cannot use "conventional connecting rods" (which sit side-by-side or use a master/slave setup, but not the specific fork/blade design necessary to share a narrow journal). **D) This is a pushrod operated overhead valve engine, with wet cylinder liners and hinged-strap, fork-and- blade connecting rods.** * **Incorrect Feature:** The use of "wet cylinder liners" is generally incorrect for the type of high-output, medium-speed V-engine that requires the "hinged-strap, fork-and-blade" rod geometry. These designs favor jacketed (dry) liners for structural integrity and thermal management.

Question 13

Question: The mollusc dredger to which you are assigned is fitted with generator set drive engines as shown in the illustration. What statement is true in terms of the combustion chamber design? Illustration MO-0005

A. The engine uses turbulence chambers with a hemispherical fire-deck.

B. The engine uses an open type combustion chamber with a hemispherical fire-deck.

C. The engine uses an open type combustion chamber with a flat fire-deck.

D. The engine uses pre-combustion chambers with a flat fire-deck.

The Correct Answer is C **Explanation for C being correct:** The question refers to a generator set drive engine for a mollusc dredger, likely a common marine or heavy-duty diesel engine used in industrial applications. While the specific illustration MO-0005 is not provided, the majority of modern medium- to high-speed, direct-injection (DI) diesel engines used for power generation (like those from manufacturers such as CAT, Cummins, MAN, etc.) utilize an **open type combustion chamber**. This design is characterized by the fuel being injected directly into the main volume of air compressed within the cylinder. Furthermore, these engines typically feature a **flat cylinder head (fire-deck)** with the combustion bowl or cavity formed entirely within the piston crown. This combination maximizes thermal efficiency, improves starting characteristics, and is standard for high-power-density DI engines. Therefore, the statement "The engine uses an open type combustion chamber with a flat fire-deck" is the most accurate description for a modern generator set engine. **Why the other options are incorrect:** * **A) The engine uses turbulence chambers with a hemispherical fire-deck.** This describes an indirect injection (IDI) system, specifically a swirl chamber (turbulence chamber). IDI engines generally have lower thermal efficiency and are less common in modern, high-power generator sets compared to DI engines. A hemispherical fire-deck is characteristic of older or specialized gasoline or two-stroke engines, not typically modern four-stroke diesel gensets. * **B) The engine uses an open type combustion chamber with a hemispherical fire-deck.** While the open type chamber (DI) is correct, a hemispherical fire-deck implies the piston crown and cylinder head form a sphere, which is incompatible with the standard flat cylinder head design used in modern DI engines where the combustion bowl is centered in the piston. * **D) The engine uses pre-combustion chambers with a flat fire-deck.** A pre-combustion chamber is another type of indirect injection (IDI) design. Like turbulence chambers (Option A), pre-combustion chambers are less efficient, produce lower specific output, and are rarely used in new heavy-duty generator set engines compared to the open (DI) design.

Question 14

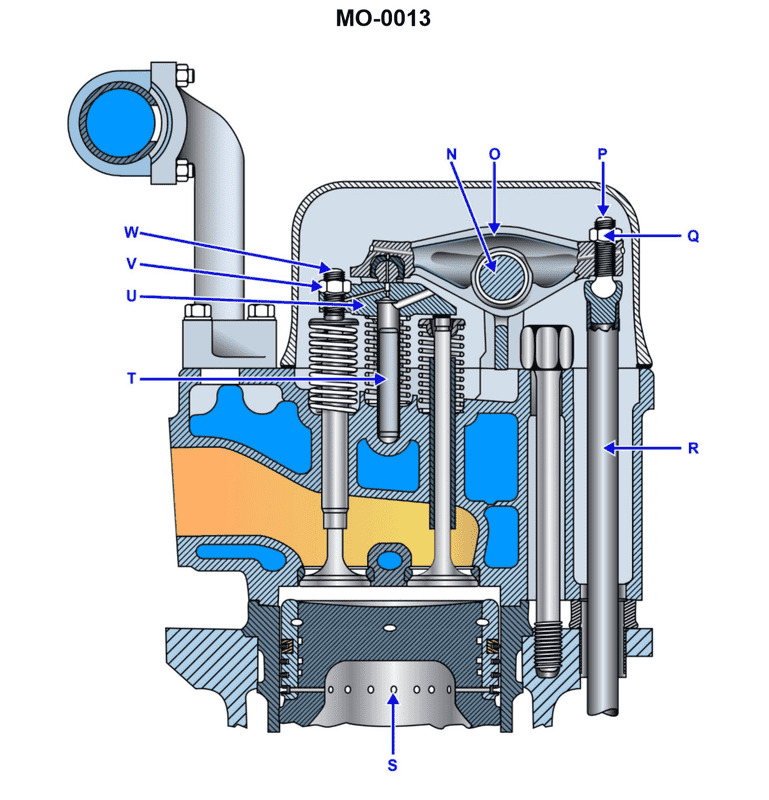

Question: The uninspected fishing trawler to which you are assigned is fitted with auxiliary engines as partly shown in the illustration. What statement is true concerning the valve guide and valve seat arrangements? Illustration MO-0013

A. The valve guides are replaceable inserts, and the valve seats are integral (non-replaceable).

B. The valve guides and the valve seats are both replaceable inserts.

C. The valve guides are integral (non-replaceable), and the valve seats are replaceable inserts.

D. The valve guides and the valve seats are both integral (non-replaceable).

The Correct Answer is B **Explanation for Option B (Correct Answer):** In modern medium-to-large diesel engines, such as those typically used as auxiliary engines on fishing trawlers, both the valve guides and the valve seats are commonly designed as replaceable inserts. 1. **Valve Seats:** Valve seats (especially exhaust valve seats, which experience high wear due to extreme heat and corrosive gases) are almost universally made as replaceable inserts (seat rings). These inserts are typically made of specialized, hard, wear-resistant alloys and are pressed or shrunk-fit into the cylinder head. This allows for easy servicing, inspection, and replacement when wear limits are reached, preserving the expensive cylinder head casting. 2. **Valve Guides:** Valve guides, which align the valve stem and guide its movement, also suffer significant wear over time due to friction and high temperatures. While some smaller, older engines may have integral guides, standard engineering practice for modern, reliable auxiliary marine engines is to use **replaceable valve guide inserts**. This facilitates efficient maintenance and prevents having to scrap the entire cylinder head assembly just because the guide is worn. Therefore, for the efficient, repairable design expected in marine auxiliary power plants, both the valve guides and valve seats are typically replaceable inserts. **Explanation of Incorrect Options:** * **A) The valve guides are replaceable inserts, and the valve seats are integral (non-replaceable).** This is incorrect. While guides are often replaceable, valve seats are almost never made integral in high-performance or high-wear applications like diesel cylinder heads because they wear out faster than the surrounding metal, and making them integral would require replacing the entire cylinder head when wear limits are reached. * **C) The valve guides are integral (non-replaceable), and the valve seats are replaceable inserts.** This is incorrect. While the valve seats being replaceable inserts is standard, the valve guides being integral is less common in modern, heavy-duty marine engines due to the desirability of easy replacement during overhaul. * **D) The valve guides and the valve seats are both integral (non-replaceable).** This is significantly incorrect for modern medium/large diesel auxiliary engines. Both components experience heavy wear and must be replaceable to ensure the cylinder head has a long service life and maintenance is practical.

