Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app

OSE01 - Chief Engineer - OSV

62 images

Question 1

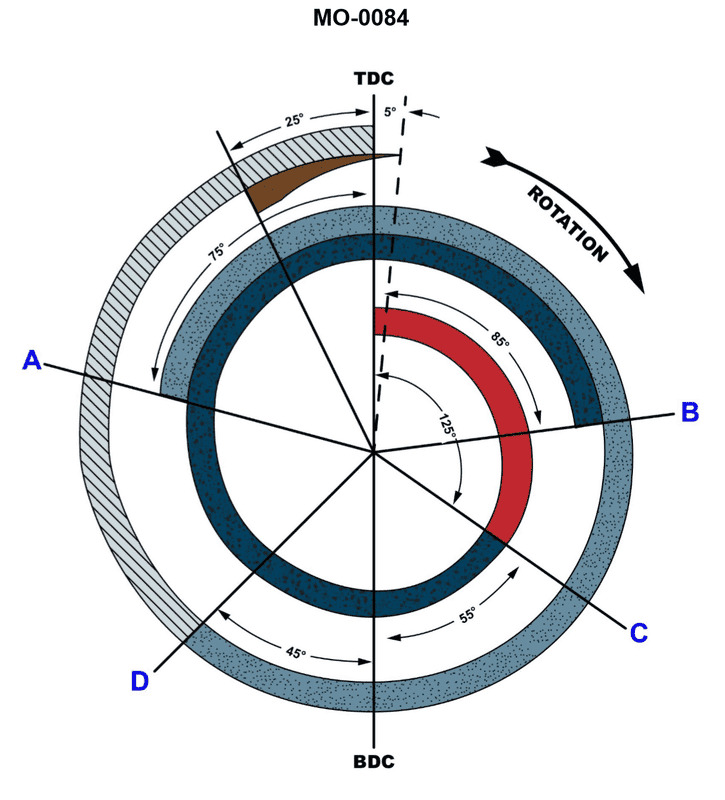

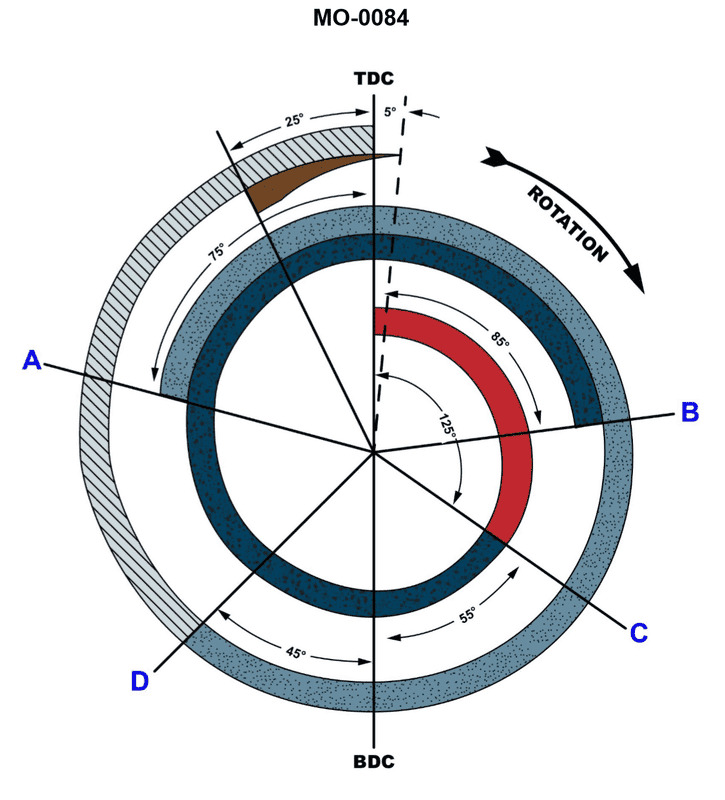

Question: You are assigned to an OSV fitted with main propulsion diesel engines operating on the cycle represented in the polar timing diagram shown in the illustration. When do the exhaust valves open and close respectively? Illustration MO-0084

A. The exhaust valves open at 55o before bottom dead center on the power stroke. The exhaust valves close at 85o after top dead center on the intake stroke.

B. The exhaust valves open at bottom dead center at the beginning of the exhaust stroke. The exhaust valves close at top dead center at the end of the exhaust stroke.

C. The exhaust valves open at top dead center at the end of the exhaust stroke. The exhaust valves close at bottom dead center at the beginning of the exhaust stroke.

D. The exhaust valves open at 85o after top dead center on the intake stroke. The exhaust valves close at 55o before bottom dead center on the power stroke.

The Correct Answer is A ### 2. Why Option A is Correct Option A describes the characteristic advanced opening and retarded closing required for efficient operation in a modern four-stroke diesel engine. The timing events are: * **Exhaust Valves Open:** **$55^{\circ}$ before bottom dead center (BDC) on the power stroke.** * This is known as advanced opening (or blowdown). The exhaust valve is opened early (before the piston reaches BDC) while the cylinder pressure is still high enough to rapidly expel the spent gases. This ensures that cylinder pressure drops significantly before the exhaust stroke begins, reducing the work required by the piston to push the gases out. * **Exhaust Valves Close:** **$85^{\circ}$ after top dead center (TDC) on the intake stroke.** * This is known as retarded closing. The valve remains open well into the beginning of the intake stroke. This late closing (along with advanced intake valve opening) creates a period of overlap around TDC. For high-speed or supercharged engines, this long overlap period (85° in this case is aggressive/long) is critical for effective scavenging—the incoming fresh air helps to push the remaining exhaust gases out, maximizing volumetric efficiency and cooling the cylinder head. The values ($55^{\circ}$ advanced opening and $85^{\circ}$ retarded closing) correspond precisely to the specific timings often shown in the standard polar timing diagram (MO-0084) for such engines. ### 3. Why Other Options Are Incorrect **B) The exhaust valves open at bottom dead center at the beginning of the exhaust stroke. The exhaust valves close at top dead center at the end of the exhaust stroke.** * **Incorrect:** This describes the theoretical, ideal timing (often shown in simple thermodynamics diagrams), but not the actual timing of a functioning engine. Actual engines require advanced opening (before BDC) and retarded closing (after TDC) to ensure full scavenging and maximum power output. **C) The exhaust valves open at top dead center at the end of the exhaust stroke. The exhaust valves close at bottom dead center at the beginning of the exhaust stroke.** * **Incorrect:** This reverses the timing and sequence. The exhaust valves must open near BDC (end of power stroke) and close near TDC (end of exhaust stroke/start of intake stroke). **D) The exhaust valves open at $85^{\circ}$ after top dead center on the intake stroke. The exhaust valves close at $55^{\circ}$ before bottom dead center on the power stroke.** * **Incorrect:** This swaps the opening and closing events. $85^{\circ}$ ATDC is the closing point (overlap), not the opening point. $55^{\circ}$ BTDC is the opening point (blowdown), not the closing point.

Question 1

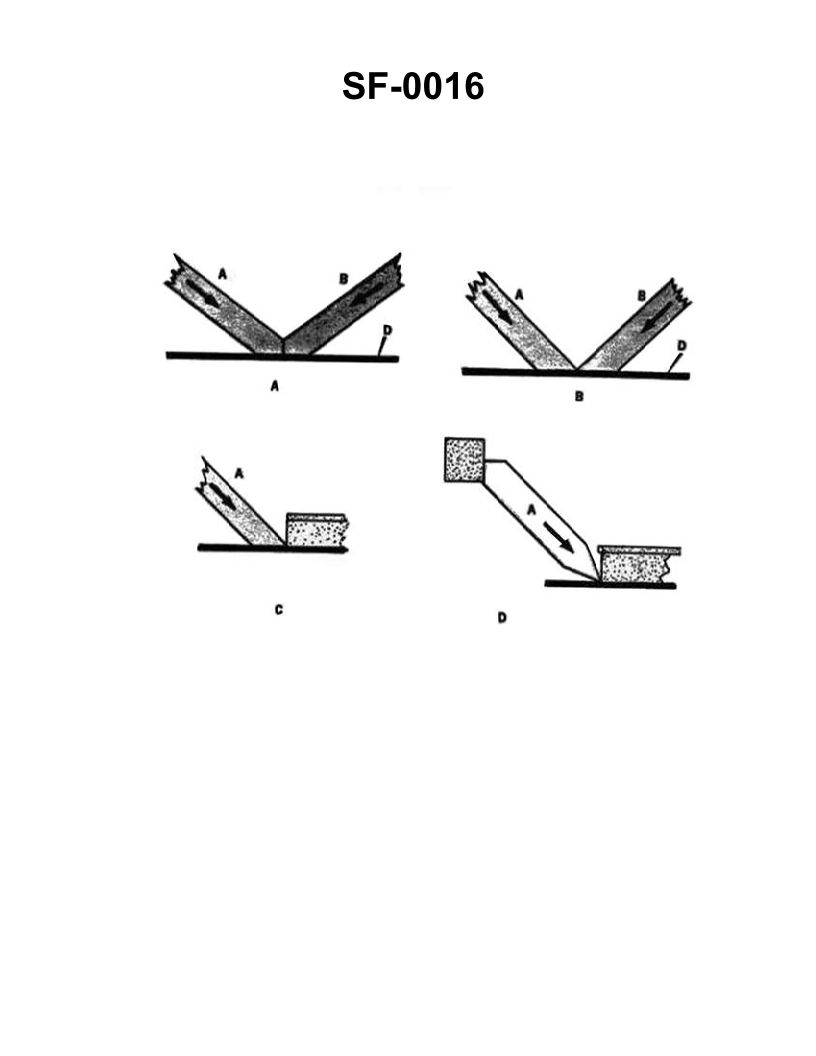

Question: Which of the methods shown in the illustration is the correct way to fit shoring? Illustration SF-0016

A. A

B. B

C. C

D. D

The Correct Answer is A. **Explanation for Option A (Correct):** Method A illustrates the correct way to fit shoring (or trench bracing) using a hydraulic jack or screw jack. The key features of a correct shoring installation shown in A are: 1. **Vertical Walers/Stringers:** The horizontal boards (walers or stringers) are installed parallel to the trench walls. 2. **Correct Placement and Orientation of Struts/Rakers:** The struts (the bracing members placed between the walers) are installed horizontally (or nearly horizontally) and are fitted tightly against the opposing walers using a hydraulic jack, screw jack, or mechanical device. 3. **Firm Contact:** This method ensures maximum lateral support by applying outward pressure against the trench walls, preventing them from collapsing. **Explanation for Other Options (Incorrect):** * **Option B (Incorrect):** This method shows a loose fit or an incorrect type of bracing. Simply placing a piece of wood (strut) without wedging, jacking, or tightening it properly will not provide adequate lateral support. The strut must be firmly fixed and exert pressure against the opposing walls to be effective. * **Option C (Incorrect):** This method incorrectly shows the strut being fitted vertically or steeply diagonally between the trench floor and the top of the shoring. Shoring struts must be placed horizontally (or slightly pitched) between the opposing walers to counteract the lateral earth pressure effectively. Vertical members are usually **posts** or **uprights/soldiers**, not horizontal **struts**. * ****Option D (Incorrect):** This method likely shows the strut being placed diagonally between the shoring timbers or positioned in a way that creates a weak point (e.g., placing the strut directly against the soil instead of the waler, or using a highly diagonal orientation that converts the horizontal load into vertical forces). Effective shoring relies on horizontal compressive forces transferred through the strut to the opposing walers.

Question 1

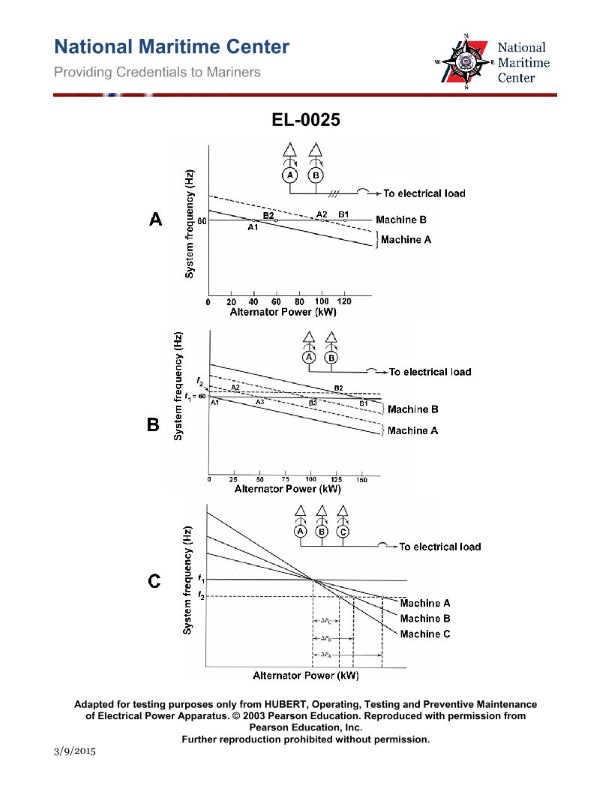

Question: What are the operational characteristics of the two alternators with the speed droop curves shown in figure "A" of the illustration? Illustration EL-0025

A. Machine "A" is a droop machine, while machine "B" is an isochronous machine

B. Machine "A" and machine "B" are both isochronous machines

C. Machine "A" is an isochronous machine, while machine "B" is a droop machine

D. Machine "A" and machine "B" are both droop machines

The Correct Answer is A ### Explanation for Option A (Correct) Option A is correct because it accurately describes the operational characteristics based on standard governor speed droop curves. 1. **Machine "A" (Droop Machine):** A droop machine exhibits a negative slope on the speed vs. load (or frequency vs. power) curve. This means that as the mechanical load (or electrical power output) increases, the rotational speed (and thus the electrical frequency) of the alternator decreases. This characteristic is essential for stable load sharing when two or more alternators operate in parallel, as it allows the governor to adjust power output proportionally to the frequency change. 2. **Machine "B" (Isochronous Machine):** An isochronous machine is one whose governor attempts to maintain the rotational speed (and therefore the system frequency) constant, regardless of the load applied, until the limits of the machine are reached. On a speed droop curve, this characteristic is represented by a vertical line, or a line with zero slope, maintaining a fixed speed (or frequency) across its operating range. This configuration is often used when a single machine controls the frequency of the system, or when sophisticated electronics manage the load sharing. Therefore, the curve labeled "A" (sloping line) represents droop operation, and the curve labeled "B" (horizontal line) represents isochronous operation. ### Explanation for Other Options (Incorrect) **B) Machine "A" and machine "B" are both isochronous machines:** This is incorrect. An isochronous machine maintains constant speed (zero slope). While machine B shows this characteristic, machine A clearly has a negative slope (speed drops as load increases), defining it as a droop machine. **C) Machine "A" is an isochronous machine, while machine "B" is a droop machine:** This is the reverse of the correct identification. Machine A is the droop machine (sloping curve), and machine B is the isochronous machine (flat curve). **D) Machine "A" and machine "B" are both droop machines:** This is incorrect. A droop machine must exhibit a decrease in speed as load increases (negative slope). While machine A shows this droop, machine B maintains constant speed (zero slope), classifying it as isochronous.

Question 2

Question: You are assigned to an OSV fitted with main propulsion diesel engines operating on the cycle represented in the polar timing diagram shown in the illustration. In consideration of the direction of rotation, what combustion cycle event occurs from point "A" to point "D"? Illustration MO-0084

A. Intake

B. Power

C. Compression

D. Exhaust

The Correct Answer is A **Explanation for Option A (Intake) being correct:** The illustration (MO-0084, which typically represents a polar timing diagram for a four-stroke or two-stroke diesel engine) shows the crank angle degrees relative to the engine cycle. Assuming the diagram represents a typical four-stroke cycle and the engine is rotating clockwise (as is standard for viewing such diagrams unless otherwise indicated, and given the progression from A to D), we can analyze the phases: 1. **Intake Phase (A to D):** The intake valves open before Top Dead Center (BTDC) or near it and remain open well past Bottom Dead Center (ABDC). In a standard four-stroke cycle, the intake stroke occurs as the piston moves down from TDC to BDC, covering approximately $180^\circ$ of crank rotation. If point "A" marks the opening of the intake valve (or the start of the piston's downward travel after TDC/near the beginning of the stroke) and point "D" marks the closing of the intake valve (or the end of the piston's downward travel at BDC/near the end of the stroke), the segment from A to D represents the downward movement of the piston drawing fresh air into the cylinder. This is the Intake stroke. **Explanation of why other options are incorrect:** * **B) Power:** The Power (or Expansion) stroke occurs immediately after injection and ignition (near TDC) and pushes the piston down toward BDC. This stroke is characterized by both the intake and exhaust valves being closed. The segment A to D, which spans a large angle of the diagram, represents a period where gas exchange is actively taking place (if A is valve opening and D is valve closing), making it inconsistent with the closed-valve Power stroke. * **C) Compression:** The Compression stroke occurs as the piston moves upward from BDC to TDC, compressing the air charge. During this $180^\circ$ period, both valves are closed. Since the segment A to D represents a period of downward piston movement or gas exchange (Intake or Exhaust), it cannot be the upward movement associated with Compression. * **D) Exhaust:** The Exhaust stroke occurs as the piston moves upward from BDC to TDC, pushing burned gases out of the cylinder. This stroke usually starts before BDC and ends after TDC. If A to D represented the Exhaust stroke, the engine would be moving upward, pushing gas out, which conflicts with the typical downward movement associated with the segment A to D (Intake) on most standard polar timing diagrams.

