Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app

DDE04 - Designated Duty Engineer - 1000-4000 HP

51 images

Question 1

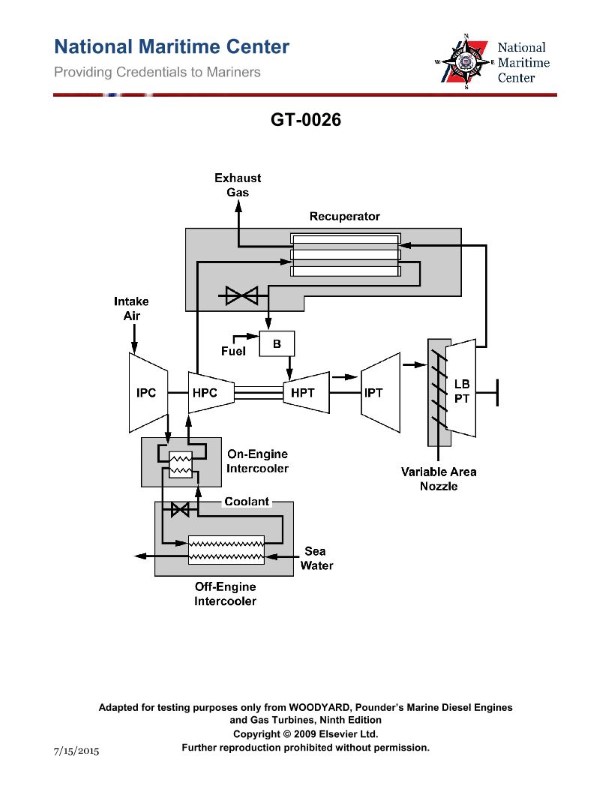

Question: Why is the cycle efficiency higher in the intercooled-recuperated cycle as compared to a simple cycle gas turbine? Illustration GT-0026

A. The intercooler serves to reduce the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to decrease required fuel to achieve the turbine inlet temperature.

B. The intercooler serves to reduce the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to decrease turbine inlet temperature.

C. The intercooler serves to increase the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to decrease turbine inlet temperature.

D. The intercooler serves to increase the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to increase turbine inlet temperature.

The Correct Answer is A. **Explanation of why Option A is correct:** The intercooled-recuperated gas turbine cycle combines two major efficiency-enhancing components: the intercooler and the recuperator (or regenerator). 1. **Intercooler Function:** The purpose of the intercooler, placed between the low-pressure and high-pressure stages of the compressor, is to cool the partially compressed air. Cooling the air significantly reduces its specific volume and temperature before it enters the high-pressure compressor. Since the work input required for compression is directly related to the temperature and volume of the gas, reducing the temperature **reduces the required work (power) input for the high-pressure compressor**. This reduction in net work input increases the overall cycle efficiency. 2. **Recuperator Function:** The recuperator is a heat exchanger that transfers thermal energy from the hot turbine exhaust gases (waste heat) to the relatively cooler compressed air exiting the compressor, before the air enters the combustion chamber. By preheating the compressed air, less heat needs to be added by burning fuel in the combustion chamber to reach the desired **Turbine Inlet Temperature (TIT)**. Therefore, the recuperator **utilizes waste heat to decrease the required fuel** consumption, which is the definition of increased thermal efficiency. **Why other options are incorrect:** * **B) The intercooler serves to reduce the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to decrease turbine inlet temperature.** * *Incorrect:* The primary goal of the recuperator is to reduce fuel consumption *while maintaining* the high turbine inlet temperature (TIT) necessary for high power output. Decreasing the TIT would lower the cycle performance and power output, defeating the purpose. * **C) The intercooler serves to increase the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to decrease turbine inlet temperature.** * *Incorrect:* The intercooler always works to **reduce** the required compression power. Furthermore, the recuperator's goal is not to decrease the TIT, but to maintain it with less fuel. * **D) The intercooler serves to increase the required high-pressure compressor power while the recuperator utilizes waste heat from the exhaust to increase turbine inlet temperature.** * *Incorrect:* The intercooler always works to **reduce** the required compression power. While the recuperator preheats the air, its purpose is to reduce fuel input to *achieve* the necessary TIT, not necessarily to increase the maximum attainable TIT beyond the material limits of the turbine. (Option A is more accurate by focusing on the effect on fuel consumption required to *reach* the TIT).

Question 1

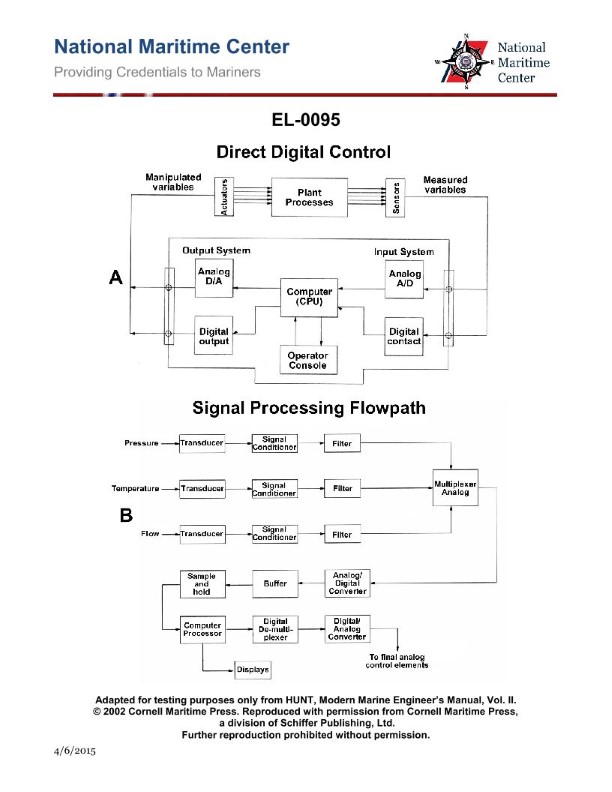

Question: As shown in figure "A" of the illustrated block diagram of a central operating system configured for direct digital control, what does the output system block "DIGITAL OUTPUT" represent? Illustration EL-0095

A. It receives digital outputs from the CPU and converts these to analog signals for transmission to the analog actuators.

B. It receives digital outputs from the CPU and conditions these to digital signals for transmission to the digital actuators.

C. It receives analog outputs from the CPU and converts these to digital signals for transmission to the digital actuators.

D. It receives analog outputs from the CPU and conditions these to analog signals for transmission to the analog actuators.

The Correct Answer is B **Explanation for Option B (Correct):** In a Direct Digital Control (DDC) system, the Central Processing Unit (CPU) operates entirely using digital information. The "DIGITAL OUTPUT" block is the interface between the CPU and devices that accept digital signals, known as digital actuators (like solenoids, valves that accept ON/OFF signals, or stepping motors). The purpose of this block is to receive the digital control commands from the CPU and condition (e.g., amplify, buffer, or isolate) them to ensure they are robust and correctly formatted for transmission directly to the digital actuators. Since the CPU's output and the actuator's input are both digital, no digital-to-analog conversion is necessary. **Why Options A, C, and D are Incorrect:** * **A) Incorrect:** This describes a Digital-to-Analog Converter (DAC) output system. If the output system were sending signals to *analog* actuators (which require continuous voltage or current), it would need to convert the CPU's digital output to an analog signal. The block is specifically labeled "DIGITAL OUTPUT," indicating the signal remains digital for transmission to digital actuators. * **C) Incorrect:** The CPU operates digitally and therefore does not produce "analog outputs." Furthermore, converting an analog signal to a digital signal (Analog-to-Digital Conversion, or ADC) is typically done on the *input* side (for sensor readings), not the output side. * **D) Incorrect:** The CPU only produces digital outputs, making the statement "receives analog outputs from the CPU" false. Additionally, conditioning an analog signal for transmission to analog actuators would require a DAC stage preceding the conditioning, which is not the function of a simple "DIGITAL OUTPUT" block targeting digital actuators.