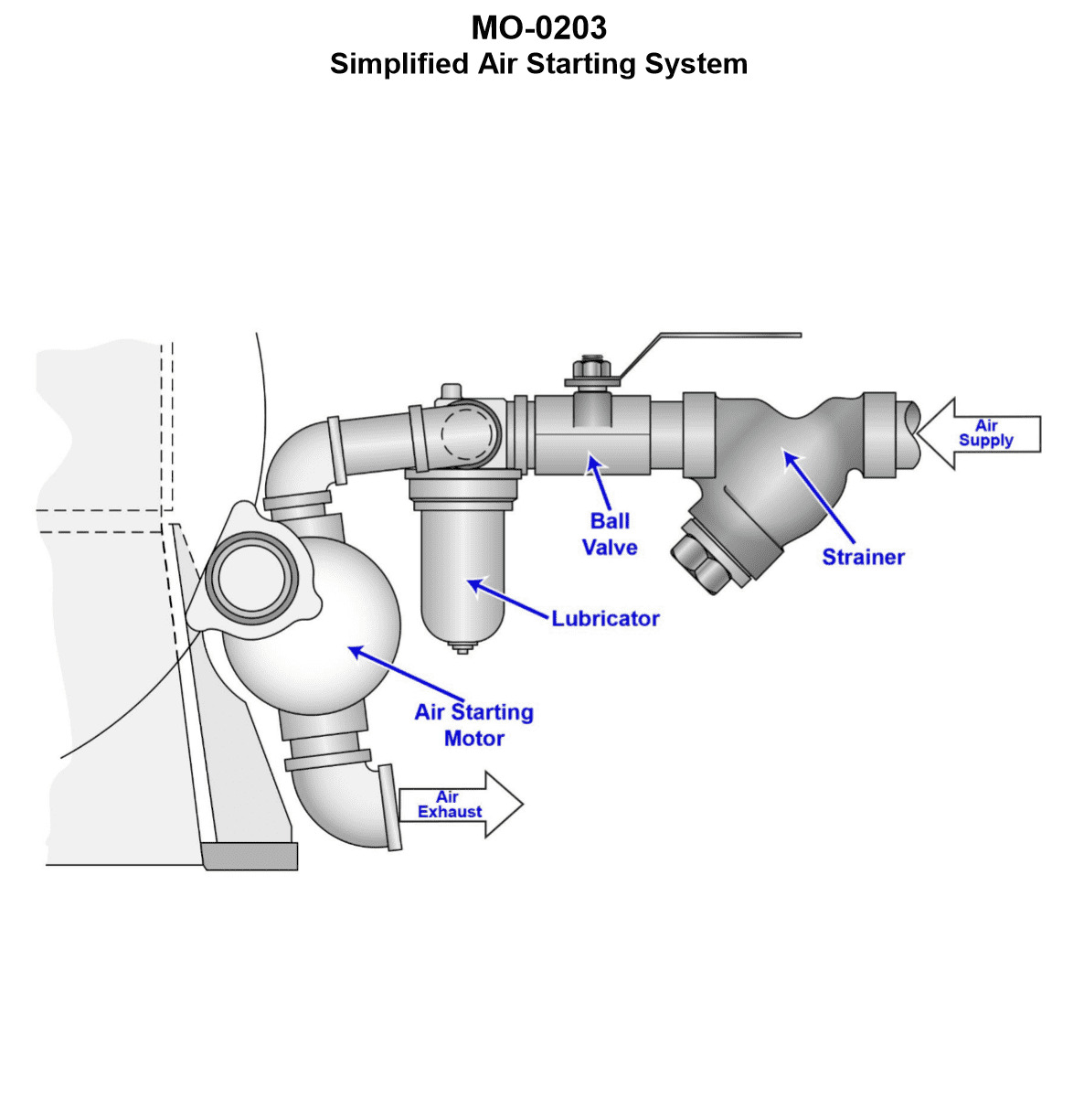

Question 15

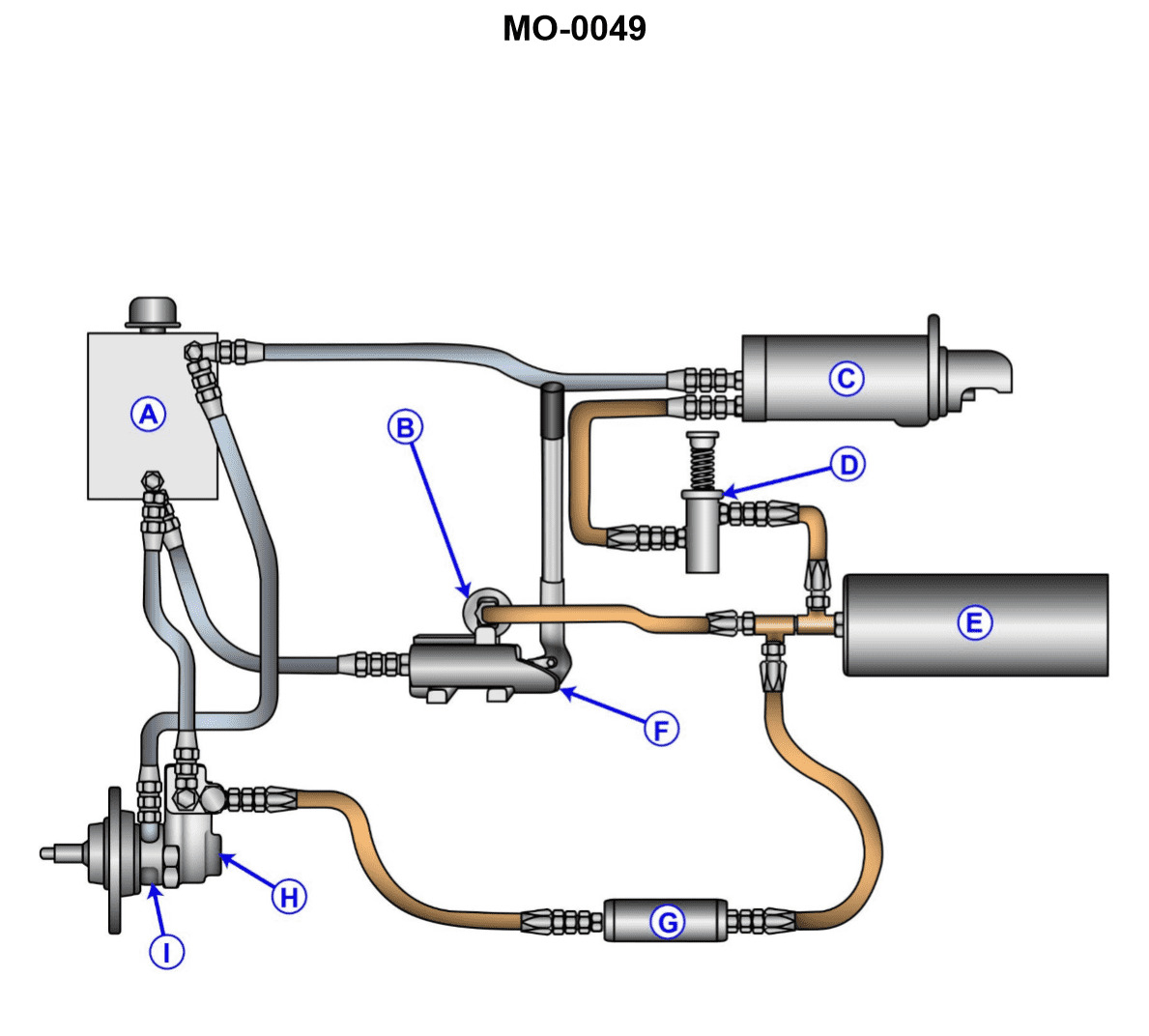

Question: The various auxiliary diesel engines fitted on your fishery research vessel may employ a variety of different starting systems. What type of starting system is shown in the illustration? Illustration MO-0049

A. Gas engine power operated system.

B. Pneumatic power operated system.

C. Hydraulic power operated system.

D. Electric power operated system.

The Correct Answer is C **Why Option C ("Hydraulic power operated system.") is correct:** The starting system shown in the illustration MO-0049 typically depicts components characteristic of a hydraulic starting system. These systems utilize a high-pressure hydraulic pump (driven by an electric motor or manually), an accumulator to store pressurized fluid, control valves, and a hydraulic motor (starter) that engages the engine flywheel. Hydraulic systems are often favored for medium-sized auxiliary engines, especially in marine environments, because they offer high torque output, reliability, and are intrinsically spark-free, making them safe for potentially hazardous areas. **Why the other options are incorrect:** * **A) Gas engine power operated system:** This option describes systems where a separate, small internal combustion engine (often running on gasoline or LPG) is used to crank the main engine. While historically used, this is a distinct method not represented by the typical components (pump, accumulator, hydraulic motor) usually implied by such illustrations. * **B) Pneumatic power operated system:** This system (often called Air Start) uses high-pressure compressed air stored in reservoirs. While common on large main engines and some auxiliary engines, the illustration's components (especially the pump and accumulator if clearly visible) would be inconsistent with a pure air-only system, which primarily features air reservoirs, reducing valves, and an air distributor/motor. * **D) Electric power operated system:** Electric starting uses heavy-duty batteries and a large DC starter motor. While the depicted system might include an electric motor to drive the hydraulic pump, the overall system architecture—relying on high-pressure fluid storage (accumulator)—defines it as hydraulic, not purely electric starting, where the starter motor connects directly to the battery bank.

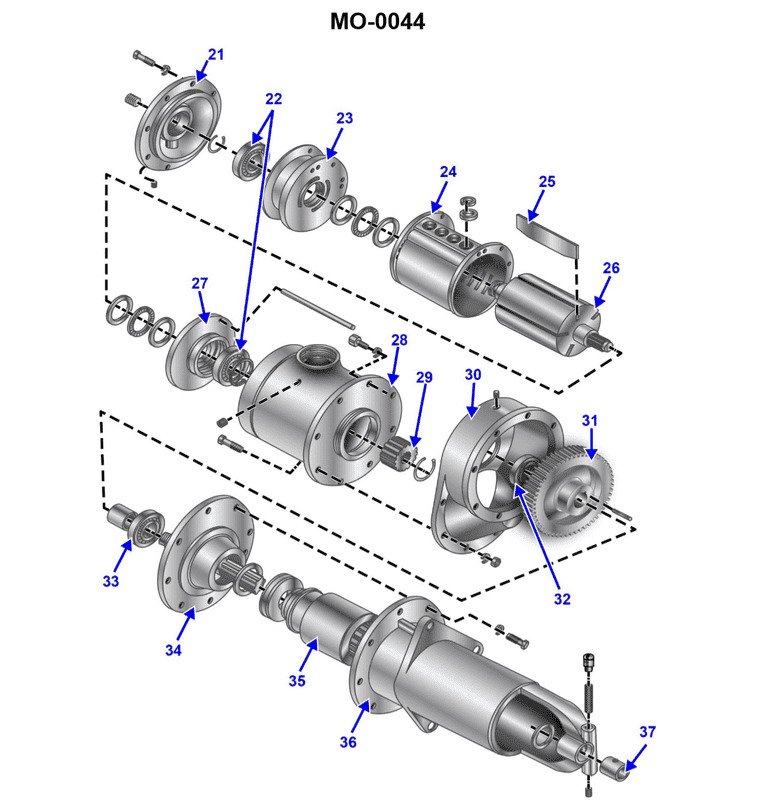

Question 16

Question: The various auxiliary diesel engines fitted on your uninspected fishing trawler may employ a variety of different cranking methods for engine starting. What type of cranking method is shown in the illustration? Illustration MO-0044