Question 4

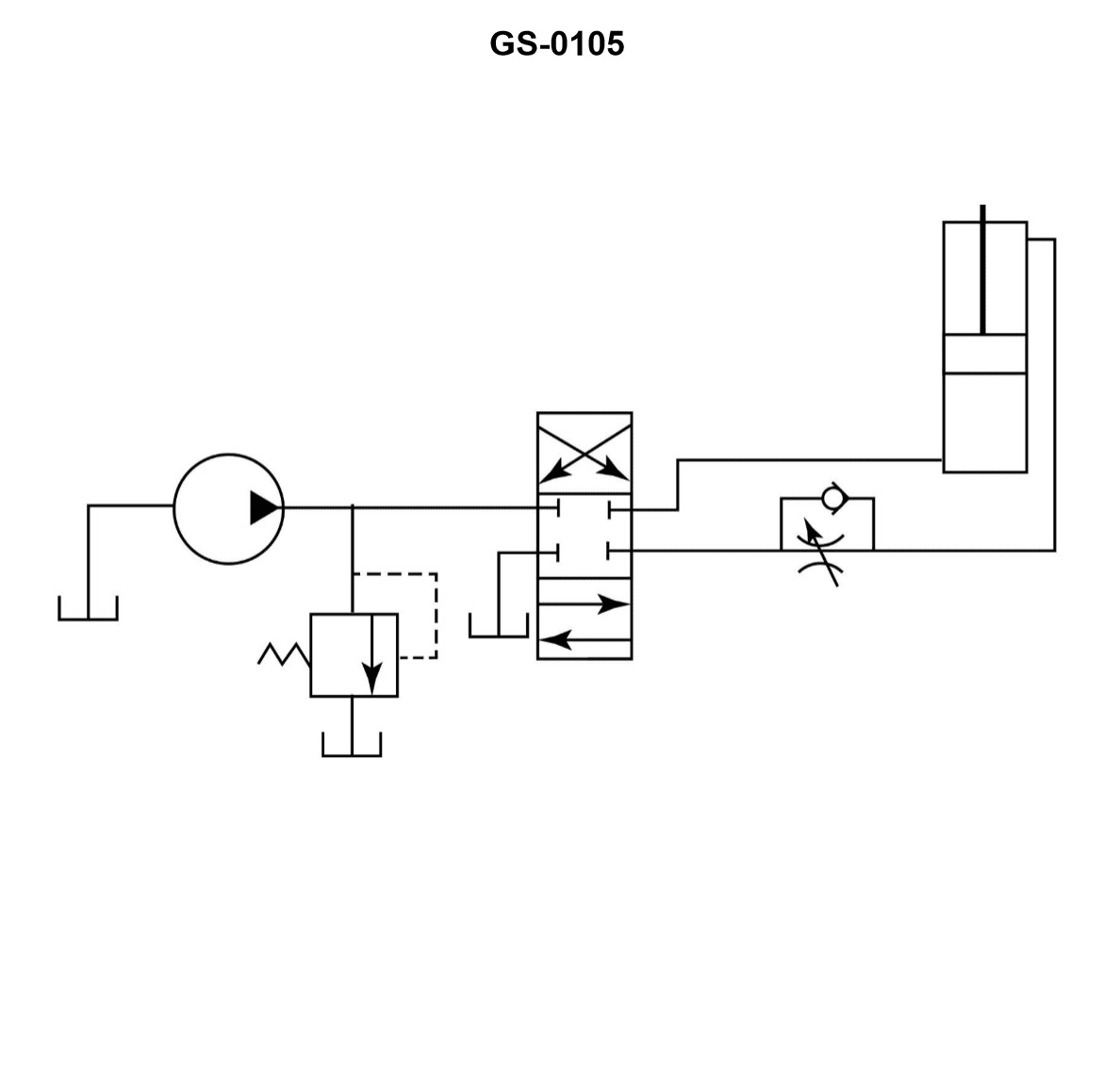

Question: A hydraulic system flow control circuit is shown in the illustration and is known as a __________. Illustration GS-0105

A. metered-in circuit

B. bleed-off circuit

C. bleed-in circuit

D. metered-out circuit

The Correct Answer is A **Explanation for Option A (metered-in circuit):** The illustration (GS-0105, which depicts a flow control valve placed in the line **before** the actuator/cylinder) shows the flow control valve regulating the amount of fluid **entering** the primary port of the actuator. When the flow control is placed directly in the inlet line to the cylinder, it controls the speed of the actuator by throttling the supply flow (the "metered" flow) **into** the actuator. This configuration is standardly defined as a **metered-in circuit**. Metered-in circuits are typically used for resistive loads (loads that resist the cylinder's movement) and provide excellent speed control when the load is consistent. **Explanation for Incorrect Options:** * **B) bleed-off circuit:** A bleed-off (or bypass) circuit controls speed by diverting (bleeding off) some of the pump's output flow directly back to the reservoir, rather than placing the valve directly in series with the actuator input line. The flow control valve would typically be installed parallel to the cylinder circuit, branching off the main pressure line. * **C) bleed-in circuit:** This term is not a standard, recognized designation for hydraulic flow control circuits. Hydraulic control schemes are generally categorized as metered-in, metered-out, or bleed-off. * **D) metered-out circuit:** A metered-out circuit controls the speed of the actuator by placing the flow control valve on the **outlet** (return) line of the actuator, throttling the fluid as it exits the cylinder. This is generally used for overrunning or regenerative loads (loads that try to push the cylinder faster than the pump dictates) to maintain back pressure and prevent cavitation. The illustrated valve is on the inlet side, not the outlet side.

Question 5

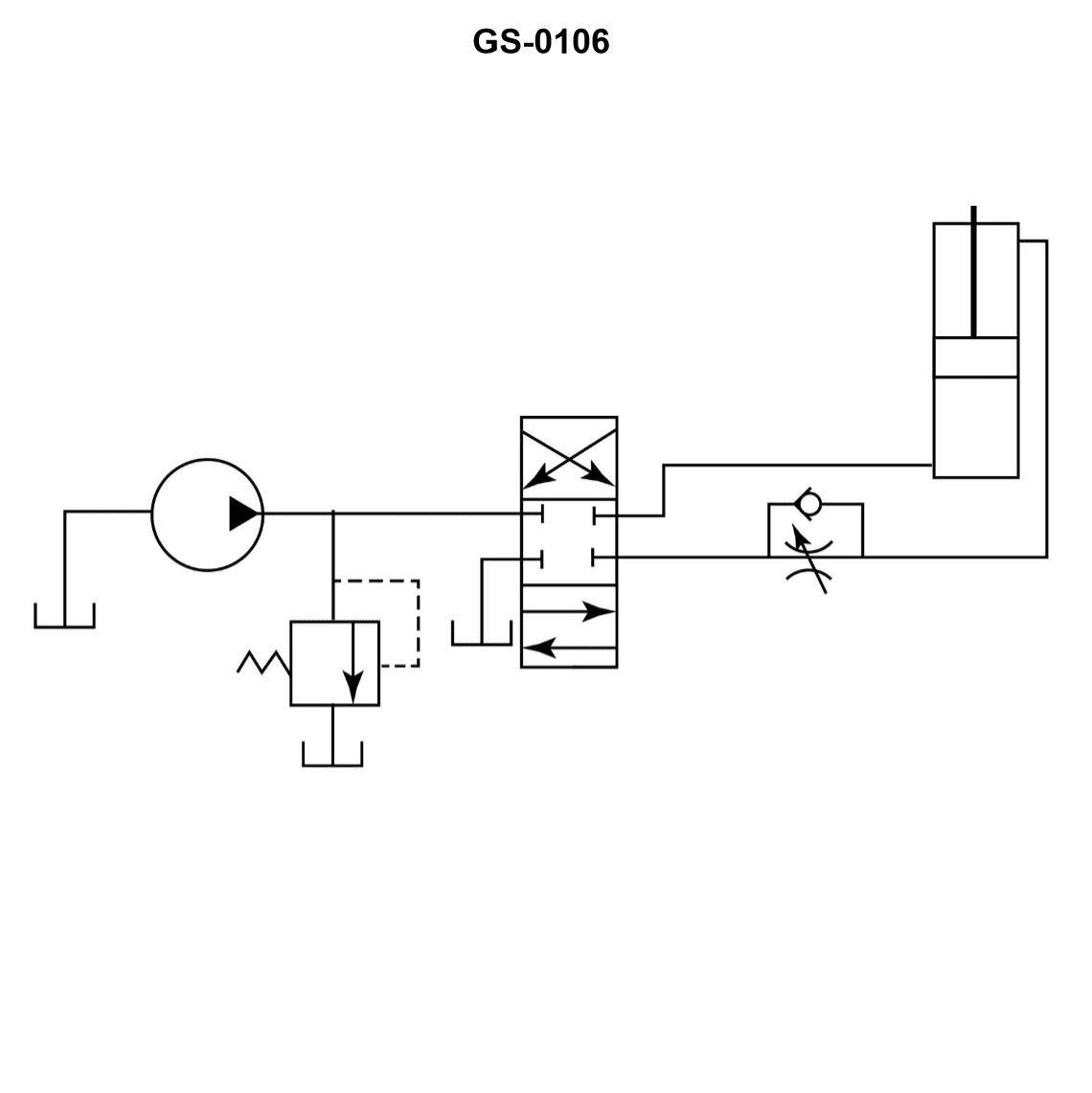

Question: A hydraulic system flow control circuit is shown in the illustration and is known as a __________. Illustration GS-0106

A. metered-out circuit

B. metered-in circuit

C. bleed-in circuit

D. bleed-off circuit

The Correct Answer is A. **Explanation for Option A (metered-out circuit):** A metered-out flow control circuit places the flow control valve (restrictor) on the **outlet (exhaust) line** of the actuator (like a hydraulic cylinder) as it extends or retracts. In this configuration, the restricted flow controls the rate at which fluid leaves the cylinder, thus governing the actuator's speed. This method is preferred when controlling loads that might go into "runaway" (overrunning or negative loads) because the restriction maintains back pressure on the moving component, providing precise speed control and preventing uncontrolled movement. The illustration GS-0106 shows the restriction regulating the fluid leaving the cylinder's rod end as the cylinder extends, which is the definition of a metered-out circuit. **Explanation for Other Options:** * **B) metered-in circuit:** This circuit places the flow control valve on the **inlet line** of the actuator, controlling the rate at which fluid enters the cylinder. While effective for resistive (positive) loads, it is generally unsuitable for overrunning loads because it does not maintain adequate back pressure, potentially allowing the load to move faster than desired. * **C) bleed-in circuit:** This term is not standard terminology for fundamental flow control methods (metered-in/out, or bleed-off). A "bleed" circuit typically refers to diverting (bleeding) a portion of the pump flow back to the tank *before* it reaches the actuator, which is defined by option D. * **D) bleed-off circuit (or bypass circuit):** This circuit takes the excess flow from the pump and routes it directly back to the tank using a bypass valve (often adjustable) placed in parallel with the actuator. It controls the actuator speed by diverting unused fluid, meaning the restriction is not placed directly in the line controlling the fluid going into or out of the actuator, unlike the metered circuits.

Question 5

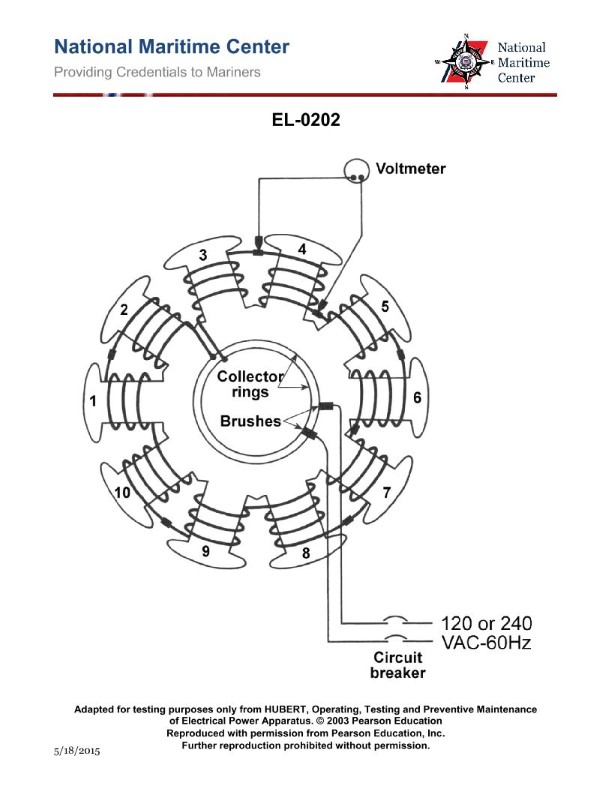

Question: As shown in the illustrated diagnostic setup for locating a shorted field coil of a ten-pole salient pole alternator, if 240 VAC/60 Hz is applied across the brushes, what would be the voltage drop across field coil No.4 if that field coil had shorted turns and the other field coils were free of shorts? Illustration EL-0202

A. 17 VAC

B. 24 VAC

C. 25 VAC

D. 32 VAC

The Correct Answer is A --- ### 1. Explanation for Option A (17 VAC) The setup describes a standard diagnostic test (AC voltage drop test) used to locate shorted turns in DC field windings. The total voltage applied (240 VAC) is distributed equally among the field coils if they are all healthy and identical. **Step 1: Determine the Healthy Voltage Drop** The alternator has 10 poles, meaning there are 10 field coils connected in series. If all coils were healthy, the voltage drop across each coil ($V_H$) would be: $$V_H = \frac{V_{Total}}{\text{Number of Coils}} = \frac{240 \text{ VAC}}{10} = 24 \text{ VAC}$$ **Step 2: Analyze the Effect of a Short** When field coil No. 4 develops shorted turns, its internal resistance ($R_4$) significantly decreases. Since the coils are connected in series, the total circuit current ($I$) remains the same through all coils. The voltage drop across any coil is determined by Ohm's Law ($V = I \times R$). Because the resistance of the shorted coil ($R_4$) decreases, the voltage drop across that coil ($V_4$) must also decrease proportionally. * A shorted coil will always show a voltage drop **less than** the healthy voltage (24 VAC). * The remaining 9 healthy coils will absorb the difference, meaning the voltage across the healthy coils will increase slightly (from 24 VAC to approximately 24.78 VAC, based on $240 - 17 = 223 \text{ VAC}$ distributed over 9 coils). Option A (17 VAC) is significantly lower than the healthy baseline of 24 VAC, which is the definitive indicator of a shorted field coil in this diagnostic test. --- ### 2. Explanation for Incorrect Options **B) 24 VAC** This is the baseline voltage expected if field coil No. 4 were **free of shorts** (healthy). If the reading were 24 VAC, the coil would pass the test. **C) 25 VAC** This reading is slightly *higher* than the baseline. While the voltage across the *healthy* coils does slightly increase when one coil shorts, 25 VAC is essentially a normal/healthy reading. It would never be the voltage drop measured across the coil with shorted turns, which must have a lower resistance and thus a lower voltage drop. **D) 32 VAC** A voltage drop higher than the healthy baseline (24 VAC) indicates that the coil has a resistance *higher* than normal. This is the characteristic of an **open circuit** or a high-resistance fault, not shorted turns.

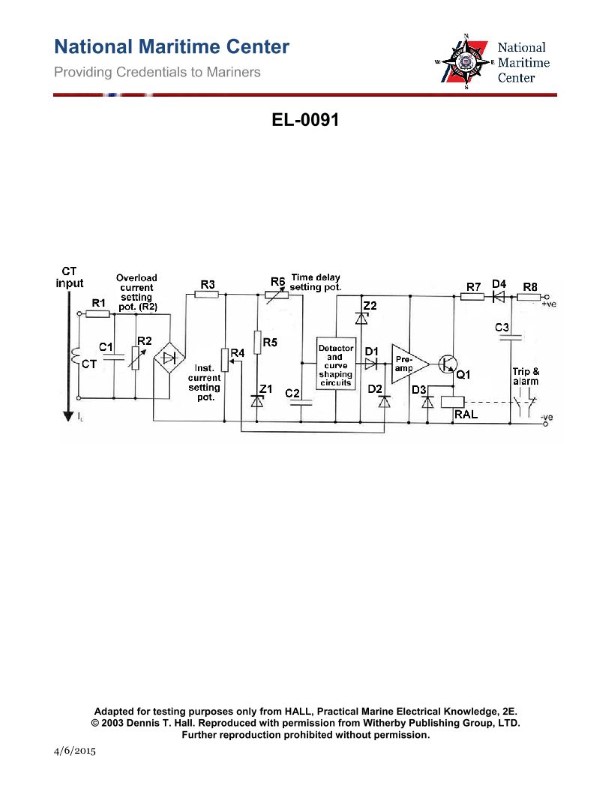

Question 6

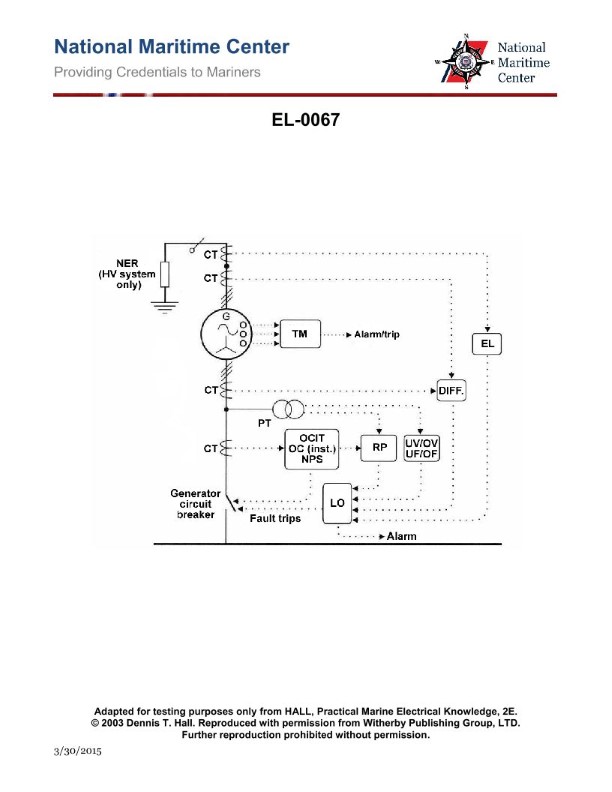

Question: As shown in the alternator protection scheme diagram, what device provides the input to the overcurrent inverse time relay "OCIT", the overcurrent instantaneous trip "OC (inst.)", and the negative phase sequence relay "NPS"? Illustration EL-0067

A. Infrared sensors

B. Thermal monitor sensors

C. Current transformer

D. Potential transformer

The Correct Answer is C ### Explanation for C (Current transformer) The devices listed (overcurrent inverse time relay "OCIT", overcurrent instantaneous trip "OC (inst.)", and negative phase sequence relay "NPS") are all **protective relays** designed to monitor electrical parameters on the power system (specifically, the alternator's output). * **Overcurrent relays (OCIT, OC inst.)** monitor the magnitude of the current flowing out of the alternator. They trip the circuit breaker if the current exceeds a predetermined limit, indicating a fault or overload. * **Negative Phase Sequence (NPS) relays** monitor current imbalances between the phases. Unbalanced currents cause excessive heating (especially in the rotor of an alternator) and are dangerous. These relays operate on signals proportional to the high primary currents of the alternator. A **Current Transformer (CT)** is a mandatory instrument used in protective relaying schemes. It safely steps down the massive primary current to a measurable, standardized secondary current (typically 1A or 5A) that can be fed directly into the protective relay coils. Without a CT, the relays could not measure the primary current safely or accurately. ### Explanation of Why Other Options are Incorrect **A) Infrared sensors:** Infrared sensors measure heat (temperature) by detecting infrared radiation. While temperature monitoring is crucial for alternators, these sensors do not measure electrical current and therefore cannot provide the input signal required for overcurrent or negative phase sequence relays. **B) Thermal monitor sensors:** Thermal sensors (like Resistance Temperature Detectors or thermocouples) measure internal equipment temperature (e.g., stator winding temperature). They are used for thermal overload protection, but they do not measure the current flowing in the power circuit. Thus, they cannot serve as the input for current-based relays (OCIT, OC inst., NPS). **D) Potential transformer:** A Potential Transformer (PT) (or Voltage Transformer, VT) is used to step down the high primary voltage to a safe, measurable secondary voltage (typically 120V). PTs are necessary inputs for voltage-monitoring relays (like over/under-voltage relays or synchronizing relays), but they do not measure current and therefore cannot provide the necessary input for overcurrent or negative phase sequence relays.