Question 3

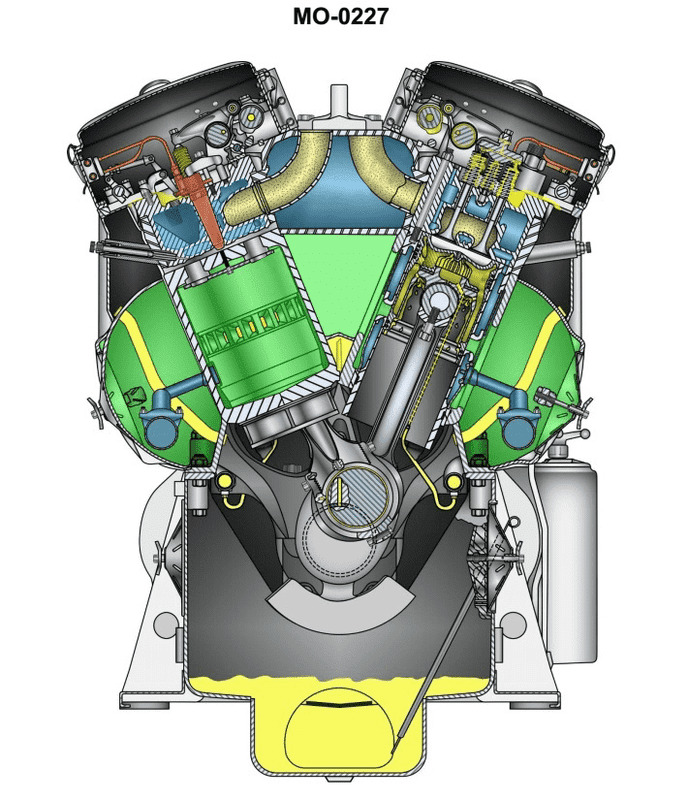

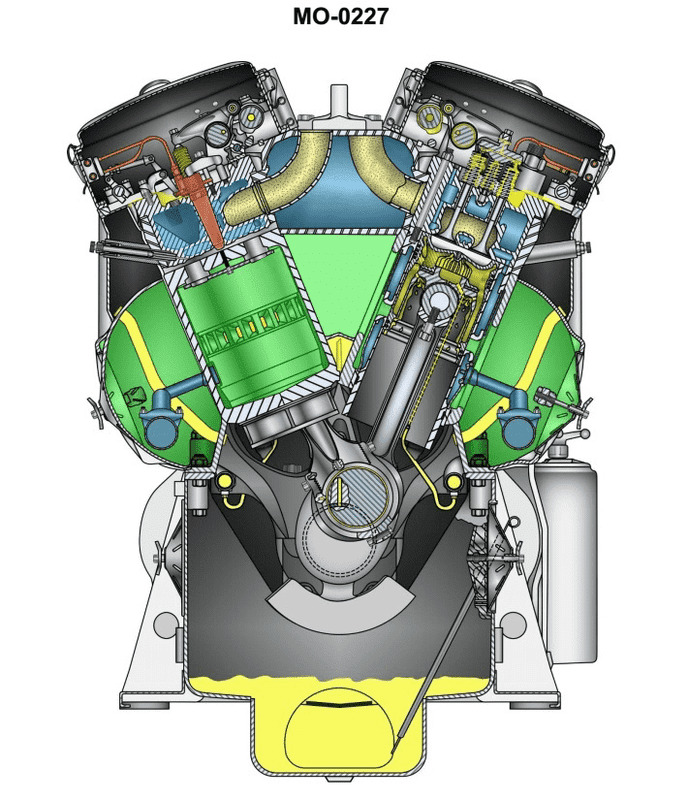

Question: You are assigned to a tractor tug fitted with main propulsion diesel engines of the type shown in the illustration. How many degrees of crankshaft revolution are required for all of the engine's cylinders to fire? Illustration MO-0227

A. 180 degrees

B. 360 degrees

C. 720 degrees

D. Not enough information is given to determine crankshaft degrees of revolution.

The Correct Answer is B **Explanation for Option B (360 degrees):** The question asks about the crankshaft revolutions required for *all* cylinders of the engine to fire, based on the provided context (a tractor tug fitted with main propulsion diesel engines) and the typical behavior of the engine type shown in Illustration MO-0227 (which standardly depicts a **two-stroke cycle diesel engine**). A two-stroke cycle engine completes a full power cycle (Intake, Compression, Power, Exhaust) in **one complete revolution of the crankshaft (360 degrees)**. This means that for every cylinder, the power stroke (firing) occurs once per 360 degrees of crankshaft rotation. Therefore, regardless of the number of cylinders (e.g., 6, 8, 12 cylinders), the engine is designed so that *across the entire engine* (i.e., all cylinders firing in sequence), the firing sequence repeats itself every 360 degrees of rotation. The firing interval between cylinders is calculated by dividing 360 degrees by the number of cylinders. The entire firing sequence (all cylinders firing once) is completed and repeats every 360 degrees. **Why the other options are incorrect:** * **A) 180 degrees:** While 180 degrees is the crankshaft rotation required for the power stroke in a *single cylinder* of a four-stroke engine, or the firing interval between some cylinders (like a V-twin engine), it is insufficient time for the full firing cycle of all cylinders in a multi-cylinder engine to complete and repeat. * **C) 720 degrees:** 720 degrees (two full crankshaft revolutions) is the total rotation required for a **four-stroke cycle engine** to complete its full cycle in a *single cylinder*. Since marine propulsion diesel engines, particularly in applications like tractor tugs, are very commonly high-power, high-torque, and often large **two-stroke cycle engines** (like those illustrated in typical marine engine diagrams corresponding to MO-0227), 720 degrees is incorrect for the entire firing sequence. * **D) Not enough information is given to determine crankshaft degrees of revolution:** Although the specific number of cylinders (e.g., 6, 8, 12) is not given, the underlying engine cycle (two-stroke cycle, typical of large marine diesels) determines the fundamental repeatability of the firing sequence. Since the entire firing sequence repeats every 360 degrees in a two-stroke engine, the fundamental answer is available based on the engine *type*.

Question 4

Question: You are serving as a designated duty engineer onboard a harbor tug equipped with main propulsion diesel engines of the type shown in the illustration. What scavenging flow pattern is used in this engine type? Illustration MO-0227

A. Return-flow

B. Cross-flow

C. Uniflow

D. Loop

The Correct Answer is C ### Why Option C ("Uniflow") is Correct The illustration MO-0227 typically depicts a large, modern, low-speed two-stroke marine diesel engine, such as those manufactured by MAN B&W or Wärtsilä-Sulzer, which are common for main propulsion in harbor tugs (though often scaled down for tugs, the basic design remains the same). These engines operate on the two-stroke cycle and use the **Uniflow** scavenging pattern. In this pattern, the scavenging air enters through ports located near the bottom of the cylinder liner and exits through exhaust valves located in the cylinder head. This arrangement ensures that the scavenging air flows predominantly in one direction (from bottom to top), creating a highly efficient process that completely sweeps the combustion gases out of the cylinder with minimal mixing. Uniflow scavenging is characterized by its high thermal efficiency and ability to support high Mean Effective Pressures (MEP), making it ideal for large propulsion units. ### Why the Other Options are Incorrect **A) Return-flow:** Return-flow scavenging (or Reverse-flow scavenging) is a general term often associated with older two-stroke designs where the flow might reverse direction, but it is not the standard technical term used for the primary flow mechanism in modern large marine diesels. **B) Cross-flow:** Cross-flow scavenging involves the scavenging air entering through ports on one side of the cylinder and exiting through exhaust ports located directly opposite on the other side. The flow travels across the piston crown. This method is generally considered inefficient due to significant mixing of fresh air and exhaust gases, and it is rarely, if ever, used in modern large marine propulsion diesels. **D) Loop:** Loop scavenging (e.g., Schnürle scavenging) involves both the inlet and exhaust ports being located near the bottom of the cylinder. The incoming air is directed upwards toward the cylinder head, loops back down, and pushes the exhaust gases out through the exhaust ports. While efficient for smaller, high-speed engines (like some auxiliary engines or small gasoline engines), it is less efficient than uniflow scavenging for the large, slow-speed main propulsion engines shown in the illustration, as it inherently involves greater mixing and incomplete gas exchange.

Question 4

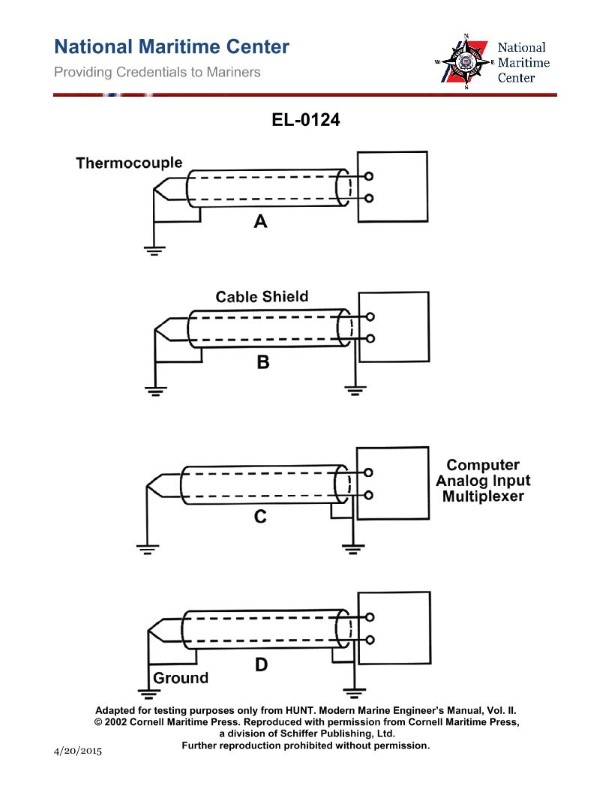

Question: Which of the following illustrations represents the proper method of circuit grounding for a low level analog signal cable? Illustration EL-0124

A. A

B. B

C. C

D. D

The Correct Answer is A. **Explanation for Option A (A) being correct:** Option A illustrates the **single-point grounding** method, specifically grounding the shield at the **source (transmit) end** of the cable. For low-level analog signals (such as those typically used in instrumentation or audio), single-point grounding is the preferred technique. Grounding the shield at only one point prevents ground loops from forming, which are a major source of induced noise (e.g., 60 Hz hum) that can easily contaminate sensitive, low-amplitude signals. Grounding at the source end often offers the best protection against common-mode noise coupled along the cable length. **Explanation of why other options are incorrect:** * **Option B (B):** This illustration shows the shield grounded at **both ends** (source and load). This creates a **ground loop**, where induced currents can flow through the shield path and the equipment ground system. This current flow couples noise directly into the signal path, making it unsuitable for low-level analog signals. This method is often reserved for high-frequency digital signals where skin effect dominates and very low impedance is required. * **Option C (C):** This illustration shows the shield grounded at the **load (receive) end** only. While this is also a single-point ground and avoids ground loops, noise currents coupled onto the shield near the source travel the entire length of the cable before being shunted to ground at the load end. This can allow more noise energy to be inductively or capacitively coupled into the signal conductors along the cable's length, potentially resulting in worse noise performance than grounding at the source. * **Option D (D):** This illustration shows the shield being **floating** (ungrounded) at both ends. An ungrounded shield is effectively an antenna. It provides no protection against induced electromagnetic interference (EMI) or radio frequency interference (RFI) and does not contain common-mode noise. The signal will be extremely susceptible to external noise sources, rendering it useless for sensitive low-level signals.