A. Hydraulic cranking motor.

B. Air cranking motor.

C. Gasoline engine cranking motor.

D. Electric cranking motor.

The Correct Answer is B **Explanation for B (Air cranking motor.)** An air cranking motor (or pneumatic starter) uses compressed air, stored in a reservoir tank, to drive a turbine or vane motor. This system is highly common on auxiliary diesel engines found on fishing trawlers and other large marine vessels because it provides extremely high torque necessary to turn over large engines, is very reliable, and avoids the maintenance and complexity associated with large battery banks dedicated solely to starting (as required by electric starters). The illustration (MO-0044) would typically depict the robust housing of the pneumatic motor with visible high-pressure air supply lines connected, clearly differentiating it from electrical components or hydraulic lines. **Why the other options are incorrect:** * **A) Hydraulic cranking motor:** A hydraulic starter uses pressurized oil or fluid from an accumulator to power the starter motor. The visible connections would be high-pressure hydraulic hoses and return lines, and the system requires a separate pump/reservoir structure, which looks distinctly different from the air piping used in pneumatic systems. * **C) Gasoline engine cranking motor:** This method involves a small, separate gasoline engine (sometimes called a "pony motor") that is mechanically coupled to crank the main diesel engine. The illustration would show a complete, small internal combustion engine assembly mounted adjacent to the main engine, which is visually obvious and unlike the compact motor unit of an air starter. * **D) Electric cranking motor:** An electric starter relies on heavy-gauge electrical cables and a solenoid to power a DC motor. The illustration would show the distinctive solenoid housing and the large electrical terminals, lacking the necessary large-diameter piping associated with compressed air delivery.

Question 17

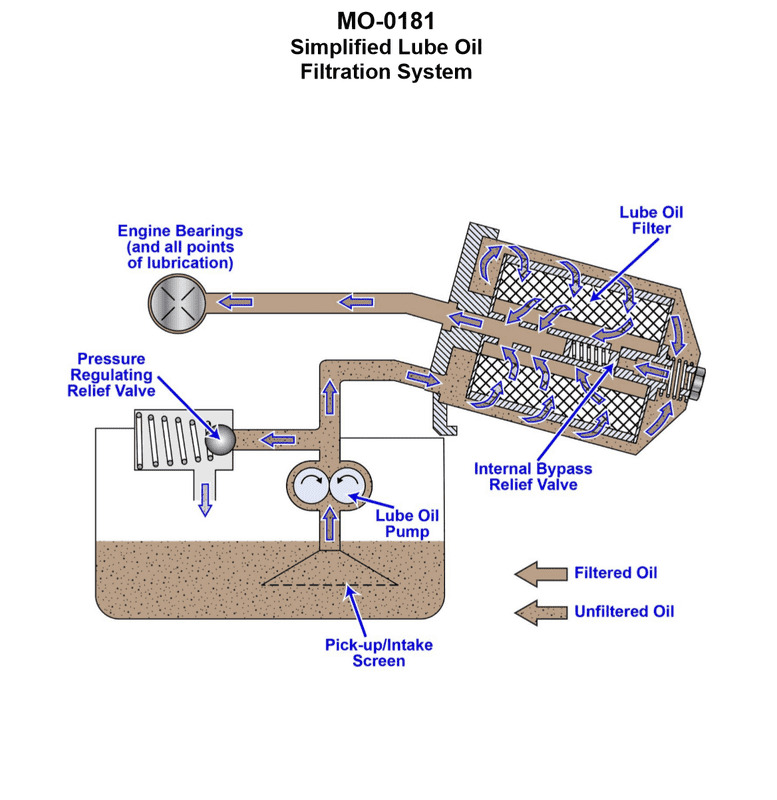

Question: The diesel generator engines onboard your mollusc dredger use a lubricating oil filtration scheme as shown in the illustration. What type of filtration system is illustrated? Illustration MO-0181

A. Full-flow filtration

B. Sump filtration

C. Bypass filtration

D. Shunt filtration

The Correct Answer is A **Explanation for Option A (Full-flow filtration):** Full-flow filtration is the correct answer because, in this system, **100% of the lubricating oil being pumped to the engine bearings and vital components passes through the filter element before reaching those points.** The illustration, MO-0181 (assuming a standard representation of diesel engine oil systems), typically shows the oil pump drawing oil from the sump and pushing it directly through the main oil cooler and filter before it enters the engine's main oil gallery. This ensures that all contaminants that could damage the engine are removed instantaneously from the main flow path, providing immediate protection to critical moving parts. **Why the other options are incorrect:** * **B) Sump filtration:** This term is generally used to describe the location of the oil intake screen (suction strainer) in the oil pan (sump), which is designed to prevent large debris from entering the oil pump. It is not a complete filtration system description. The primary filtration occurs after the pump. * **C) Bypass filtration:** A bypass system (or auxiliary system) only filters a small percentage (typically 5–10%) of the total oil flow at any given time, using a high-efficiency filter to remove very fine particles and soot. The oil is often returned directly to the sump, bypassing the main oil gallery. This system is used *in addition* to, but not *instead of*, the main full-flow filter. * **D) Shunt filtration:** This term is sometimes used interchangeably with bypass filtration or partial-flow filtration, describing a system where only a portion of the oil is filtered, but it is not the standard industrial term for the primary filtration loop that protects the engine immediately.

Question 18

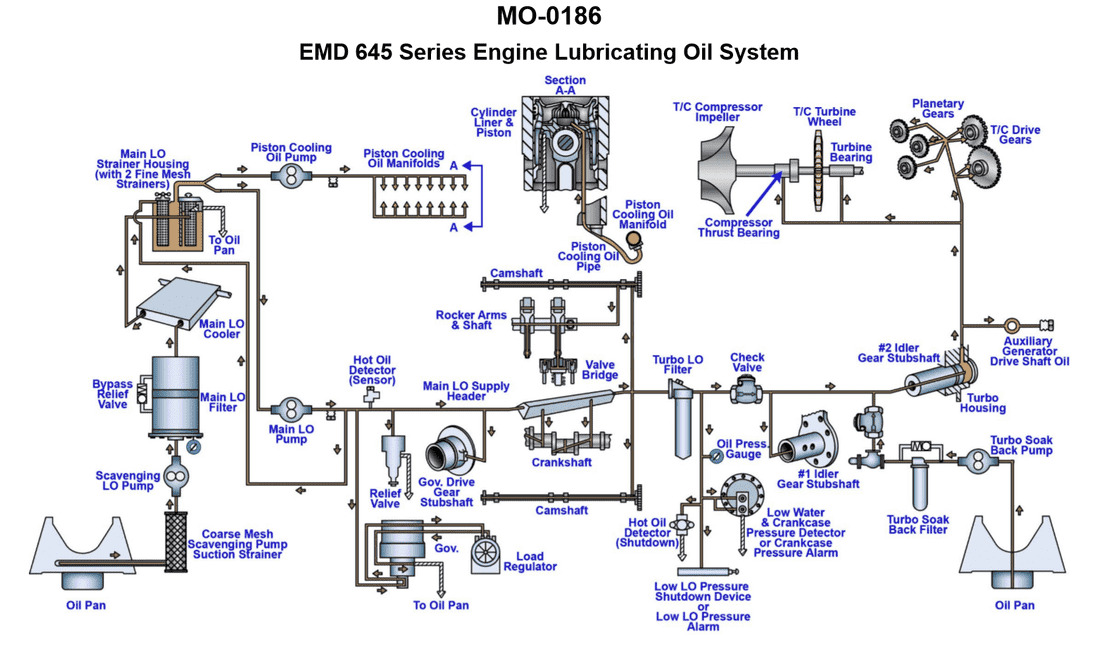

Question: The main propulsion engines onboard your fishery research vessel use a lubricating oil system as shown in the illustration. Under what circumstances will the turbo soak-back pump operate? Illustration MO-0186

A. It will run for a period of time after engine shutdown only.

B. It will operate at all times while the engine is running.

C. It will run for period of time before engine start-up and after engine shutdown.

D. It will run for a period of time prior to engine start-up only.

The Correct Answer is C ### Explanation of the Correct Answer (C) The turbo soak-back pump (or turbo auxiliary pump) is designed to ensure the turbocharger's bearings are properly lubricated and cooled during critical phases of engine operation, specifically during start-up and shutdown, when the main engine-driven lube oil pump may not be providing adequate pressure or flow, or when the turbocharger is still extremely hot after the engine has stopped. 1. **Before Engine Start-up (Pre-lubrication):** Running the soak-back pump briefly before the engine starts ensures that the turbocharger bearings are pre-lubricated. This is crucial because the turbocharger spins at extremely high speeds immediately upon engine ignition, and waiting for the main lube oil pump to build sufficient pressure could cause damage due to dry running. 2. **After Engine Shutdown (Soak-back/Post-cooling):** When the engine stops, the main oil pump stops immediately, but the turbocharger rotor continues to spin (coast down) due to inertia, and the turbocharger housing remains extremely hot (heat soak). The soak-back pump runs for a predetermined period (e.g., 5 to 30 minutes) after shutdown to continuously circulate cooler oil through the bearings. This removes residual heat (preventing carbonization of oil inside the bearings) and provides lubrication until the rotor stops spinning completely, thus protecting the high-speed bearings from heat damage. Therefore, the pump is required to run both before start-up and after shutdown. ### Explanation of Incorrect Options **A) It will run for a period of time after engine shutdown only.** This is partially correct (the post-shutdown operation is essential for cooling), but it ignores the equally important pre-lubrication function required before engine start-up to prevent dry-running wear. **B) It will operate at all times while the engine is running.** While the turbocharger needs lubrication constantly, this specific auxiliary/soak-back pump typically does not run while the engine is running. When the engine is operating, the **main engine-driven lube oil pump** provides sufficient flow and pressure to lubricate the turbocharger (often 4 to 6 bar), making the auxiliary soak-back pump redundant during normal operation. **D) It will run for a period of time prior to engine start-up only.** This is partially correct (the pre-lubrication function is necessary), but it fails to account for the most common and crucial function: the post-shutdown cooling/soak-back period required to prevent heat damage to the turbocharger bearings.