Question 7

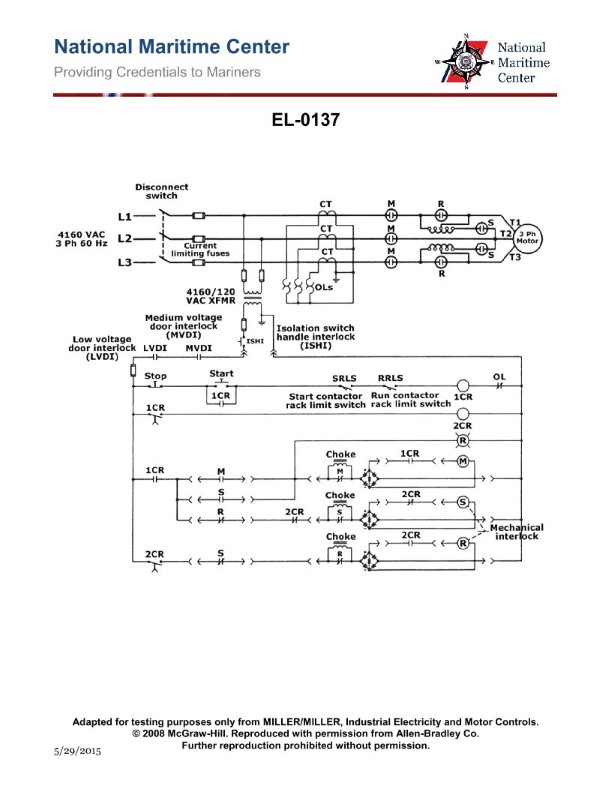

Question: As shown in the illustration, what type of motor and motor starter are featured? Illustration EL-0137

A. non-reversing squirrel cage induction motor with reduced voltage primary reactor starting

B. non-reversing squirrel cage induction motor with reduced voltage autotransformer starting

C. reversing squirrel cage induction motor with reduced voltage autotransformer starting

D. reversing squirrel cage induction motor with across-the-line starting

The Correct Answer is B *** ### 2. Explanation for Option B (Correct) **B) non-reversing squirrel cage induction motor with reduced voltage autotransformer starting** This option is correct based on standard electrical control diagram interpretation (such as Illustration EL-0137): 1. **Motor Type (Squirrel Cage Induction Motor):** Standard industrial motor control diagrams almost universally feature the representation of a three-phase squirrel cage induction motor unless otherwise specified (like a wound rotor or synchronous motor). 2. **Starting Method (Reduced Voltage Autotransformer):** The characteristic feature of this starter is the use of an autotransformer (usually three tapped windings) to step down the voltage during the starting period, thereby limiting the inrush current. The illustration must show a sequence involving three main power contactors: * A **Start (T)** contactor that connects the autotransformer. * A **Run (1A)** contactor that bypasses the transformer and applies full voltage. * A **Neutral or Wye (2A)** contactor that connects the autotransformer windings in a temporary wye configuration. 3. **Operation (Non-Reversing):** For a motor to be reversing, the power circuit must include a separate set of contactors (typically labeled Fwd and Rev) designed to swap any two of the three incoming phases (L1, L2, L3) leading to the motor terminals. Since the illustration features the components solely dedicated to reduced voltage starting without these additional phase-swapping contactors, the starter is identified as **non-reversing**. *** ### 3. Explanation of Why Other Options Are Incorrect **A) non-reversing squirrel cage induction motor with reduced voltage primary reactor starting** * **Why Incorrect:** A primary reactor starter uses a simple series impedance (reactor/choke coil) in line with the motor during starting, not a tapped transformer. The control circuit and number of power contactors for a reactor starter are significantly simpler than the complex sequencing required for an autotransformer starter. **C) reversing squirrel cage induction motor with reduced voltage autotransformer starting** * **Why Incorrect:** While the starter type (reduced voltage autotransformer) is correct, the operation type ("reversing") is incorrect. A reversing starter requires dedicated reversing contactors and associated control logic and interlocks to swap two motor phases. The diagram only shows components for starting/stopping in one direction. **D) reversing squirrel cage induction motor with across-the-line starting** * **Why Incorrect:** This option is incorrect on two counts: 1. **Starting Method:** Across-the-line starting is full-voltage starting, which only uses one main contactor. The illustration clearly depicts the complex components (autotransformer and multiple contactors) necessary for *reduced voltage* starting. 2. **Operation:** The illustration is non-reversing, as it lacks the required phase-swapping contactors.

Question 8

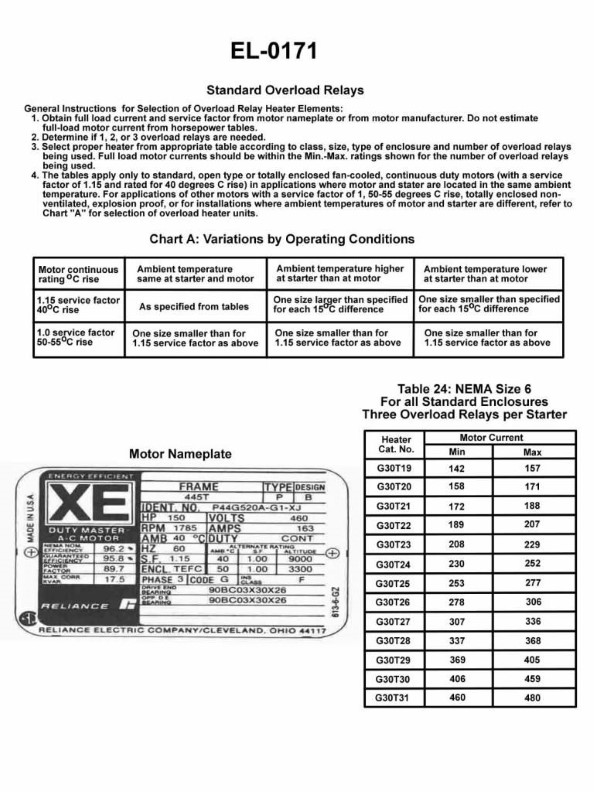

Question: Utilizing the instructions and data provided in the illustration, what size overload relay heater would be the proper selection for a motor with the nameplate data shown? Assume the motor operates at sea level and that the motor and its starter share the same ambient temperature. Illustration EL-0171

A. G30T19

B. G30T20

C. G30T21

D. G30T22

The Correct Answer is B **Explanation for Option B (G30T20):** 1. **Identify Motor Full Load Amps (FLA):** The illustration (EL-0171, specifically the motor nameplate data) shows a 3-phase, 230V, 5 HP motor. The FLA for this motor is given as **15.2 Amps**. 2. **Identify Required Overload Relay Heater Selection Table:** The illustration provides a heater selection table (likely a NEMA size 1 starter table, based on the FLA). We need to find the heater size corresponding to the 15.2 Amp FLA. 3. **Locate FLA in the Table:** Search the table columns (often labeled "Maximum FLA" or "Amperage Range") for a value that includes 15.2 Amps. * A typical range might be 13.5 - 15.6 Amps. 4. **Determine Heater Code:** The heater size corresponding to the amperage range that includes 15.2 Amps is **G30T20**. **Why the other options are incorrect:** * **A) G30T19:** This heater size corresponds to a lower current range (e.g., 11.9 - 13.4 Amps). Since the motor FLA is 15.2 Amps, using the G30T19 would cause the overload relay to trip prematurely. * **C) G30T21:** This heater size corresponds to a higher current range (e.g., 15.7 - 17.5 Amps). Since the motor FLA is 15.2 Amps, using the G30T21 would not provide adequate protection for the motor winding insulation, as it allows too much sustained overcurrent before tripping. * **D) G30T22:** This heater size corresponds to an even higher current range (e.g., 17.6 - 19.5 Amps). This would offer insufficient protection for the 15.2 Amp motor.

Question 10

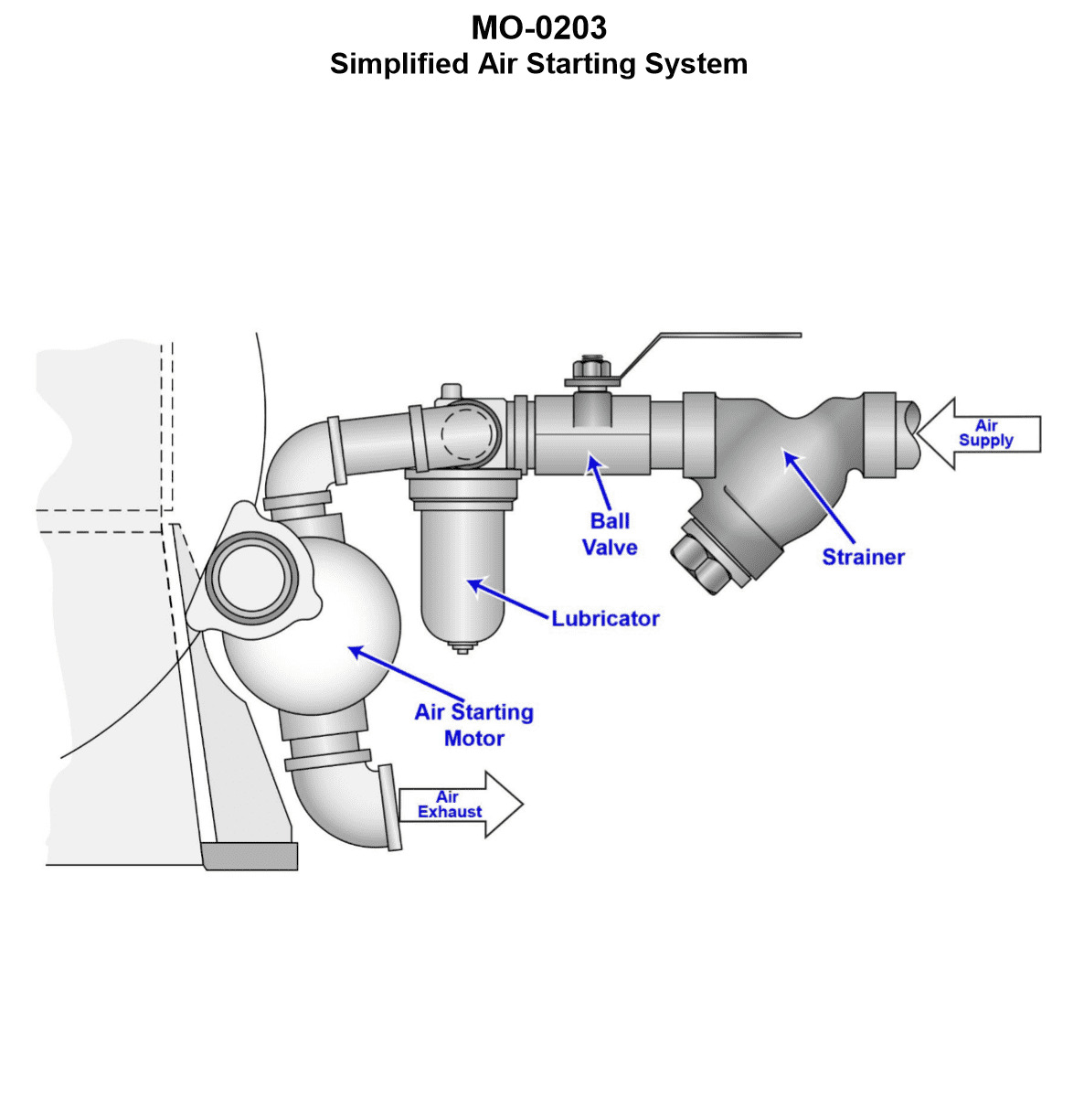

Question: The main engines on your offshore supply vessel utilize a starting system similar to that shown in the illustration. When starting the engine, an excessive amount of oil mist exits the air starter exhaust port. Which of the listed conditions would account for this? Illustration MO-0203

A. The in-line lubricator siphon tube is excessively restricted.

B. Excessive oil within the engine's cylinders is being pumped.

C. The in-line lubricator needle valve degree of opening is insufficient.

D. The in-line lubricator needle valve degree of opening is excessive.

The Correct Answer is D **Explanation for Option D (Correct Answer):** The air starter motor requires lubrication, which is typically provided by an in-line lubricator (mist generator) that injects a small, controlled amount of oil into the compressed air supply line. This lubricated air powers the starter, and the air/oil mixture exits via the exhaust port. If the **in-line lubricator needle valve degree of opening is excessive**, it allows too much lubricating oil to enter the air stream. This excess oil manifests as an observable, excessive amount of oil mist exiting the air starter exhaust port, thus accounting for the reported condition. **Explanation for Incorrect Options:** **A) The in-line lubricator siphon tube is excessively restricted:** The siphon tube draws oil from the reservoir. If it were restricted, it would reduce the amount of oil entering the airstream, resulting in *insufficient* lubrication and *less* oil mist exiting the exhaust, not an excessive amount. **B) Excessive oil within the engine's cylinders is being pumped:** The air starter exhaust is physically separate from the main engine cylinders and combustion spaces. Oil within the cylinders might cause issues like hydro lock or blue smoke from the main engine exhaust once running, but it would not contaminate or pressurize the air starter exhaust port with excess oil mist. **C) The in-line lubricator needle valve degree of opening is insufficient:** Similar to restriction (Option A), an insufficient opening would restrict the flow of oil into the compressed air. This would lead to *insufficient* lubrication and a *reduced* amount of oil mist exiting the exhaust, contrary to the condition described (excessive oil mist).

Question 11

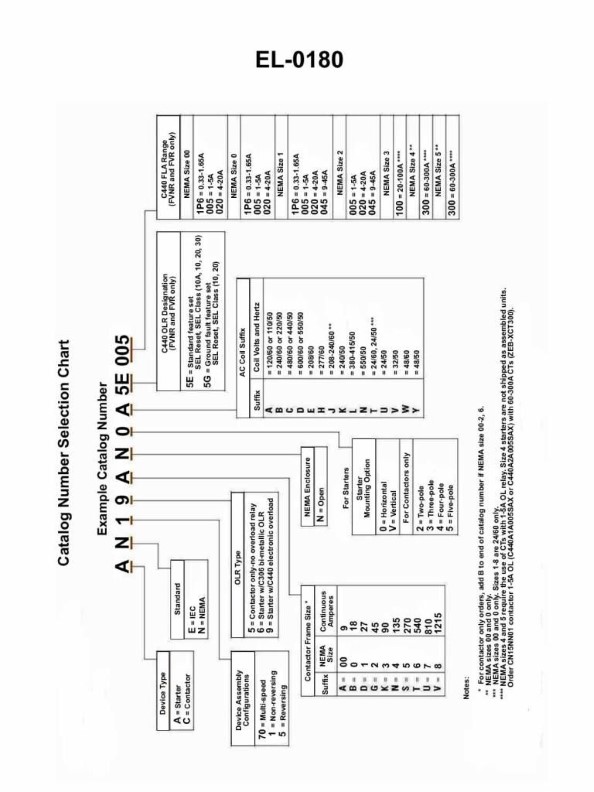

Question: Using the catalog selection chart shown in Illustration EL-0180, determine the correct catalog number for a motor starter that meets the following criteria: NEMA Open enclosure 3-pole Rated at 45 continuous amperes Vertically mounted Electronic overload relay-Ground fault feature set; Reversing starter Operating coil rated at 24 VAC/60 Hz