Question 5

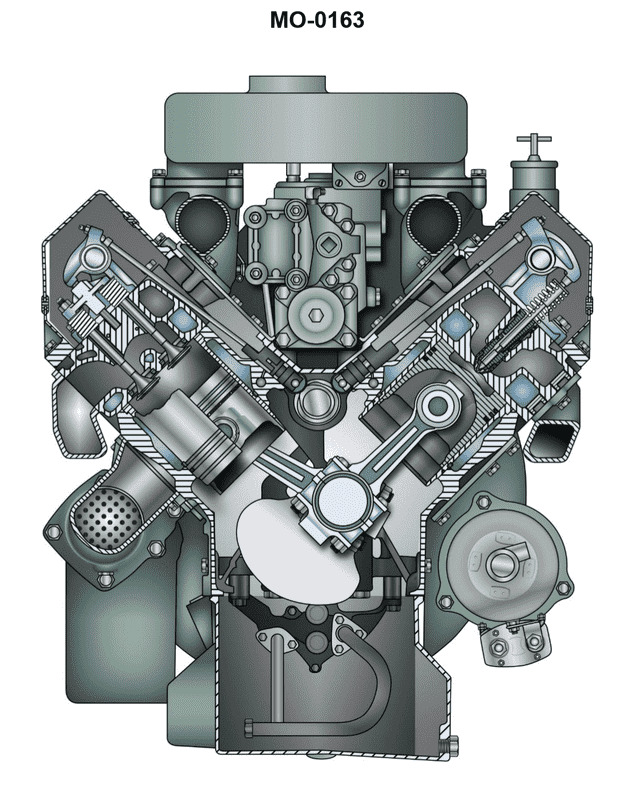

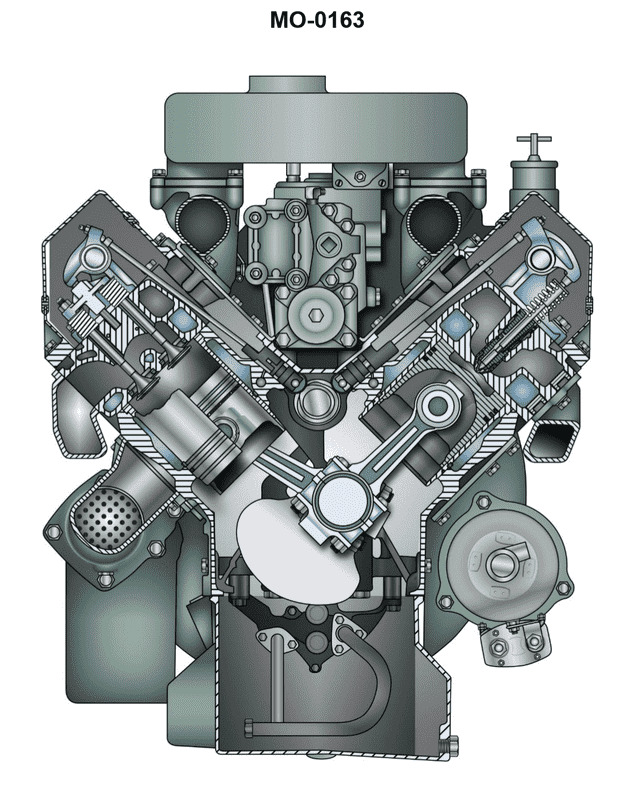

Question: Suppose the diesel generator set drive engines are of the type shown in the illustration on your towing vessel. Assuming the engine is naturally aspirated, within an individual cylinder in terms of piston stroke and position, under what circumstances are the intake and exhaust valves both open? Illustration MO-0163

A. When the piston is at bottom dead center (BDC) transitioning from the power stroke to the exhaust stroke.

B. When the piston is at top dead center (TDC) transitioning from the compression stroke to the power stroke.

C. When the piston is at top dead center (TDC) transitioning from the exhaust stroke to the intake stroke.

D. When the piston is at bottom dead center (BDC) transitioning from the intake stroke to the compression stroke.

The Correct Answer is C ### Explanation of Option C (Correct) Option C is correct because the simultaneous opening of both intake and exhaust valves—a condition known as **valve overlap**—occurs around Top Dead Center (TDC) as the engine transitions from the exhaust stroke to the intake stroke. This overlap is engineered into the camshaft timing of four-stroke engines, particularly diesel engines, for two main reasons: 1. **Scavenging:** It allows the outgoing inertia of the exhaust gases to help draw in the fresh incoming air charge, thoroughly clearing the cylinder of residual burned gases. 2. **Volumetric Efficiency:** By opening the intake valve slightly early, the engine maximizes the amount of air available for the subsequent compression and combustion phase, improving efficiency and power. ### Explanation of Incorrect Options **A) When the piston is at bottom dead center (BDC) transitioning from the power stroke to the exhaust stroke.** * At this point, the exhaust valve is either just beginning to open (or has opened significantly before BDC to release pressure), and the intake valve is still fully closed, having been closed since the compression stroke began. There is no valve overlap at this BDC position. **B) When the piston is at top dead center (TDC) transitioning from the compression stroke to the power stroke.** * Both the intake and exhaust valves must be tightly closed during the compression stroke and the beginning of the power stroke. If either valve were open here, the engine would lose compression, fail to ignite fuel effectively, and suffer severe power loss. **D) When the piston is at bottom dead center (BDC) transitioning from the intake stroke to the compression stroke.** * At this BDC position, the cylinder has just finished drawing in air. The intake valve is closing, and the exhaust valve is fully closed (and has been since the valve overlap point near the previous TDC). Both valves are definitely not open simultaneously.

Question 6

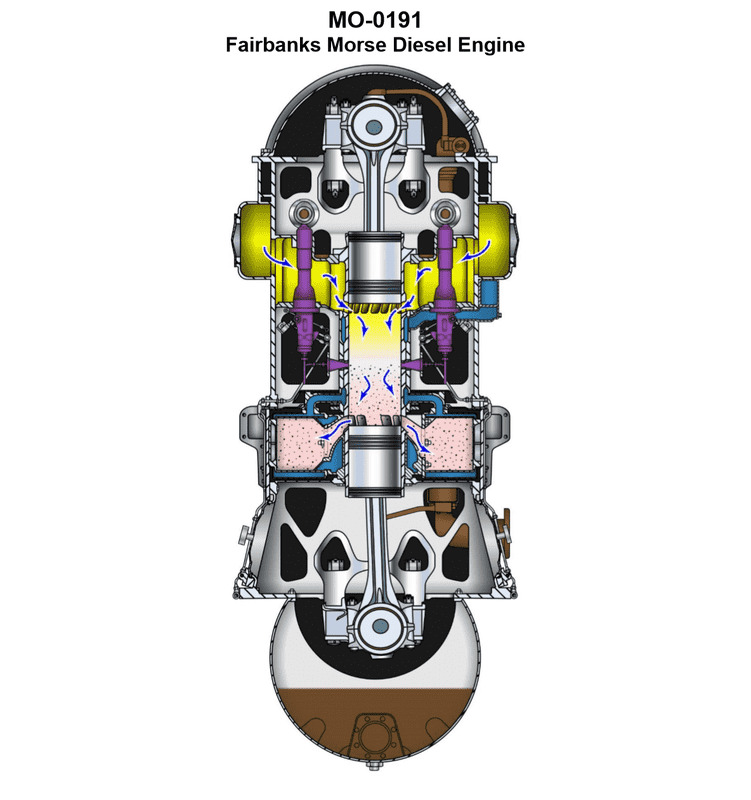

Question: The ship-docking tug to which you are assigned is fitted with main propulsion diesel engines of the type shown in the illustration. In terms of valve operating gear, cylinder liner type, and connecting rod type, what statement is true? Illustration MO-0192