Question 20

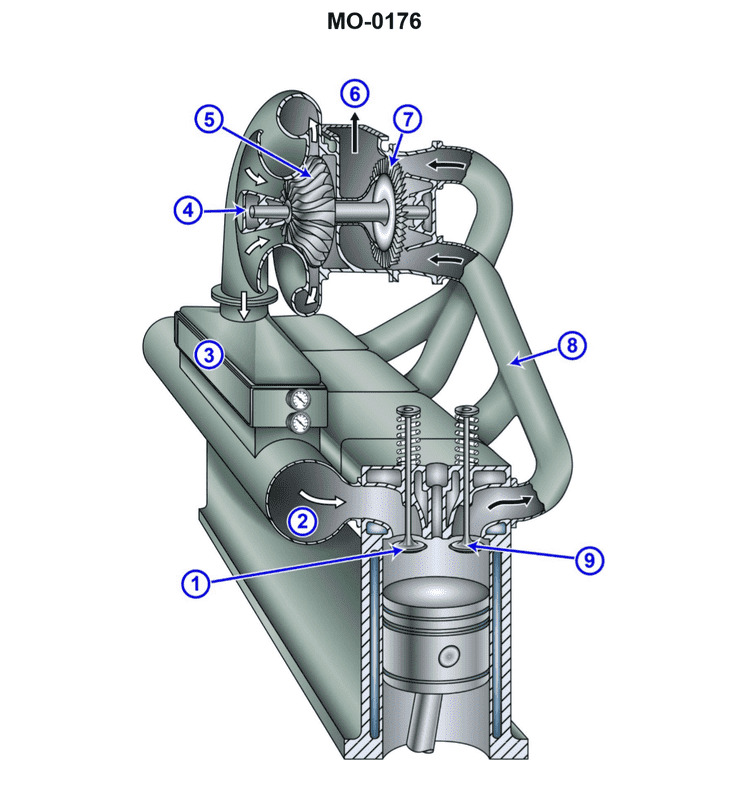

Question: The mollusc dredger to which you are assigned has diesel generator engines fitted with intake and exhaust systems as shown in the illustration. What type of turbo charging configuration is used? Illustration MO-0176

A. Constant pressure turbo charging

B. Boost-controlled turbo charging

C. Pulse turbo charging

D. 2-stage turbo charging

The Correct Answer is C ### 2. Explanation for Option C ("Pulse turbo charging") Pulse turbo charging (or pressure pulse turbo charging) is characterized by the manifold being divided into smaller, shorter sections that group cylinders based on their firing order. These separate sections lead directly to the turbine, often utilizing a multi-entry turbine casing. The primary purpose of this configuration is to preserve the high kinetic energy (pressure pulse) created immediately after the exhaust valve opens. By keeping the manifolds small and segregated, the energy in the pressure wave is not damped by interfering pulses from other cylinders. This system provides: 1. **Rapid Acceleration/Response:** The strong initial pulse provides immediate energy to spin up the turbocharger quickly. 2. **Good Efficiency at Low Load:** Unlike constant pressure systems, pulse charging maintains good efficiency and boost pressure even when the engine is operating at partial loads, which is essential for dredger operations that require frequent power changes and maneuvering. Since marine diesel generators, especially those operating under variable load conditions common on vessels like dredgers, historically prioritize low-load efficiency and rapid response, the illustration (MO-0176) would typically show the characteristic divided manifold structure associated with pulse charging. ### 3. Explanation for Incorrect Options **A) Constant pressure turbo charging:** This configuration uses a large, common exhaust manifold that collects the gas from all cylinders before it enters the turbine at a relatively steady pressure. While highly efficient at maximum load and continuous speed, it is inefficient and exhibits poor turbocharger response at low loads. If the illustration showed a single, large manifold, this would be the correct answer, but for systems prioritizing response (like those on variable-speed dredgers), pulse charging is usually depicted. **B) Boost-controlled turbo charging:** This is not a description of the core turbocharging configuration (manifold design). It is a method of controlling the maximum pressure delivered by the compressor, typically using a wastegate or variable geometry turbine (VGT). The fundamental arrangement of the exhaust manifold leading to the turbine would still be either pulse or constant pressure. **D) 2-stage turbo charging:** This system involves two separate turbochargers working in series (a low-pressure stage followed by a high-pressure stage) to achieve extremely high compression ratios. This configuration is highly complex and usually reserved for modern, high-performance engines needing maximum power density. It would be highly recognizable in the illustration due to the two distinct sets of compressors and turbines. Standard marine medium-speed diesel generators usually use single-stage turbocharging.

Question 21

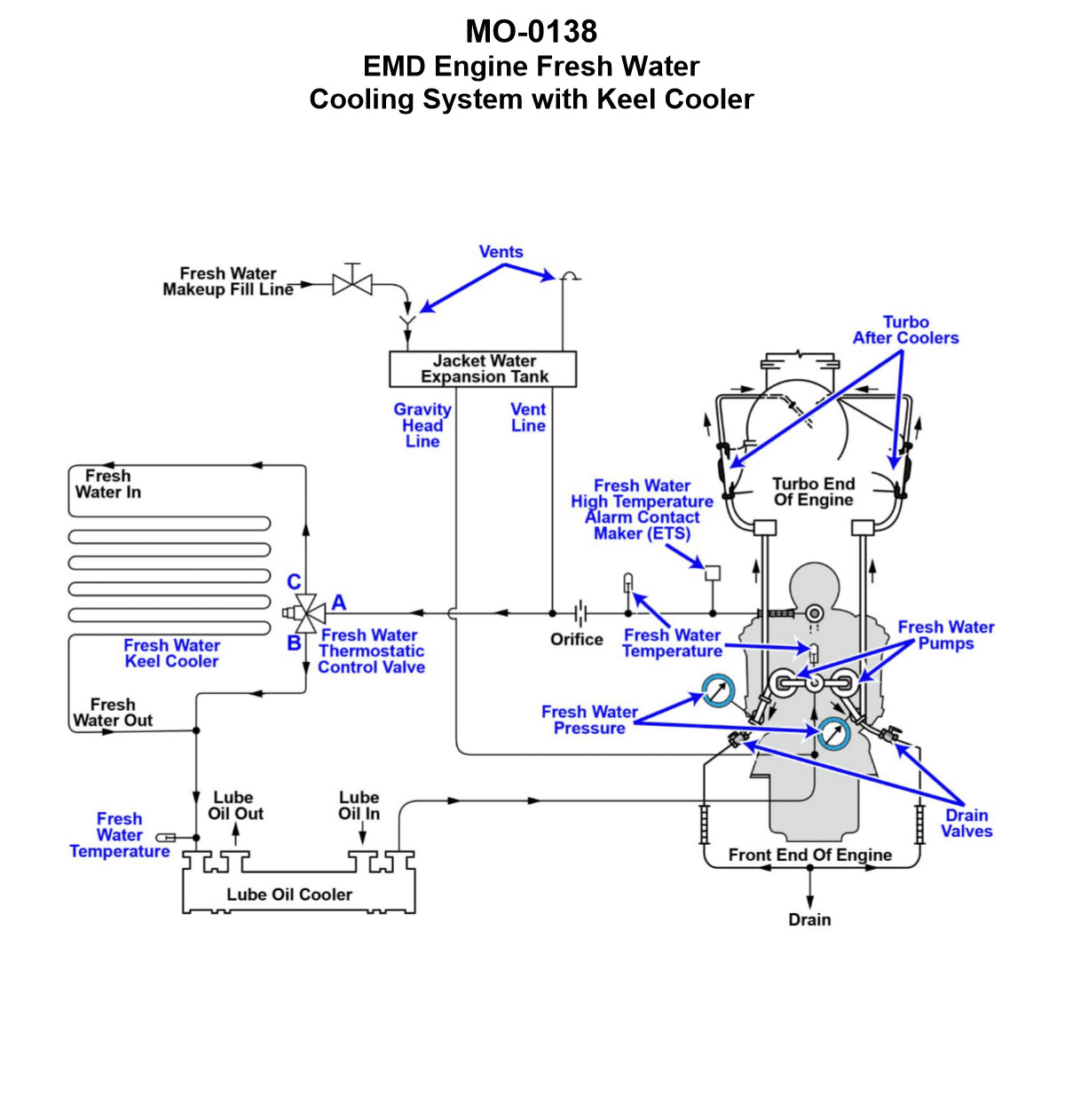

Question: The freshwater cooling systems serving the main engines of the fishery research vessel to which you are assigned are arranged as shown in the illustration. What statement best describes the arrangement of the freshwater keel cooler shown in the system diagram? Illustration MO-0138