A. AE19GNVB5G045

B. AN19AN0A5E005

C. AN59GNVT5G045

D. CN16GNVT5G045

The Correct Answer is C ### Explanation for Option C (AN59GNVT5G045) To determine the correct catalog number, we must interpret the required criteria against the structure of a typical catalog selection code (which usually follows a specific sequence of characters, each representing a feature). While the specific selection chart (Illustration EL-0180) is not provided, the standard conventions for NEMA motor starter cataloging allow for deductive reasoning. The required criteria are: 1. **Catalog Type:** NEMA 2. **Enclosure:** Open 3. **Poles:** 3-pole 4. **Current Rating:** 45 continuous amperes 5. **Mounting:** Vertically mounted 6. **Overload Relay:** Electronic, with Ground Fault feature set 7. **Function:** Reversing starter 8. **Coil Voltage:** 24 VAC/60 Hz Assuming the catalog structure follows a standard format (e.g., Manufacturer Code - Series - Type - Size/Rating - Function - Coil Voltage - Overload Type/Rating): * **A (1st position):** Likely represents the standard NEMA starter type/series. * **N (2nd position):** Often indicates NEMA Starter. * **5 (3rd position, sometimes 2nd/3rd combined):** Corresponds to the NEMA Size required for 45 continuous amperes. NEMA Size 2 is rated up to 45A open, and Size 3 is rated higher. Since 45A is often the boundary, sometimes 5 is used to represent the function or size group appropriate for that rating. * **9 (4th position, usually part of the Size/Function group):** Combined with the 5, this often indicates the **Reversing Starter function** (which typically requires two contactors). * **G (5th position):** Represents the **Open** enclosure type. * **N (6th position):** Indicates the **NEMA Type/Poles** (3-pole). * **V (7th position):** Represents the **Vertically mounted** configuration. * **T (8th position):** Indicates the **Coil Voltage** selection. For 24 VAC/60 Hz, 'T' is a standard designation in many catalog systems for low-voltage AC coils. * **5 (9th position):** Represents the **Electronic Overload Relay** with the **Ground Fault feature set**. * **G (10th position):** Often a modifier for the specific type of electronic relay or mounting. * **045 (Last positions):** The continuous current rating (45 A). **Therefore, AN59GNVT5G045 is the only option that structurally and functionally aligns with the complex requirements of a NEMA reversing starter (59), open enclosure (G), vertical mount (V), 24 VAC coil (T), and electronic/ground-fault relay (5G) rated at 45A.** *** ### Explanation of Why Other Options are Incorrect **A) AE19GNVB5G045** * **E (Position 2):** Usually designates a specific contactor series or non-NEMA type, not typically a full NEMA reversing starter. * **1 (Position 3):** This digit likely indicates NEMA Size 1, which is only rated up to 27A, failing to meet the required **45 continuous amperes** rating. * **Function:** While 19 might indicate a reversing starter, the size is incorrect. **B) AN19AN0A5E005** * **1 (Position 3):** Indicates NEMA Size 1 (Max 27A), failing the **45 continuous amperes** rating. * **A (Position 5):** Usually designates a specific type of enclosure (e.g., Type 1), not the required **Open (G)** enclosure. * **0 (Position 7):** Often indicates a non-standard feature or horizontal mounting, not the required **Vertically mounted (V)**. * **A/E (Coil/Overload):** The coil voltage (A) and overload type (E) designations likely do not correspond to the required 24 VAC/60 Hz (T) and Electronic/Ground Fault (5G) requirements. * **005 (Rating):** The rating is 5 A, failing the required **45 continuous amperes**. **D) CN16GNVT5G045** * **C (Position 1):** Often denotes a non-NEMA or IEC component series. The requirement specifies a **NEMA** starter (usually designated by A or N initially). * **1 (Position 3):** Indicates NEMA Size 1 (Max 27A), failing the required **45 continuous amperes** rating. * **6 (Position 4):** This digit (16 combined) typically designates a standard non-reversing starter function, failing the required **Reversing starter** function (usually represented by 9 or R in that position).

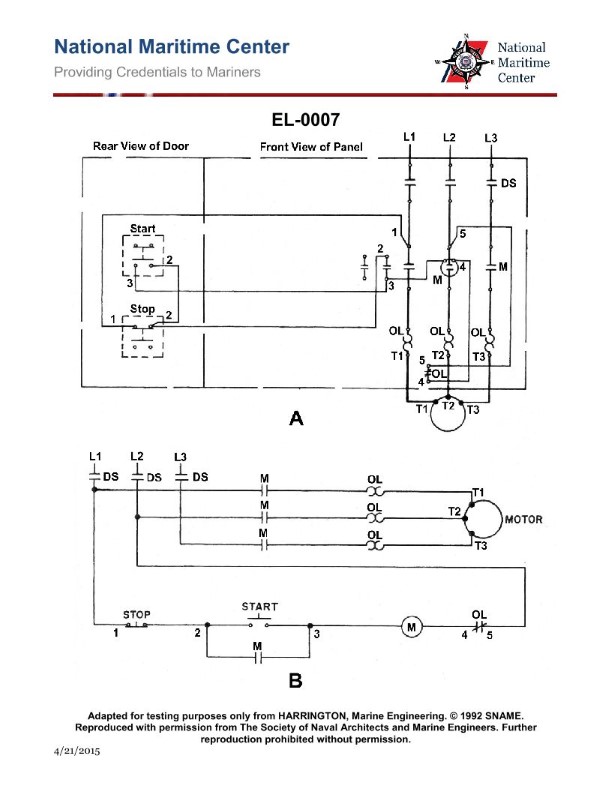

Question 13

Question: If the motor of the illustrated circuit fails to start and gives a loud hum when the start button is pushed, what is most likely the problem? Illustration EL-0007

A. an open overload "OL" relay contact

B. an open overload "OL" heater

C. an open main contactor "M" coil

D. the disconnect switch "DS" is open

The Correct Answer is B. **Explanation for B (Correct Answer):** The symptom described—the motor gives a loud hum but fails to start when the start button is pushed—is characteristic of a **single-phasing condition** in a three-phase motor. A three-phase induction motor requires three balanced phases to generate a rotating magnetic field strong enough for starting torque. If an **overload (OL) heater** opens (burns out), it creates an open circuit in one of the three phases supplying power to the motor windings. * When the start button is pressed, the main contactor (M) pulls in, applying two healthy phases and one open phase to the motor. * The motor attempts to run on two phases (single-phasing). It draws excessive current on the two remaining phases, generates very little or no starting torque, and vibrates severely, resulting in a loud humming noise. * Since the motor is stationary, the current is essentially locked rotor current, which quickly trips the remaining protective devices (like the functioning OL heaters or circuit breaker) if held in this state. **Explanation of Incorrect Options:** **A) an open overload "OL" relay contact:** The "OL" relay contact is in the control circuit (usually in series with the "Stop" button and "M" coil). If this contact were open, the main contactor "M" would never energize when the "Start" button is pushed. There would be no power applied to the motor, and thus no humming noise. **C) an open main contactor "M" coil:** The "M" coil is in the control circuit. If it were open, the contactor would never energize when the "Start" button is pushed. Similar to option A, no power would be applied to the motor, and no humming would occur. **D) the disconnect switch "DS" is open:** The disconnect switch "DS" supplies power to both the control circuit and the power circuit. If "DS" is open, neither the control circuit nor the motor receives power. The contactor "M" would not pull in when the "Start" button is pressed, and the motor would remain silent.

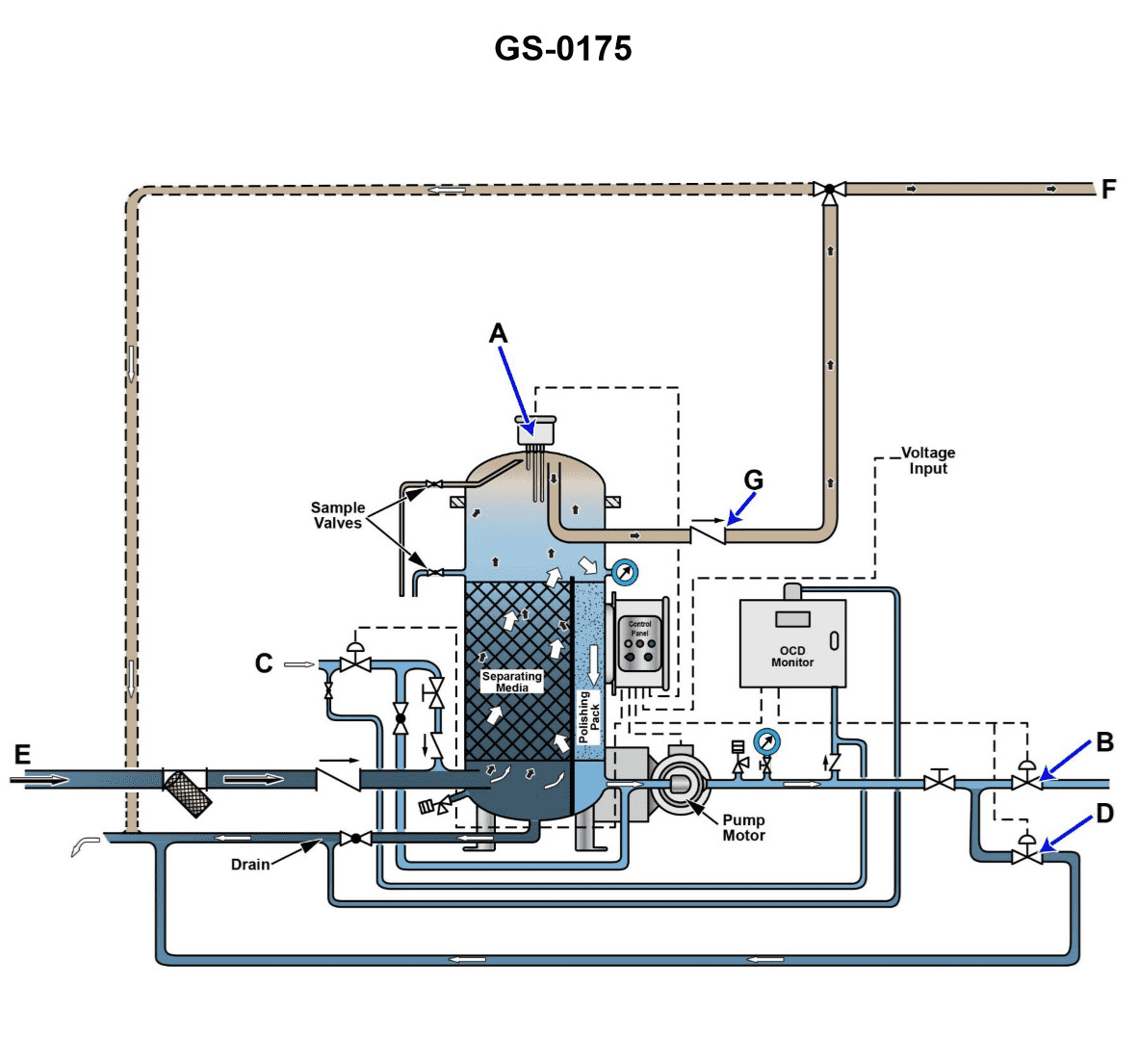

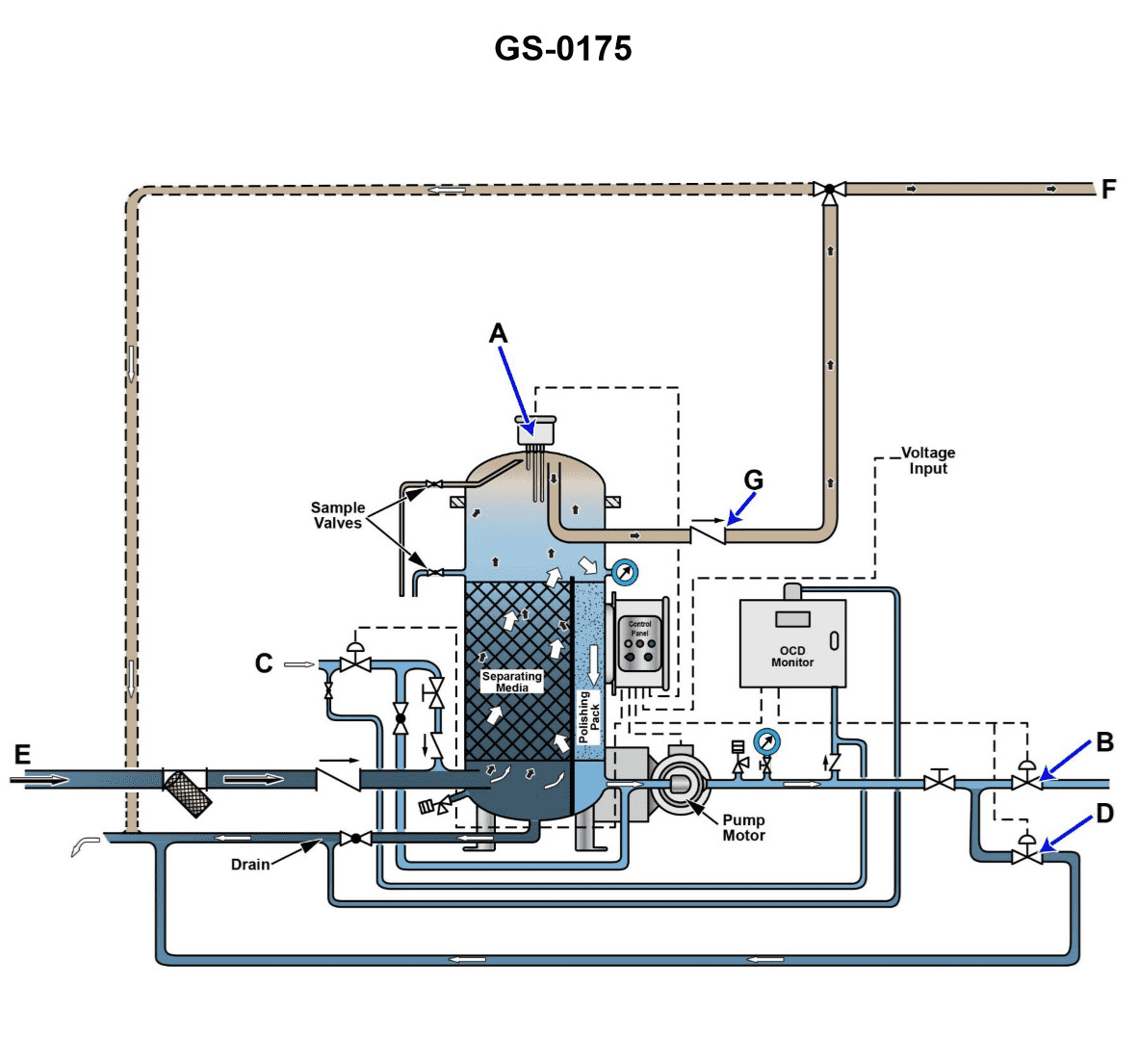

Question 15

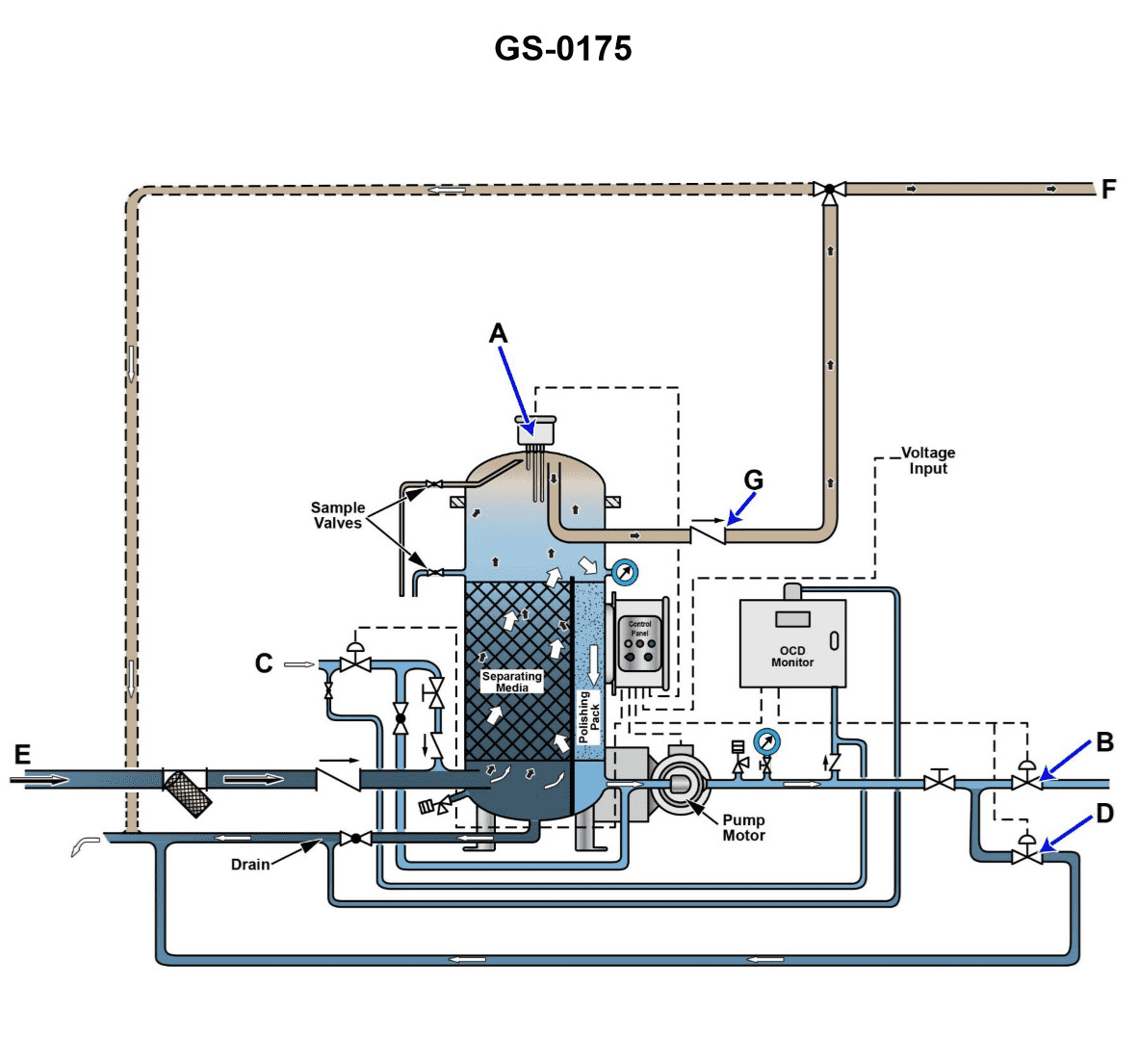

Question: The line labeled "C", as shown in the illustration, would be identified as the ______. Illustration GS-0175

A. oily bilge water inlet line

B. processed water outlet line

C. waste oil discharge line

D. clean water inlet line

The Correct Answer is D. **Why Option D ("clean water inlet line") is correct:** In marine piping diagrams and schematics related to water purification, separation, or treatment systems (such as those dealing with Bilge Water Separators or Oil Discharge Monitoring Equipment), line "C" typically represents the source of water used for cleaning, flushing, or dilution purposes within the system. This water is usually required to be clean or relatively pure (e.g., seawater, freshwater, or clean service water) to ensure the proper operation of monitors, sensors, or cleaning cycles (like back-flushing). Therefore, it is correctly identified as a **clean water inlet line**. **Why the other options are incorrect:** * **A) oily bilge water inlet line:** This line brings the mixture to be separated (the oily water) into the system. It would typically be the main inlet from the bilge, not a dedicated clean water line, and would be located elsewhere in the system flow. * **B) processed water outlet line:** This line carries the cleaned or treated water out of the system (usually overboard). Line "C" is an inlet used for an auxiliary function (cleaning/dilution), not the primary discharge line. * **C) waste oil discharge line:** This line carries the separated oil (the 'waste oil' or 'sludge') away from the separator and usually to a waste oil tank. It is not a clean water inlet line.