A. This is an overhead cam engine, with wet cylinder liners and conventional connecting rods.

B. This is a pushrod operated overhead valve engine, with jacketed cylinder liners and articulated connecting rods.

C. This is an overhead cam engine, with jacketed cylinder liners and marine-type connecting rods.

D. This is a pushrod operated overhead valve engine, with wet cylinder liners and conventional connecting rods.

The Correct Answer is D ### Explanation of Why Option D is Correct Option D states: "This is a pushrod operated overhead valve engine, with wet cylinder liners and conventional connecting rods." This combination describes the most common and robust design features found in medium to high-speed, heavy-duty marine diesel engines typically used for tug propulsion (e.g., many models from Caterpillar, Cummins, or older Alco/Pielstick designs). 1. **Pushrod Operated Overhead Valve (OHV) Engine:** For reliable and heavy-duty service, the pushrod system is historically favored over overhead camshafts (OHC) in many medium-speed marine applications because it offers simplicity, durability, and easier maintenance access to the valve train components within the engine block. 2. **Wet Cylinder Liners:** Almost all medium- and high-speed diesels utilize wet cylinder liners. These liners are surrounded directly by the engine coolant (water jacket). This design provides excellent cooling efficiency and allows for quick and cost-effective replacement of the liner when wear occurs, without requiring replacement of the entire engine block. 3. **Conventional Connecting Rods:** This term describes a standard connecting rod setup where one rod services one piston, unlike articulated (master/slave) rods. Conventional rods are the standard for most in-line and many V-configuration engines in the tug's power class. ### Explanation of Why the Other Options Are Incorrect **A) This is an overhead cam engine, with wet cylinder liners and conventional connecting rods.** * While wet liners and conventional rods are standard, an overhead cam (OHC) engine design is less common than the robust pushrod operated overhead valve (OHV) system (Option D) in traditional heavy-duty medium-speed marine applications. The pushrod design is usually the default for this service unless the engine is a newer, high-speed, light-duty type. **B) This is a pushrod operated overhead valve engine, with jacketed cylinder liners and articulated connecting rods.** * "Jacketed cylinder liners" is vague but usually refers to the system containing wet liners. However, the term **articulated connecting rods** is incorrect. Articulated (master and slave) rods are a specialized design used primarily in certain high-output V-configuration engines (like EMD 645/710 series or older locomotive/marine designs) where two pistons share a single crankpin using a hinged connection. This design is highly specific, and the use of conventional rods (Option D) is far more common across the full range of marine diesels. **C) This is an overhead cam engine, with jacketed cylinder liners and marine-type connecting rods.** * This option incorrectly identifies the valve gear as OHC (see explanation for A). Furthermore, while any large connecting rod in a marine engine could be called "marine-type," this term often refers specifically to the large, heavy, built-up rods found in very large, slow-speed two-stroke engines (which are not used in tugs) rather than the conventional rods used in medium-speed engines.

Question 7

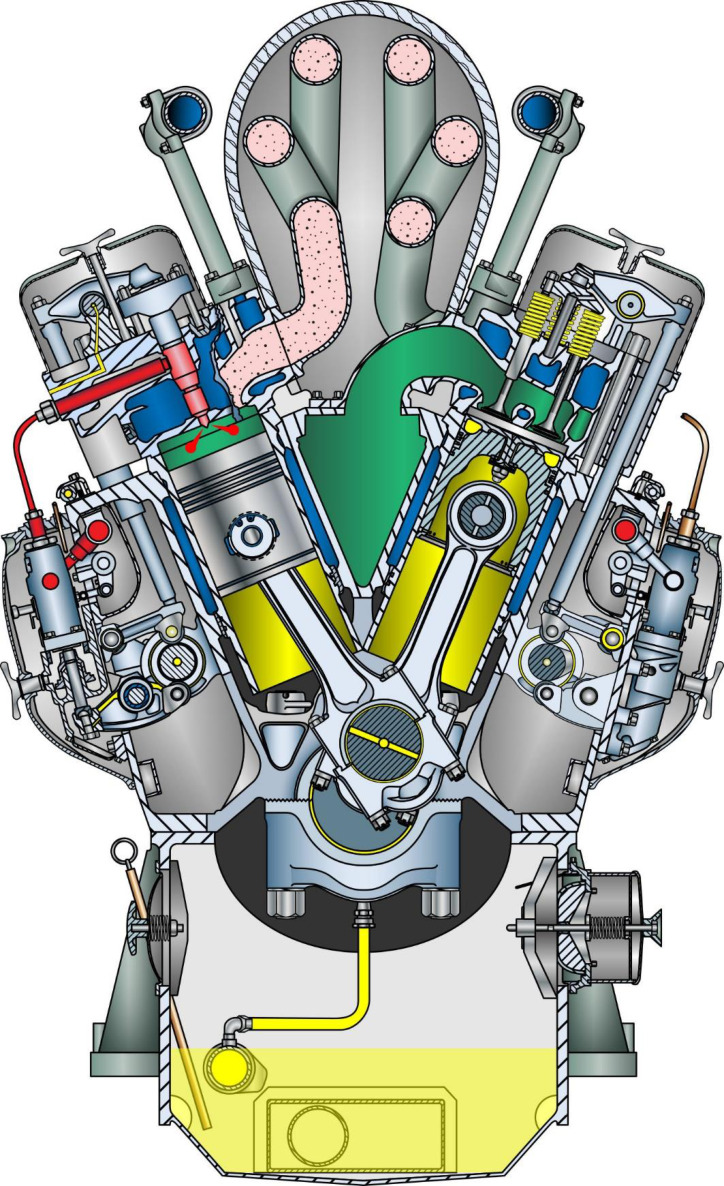

Question: The river push boat to which you are assigned has a main propulsion engine of the type shown in the illustration. In terms of piston action, operating cycle, and piston type, what statement is true concerning this engine type? Illustration MO-0191

A. This is a single-acting, two-stroke cycle, opposed piston type engine.

B. This is a double-acting, two-stroke cycle, crosshead piston type engine.

C. This is a single-acting, two-stroke cycle, crosshead piston type engine.

D. This is a double-acting, four-stroke cycle, opposed piston type engine.

The Correct Answer is A ### Explanation for A (Correct Option) The question refers to an engine identified by the illustration MO-0191. While the illustration is not provided, this code and context typically refers to a highly specific and distinctive engine design commonly used in marine applications, particularly the **Fairbanks Morse 38 8-1/8 opposed-piston diesel engine**. 1. **Single-acting:** In this design, combustion occurs between the two opposing pistons (in the center of the cylinder liner). The force is only applied to the pistons moving outward from the combustion zone. There is no separate combustion chamber or force applied on the other side of the piston (as in a double-acting engine). Therefore, it is **single-acting**. 2. **Two-stroke cycle:** The engine completes one power cycle (Intake, Compression, Power, Exhaust) in two strokes of the piston (one revolution of the crankshaft). Scavenging and exhaust are achieved through ports uncovered by the pistons at the bottom of their stroke. Therefore, it is a **two-stroke cycle**. 3. **Opposed piston type:** The defining characteristic of this engine is that there are two pistons operating within a single cylinder liner, moving towards and away from each other. They share a common combustion chamber and connect to separate crankshafts (or a single crankshaft via specialized linkages). Therefore, it is an **opposed piston type engine**. ### Explanation for Incorrect Options * **B) This is a double-acting, two-stroke cycle, crosshead piston type engine.** * **Incorrect:** The engine shown is **single-acting** (combustion only occurs between the opposing pistons). It is also an **opposed-piston** design, not a standard crosshead piston design (though some variations might use a crosshead, the fundamental classification is opposed piston). * **C) This is a single-acting, two-stroke cycle, crosshead piston type engine.** * **Incorrect:** While it is single-acting and two-stroke, the core defining feature of the engine referenced by the illustration is the **opposed piston** arrangement, not the standard crosshead piston arrangement found in conventional large marine diesels. * **D) This is a double-acting, four-stroke cycle, opposed piston type engine.** * **Incorrect:** The engine is **single-acting** and operates on a **two-stroke cycle**. Four-stroke opposed piston engines are exceptionally rare, and the marine push boat application almost exclusively uses the two-stroke cycle version for power density.