A. The keel cooler is mounted on the outside of the hull below the water line

B. The keel cooler is mounted on the inside of the hull above the water line

C. The keel cooler is mounted on the inside of the hull below the water line

D. The keel cooler is mounted on the outside of the hull above the water line

The Correct Answer is A. **Why option A is correct:** A keel cooler is a type of heat exchanger used primarily on vessels. It is designed to dissipate heat from the engine's closed-loop freshwater cooling system directly into the surrounding seawater. To function effectively, the keel cooler must be in constant, direct contact with the maximum volume of cooling medium (the seawater). Therefore, it is always mounted externally, directly onto the hull structure, and specifically **below the water line** where it is fully submerged. **Why other options are incorrect:** * **B) The keel cooler is mounted on the inside of the hull above the water line:** If mounted inside the hull, it would be an internal heat exchanger (like a plate heat exchanger) cooled by pumped seawater, not a keel cooler. If mounted above the water line, it would be exposed to air, not water, making it useless for transferring heat into the sea. * **C) The keel cooler is mounted on the inside of the hull below the water line:** Although below the water line, mounting it inside the hull would require the heat to transfer through the hull material (which is a poor conductor of heat compared to direct water contact) and would classify it as a box cooler or similar internal heat exchanger, not a traditional external keel cooler. * **D) The keel cooler is mounted on the outside of the hull above the water line:** Mounting it outside is correct, but mounting it above the water line means it would be cooled primarily by air (and occasional spray), severely limiting its cooling capacity and rendering it ineffective for marine engine cooling.

Question 22

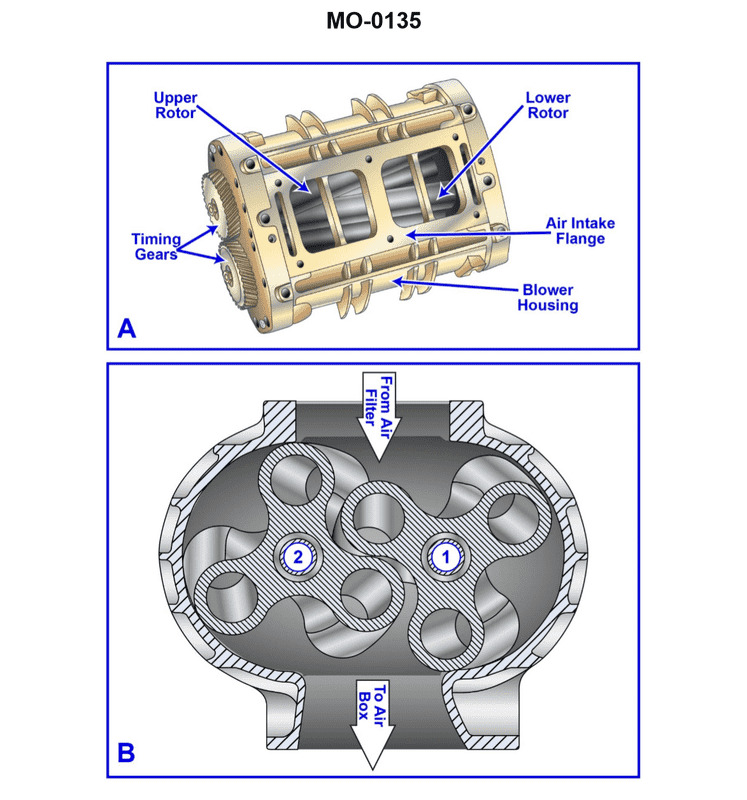

Question: The auxiliary engines on the uninspected fishing trawler to which you are assigned are fitted with Roots- blowers as shown in the illustration. What statement is true concerning the timing gears as shown in figure "A"? Illustration MO-0135

A. The timing gears are straight cut and ensure that the blower rotor lobes are properly spaced apart with a close tolerance.

B. The timing gears are straight cut and ensure that the blower is properly timed to the engine's crankshaft.

C. The timing gears are helically cut and ensure that the blower is properly timed to the engine's crankshaft.

D. The timing gears are helically cut and ensure that the blower rotor lobes are properly spaced apart with a close tolerance.

The Correct Answer is D **Explanation for Option D (Correct Answer):** Option D is correct because it accurately describes the function and design of the timing gears in a typical Roots-type blower used on auxiliary engines (like those found on fishing trawlers). 1. **Helically Cut Gears:** Roots blowers, especially those used in engine applications where noise reduction is important, utilize **helically cut (or helical) gears**. Straight-cut gears (spur gears) are much noisier and produce vibration, making helical gears the preferred design for smoother operation and reduced noise level. 2. **Function of Timing Gears:** The primary purpose of the timing gears in a Roots blower is *not* to time the blower to the engine crankshaft (that is handled by the drive mechanism). Instead, the timing gears link the two separate rotor shafts. They ensure the precise synchronization of the two rotors, maintaining the extremely small, critical clearance between the rotor lobes and between the rotors and the housing. If this clearance is lost (if the rotors touch), the blower will fail instantly. Therefore, the gears **ensure that the blower rotor lobes are properly spaced apart with a close tolerance**. **Explanation for Incorrect Options:** * **A) The timing gears are straight cut and ensure that the blower rotor lobes are properly spaced apart with a close tolerance.** This is incorrect because modern, high-speed Roots blowers typically use **helically cut** gears for quieter operation, not straight-cut gears. The function described (spacing the lobes) is correct, but the gear type is wrong. * **B) The timing gears are straight cut and ensure that the blower is properly timed to the engine's crankshaft.** This is incorrect for two reasons: they are usually helical (not straight cut), and their function is to time the *rotors relative to each other*, not to time the blower to the crankshaft. * **C) The timing gears are helically cut and ensure that the blower is properly timed to the engine's crankshaft.** This is incorrect because the timing gears' role is internal to the blower (synchronizing the rotors), not external (timing the entire blower assembly relative to the crankshaft).

Question 23

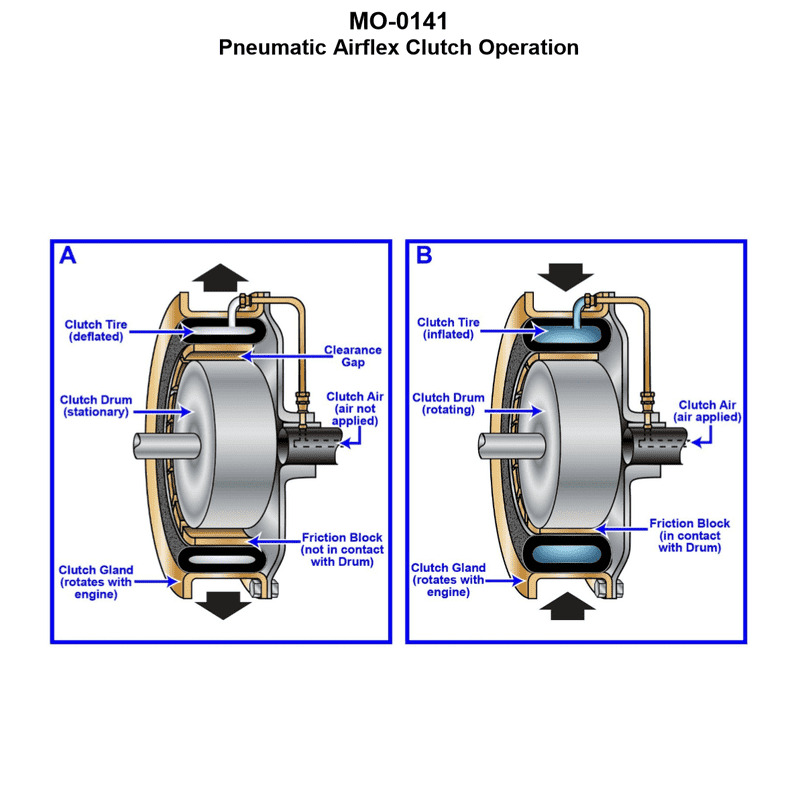

Question: The fishing industry factory ship to which you are assigned is fitted with main propulsion engines driving through pneumatic airflex clutches as shown in the illustration. What statement is true concerning this type of clutch? Illustration MO-0141

A. The clutch is an expanding type clutch and expands to engage against the clutch gland when inflated.

B. The clutch is an expanding type clutch and expands to engage against the clutch drum when inflated.

C. The clutch is a constricting type clutch and constricts to engage against the clutch drum when inflated.

D. The clutch is a constricting type clutch and constricts to engage against the clutch gland when inflated.

The Correct Answer is C **Explanation for Option C (Correct Answer):** Pneumatic Airflex clutches (often manufactured by companies like Eaton, Fawick, or their successors) used in marine propulsion systems for large vessels are typically of the drum type. In this configuration, the clutch mechanism consists of a flexible, toroidal rubber tube (the air bladder or tire) mounted externally to the driving or driven shaft component. When this tube is inflated with compressed air, it **constricts** (squeezes inwards) to grip the outer surface of a surrounding component, usually referred to as the **clutch drum** or friction rim. This action creates the friction necessary to transmit torque, thus engaging the clutch. Therefore, the clutch is a constricting type engaging the clutch drum when inflated. **Why the Other Options are Incorrect:** * **A) The clutch is an expanding type clutch and expands to engage against the clutch gland when inflated.** This is incorrect. While there are expanding pneumatic clutches (where the tube expands outwards to engage an inner drum surface), the standard, highly robust Airflex CB/VC/Wichita type clutches commonly used in marine propulsion applications are constricting. Furthermore, the term "clutch gland" is generally associated with seals and stuffing boxes, not the friction surface of the drum. * **B) The clutch is an expanding type clutch and expands to engage against the clutch drum when inflated.** This is incorrect because, as discussed, the widely used high-torque pneumatic clutches in marine propulsion (especially those described as "Airflex") are typically designed to constrict (squeeze inwards) onto the drum, not expand outwards. * **D) The clutch is a constricting type clutch and constricts to engage against the clutch gland when inflated.** This is incorrect. While the clutch is a constricting type, it engages the friction surface, which is the **clutch drum** (or friction rim), not the "clutch gland."