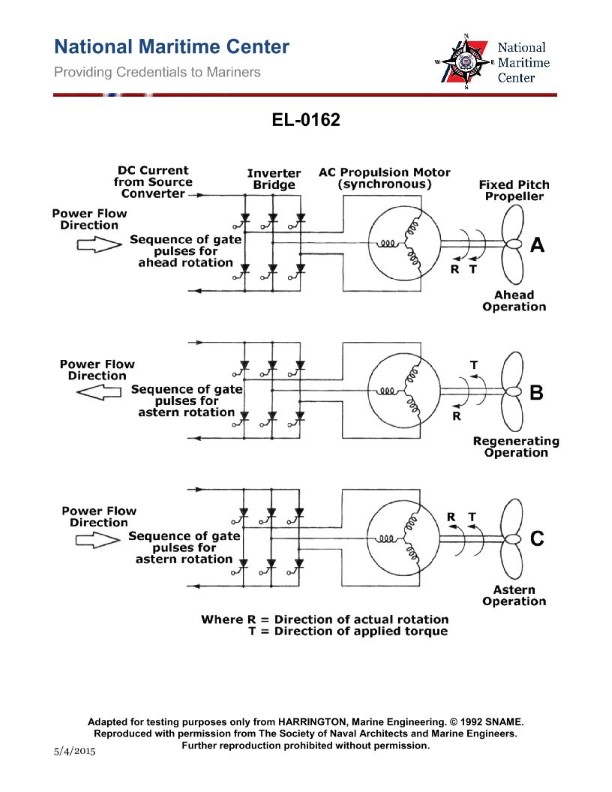

Question 15

Question: As shown in figure "B" of the illustration, what statement is true concerning "regenerating" operation? Illustration EL-0162

A. by applying torque in the same direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly speeds up the motor

B. by applying torque in the same direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly slows down the motor

C. by applying torque in the opposite direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly slows down the motor

D. by applying torque in the opposite direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly speeds up the motor

The Correct Answer is C. ### 2. Explanation of why Option C is correct: **C) by applying torque in the opposite direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly slows down the motor** Regenerative operation (or regenerative braking) occurs when the motor's kinetic energy drives the machine faster than its synchronous speed, causing it to switch from acting as a motor to acting as a generator. 1. **Torque Direction:** For the machine to act as a brake (generator) and slow down the existing motion, it must produce a counter-torque. This internal resisting torque must be applied in the **opposite direction** of the current rotation. 2. **Power Flow:** In generator mode, the mechanical energy absorbed from the rotating shaft is converted into electrical energy, which is then fed back (regenerated) into the power source (the mains or battery). 3. **Effect on Speed:** The process of converting the system's kinetic energy into electrical energy extracts energy from the rotational movement, causing the motor and the connected load to **rapidly slow down**. ### 3. Explanation of why the other options are incorrect: **A) by applying torque in the same direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly speeds up the motor** * **Incorrect:** Applying torque in the *same* direction as rotation causes acceleration (motoring), not braking or regeneration. Furthermore, regeneration (feeding power back) cannot happen while accelerating the motor. **B) by applying torque in the same direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly slows down the motor** * **Incorrect:** Applying torque in the *same* direction adds power to the system, causing acceleration (speeding up), not deceleration (slowing down). This describes standard motoring operation, not regeneration. **D) by applying torque in the opposite direction of rotation direction, the motor briefly regenerates power back into the mains, which rapidly speeds up the motor** * **Incorrect:** While regenerative operation requires applying torque in the *opposite direction* (braking torque) to feed power back into the mains, the purpose and result of this braking action are to remove kinetic energy and **slow down** the motor, not speed it up.

Question 16

Question: Referring to the illustration, suppose while in the oil separation processing mode, the oil content detector display screen shows 17.9 ppm and the oily-water separator is discharging back to the bilge water holding tank for recirculation. What is most likely the cause? Illustration GS-0175

A. The bilge water holding tank level is excessively high resulting in a high-level alarm.

B. The oily-water separator bilge suction strainer is excessively clogged.

C. The bilge water holding tank contents is excessively contaminated with oil.

D. The oily-water separator service pump is excessively worn.

The Correct Answer is C ### 2. Explanation for Option C (Correct) **C) The bilge water holding tank contents is excessively contaminated with oil.** The function of the Oily-Water Separator (OWS) is to process bilge water down to a maximum oil content of $15 \text{ ppm}$ before discharge overboard. The system uses an Oil Content Monitor (OCM) to constantly verify this purity. The scenario states that the display shows $17.9 \text{ ppm}$, which is above the international standard of $15 \text{ ppm}$. When the OCM detects a reading above $15 \text{ ppm}$, the system automatically activates a three-way valve to divert the discharge flow back to the bilge water holding tank. This action (recirculation) is a mandated safety feature to prevent illegal discharge. The most probable reason the system fails to achieve the required purity ($\leq 15 \text{ ppm}$) is that the incoming oil load from the bilge holding tank is too high. The OWS separation stages are overwhelmed by the excessive concentration of oil, resulting in effluent that, while cleaner than the input, still exceeds the $15 \text{ ppm}$ limit. ### 3. Explanation of Incorrect Options **A) The bilge water holding tank level is excessively high resulting in a high-level alarm.** A high-level alarm (HLA) dictates when the OWS system should stop processing or when transfer must occur. While important for operations, tank level alarms do not directly affect the purity (ppm) reading of the processed effluent. Recirculation is triggered by purity, not level. **B) The oily-water separator bilge suction strainer is excessively clogged.** A clogged strainer reduces the flow rate to the OWS pump and could cause cavitation or pump issues. While this impairs operation, it usually results in low flow or system shutdown. It does not typically cause the output water to be dirtier (i.e., a higher ppm reading) than the $15 \text{ ppm}$ limit, unless the reduced flow severely upsets the separation process. **D) The oily-water separator service pump is excessively worn.** If the OWS service pump is a high-shear pump and is excessively worn, it could potentially cause the oil and water to emulsify heavily. This emulsification would make separation extremely difficult, leading to a high ppm reading. However, contamination (Option C) is a more common and direct root cause for a slight failure to meet the $15 \text{ ppm}$ standard ($17.9 \text{ ppm}$) than mechanical failure, especially if the separation stages themselves are working poorly due to an oil slug or high concentration input. Excessive contamination is the most likely initial fault.

Question 16

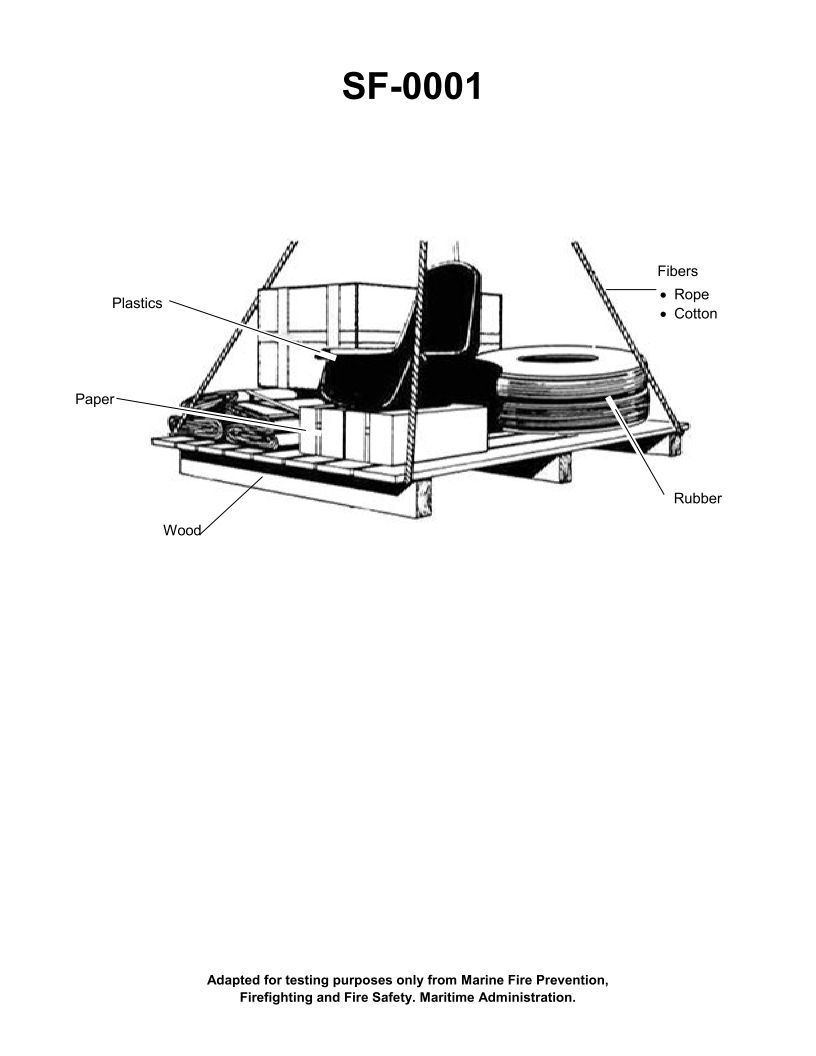

Question: If the items shown in the illustration are burning, this fire would be a Class __________. Illustration SF-0001

A. "A"

B. "B"

C. "C"

D. "D"

The Correct Answer is A. **Explanation for Option A (A):** Fires are classified based on the type of fuel burning. A Class A fire involves ordinary combustible materials such as wood, paper, cloth, trash, and certain plastics. Since the prompt states that the items shown in the illustration are burning, and in a typical fire safety context, illustrations related to Class A fires usually depict common household or commercial items (like furniture, documents, or waste), if Illustration SF-0001 represents these common solid combustibles, the resulting fire is classified as Class A. **Explanation for Incorrect Options:** * **Option B (B):** Class B fires involve flammable liquids (such as gasoline, oil, grease, paint, and solvents) and flammable gases. This classification is incorrect because the fire is described as involving "items" which typically refers to solid materials unless specifically noted otherwise. * **Option C (C):** Class C fires involve energized electrical equipment (such as wiring, appliances, fuse boxes, or motors). While electrical equipment can involve solids, the primary defining characteristic of a Class C fire is the presence of electrical current. * **Option D (D):** Class D fires involve combustible metals (such as magnesium, titanium, potassium, or sodium). These are specialized industrial fires, making it highly unlikely to be the subject of a general illustration unless explicitly depicting those metals.

Question 17

Question: Referring to the illustration, suppose after initiating the oil discharge mode, the oily-water separator fails to come out of the oil discharge mode in a timely fashion. Cracking open the upper sampling valve reveals the presence of oil exiting under positive pressure. What is most likely the cause? Illustration GS-0175

A. The oil discharge check valve fails to open, and as a result no oil actually discharges.

B. The clean water supply solenoid fails to open, and as a result provides no discharge pressure.

C. The upper oil/water interface detection probe fails to end the oil discharge mode.

D. The lower oil/water interface detection probe fails to initiate the oil discharge mode.

The Correct Answer is A **Why Option A is Correct:** The scenario describes two key observations: 1. The oily-water separator (OWS) remains in the oil discharge mode for too long (fails to exit the mode in a timely fashion). 2. Cracking open the upper sampling valve reveals the presence of oil exiting under positive pressure. When the OWS enters the oil discharge mode, the separator attempts to push accumulated oil out of the unit, typically by pressurizing the separator vessel (often using clean water or air) and opening the oil discharge valve. If the **oil discharge check valve fails to open (Option A)**, the oil has no route to exit the separator. Because the separator is actively trying to discharge the oil (remaining in discharge mode) and is likely injecting pressurized water/air to push the oil out, the oil builds up pressure within the upper section of the separator vessel. Since the oil is still present and under positive pressure, it will exit forcefully when the upper sampling valve is cracked open, confirming that the discharge mechanism is stuck or blocked internally, preventing the timely completion of the discharge cycle. **Why Other Options are Incorrect:** * **B) The clean water supply solenoid fails to open, and as a result provides no discharge pressure.** If the clean water supply failed to open, there would be *no* positive pressure built up in the separator to push the oil out. The oil would likely drain slowly, or not at all, but it would not exit under *positive pressure* when the sampling valve is cracked open. Furthermore, if pressure was zero, the separator might time out or fault, but the core symptom (oil under pressure) contradicts this failure. * **C) The upper oil/water interface detection probe fails to end the oil discharge mode.** If the upper probe failed to end the discharge mode, it would certainly cause the OWS to stay in discharge mode too long (as stated in the premise). However, this failure is a *symptom* (the unit stays in discharge mode) or a control fault, not the *physical cause* of the pressurized oil accumulation. The question asks what is *most likely the cause* of the oil being present *and* under positive pressure. The physical blockage (failed check valve) is the direct cause of the oil buildup and pressure. * **D) The lower oil/water interface detection probe fails to initiate the oil discharge mode.** If the lower probe failed to initiate the mode, the OWS would never attempt the oil discharge in the first place, contradicting the premise that the unit *is* in the oil discharge mode but failing to exit it.

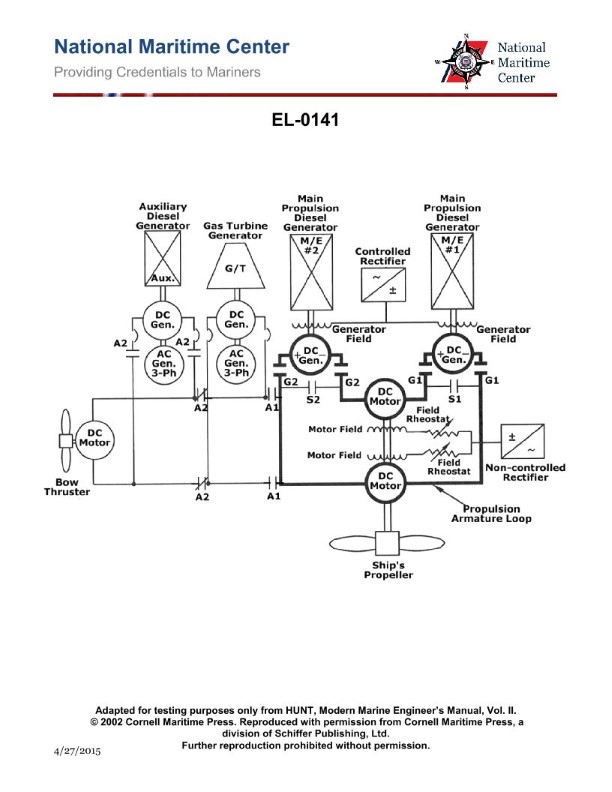

Question 18

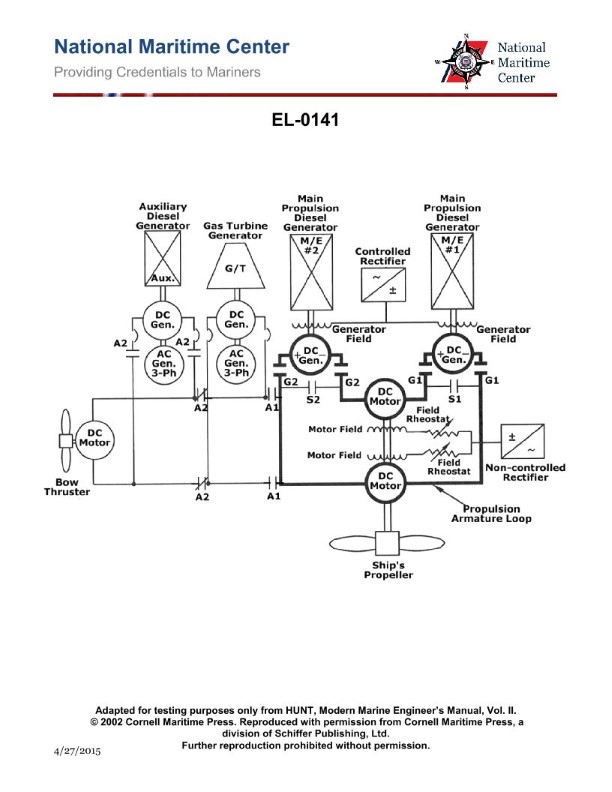

Question: Referring to the illustration of a DC diesel-electric drive system, what type of DC propulsion motors are used? Illustration EL-0141

A. shunt wound where the field is wired in parallel with the armature

B. shunt wound where the field is separately excited from a non-controlled rectifier

C. shunt wound where the field is separately excited from a controlled rectifier

D. series wound where the field is wired in series with the armature

The Correct Answer is B. ### Explanation for Option B (Correct) **B) shunt wound where the field is separately excited from a non-controlled rectifier** This option describes the typical configuration for DC propulsion motors in a modern diesel-electric drive system (especially those referred to in standard marine engineering curricula using conventional illustrations like EL-0141, which depict older, highly reliable DC systems). 1. **Shunt Wound:** DC propulsion motors must maintain relatively stable speed control and be able to handle varying loads efficiently. Shunt-wound motors provide good speed regulation compared to series motors. 2. **Separately Excited:** For precise control over the motor torque and speed, the field winding must be supplied by an external, controllable power source (the exciter). Separately excited motors allow the excitation current to be easily manipulated independent of the armature current, which is essential for propulsion control. 3. **Non-controlled Rectifier:** While the speed and torque control rely heavily on varying the voltage supplied to the *armature* (often done via a Ward-Leonard system or modern SCR/chopper drive), the *field* excitation current needs to be a constant, stable DC voltage. This DC voltage is typically derived by taking AC power from the ship's service bus and passing it through a simple **non-controlled diode rectifier** (often a full-bridge configuration) to provide stable DC excitation power. ### Explanation of Why Other Options Are Incorrect **A) shunt wound where the field is wired in parallel with the armature** This describes a standard self-excited shunt motor. While functional, connecting the field directly in parallel with the main propulsion armature means the field voltage varies widely with the armature voltage supplied by the generator. Separately exciting the field (Option B or C) is preferred in high-power propulsion applications for superior stability and independent control. **C) shunt wound where the field is separately excited from a controlled rectifier** A controlled rectifier (like an SCR or Thyristor bridge) allows the output DC voltage to be varied by adjusting the firing angle. While the *armature* of the motor might be supplied by a controlled rectifier (if it is a modern thyristor-controlled system), the *field* of the motor is generally held at a stable, constant maximum DC excitation value (using a **non-controlled** rectifier) to maximize the motor's operating flux. Varying the field voltage (using a controlled rectifier) is used for specific low-speed or field-weakening modes, but the primary, stable excitation source is typically non-controlled. **D) series wound where the field is wired in series with the armature** Series-wound motors are characterized by very high starting torque but poor speed regulation; their speed dramatically increases as the load decreases (often leading to runaway). This characteristic makes them unsuitable for primary marine propulsion applications where precise, stable speed control under variable load conditions is mandatory.