Question 9

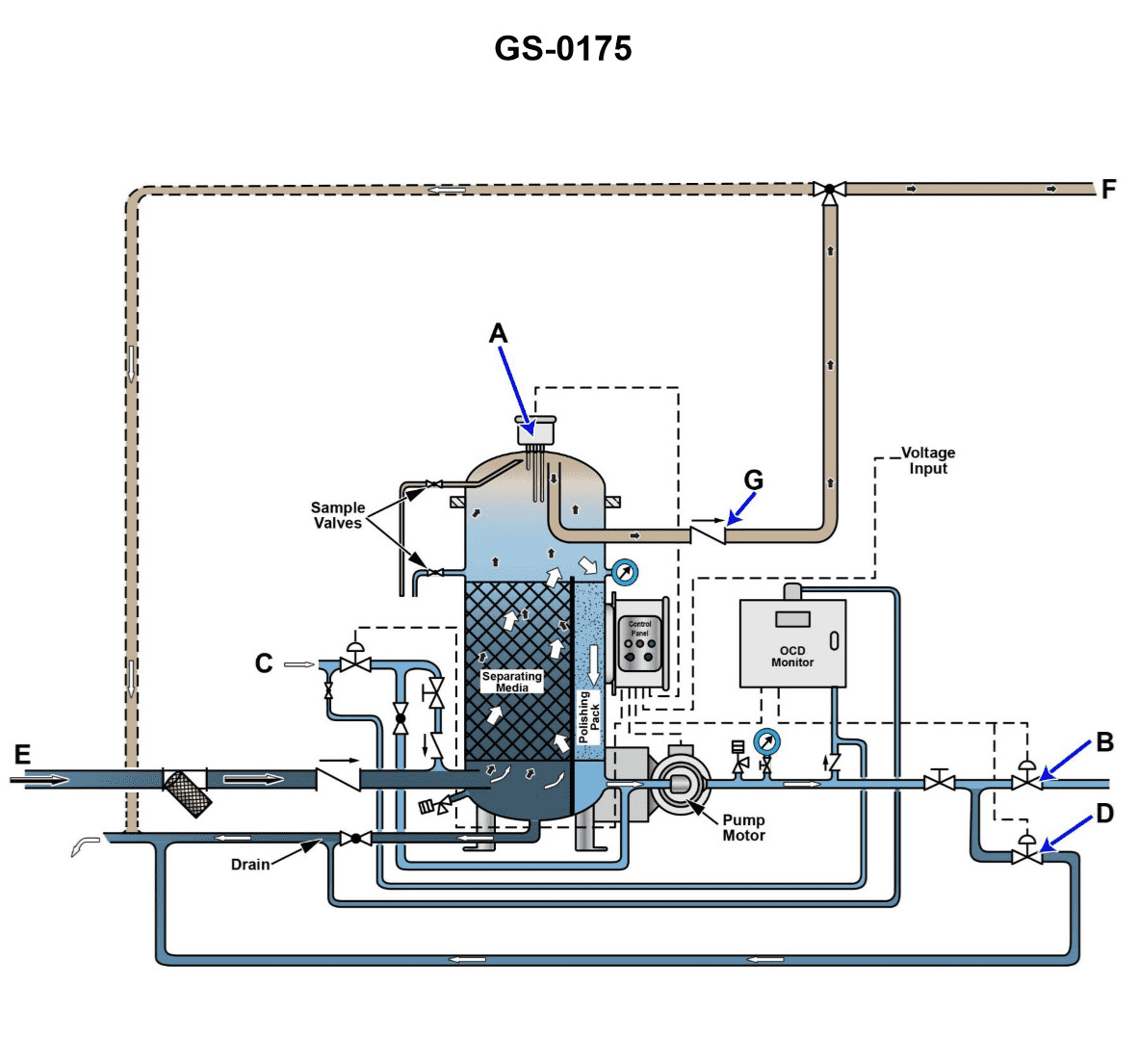

Question: Referring to the illustration, note that the solenoid in line "C" is closed. The check valve in line "E" is open. The separator service pump is running. The check valve in line "G" is closed. Valve "B" is closed. Valve "D" is open. What is the operational status of the oily-water separator unit? Illustration GS-0175

A. The oily-water separator is in the bilge water separation processing mode with water discharging back to the bilge water holding tank with an oil content greater than 15 ppm.

B. The oily-water separator is in the bilge water separation processing mode with water discharging overboard with an oil content less than 15 ppm.

C. The oily-water separator is in the bilge water separation processing mode with water discharging back to the bilge water holding tank with an oil content less than 15 ppm.

D. The oily-water separator is in the bilge water separation processing mode with water discharging overboard with an oil content greater than 15 ppm.

The Correct Answer is A ### Explanation for Option A being Correct Option A states that the oily-water separator (OWS) is in the bilge water separation processing mode with water discharging back to the bilge water holding tank with an oil content greater than 15 ppm. 1. **Processing Mode Confirmation:** The statement specifies that the "separator service pump is running," which immediately confirms the unit is actively in the **bilge water separation processing mode**. 2. **Flow Path Determination:** * The solenoid in line "C" (typically the overboard discharge line) is **closed**. This prevents discharge to the environment. * The check valve in line "E" (typically the recirculation or back-to-tank line) is **open**. * Because the overboard path (C) is closed and the recirculation path (E) is open, the separated water is flowing **back to the bilge water holding tank**. 3. **Oil Content Logic:** In a standard OWS control system, the flow path is automatically dictated by the Oil Content Monitor (OCM). When the OCM detects that the cleaned water exceeds the regulatory limit (15 ppm), the control system automatically closes the overboard valve (C) and opens the recirculation valve (E). Therefore, the system is recirculating because the effluent quality is **greater than 15 ppm**. ### Why Other Options Are Incorrect * **B) The oily-water separator is in the bilge water separation processing mode with water discharging overboard with an oil content less than 15 ppm.** * This is incorrect because the solenoid in line "C" (overboard discharge) is explicitly stated as **closed**. If the OCM registered less than 15 ppm, line C would be open, and line E would be closed. * **C) The oily-water separator is in the bilge water separation processing mode with water discharging back to the bilge water holding tank with an oil content less than 15 ppm.** * While the flow path (back to tank via E) is correct, the OCM status is incorrect. If the oil content were less than 15 ppm, the system's control logic would automatically discharge overboard (C open) rather than recirculating (E open). Recirculation is the result of exceeding the 15 ppm limit. * **D) The oily-water separator is in the bilge water separation processing mode with water discharging overboard with an oil content greater than 15 ppm.** * This is incorrect based on the flow path (Line C is closed, preventing overboard discharge). Furthermore, discharging water with an oil content greater than 15 ppm overboard is illegal and would indicate a major system failure, which contradicts the OWS actively engaging its recirculation protection mechanism (E being open).

Question 10

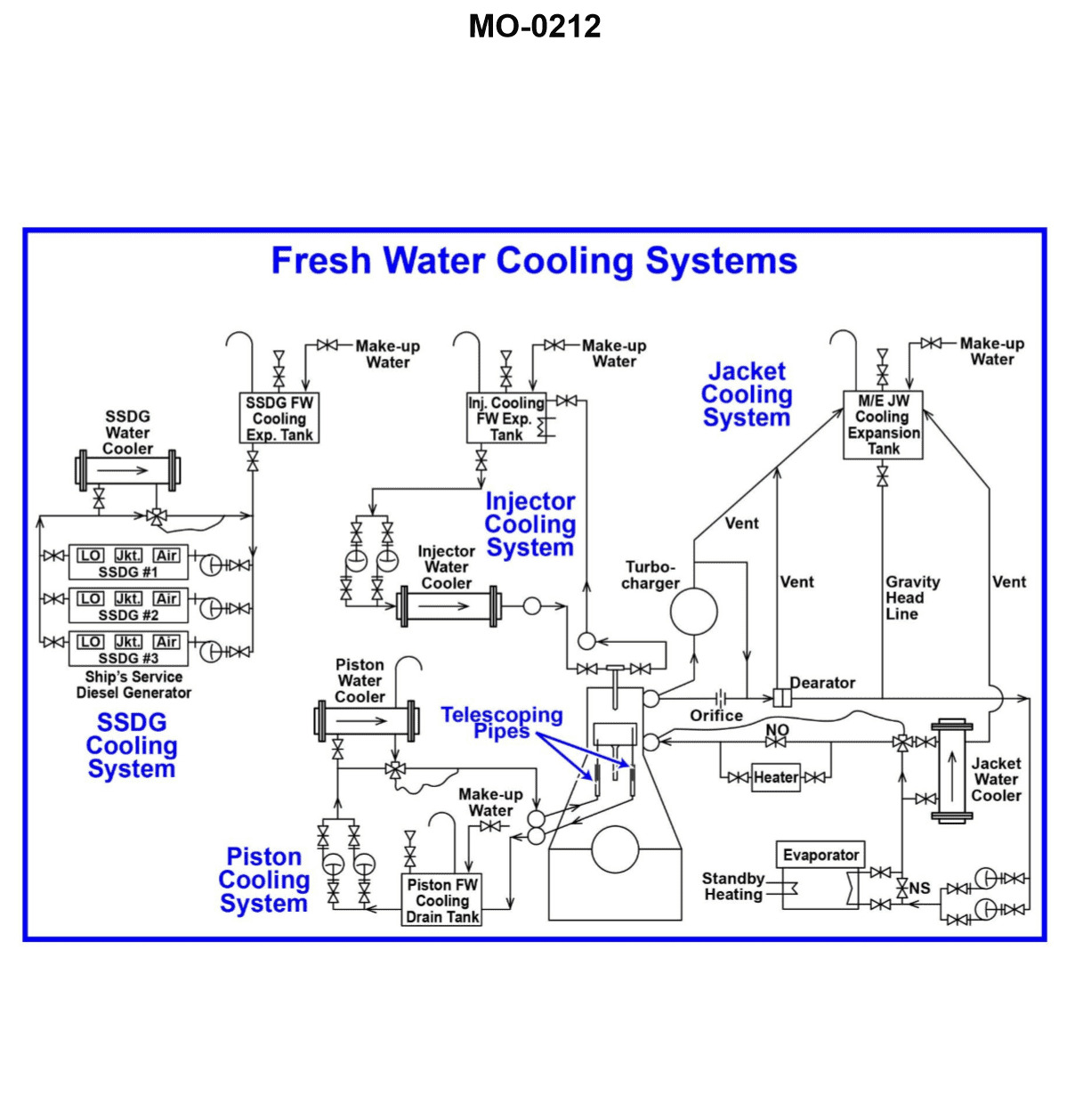

Question: Referring to the illustrated motorship freshwater cooling system drawing, what statement is true concerning the evaporator? Illustration MO-0212

A. The evaporator uses heat recovered from the main engine cooling water as a heat source to generate fresh water and is piped in series with and prior to the jacket water cooler.

B. The evaporator uses heat recovered from the main engine cooling water as a heat source to generate fresh water and is piped in parallel with the jacket water cooler.

C. The evaporator uses heat recovered from the main engine cooling water as a heat source to generate fresh water and is piped in series with and after the jacket water cooler.