Question 23

Question: What is the drive arrangement of refrigeration compressor shown in figure "B" of the illustration? Illustration RA-0041

A. open

B. welded, fully hermetic

C. external drive

D. serviceable, bolted, accessible semi-hermetic

The Correct Answer is B **Explanation for Option B (welded, fully hermetic):** Option B is correct because Figure B in illustration RA-0041 typically depicts a modern, small-to-medium capacity refrigeration compressor used in domestic refrigerators, freezers, and small commercial applications. This type of compressor is characterized by: 1. **Welded Casing:** The motor and compressor mechanisms are sealed inside a steel shell that is permanently welded shut. This design prevents refrigerant leakage. 2. **Fully Hermetic:** Since the casing is welded and cannot be opened for repair (it must be replaced if it fails), it is classified as "fully hermetic." The drive motor and compressor are permanently sealed together within the refrigerant atmosphere. **Why the Other Options are Incorrect:** * **A) open:** "Open drive" compressors (or simply "open" compressors) have the motor separate from the compressor body, connected by a shaft that passes through a seal (often involving a belt or coupling). Figure B shows a single, sealed unit, not an open drive arrangement. * **C) external drive:** While technically the electrical power is external, "external drive" specifically refers to the mechanical drive mechanism being outside the compressor casing, usually seen in open-drive systems. Figure B shows an internal, integrated motor (hermetic design). * **D) serviceable, bolted, accessible semi-hermetic:** A semi-hermetic compressor (or serviceable hermetic) has a bolted casing (usually with access panels or heads) that allows technicians to open and service the internal motor and compressor components. Figure B clearly shows a smooth, welded shell, which is not designed for servicing.

Question 24

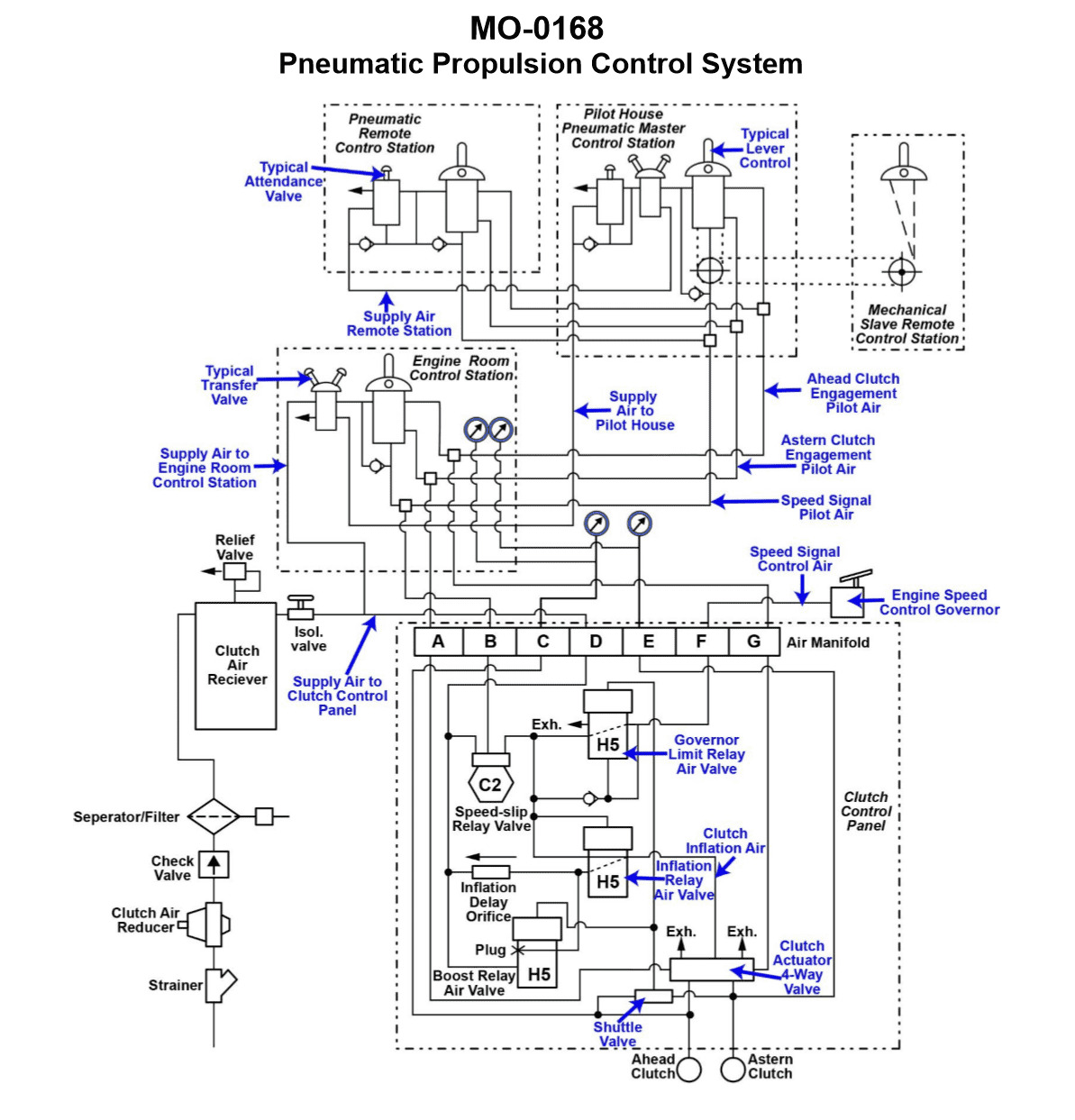

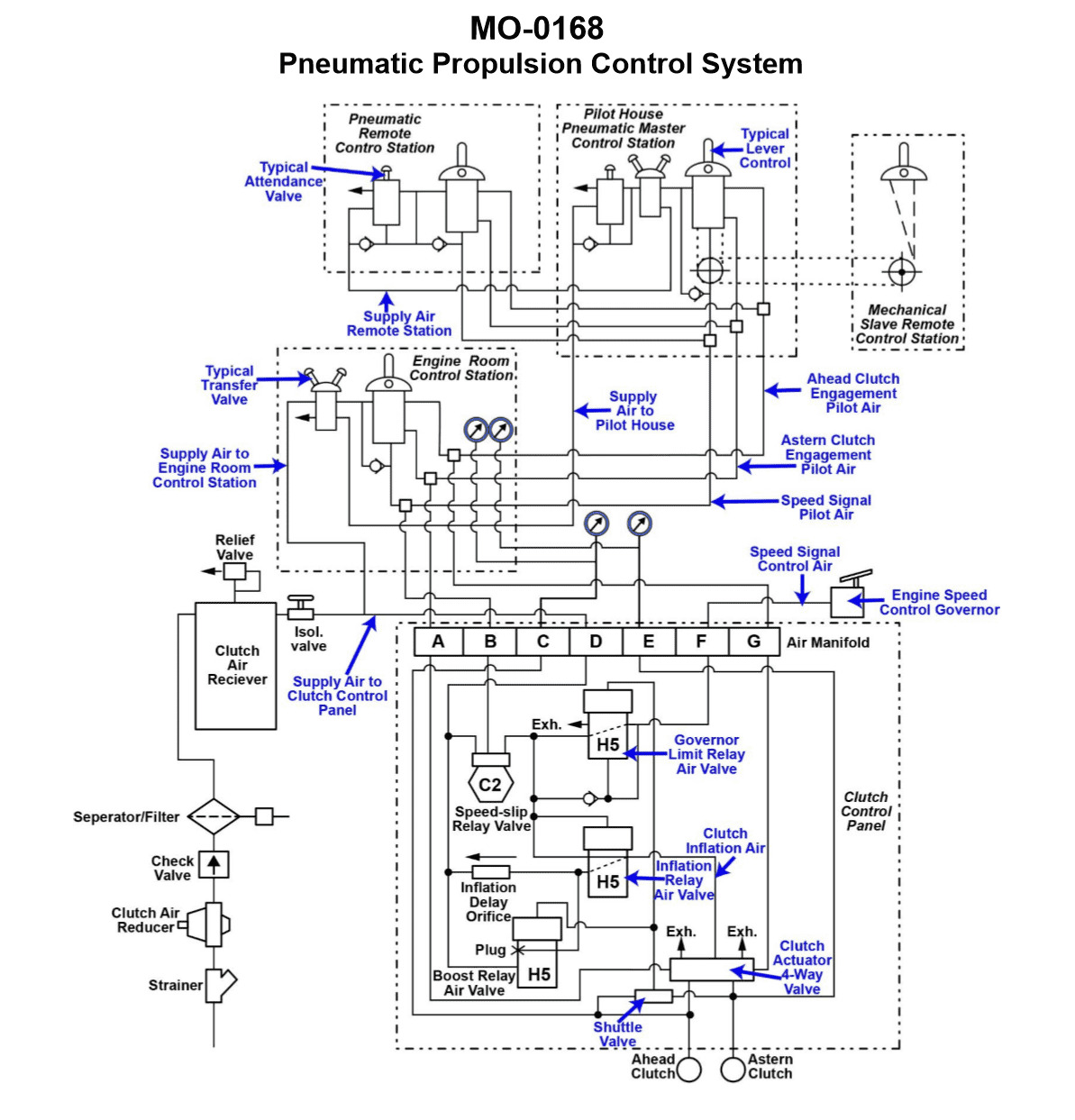

Question: The mollusc dredger to which you are assigned has a pneumatic propulsion control system as shown in the illustration. What statement is true concerning transfer of control? Illustration MO-0168

A. The transfer valve at the engine room control station is used to transfer control of propulsion from the engine room control station to the pilot house pneumatic master control station or vice versa.