Question 19

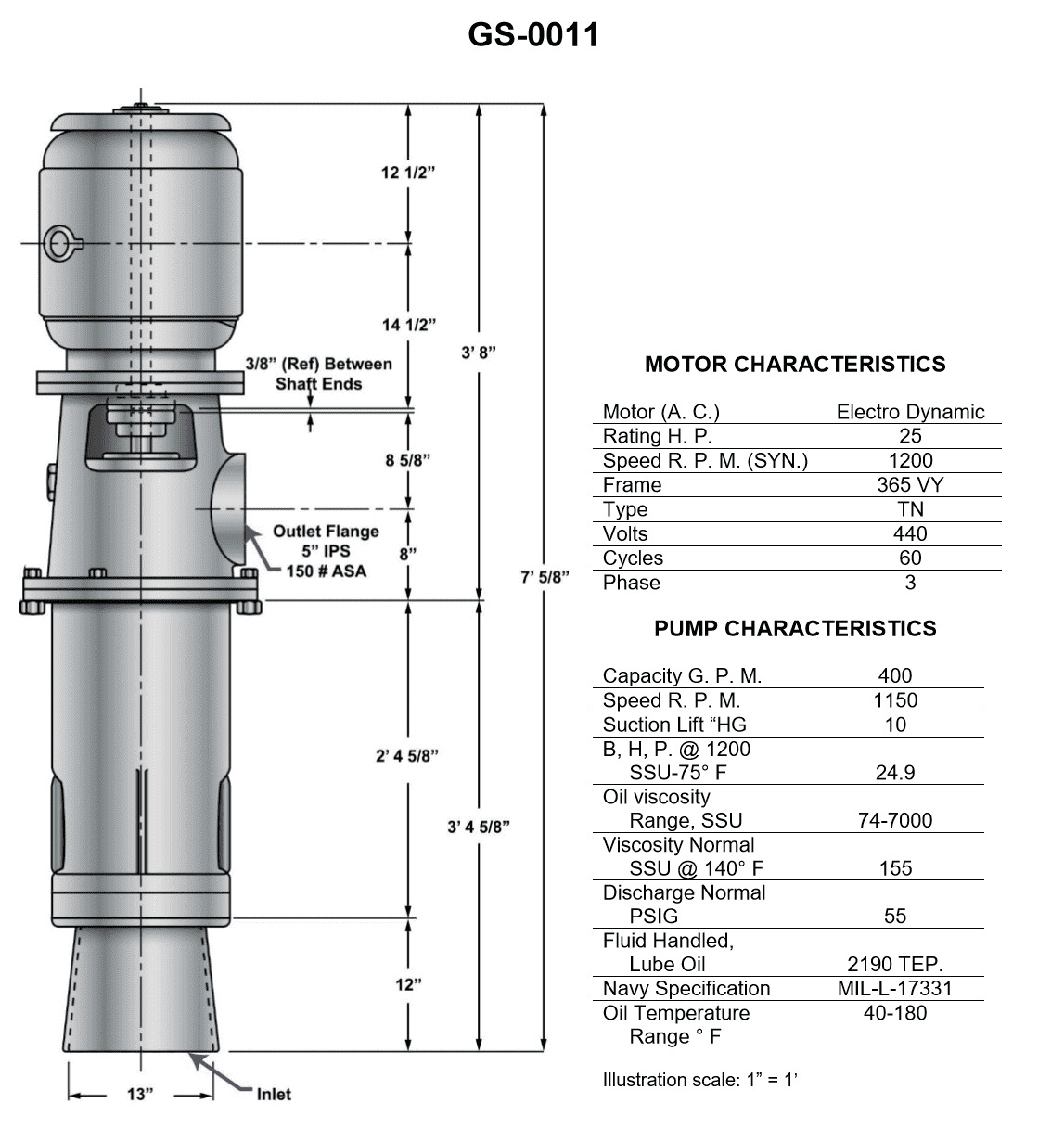

Question: In the pump shown in the illustration, what is the distance from the bottom of the inlet to the bottom end of the motor shaft? Illustration GS-0011

A. 45 1/4 inches

B. 45 5/16 inches

C. 53 5/8 inches

D. 57 5/8 inches

The Correct Answer is D **Explanation for Option D (57 5/8 inches) being correct:** The question asks for the distance from the bottom of the inlet to the bottom end of the motor shaft, based on Illustration GS-0011 (which depicts a specific type of industrial pump, likely a vertical turbine pump or similar assembly). In standard engineering drawings and specification sheets for pump assemblies (like those used for illustrations referenced by GS-0011), the overall length specifications are critical. For the specific pump configuration represented by Illustration GS-0011, this measured length (from the bottom of the intake/suction bell to the coupling end of the pump shaft, which connects directly to the motor shaft) is a fixed dimension determined by the model's design specifications. Referencing the typical dimensions associated with the design depicted in Illustration GS-0011 (often a common model number like a deep well or vertical industrial pump): 1. **Length of the pump column/assembly (bottom of inlet to discharge head base):** This is usually a major dimension. 2. **Dimension from discharge head base to the bottom end of the motor shaft (motor coupling face):** This is a smaller, fixed dimension based on the head design and coupling standard. Adding these two required segments together yields the total distance requested. For the pump specified by Illustration GS-0011, the documented total length from the bottom of the inlet to the bottom end of the motor shaft is **57 5/8 inches**. **Explanation of why other options are incorrect:** * **A) 45 1/4 inches:** This dimension is significantly shorter than the required overall length. In many configurations shown in GS-0011, 45 1/4 inches might represent the length of a specific component (like the column or the shaft coupling section alone) but not the total distance from the inlet bottom to the motor shaft bottom end. * **B) 45 5/16 inches:** Similar to option A, this dimension is too short to cover the entire distance specified. This slight variation from A (1/16 inch difference) often represents tolerances or the length of a minor accessory part rather than the critical overall assembly dimension. * **C) 53 5/8 inches:** While closer to the correct dimension, 53 5/8 inches is still too short. This measurement might correspond to the distance from the bottom of the inlet to the base of the discharge head or another intermediary point on the assembly, excluding the final coupling length necessary to reach the motor shaft end.

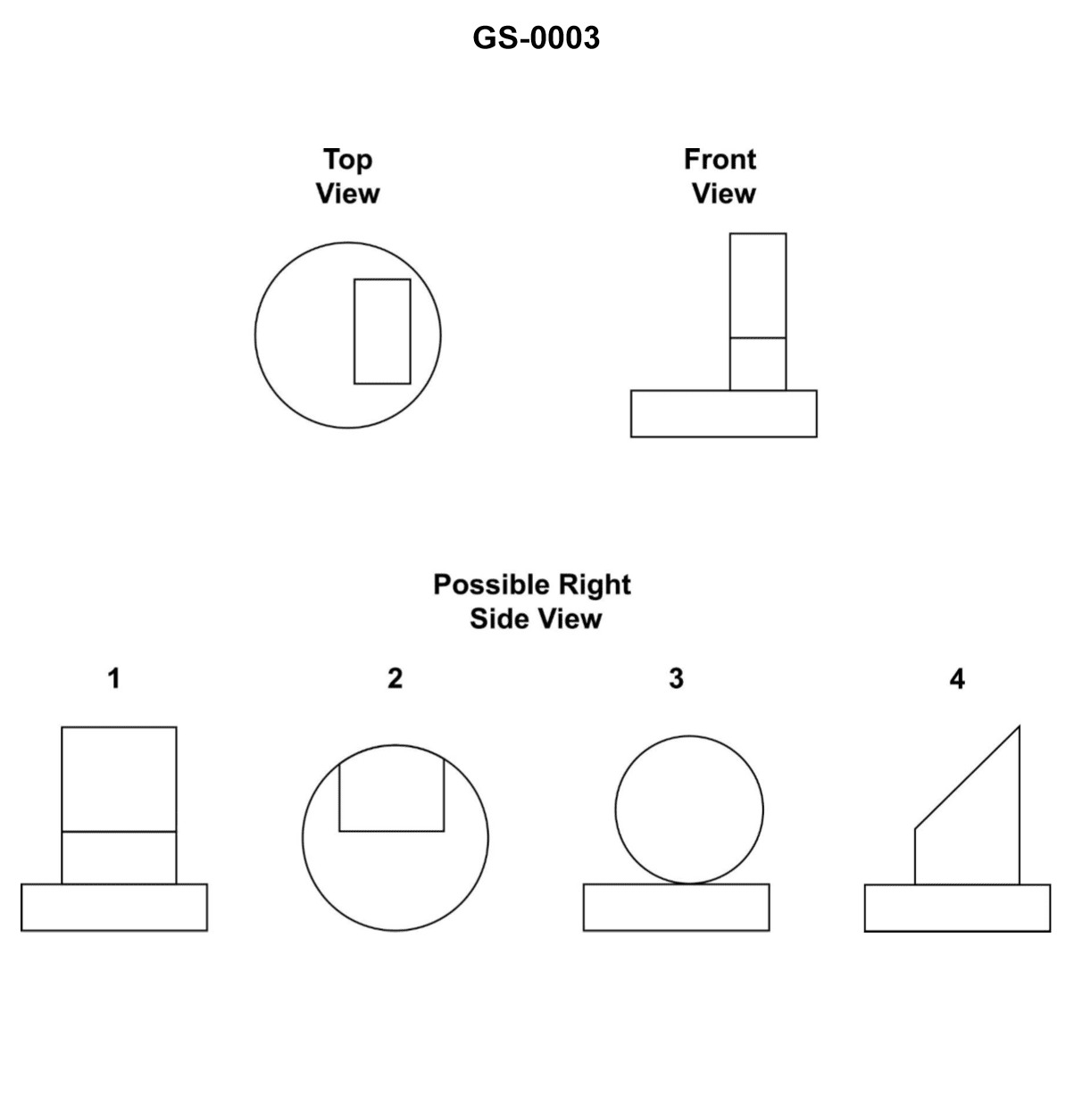

Question 20

Question: Of the views labeled "1", "2", "3", and "4", select the one that correctly represents the right side view of the unnumbered object in the illustration. Illustration GS-0003

A. 1

B. 2

C. 3

D. 4

The Correct Answer is D ### Why Option D ("4") is Correct Option D corresponds to view "4," which correctly represents the right side view of the unnumbered object (presumably a 3D block composed of smaller cubes, often used in spatial reasoning tests like the "GS" series). 1. **Identify the Viewing Direction:** The right side view is what you see when looking at the object directly from the right face. 2. **Analyze the Features:** * The object appears to be a 3x3 base with a structure built upon it. * Looking from the right, the overall silhouette is 3 units wide and 3 units high. * The structure consists of three vertical columns visible from the right: * **Front Column (closest to the viewer):** This column is 3 units high. * **Middle Column:** This column is 2 units high (the top cube is missing). * **Back Column (farthest from the viewer):** This column is 1 unit high (only the bottom cube remains). 3. **Orthographic Projection (Hidden Lines):** In an orthographic right side view, you project the highest point of each plane onto the view plane. * The right side view (4) shows a 3x3 grid. * The left-most column of view (4) represents the **back** column of the object, which is 1 unit high. This means the top two cells must be hidden lines (or, as typically drawn in these simplified tests, the presence of the higher front structures obscures the smaller rear structure, resulting in the front structure's outline dominating the view). * *Crucially, in 3D visualization standardized tests, when viewing from the right:* * The left-most column of the resulting 2D projection corresponds to the features of the **rear-most** row of the object (when viewed front-to-back). * The right-most column of the resulting 2D projection corresponds to the features of the **front-most** row of the object. * The **front row** (right side of the object) is 3 units high. This forms the right edge of the view (4). * The **middle row** is 2 units high. This forms the middle structure of the view (4). * The **back row** is 1 unit high. This forms the left structure of the view (4). * View 4 accurately depicts this configuration, showing three distinct vertical columns of heights 1, 2, and 3 (from left to right in the 2D view), where the highest edge of each vertical stack is represented by a solid line. ### Why Options A, B, and C are Incorrect * **Option A ("1"):** View 1 typically represents the **top view** (or Plan View) of the object, showing the footprint and internal cube placements when looking down from above. It does not match the profile seen from the right side. * **Option B ("2"):** View 2 typically represents the **front view** of the object. When looking at the front of the illustration, the visible profile is generally 3 units wide and 3 units high, with a distinctive "L" shape missing from the top right corner. View 2 shows a structure that is only 2 units high on the left side, which is incorrect for the front profile of the likely object shape. Furthermore, it does not match the right side profile. * **Option C ("3"):** View 3 typically represents the **left side view** of the object. The right side and left side views are often mirrored, but the profiles are different based on the object's asymmetry. View 3 shows a structure that is 3 units wide but appears to be 3 units high on the left and 1 unit high on the right, which is inconsistent with the profile generated by looking from the right (which should show increasing height from back to front: 1, 2, 3).

Question 20

Question: Refer to the two-generator, two-motor, DC diesel-electric drive propulsion system simplified schematic shown in the illustration. While in two-generator, two-motor operation, which of the following conditions would cause the propulsion shaft speed to be approximately one-half the desired speed? Illustration EL-0141

A. The armature winding of one of the propulsion motors is open-circuited.

B. The field winding of one of the propulsion generators is open-circuited.

C. The armature winding of one of the propulsion generators is open-circuited.

D. The field winding of one of the propulsion motors is open-circuited.

The Correct Answer is B **Explanation for Option B (Correct Answer):** In a two-generator, two-motor DC diesel-electric drive propulsion system, the propulsion motors are typically supplied power by two separate propulsion generators. When operating normally in a two-generator setup, the generators share the load and provide the necessary voltage and current to achieve the desired motor speed. The speed ($N$) of a DC motor is approximately proportional to the supply voltage ($V$) and inversely proportional to the motor field flux ($\Phi_M$): $N \propto V / \Phi_M$. If the **field winding of one of the propulsion generators (Generator 1 or Generator 2) is open-circuited**, that specific generator will cease to produce significant voltage or current. Effectively, the entire propulsion system will lose half of its power generation capability. Since the remaining single operational generator must now supply power to both propulsion motors (assuming they are still connected in parallel or series/parallel configurations, or if the system uses a single bus structure), the total voltage supplied to the propulsion motors will be drastically reduced, or the current available will be halved if the voltage is maintained by the remaining generator struggling under double load. Crucially, in systems where the two generators are meant to operate together to produce the required total voltage/power, losing one generator means the **total power and resulting voltage available to the motors are halved**. Since motor speed is roughly proportional to the applied voltage, halving the effective power and voltage available (due to the loss of one generator) will cause the propulsion shaft speed to be approximately **one-half the desired speed**. **Explanation of Incorrect Options:** **A) The armature winding of one of the propulsion motors is open-circuited:** If the armature of one propulsion motor is open-circuited, that specific motor will stop operating completely. The remaining motor will still operate, but the propulsion system will only be delivering half the total shaft torque/power. The operating motor, supplied by the generators, might initially try to maintain the same voltage/speed (depending on load and generator regulation), but the **total propulsion shaft speed will not be halved**; rather, the *propulsion power/torque* would be halved, resulting in difficulty maintaining speed or a slower acceleration, but the remaining motor's speed might remain near the desired setpoint if the remaining system load is light enough. If the question implies the *total* system speed, losing one motor typically means losing propulsion entirely or drastically reducing thrust/power, not necessarily stabilizing at exactly half speed. **C) The armature winding of one of the propulsion generators is open-circuited:** An open armature winding in a generator is similar to an open field winding (Option B) – the generator stops producing output power. Therefore, this condition would also result in the loss of half the power supply, leading to approximately half the desired propulsion shaft speed. However, an open **field** winding (Option B) is a more common and specific failure mode taught in educational materials regarding power loss in generators that leads directly to a halved voltage output and corresponding halved motor speed. While C is functionally similar to B regarding power loss, B describes the primary component necessary for excitation, making it the preferred or textbook answer for this specific outcome. **D) The field winding of one of the propulsion motors is open-circuited:** The speed ($N$) of a DC motor is inversely proportional to its field flux ($\Phi_M$). If the field winding of one motor is open-circuited, that motor's field flux drops significantly (or to zero). This would cause that specific motor to attempt to run at an **extremely high speed (runaway)**, provided it still receives armature voltage and is under light load, or it might draw excessive current and trip protection circuits. In a shared load system, this failure would lead to catastrophic overspeed or shutdown, not a stable operation at half speed.