D. The evaporator uses heat recovered from the jacket water cooler sea water as a heat source to generate fresh water and is piped in series with and prior to the jacket water cooler.

The Correct Answer is A. **Explanation for Option A (Correct):** Option A states that the evaporator uses heat recovered from the main engine cooling water (specifically, the jacket cooling water) as a heat source to generate fresh water, and is piped in series with and prior to the jacket water cooler. In shipboard freshwater cooling systems designed for heat recovery, the evaporator (or freshwater generator) is strategically placed to utilize the hottest available source of low-grade heat, which is the main engine jacket water. To maximize efficiency and ensure the jacket water temperature remains high enough for evaporation before it enters the main jacket water cooler, the flow is routed directly from the engine, through the evaporator (where it drops some heat), and then onwards to the jacket water cooler (where the rest of the heat is dumped to the sea). This placement ensures a series arrangement where the evaporator sees the water **prior** to the main cooler. **Explanation for Incorrect Options:** * **B) The evaporator uses heat recovered from the main engine cooling water as a heat source to generate fresh water and is piped in parallel with the jacket water cooler.** * While the heat source (main engine cooling water) is correct, piping the evaporator in parallel with the jacket water cooler would split the flow, potentially complicating temperature control and reducing the overall heat input to the evaporator (as not all the hottest water would pass through it), or reducing flow through the main cooler. Standard designs for maximizing heat recovery place the evaporator in series before the cooler. * **C) The evaporator uses heat recovered from the main engine cooling water as a heat source to generate fresh water and is piped in series with and after the jacket water cooler.** * This arrangement is incorrect because if the evaporator were placed **after** the jacket water cooler, the jacket cooling water would have already dumped most of its heat load to the sea water in the cooler. The water temperature entering the evaporator would be too low to efficiently produce fresh water, making the evaporator functionally useless for heat recovery. * **D) The evaporator uses heat recovered from the jacket water cooler sea water as a heat source to generate fresh water and is piped in series with and prior to the jacket water cooler.** * This is incorrect because the evaporator uses the **hot main engine jacket cooling water** (the high-temperature loop) as its heat source, not the warmed sea water discharge from the jacket water cooler. The heat transferred to the sea water is a waste product, whereas the jacket water is the intended recovery source.

Question 11

Question: The river push boat to which you are assigned is fitted with generator engines as partly shown in the illustration. What statement is true concerning the cylinders? Illustration MO-0163

A. The cylinder liners are of the wet type and are replaceable inserts.

B. The cylinder liners are of the dry type and are replaceable inserts.

C. The cylinder liners are of the jacketed type and are replaceable inserts.

D. The cylinder walls are integral (non-replaceable) to the cylinder block.

The Correct Answer is A ### Why Option A is Correct Option A states that **"The cylinder liners are of the wet type and are replaceable inserts."** This is the characteristic design choice for medium-to-large high-output diesel engines, such as those typically found powering river push boats (towboats). 1. **Wet Type Liners:** A wet liner is directly exposed to the engine coolant on its outer surface. This design offers superior heat dissipation because the cooling medium is in direct contact with the liner wall, which is essential for managing the high thermal loads of continuous duty marine diesel engines. 2. **Replaceable Inserts:** Cylinder liners are wear components. Designing them as replaceable inserts allows for significant maintenance savings. Instead of replacing the entire engine block when the cylinder bore wears down (or is damaged), technicians simply remove and replace the relatively inexpensive liner, restoring the engine to original specifications efficiently and cost-effectively. ### Why Other Options Are Incorrect **B) The cylinder liners are of the dry type and are replaceable inserts.** * **Incorrect:** Dry liners are fitted into a bored hole in the block and are not in direct contact with the coolant; the coolant contacts the block material surrounding the liner. While dry liners are used in some smaller engines, they do not offer the necessary cooling capacity for the sustained, high-power operation characteristic of large marine propulsion engines like those in a push boat. **C) The cylinder liners are of the jacketed type and are replaceable inserts.** * **Incorrect:** While the entire engine block is "jacketed" (surrounded by coolant passages), "jacketed type" is not the standard descriptive terminology used to differentiate liner types. The distinction is fundamentally between "wet" (direct coolant contact) and "dry" (indirect coolant contact). Therefore, this option uses non-standard or confusing terminology. **D) The cylinder walls are integral (non-replaceable) to the cylinder block.** * **Incorrect:** Integral cylinder walls (sometimes called parent bores) mean that the cylinder bore is machined directly into the cast iron of the engine block, with no separate liner. This design is almost exclusively limited to small automotive or low-duty industrial engines. It is fundamentally impractical for large, high-power marine diesel engines because it would necessitate scrapping or major remachining of the expensive engine block every time the cylinder bores wore out or were damaged. High-output marine diesels require the longevity and maintainability provided by replaceable liners.

Question 14

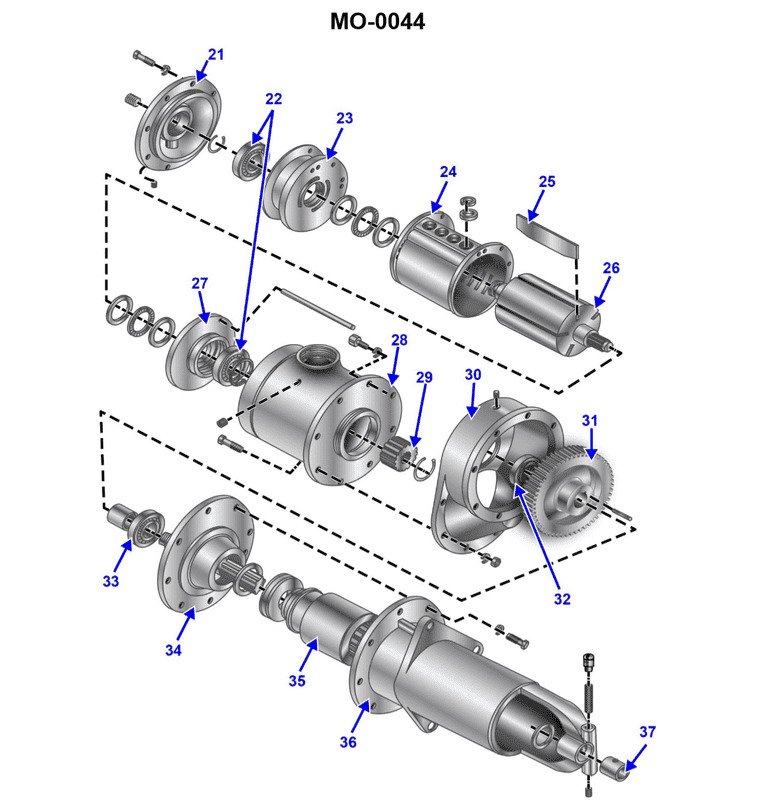

Question: The various auxiliary diesel engines fitted on your harbor tug may employ a variety of different cranking methods for engine starting. What type of cranking motor is shown in the illustration? Illustration MO-0044

A. Gasoline engine cranking motor

B. Hydraulic cranking motor

C. Air cranking motor

D. Electric cranking motor

The Correct Answer is C **Explanation for Option C (Air cranking motor):** An air cranking motor (or pneumatic starter) utilizes high-pressure compressed air to turn a turbine or vane mechanism, which subsequently engages the engine flywheel to initiate rotation. In marine and heavy industrial applications, these starters are very common on medium-sized diesel engines, such as those used for auxiliary power on tugboats. The illustration (MO-0044) typically depicts the distinct features of an air motor: a robust, often cylindrical housing containing the turbine or vanes, and a large inlet port specifically designed for connecting the high-pressure air supply line (lacking the heavy electrical terminals characteristic of electric motors). Air starting is favored in marine environments due to its high torque output and reliability, utilizing the ship's readily available compressed air system. **Explanation for Incorrect Options:** **A) Gasoline engine cranking motor:** This option is incorrect because a gasoline starting motor is typically a very small auxiliary engine used to turn over the main engine (common on vintage tractors or large, old stationary engines). Modern marine auxiliary diesels do not use this method. **B) Hydraulic cranking motor:** While powerful, hydraulic starters are less common than air or electric starters in standard auxiliary marine applications. They rely on high-pressure oil lines rather than air lines and possess a distinct internal gear pump structure, which would not match the appearance of a pneumatic turbine starter. **D) Electric cranking motor:** Electric motors are extremely common, but they are visually distinguished by the presence of heavy electrical terminals (for high amperage battery cables) and a large solenoid housing. If the illustration shows a robust starter with large inlet ports suitable for high-pressure air and lacks heavy copper terminals, it is definitively an air motor, not an electric motor.