B. The transfer valve at the pilot house pneumatic master control station is used to transfer control of propulsion from the pilot house master control station to the mechanical slave remote control station or vice versa.

C. The transfer valve at the pilot house pneumatic master control station is used to transfer control of propulsion from the pilot house master control station to the engine room control station or vice versa.

D. The transfer valve at the pneumatic remote-control station is used to transfer control of propulsion from the pneumatic remote-control station to the mechanical slave remote control station or vice versa.

The Correct Answer is A ### Explanation of Why Option A is Correct: In typical marine propulsion control systems, especially those using pneumatic remote control (like the one described for the mollusc dredger), the main transfer of control authority is handled at the **engine room** control station. The engine room (or local control station) generally holds the ultimate local control and is the point where the operator determines whether the engine is controlled locally (at the engine room control station) or remotely (usually the pilot house/bridge). Therefore, the transfer valve located at the engine room station is the mechanism used to shift control priority between the **Engine Room Control Station** (local/emergency) and the **Pilot House Pneumatic Master Control Station** (remote operating station). ### Explanation of Why Other Options Are Incorrect: **B) The transfer valve at the pilot house pneumatic master control station is used to transfer control of propulsion from the pilot house master control station to the mechanical slave remote control station or vice versa.** * **Incorrect:** The pilot house station is usually the primary remote control point (the master). It does not typically house a valve to transfer control to a "mechanical slave remote control station." Control transfer is almost universally managed between the *local* (engine room) and the *remote master* (pilot house). **C) The transfer valve at the pilot house pneumatic master control station is used to transfer control of propulsion from the pilot house master control station to the engine room control station or vice versa.** * **Incorrect:** While this describes the correct control points involved in the transfer (Pilot House $\leftrightarrow$ Engine Room), the physical transfer valve used to switch control authority is almost always located and operated at the **Engine Room Control Station**, not the Pilot House Master Control Station. **D) The transfer valve at the pneumatic remote-control station is used to transfer control of propulsion from the pneumatic remote-control station to the mechanical slave remote control station or vice versa.** * **Incorrect:** This option describes a transfer between two types of remote stations (pneumatic and mechanical slave). This configuration is highly atypical. The fundamental control transfer involves moving authority between the local control (Engine Room) and the main remote control (Pilot House/Bridge).

Question 25

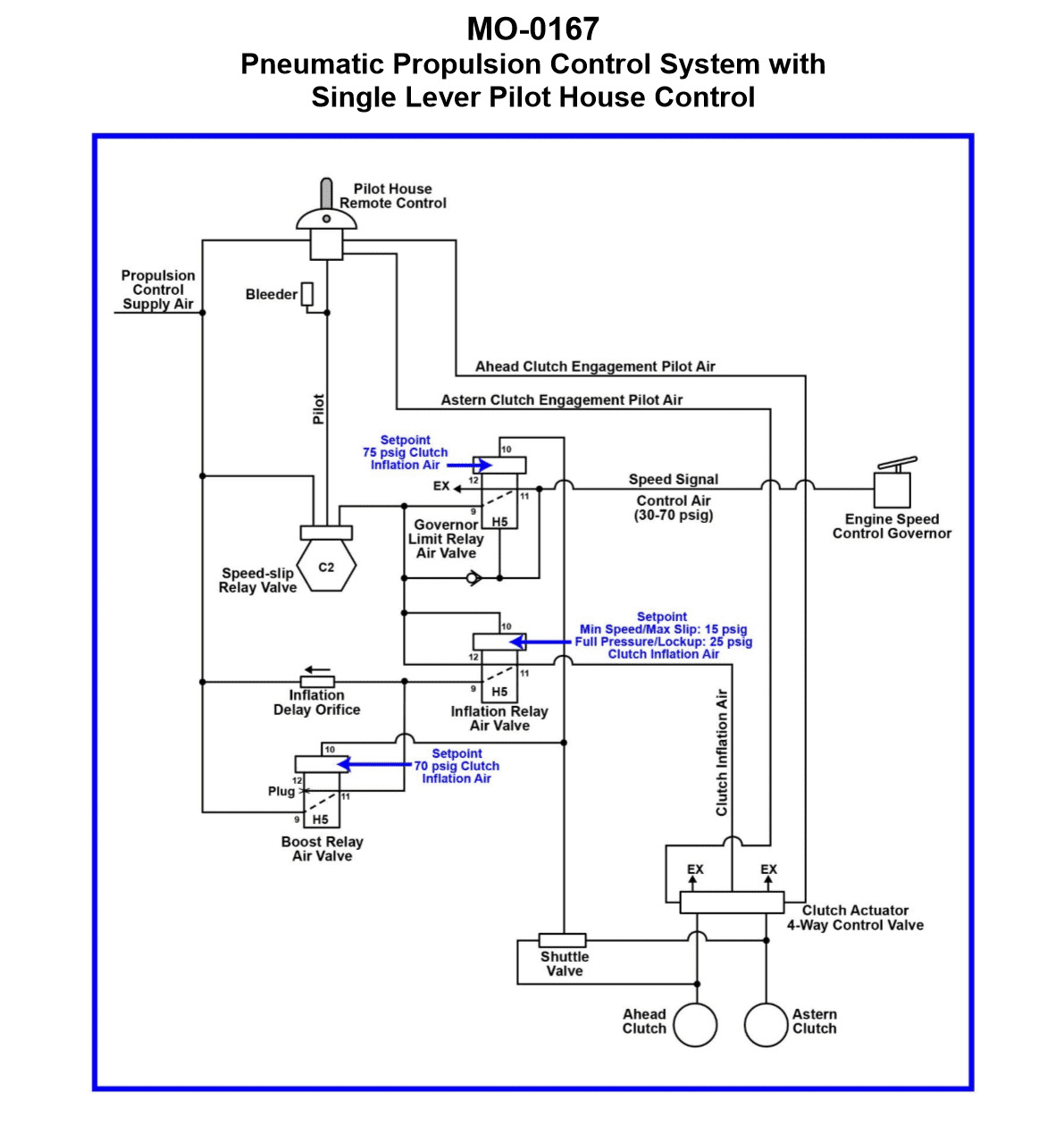

Question: The fishing industry factory ship to which you are assigned has a pneumatic propulsion control system as shown in the illustration. Which control valve is responsible for bypassing the inflation delay orifice to insure rapid and positive reversals and to protect the clutches from excessive slip? Illustration MO-0167

A. H5 inflation air relay valve

B. C2 speed-slip relay valve

C. H5 boost relay air valve

D. H5 governor limit relay air valve

The Correct Answer is C The **H5 boost relay air valve** (Option C) is the component specifically designed to bypass the normal restriction (inflation delay orifice) during rapid maneuvers, such as reversing the direction of the propeller. The primary function of the delay orifice is to slow down the inflation of the pneumatic clutch to allow for smooth engagement under normal operating conditions. However, during rapid reversals, this slow engagement would cause excessive clutch slip, leading to overheating, wear, and potential failure. The H5 boost relay valve senses the demand for rapid change (often triggered by high pressure from the propulsion control system) and momentarily supplies high-volume, unrestricted air ("boost") to quickly and positively engage the clutch, minimizing slip and protecting the clutch components. **Why the other options are incorrect:** * **A) H5 inflation air relay valve:** While the H5 inflation relay valve controls the primary flow of air into the clutch, it generally operates in conjunction with the delay orifice to ensure smooth, slow engagement during normal acceleration or standard maneuvering. It is not the specific valve responsible for the *bypassing* or "boost" function during rapid reversals. * **B) C2 speed-slip relay valve:** The C2 speed-slip relay valve is typically involved in monitoring the rotational speeds of the input and output shafts (or propeller shaft) and adjusting the clutch pressure to minimize sustained slip under normal load conditions, often to protect the clutch from overheating, but it is not the valve that provides the rapid pressure boost for immediate engagement during reversals. * **D) H5 governor limit relay air valve:** The H5 governor limit relay valve is usually involved in limiting the maximum speed or power output of the engine or propulsion system under certain conditions (e.g., preventing overspeed or limiting torque). It does not function as the specific bypass valve for quick clutch engagement during reversals.