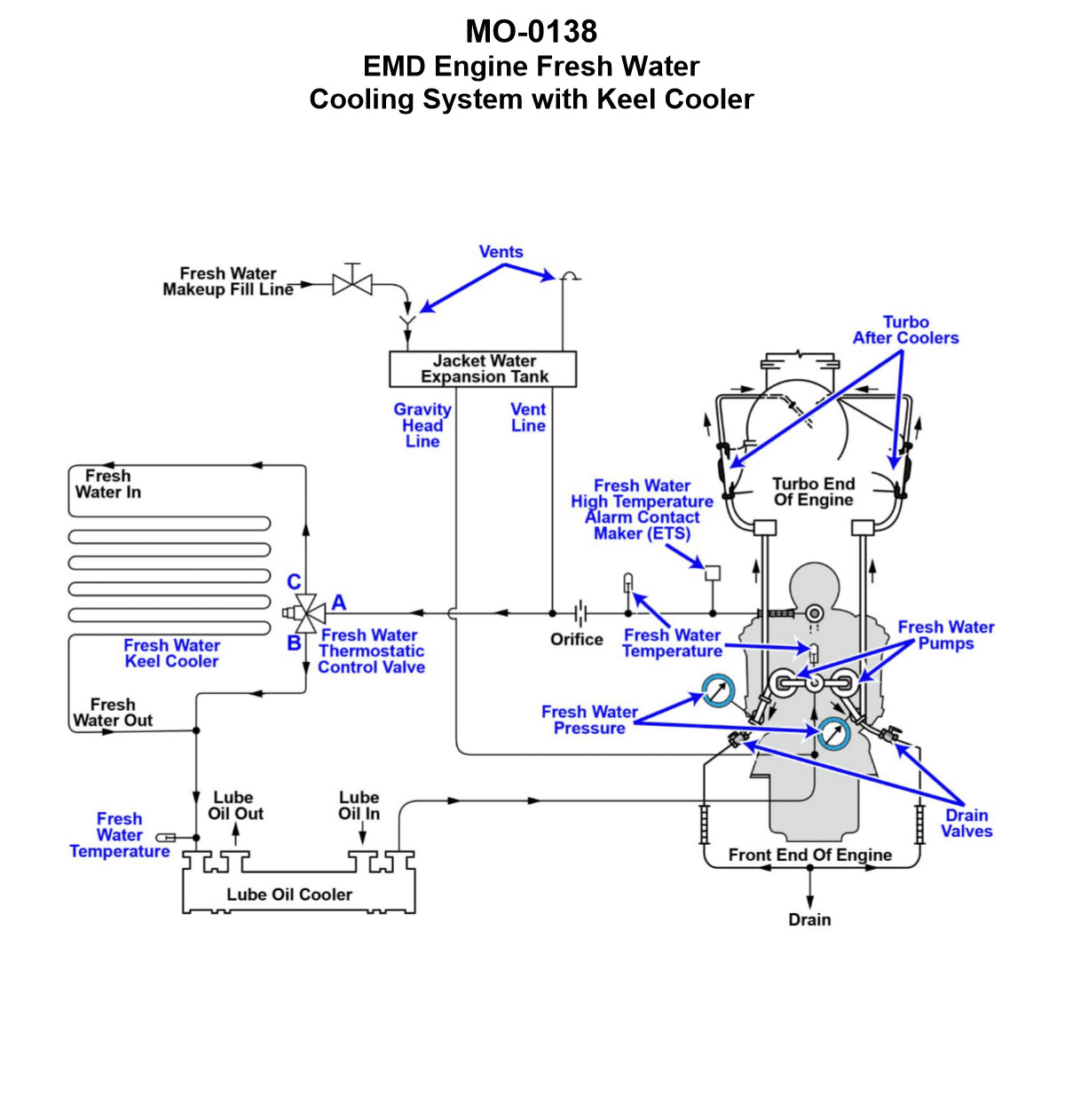

Question 23

Question: The freshwater cooling systems serving the main engines on your general-purpose supply vessel are arranged as shown in the illustration. If coolant drain valves are inadvertently opened during engine operation, what combination set of symptoms would most likely result? Illustration MO-0138

A. Low level in the jacket water expansion tank. Low freshwater outlet temperature from the engine. Low freshwater pump(s) discharge pressure.

B. Low level in the jacket water expansion tank. High freshwater outlet temperature from the engine. Low freshwater pump(s) discharge pressure.

C. High level in the jacket water expansion tank. High freshwater outlet temperature from the engine. High freshwater pump(s) discharge pressure.

D. Low level in the jacket water expansion tank. High freshwater outlet temperature from the engine. High freshwater pump(s) discharge pressure.

The Correct Answer is B ### 2. Explanation of Why Option B is Correct **Option B: Low level in the jacket water expansion tank. High freshwater outlet temperature from the engine. Low freshwater pump(s) discharge pressure.** When coolant drain valves are inadvertently opened during engine operation, the closed cooling system immediately loses volume under pressure. This leads to the following sequence of events: 1. **Low level in the jacket water expansion tank:** The expansion tank serves as the system's reservoir. As coolant actively drains out through the open valves, the total volume of fluid in the system decreases rapidly, resulting in a low level indication in the expansion tank. 2. **Low freshwater pump(s) discharge pressure:** Opening a drain constitutes a significant leak or bypass in the system piping. This reduces the hydraulic resistance against which the pump is operating. A centrifugal pump operating against significantly reduced system resistance (or experiencing cavitation/drawing air as the level drops) will produce a much lower discharge pressure (head). 3. **High freshwater outlet temperature from the engine:** The low system volume and reduced pump pressure lead to a severe reduction in the circulation rate of coolant through the engine jacket passages. If heat is not effectively removed by circulating coolant, the engine heat will be absorbed by the stagnant or slow-moving water, causing the engine's jacket water outlet temperature to rise rapidly (overheating). ### 3. Explanation of Why Other Options are Incorrect **A) Low level in the jacket water expansion tank. Low freshwater outlet temperature from the engine. Low freshwater pump(s) discharge pressure.** * This option is incorrect because the predicted temperature is wrong. Loss of coolant flow inevitably causes engine overheating, resulting in a **High** freshwater outlet temperature, not a low one. **C) High level in the jacket water expansion tank. High freshwater outlet temperature from the engine. High freshwater pump(s) discharge pressure.** * This option is incorrect on two counts. The level would be **Low** (due to draining), not high. The pressure would be **Low** (due to the leak reducing system resistance), not high. **D) Low level in the jacket water expansion tank. High freshwater outlet temperature from the engine. High freshwater pump(s) discharge pressure.** * This option is incorrect because the predicted pump pressure is wrong. An open drain drastically reduces system resistance and volume, leading to a **Low** pump discharge pressure, not a high one.

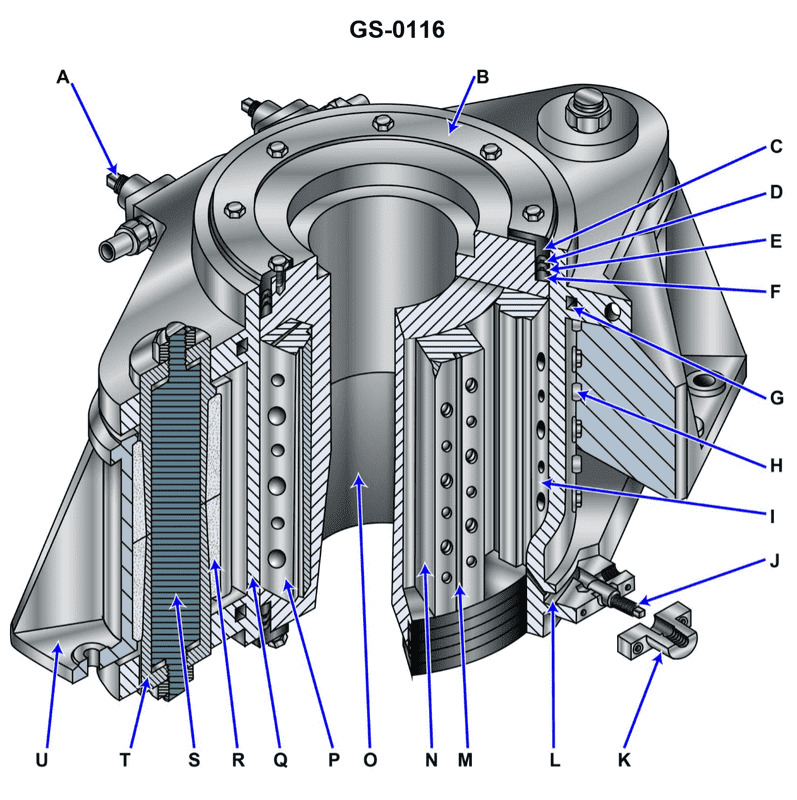

Question 23

Question: Referring to the device shown in the illustration, which statement is TRUE in regard to what happens when the rudder stock rotates? Illustration GS-0116

A. All items similar to "I" move

B. All items similar to "N" move

C. All items similar to both "I" and "N" move

D. None of the items similar to "I" nor "N" move

The Correct Answer is B **Explanation for Option B (Correct):** The illustration GS-0116 typically depicts a ship's steering gear system, often showing the mechanisms that translate the rotation of the rudder stock into movement of the rudder blade itself, and potentially the mechanisms used to move the rudder stock (like ram units or hydraulic cylinders). * **Item "N"** generally points to the **ram unit, hydraulic cylinder, or tiller/crosshead assembly** which is mechanically or hydraulically linked to the rudder stock. In a typical steering gear arrangement (e.g., Rapson slide or simple linkage), the rudder stock rotates, and this rotation is directly associated with the movement of the components that push or pull the stock (the rams/cylinders). For the rudder stock to rotate, the hydraulic system must actuate the rams/cylinders (N), causing them to move. Conversely, if the rudder is rotating, the linkage components (N) must also be moving. Therefore, when the rudder stock rotates, all items similar to "N" move. **Explanation for Incorrect Options:** * **A) All items similar to "I" move:** Item **"I"** typically represents the **fixed structure, foundation, or housing** of the steering gear or components that guide the moving parts (like the fixed cylinder casings, supports, or the deck structure itself). These components are non-moving fixtures designed to absorb the reaction forces. They do not move when the rudder stock rotates. * **C) All items similar to both "I" and "N" move:** This is incorrect because, as explained above, item "I" (fixed structure) does not move. * **D) None of the items similar to "I" nor "N" move:** This is incorrect because the movement of the steering gear rams/cylinders (N) is necessary and integral to the rotation of the rudder stock.

Question 23

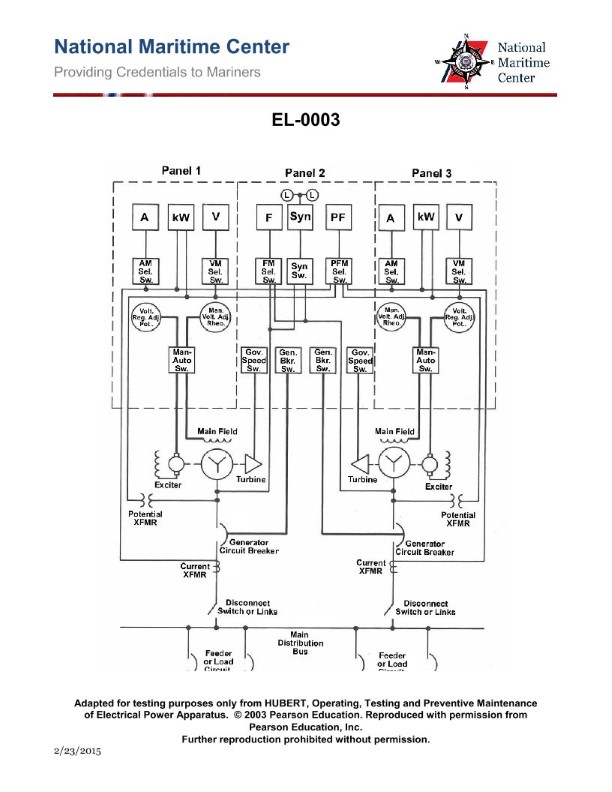

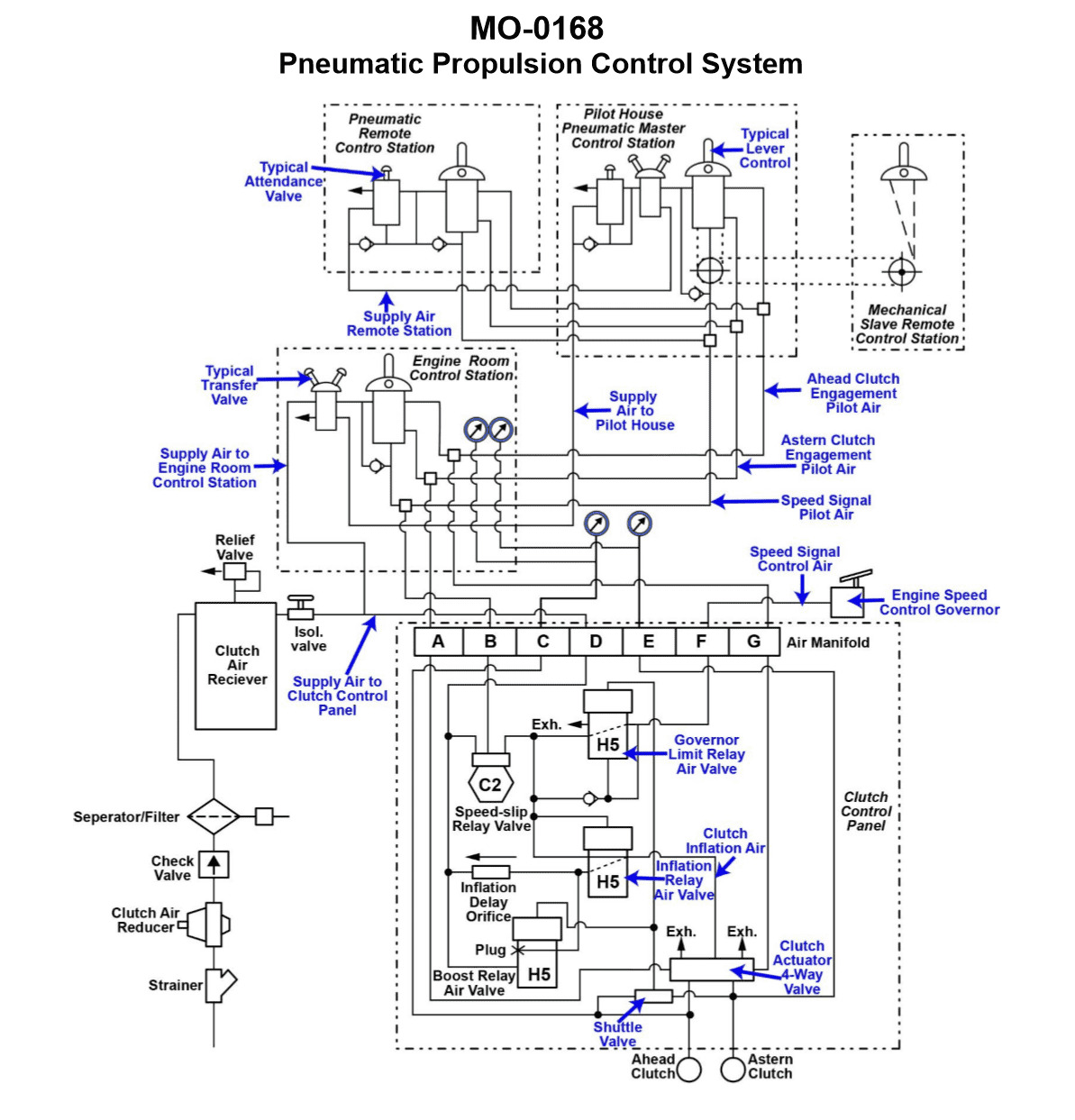

Question: What is the purpose of the device labeled "Man-Auto Sw." in the illustrated switchboard? Illustration EL-0003

A. to shift the governor control from manual to automatic/zero droop or vice versa

B. to shift from the automatic voltage regulator to manual voltage control or vice versa

C. to supply regulated control power to the switchboard

D. to enable the operator to read the field voltage on device "Volt. Reg. Adj. Pot." or device "Man. Volt. Adj. Rheo."

The Correct Answer is B **Explanation for Option B (Correct):** The device labeled "Man-Auto Sw." (Manual-Automatic Switch) in a standard switchboard associated with generator control, particularly in the context of voltage regulation, is designed to transfer control authority. When dealing with the Automatic Voltage Regulator (AVR), this switch allows the operator to select between two modes of excitation control: 1. **Automatic Mode (Auto):** Where the AVR actively regulates the generator output voltage to a set point. 2. **Manual Mode (Man):** Where the operator directly controls the excitation current (field voltage) via a separate device (often a manual voltage adjuster or rheostat) to maintain the terminal voltage. Therefore, its purpose is precisely "to shift from the automatic voltage regulator to manual voltage control or vice versa." **Explanation for Other Options (Incorrect):** * **A) to shift the governor control from manual to automatic/zero droop or vice versa:** This function is handled by a separate switch, typically labeled "Speed/Governor Man-Auto Sw." or similar, which controls the prime mover (engine/turbine) speed/load regulation system, not the electrical excitation system (voltage regulation). * **C) to supply regulated control power to the switchboard:** Control power is supplied by auxiliary transformers, battery systems, or DC power supplies, often through fuses or circuit breakers. A simple "Man-Auto Sw." is a selector switch, not a power source or power supply regulator. * **D) to enable the operator to read the field voltage on device "Volt. Reg. Adj. Pot." or device "Man. Volt. Adj. Rheo.":** While the switch selects the mode of control (Auto or Man), the actual reading of parameters (like field voltage) is done via metering devices (voltmeters and ammeters). The selection switch itself does not facilitate meter reading; it facilitates control mode selection.