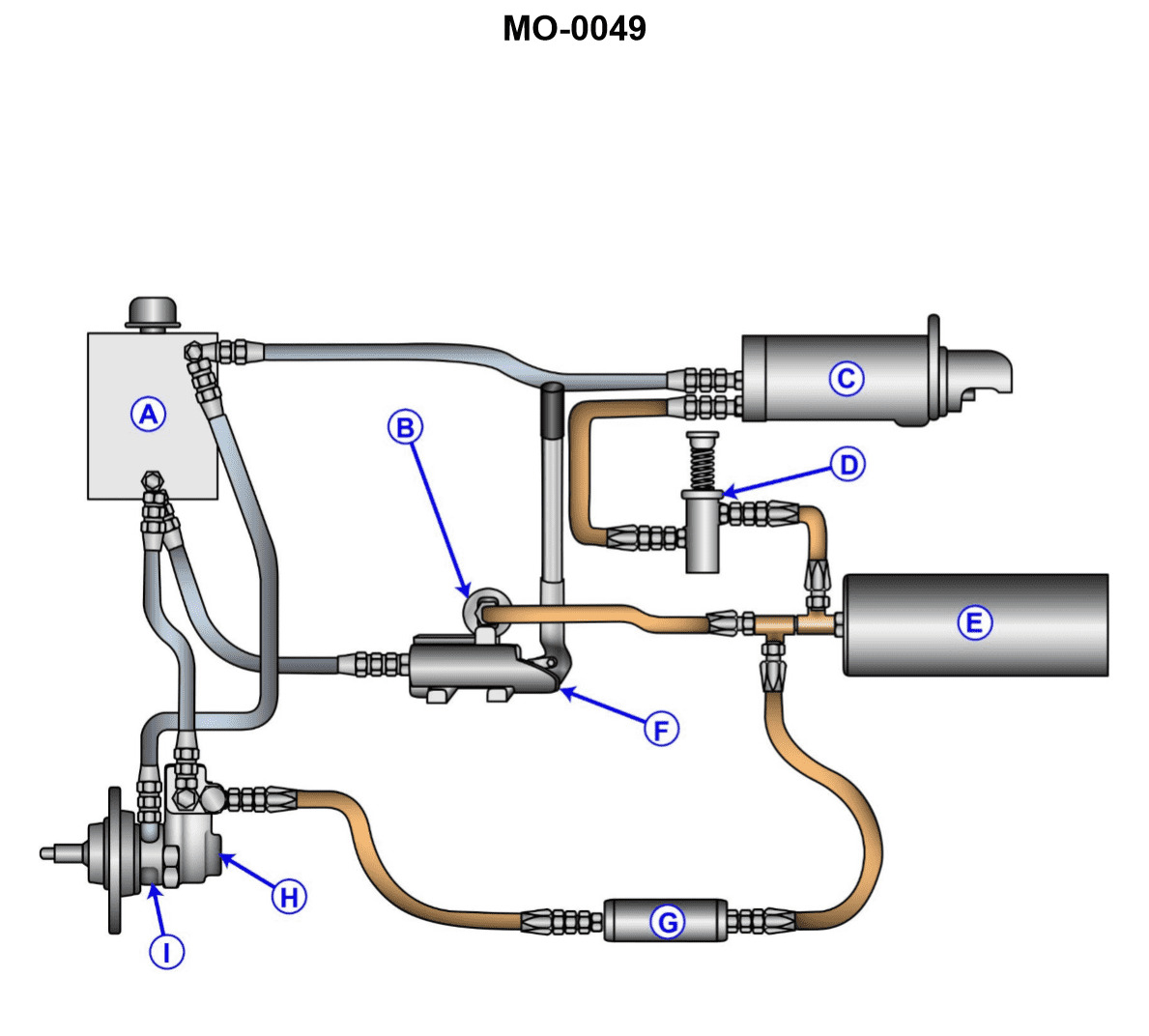

Question 15

Question: The various auxiliary diesel engines fitted on your sea-going tug may employ a variety of different starting systems. What type of starting system is shown in the illustration? Illustration MO-0049

A. Electric power operated system

B. Gas engine power operated system

C. Pneumatic power operated system

D. Hydraulic power operated system

The Correct Answer is D **Explanation for Option D (Hydraulic power operated system) being correct:** The starting system illustrated in typical marine engineering references (often identified by the number MO-0049 or similar designations in training materials) usually depicts the key components of a hydraulic starting system. These components typically include a manually operated or engine-driven pump (to charge the accumulator), a high-pressure accumulator (a storage vessel for pressurized oil), a control valve, and a hydraulic motor/starter unit directly mounted on the engine flywheel or pinion gear. The defining feature is the high-pressure fluid (oil) stored in the accumulator used to drive the starting motor, distinguishing it clearly from air (pneumatic) or electrical systems. **Explanation for why the other options are incorrect:** * **A) Electric power operated system:** This system uses batteries and a conventional electric starter motor (like those found in cars, but usually larger for marine auxiliary engines). The illustration would primarily show large cables, batteries, and the starter motor itself, lacking the pumps, accumulator, and hydraulic lines characteristic of option D. * **B) Gas engine power operated system:** This is a very uncommon or specialized starting method for modern marine auxiliary diesels. If used, it would typically involve a small gasoline or LPG engine used solely to spin the main diesel engine. The components illustrated do not match a small auxiliary combustion engine setup. * **C) Pneumatic power operated system:** This system uses high-pressure compressed air stored in receivers (air bottles) to turn the engine. While it uses an accumulator/receiver like a hydraulic system, the starter motor and lines are designed for air, and the illustration would typically show an air compressor and large air receivers, but not the distinct oil pump and fluid accumulator components used specifically in hydraulic starters.

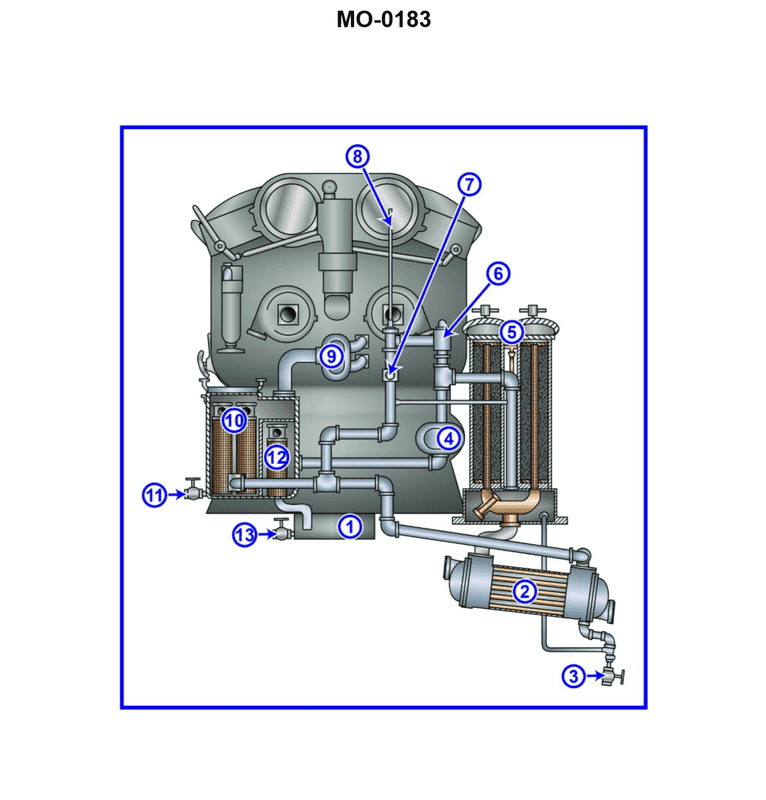

Question 16

Question: The main propulsion engines onboard your tractor tug use a lubricating oil system as shown in the illustration. What item number represents the lubricating oil filter? Illustration MO-0183

A. 2

B. 5

C. 10

D. 12

The Correct Answer is B. The item number representing the lubricating oil filter is **5**. In a typical forced-lubrication system for marine diesel engines, the oil must be continuously filtered to remove contaminants, sludge, and wear particles before being recirculated to the bearings and moving parts. Item 5 is positioned downstream of the oil cooler (4) and upstream of the main engine lubrication points (12), which is the standard location for the main engine lubricating oil filter in this type of system layout. **A) 2 is incorrect.** Item 2 represents the **Lubricating Oil Pump**. This pump draws oil from the sump (1) and provides the necessary pressure to circulate the oil throughout the system. **C) 10 is incorrect.** Item 10 typically represents the **Pressure Regulating Valve** or a control valve that dictates the flow of oil to a specific component, such as the Governor, or regulates system pressure by returning excess oil back to the pump suction or sump. **D) 12 is incorrect.** Item 12 represents the various **Main Engine Lubrication Points**, such as the main bearings, connecting rod bearings, camshaft bearings, and turbocharger bearings, where the clean, cooled oil is delivered under pressure.