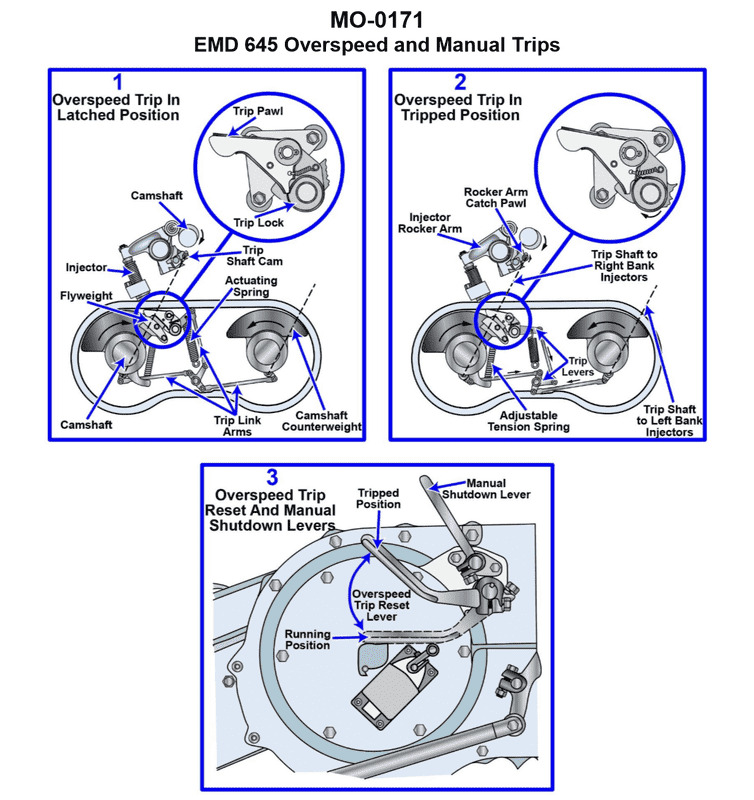

Question 26

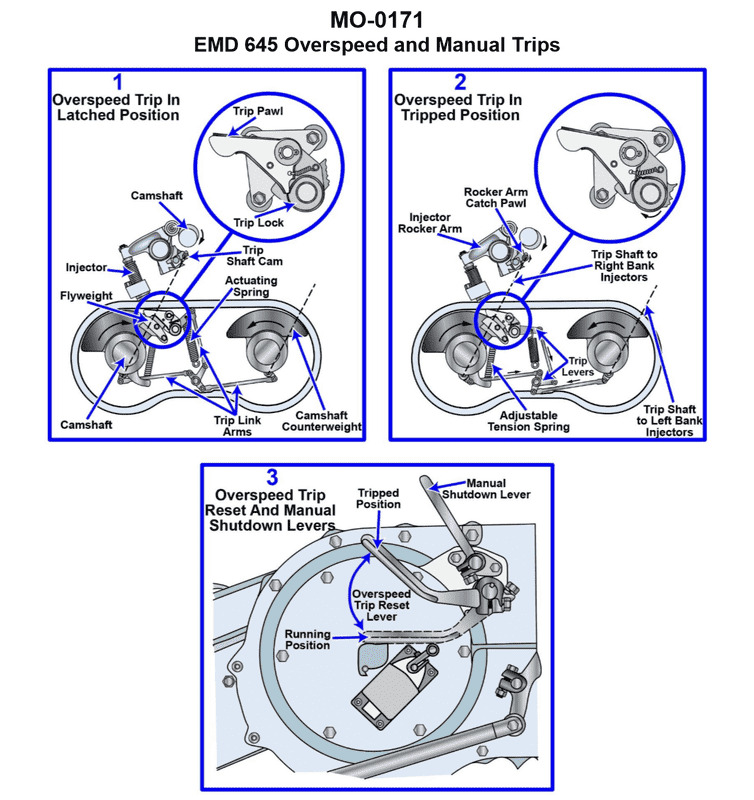

Question: The main engines on your fishing industry line vessel are equipped with manual shutdown levers as shown in the illustration. What statement concerning manual shutdown is true? Illustration MO-0171

A. The manual shutdown lever is operated by means of a remote pull cable and uses the governor fuel control linkage to accomplish engine shutdown.

B. The manual shutdown lever is operated by means of the emergency trip reset lever and uses the governor fuel control linkage.

C. The manual shutdown lever is operated by means of the over speed trip reset lever and uses the over speed trip mechanism to accomplish engine shutdown.

D. The manual shutdown lever is operated by means of a remote pull cable and uses the over speed trip mechanism to accomplish engine shutdown.

The Correct Answer is D **Explanation for Option D (Correct):** Manual shutdown systems designed for emergency use on large marine diesel engines (like those found on fishing industry line vessels) typically utilize a robust and immediate mechanism. This mechanism is usually the **over speed trip mechanism**. Activating this mechanism, even manually via a lever, forces the engine to shut down instantly by cutting off fuel supply, independent of the normal governor control. The lever itself is often connected to an easily accessible **remote pull cable** (or push rod) located away from the hot engine, making it suitable for emergency stops from a safe distance or remote station. **Explanation of Incorrect Options:** * **A) The manual shutdown lever is operated by means of a remote pull cable and uses the governor fuel control linkage to accomplish engine shutdown.** While a remote pull cable is common, using only the standard governor fuel control linkage for an *emergency* shutdown is generally incorrect. The governor linkage is designed for speed control; emergency systems prioritize immediate, forceful fuel cutoff, which is better achieved by triggering the dedicated trip mechanism. * **B) The manual shutdown lever is operated by means of the emergency trip reset lever and uses the governor fuel control linkage.** This is incorrect for two reasons: 1) The shutdown lever *activates* the trip, it does not use the *reset* lever. 2) As noted above, the emergency shutdown uses the trip mechanism, not the standard governor linkage, for execution. * **C) The manual shutdown lever is operated by means of the over speed trip reset lever and uses the over speed trip mechanism to accomplish engine shutdown.** The purpose of the manual shutdown lever is to *activate* the trip mechanism to stop the engine. The trip **reset** lever is used to prepare the engine for starting *after* a trip has occurred. Therefore, operating the shutdown lever via the reset mechanism is mechanically backward and incorrect.

Question 26

Question: Which of the following statements is true? Illustration RA-0012

A. Valve "14" is the king solenoid, valves "28" and "36" are both freeze box solenoids.

B. Valve "14" is the king solenoid, valves "28" and "36" are both chill box solenoids.

C. Valve "14" is the king solenoid, valve "28" is the chill box solenoid, and valve "36" is the freeze box solenoid.

D. Valve "14" is the king solenoid, valve "36" is the chill box solenoid, and valve "28" is the freeze box solenoid.

The Correct Answer is C ### 2. Explanation for Option C (Correct Answer) Option C is correct because it accurately identifies the standard nomenclature and function of the solenoids in the refrigeration system typically depicted in illustrations like RA-0012 (which represents a standard dual-temperature zone reefer system, often found in transport refrigeration). * **Valve "14" (King Solenoid):** Valve "14" is universally identified as the King Solenoid (or Main Solenoid/Suction Modulation Valve) in these diagrams. Its primary function is to control the overall flow of refrigerant to the entire unit, acting as the main shut-off valve for the suction side. * **Valve "28" (Chill Box Solenoid):** Valve "28" controls the flow of refrigerant specifically to the chill compartment (the zone requiring cooling but not freezing, typically the warmer zone). The chill box solenoid is often positioned before the freeze box solenoid in the circuit controlling the primary compartment. * **Valve "36" (Freeze Box Solenoid):** Valve "36" controls the flow of refrigerant specifically to the freeze compartment (the zone requiring deep cooling/freezing, typically the colder zone). This arrangement allows the system to independently modulate the temperature in the two distinct cargo zones (chill and freeze). ### 3. Explanation of Incorrect Options **A) Valve "14" is the king solenoid, valves "28" and "36" are both freeze box solenoids.** * **Incorrect:** While Valve "14" is correctly identified as the King Solenoid, valves "28" and "36" cannot both be freeze box solenoids in a standard dual-zone system. They must control separate zones (chill and freeze). **B) Valve "14" is the king solenoid, valves "28" and "36" are both chill box solenoids.** * **Incorrect:** Similar to Option A, while Valve "14" is correct, "28" and "36" cannot both be chill box solenoids. This would negate the system's ability to maintain a deep freeze temperature in the secondary compartment. **D) Valve "14" is the king solenoid, valve "36" is the chill box solenoid, and valve "28" is the freeze box solenoid.** * **Incorrect:** This option misidentifies the roles of "28" and "36" relative to the standard layout. Although the precise numbering varies slightly, in the typical configuration represented by RA-0012, Valve "28" is dedicated to the Chill Box, and Valve "36" is dedicated to the Freeze Box. This option swaps the functions of the two zone solenoids.

Question 27

Question: The main engines on your uninspected fishing trawler are equipped with over speed trip devices as shown in the illustration. What statement concerning the operation of the over speed trip is true? Illustration MO-0171

A. The over speed trip senses centrifugal force proportional to engine speed and limits the engine speed to the rated speed, while allowing the engine to continue to run at the rated speed.

B. The over speed trip senses oil pressure proportional to engine speed and limits the engine speed to the rated speed, while allowing the engine to continue to run at the rated speed.

C. The over speed trip senses centrifugal force proportional to engine speed and shuts the engine down at a pre-determined, specified maximum speed setting.

D. The over speed trip senses oil pressure proportional to engine speed and shuts the engine down at a pre- determined, specified maximum speed setting.