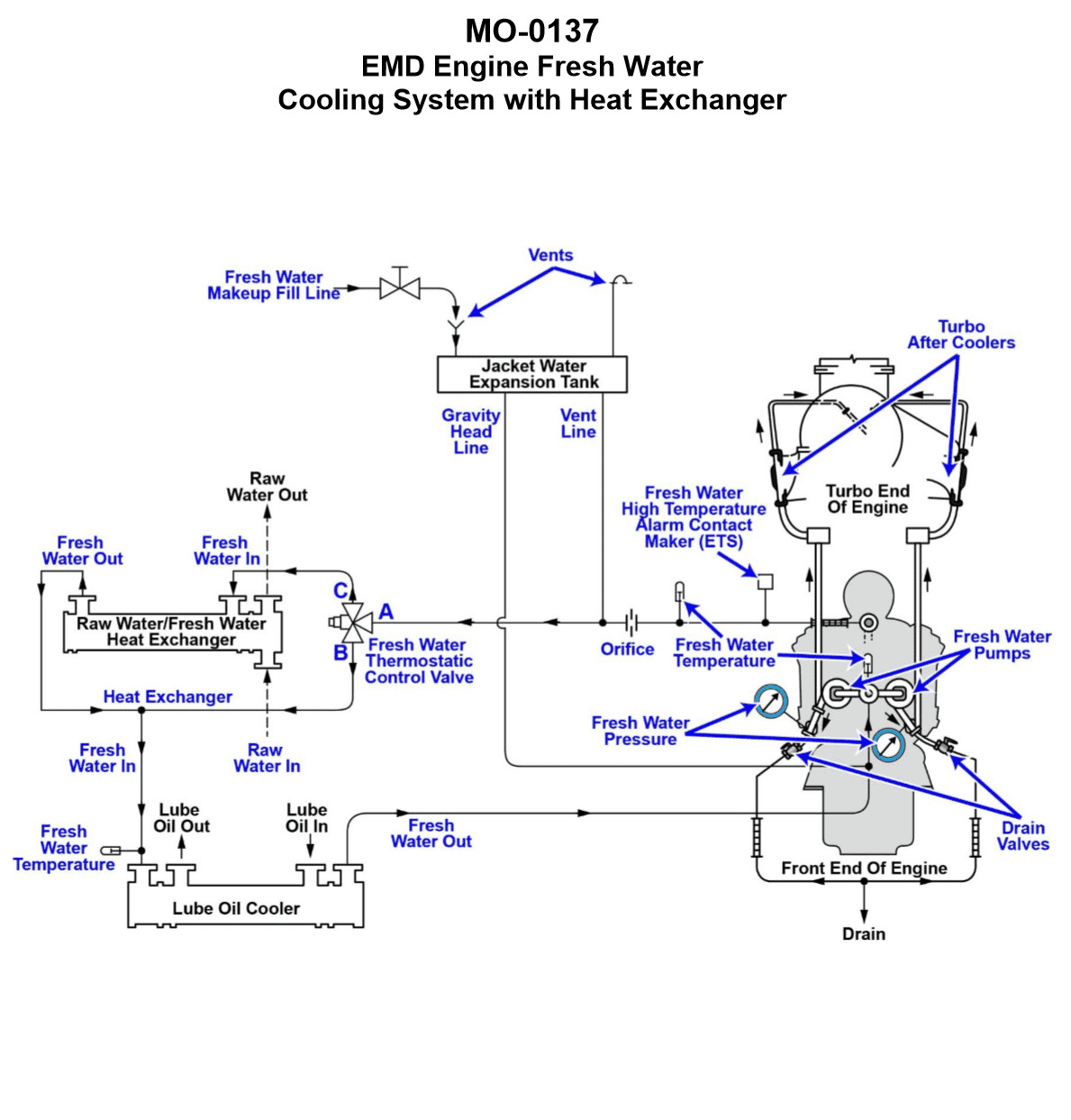

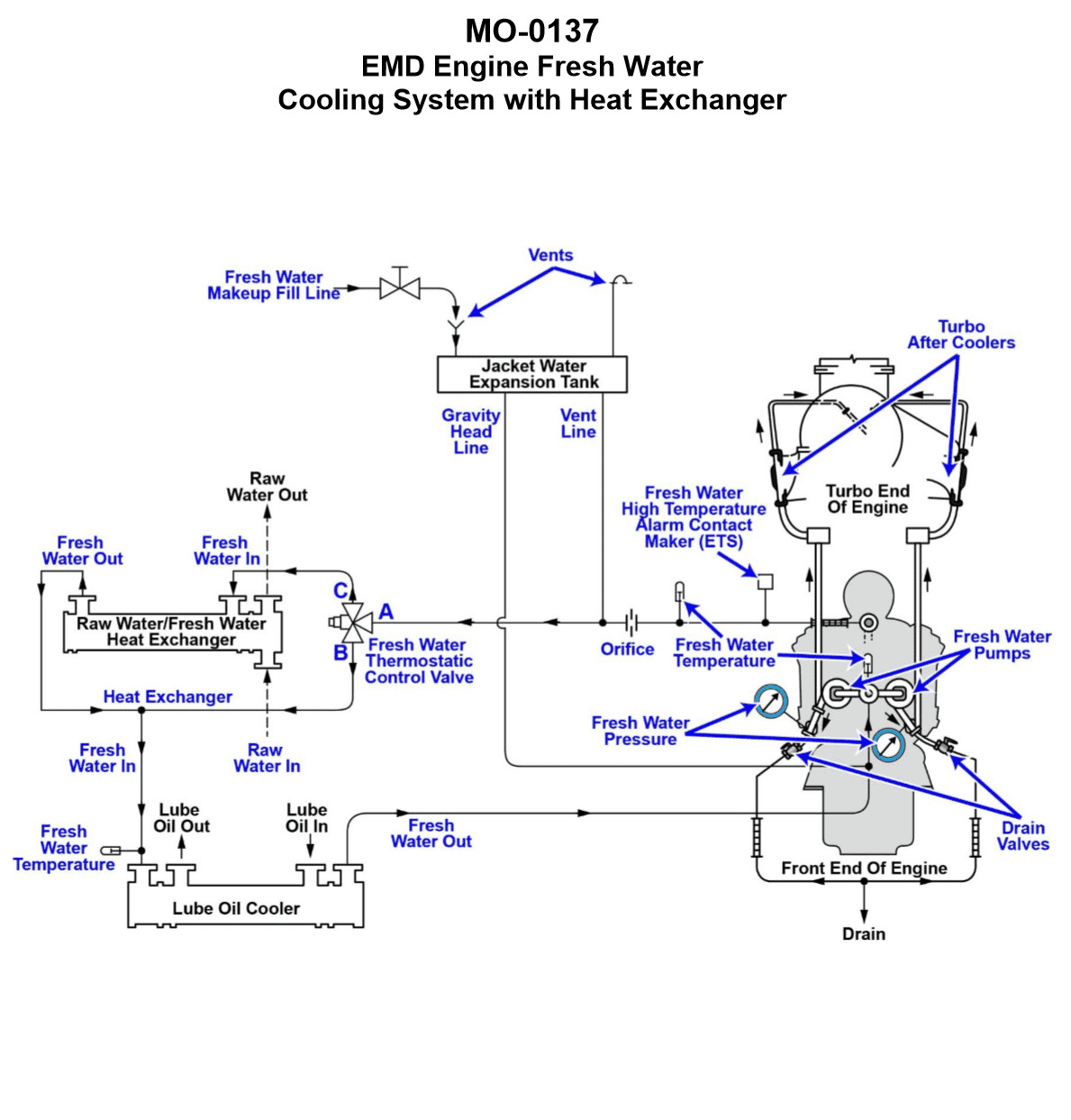

Question 24

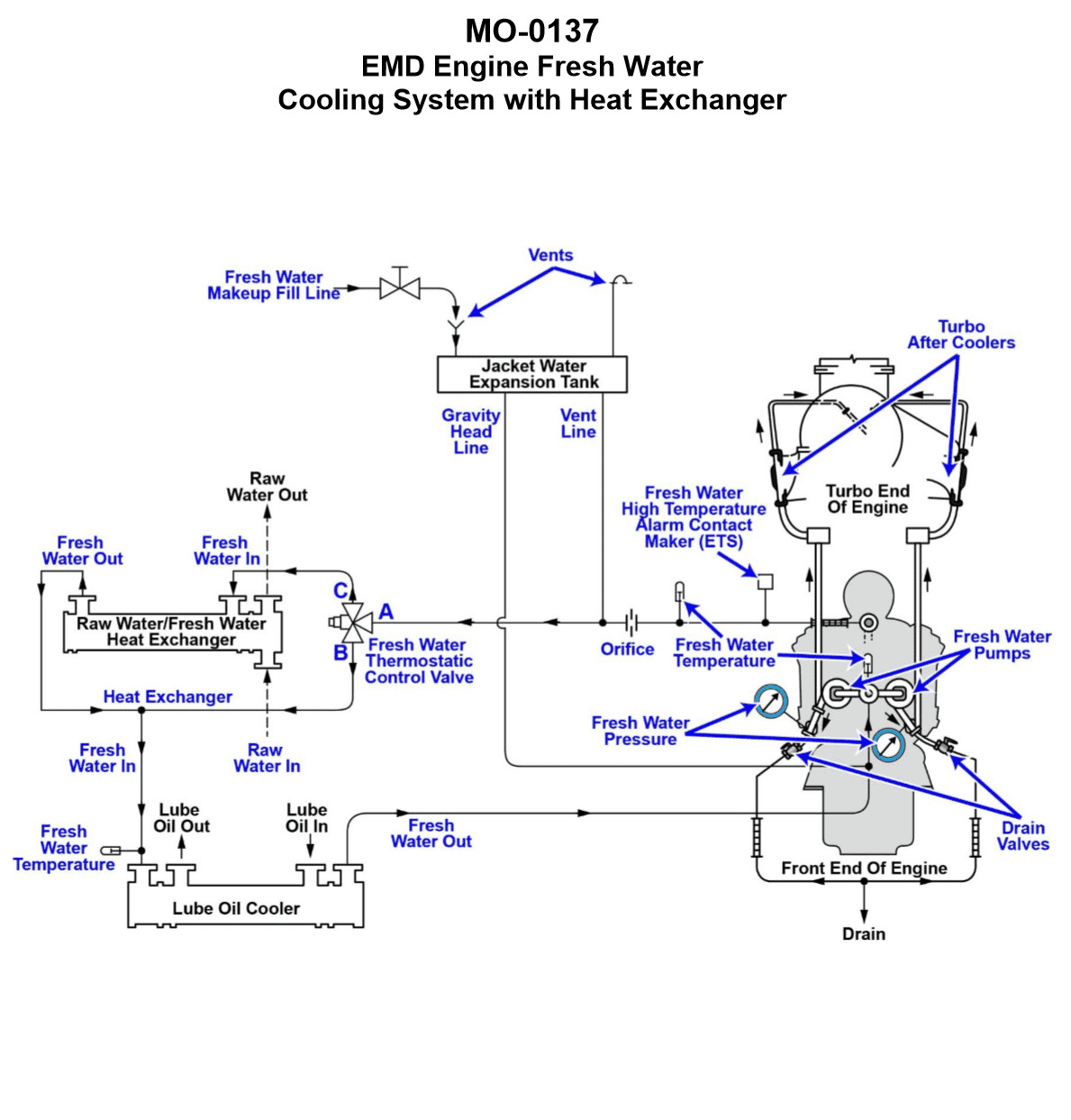

Question: The freshwater cooling systems serving the main engines on your OSV are arranged as shown in the illustration. If the fresh water thermostatic control valve fails in the position where 100% of the flow from flange "A" is permanently ported to flange "B" and flange "C" is permanently blocked, while starting and warming the engine with no load, what would be the resulting warm up time period? Illustration MO-0137

A. With no load, it is not possible to describe the time frame required to warm up the engine.

B. With no load, the engine would require a much longer than normal time frame to warm up.

C. With no load, the engine would require a much shorter than normal time frame to warm up.

D. With no load, the engine would require a relatively normal time frame to warm up.

The Correct Answer is D **Explanation for Option D (Correct Answer):** The question describes a failure scenario where the fresh water thermostatic control valve fails, permanently porting 100% of the flow from the engine's outlet (flange "A") to the engine's inlet (flange "B"), while completely blocking flow to the radiator/heat exchanger (flange "C"). This configuration results in the cooling fresh water being 100% recirculated through the engine jacket without being cooled by the external system (radiator or heat exchanger). This is effectively a closed-loop recirculation, bypassing the primary cooling mechanism. During engine startup and warming up with **no load**, the engine is producing minimal waste heat. Since the valve has failed in the **recirculation/bypass position**, the limited heat generated by the engine is retained entirely within the closed cooling system loop. Because the heat is being retained and is not being actively rejected to the environment (or seawater), the temperature of the cooling water will rise rapidly and efficiently, leading to a relatively **normal or even slightly faster** warm-up period until the desired operating temperature is reached. The warm-up phase is characterized by retaining heat, which this failure mode achieves perfectly. **Explanation of Why Other Options Are Incorrect:** * **A) With no load, it is not possible to describe the time frame required to warm up the engine.** This is incorrect. While precise timing depends on specific engine parameters, the mechanism of heat retention (100% recirculation) clearly defines the system's behavior, allowing for a qualitative description of the warm-up period (i.e., normal to fast). * **B) With no load, the engine would require a much longer than normal time frame to warm up.** This is incorrect. A longer warm-up time occurs when heat is aggressively rejected, such as if the thermostat failed wide open, sending 100% of the flow through the heat exchanger even when cold. Since the thermostat failed in the *recirculation* position, heat retention is maximized, minimizing warm-up time. * **C) With no load, the engine would require a much shorter than normal time frame to warm up.** While the warm-up period might be slightly accelerated due to perfect recirculation (no heat loss to the environment through the cooling system), labeling it "much shorter" is typically an overstatement for standard operational procedures. A **relatively normal** time frame (D) is the most accurate description because the time is dictated more by the engine's idle heat generation rate than by small changes in circulation efficiency. Furthermore, once the engine warms up, this failure will lead to immediate overheating. However, during the specific *warm-up* phase, heat retention is high, resulting in a functionally normal warm-up time.

Question 26

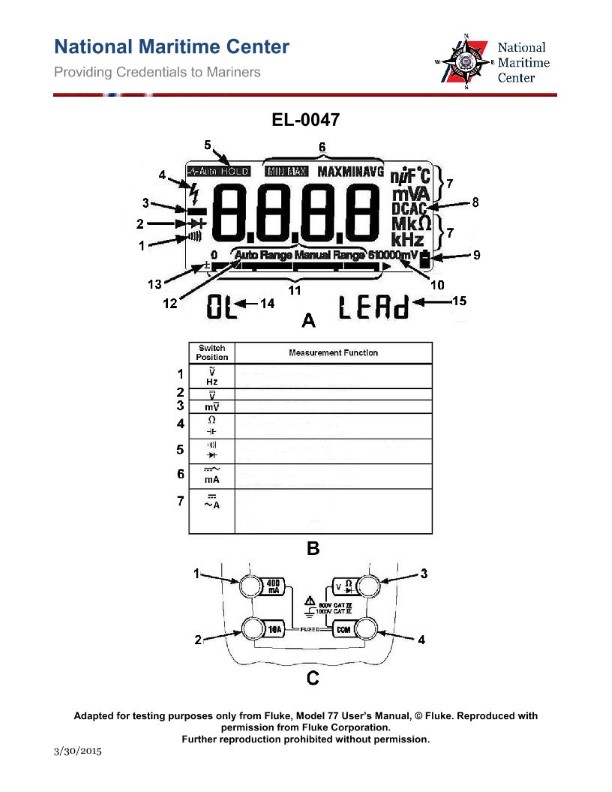

Question: As shown in figures "B" and "C" of the illustration, what should be the switch position and which test lead terminal jacks should be used if your intent is to measure AC currents anticipated as high as 5 amps? Illustration EL-0047

A. switch position "1" and terminal jacks "1 and 4"

B. switch position "6" and terminal jacks "1 and 4"

C. switch position "7" and terminal jacks "1 and 2"

D. switch position "7" and terminal jacks "2 and 4"

The Correct Answer is D ### Explanation of Why Option D is Correct To measure an alternating current (AC) anticipated as high as 5 amps, the multimeter must be set to the correct function (AC Amperes) and the test leads must be inserted into the jacks designed to handle high current. 1. **Switch Position (Function/Range):** Position **"7"** is the setting used to select the high range of AC Current measurement (AC Amps). This ensures the meter is prepared to measure the correct type and magnitude of the electrical flow. 2. **Terminal Jacks (Current Input):** * Jack **"2"** is the Common (COM) terminal, which is required for all measurements. * Jack **"4"** is typically labeled for high current input (e.g., "10A" or "High Amps") and is designed to handle currents up to the meter's maximum capacity (like 5 amps in this scenario). Therefore, setting the function to high AC Amps ("7") and connecting the leads between COM ("2") and the high current input ("4") is the required procedure. ### Explanation of Why Other Options Are Incorrect **A) switch position "1" and terminal jacks "1 and 4"** * **Switch Position "1"**: This position usually corresponds to a voltage (AC or DC V) or a low-range DC current function, not high AC current. * **Terminal Jacks "1 and 4"**: These connections omit the necessary Common (COM) jack (usually Jack 2) and are electrically incorrect for measurement. **B) switch position "6" and terminal jacks "1 and 4"** * **Switch Position "6"**: This position usually corresponds to a voltage or resistance ($\Omega$) measurement function, not current. * **Terminal Jacks "1 and 4"**: These connections omit the necessary Common (COM) jack (usually Jack 2) and are electrically incorrect for measurement. **C) switch position "7" and terminal jacks "1 and 2"** * **Switch Position "7"**: The function is correctly set to AC Amps. * **Terminal Jacks "1 and 2"**: Jack 2 is COM (correct), but Jack **"1"** is the low-current input terminal (typically labeled mA or $\mu$A). Attempting to measure 5 amps using the low-current terminal (Jack 1) would immediately blow the internal fuse, as this jack is not rated for high current.

Question 28

Question: As shown in figure "D" of the illustrated digital power meter, what type of single-phase load is under test for power measurement? Illustration EL-0256

A. a resistive-capacitive load

B. an inductive-resistive load

C. a purely inductive load

D. a purely resistive load