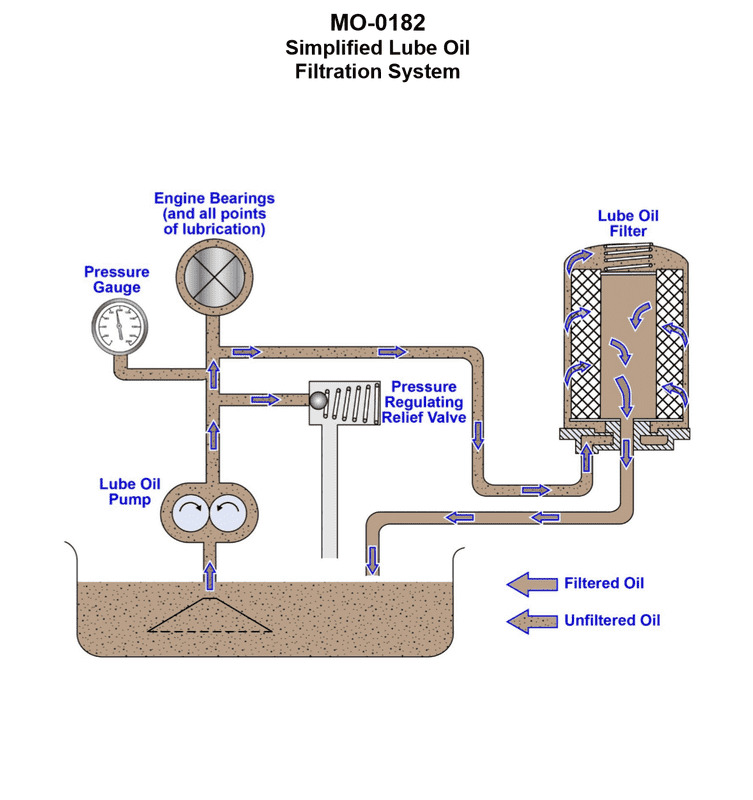

Question 17

Question: The deck winch drive engine onboard your salvage tug uses a lubricating oil filtration scheme as shown in the illustration. What type of filtration system is illustrated? Illustration MO-0182

A. Shunt filtration

B. Full-flow filtration

C. Sump filtration

D. Bypass filtration

The Correct Answer is D **Explanation for Option D (Bypass filtration) being correct:** The illustration MO-0182 typically depicts a system where only a small percentage (usually 5% to 15%) of the total lubricating oil flow from the main pump is diverted through a high-efficiency filter (often a depth-type or centrifugal filter) and then returned directly to the main oil sump, bypassing the main bearing supply line. The filter is often designed to remove extremely fine particulates and water, which a standard full-flow filter might miss. Since the majority of the oil is not filtered by this system before going to the bearings, and the filter operates continuously by filtering a *portion* of the oil *past* the main lubrication circuit, it is classified as a **Bypass filtration** system. **Explanation for why the other options are incorrect:** * **A) Shunt filtration:** While "shunt" is sometimes used interchangeably with "bypass" in general engineering terms, in the context of marine engine lubrication, "bypass filtration" is the standard and specific industry term for a system filtering a partial flow of oil and returning it to the sump. "Shunt filtration" is not the typical or preferred nomenclature. * **B) Full-flow filtration:** A full-flow system filters 100% of the oil before it is supplied to the bearings and critical components. If the illustration shows the filtered oil returning to the sump instead of supplying the main engine header, it is not a full-flow system. * **C) Sump filtration:** This term is generally too broad. While oil is drawn from the sump and returned to the sump, it does not describe the specific configuration of the filtration loop relative to the main lubrication circuit (i.e., whether it filters all or only a portion of the oil, or where the filtered oil is returned).

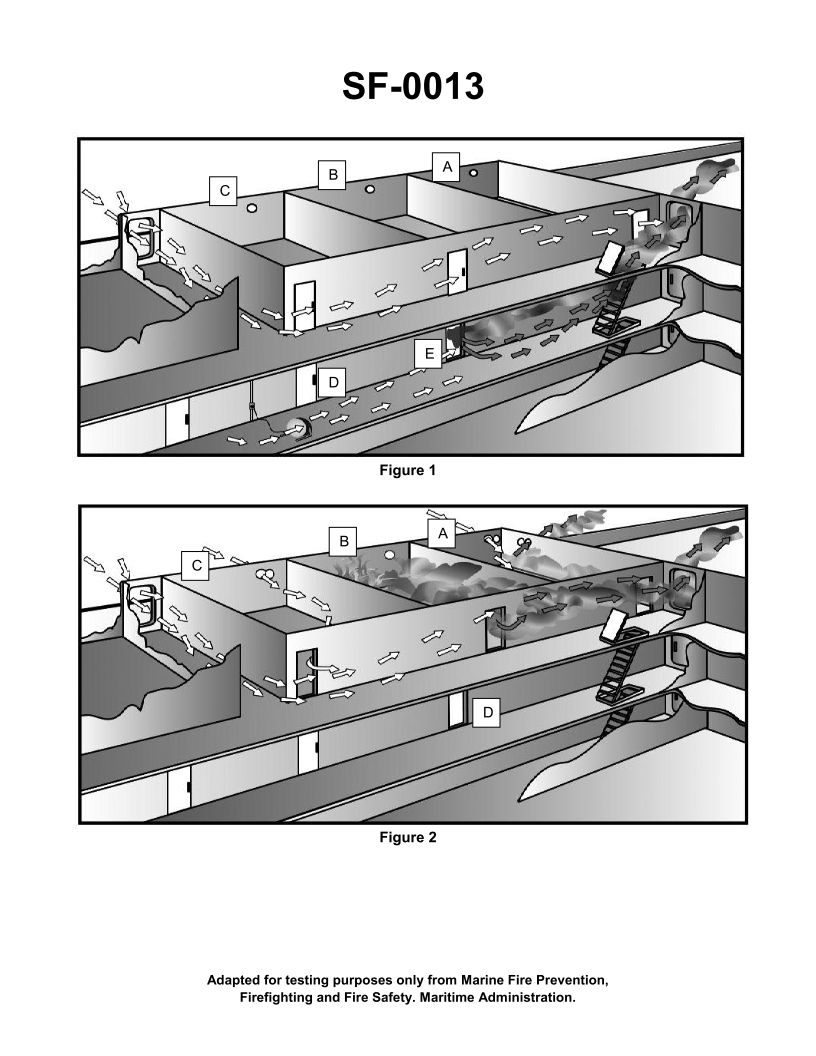

Question 18

Question: What is the purpose of opening the doors and portholes in figure 2 of the illustration? Illustration SF-0013

A. To allow venting of combustion products from the fire to the atmosphere

B. To allow water used to fight the fire to flow out of the superstructure

C. To keep the hose teams cool

D. To provide air flow around the compartment in order to contain the fire

The Correct Answer is A. **Explanation for why Option A is correct:** In firefighting operations, particularly aboard ships (as implied by the mention of "superstructure" and typical naval/maritime firefighting illustrations like SF-0013 often depict), the immediate ventilation of the compartment is critical once the fire is under control or suppression is actively underway. Opening doors and portholes (or other ventilation points) serves primarily to allow the hot gases, smoke, and toxic combustion products to escape to the atmosphere. This process, known as vertical or horizontal ventilation, significantly improves conditions for the firefighting teams (visibility, reduced heat stress, and lower exposure to toxic gases) and prevents the dangerous buildup of flammable gases (smoke explosion/flashover risk). Therefore, venting combustion products is the primary purpose of opening access points during the fire fighting phase shown in the illustration. **Explanation for why the other options are incorrect:** * **B) To allow water used to fight the fire to flow out of the superstructure:** While water drainage is necessary, it is usually a secondary benefit or a separate action (e.g., using elephant trunks or specific drainage systems) after the fire is suppressed. The *primary* and immediate reason for opening doors/portholes during active firefighting is atmospheric venting, not water drainage, which often occurs at deck level. * **C) To keep the hose teams cool:** While venting the compartment does reduce ambient temperatures and helps keep teams cooler, this is a *result* of venting the hot combustion gases, not the primary strategic purpose for initiating the ventilation. The main goal is atmospheric management and gas removal. * **D) To provide air flow around the compartment in order to contain the fire:** Providing airflow usually *feeds* the fire (oxygenating it). Controlled ventilation is used to remove harmful gases *after* the fire is being suppressed or contained, or in tactical ways to direct heat/smoke away, but generally, introducing fresh air into a burning compartment without control intensifies the fire, making this purpose contradictory to containment.

Question 19

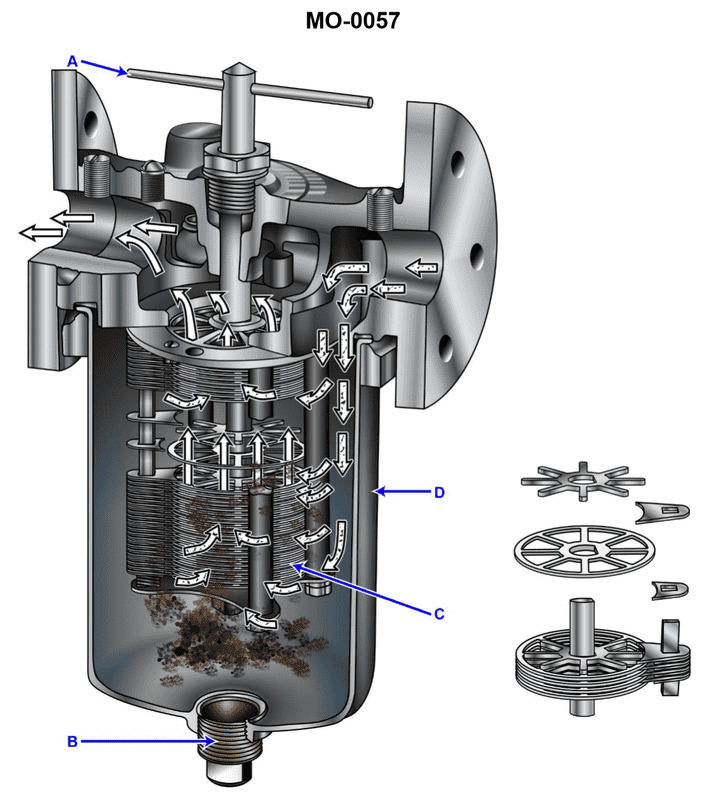

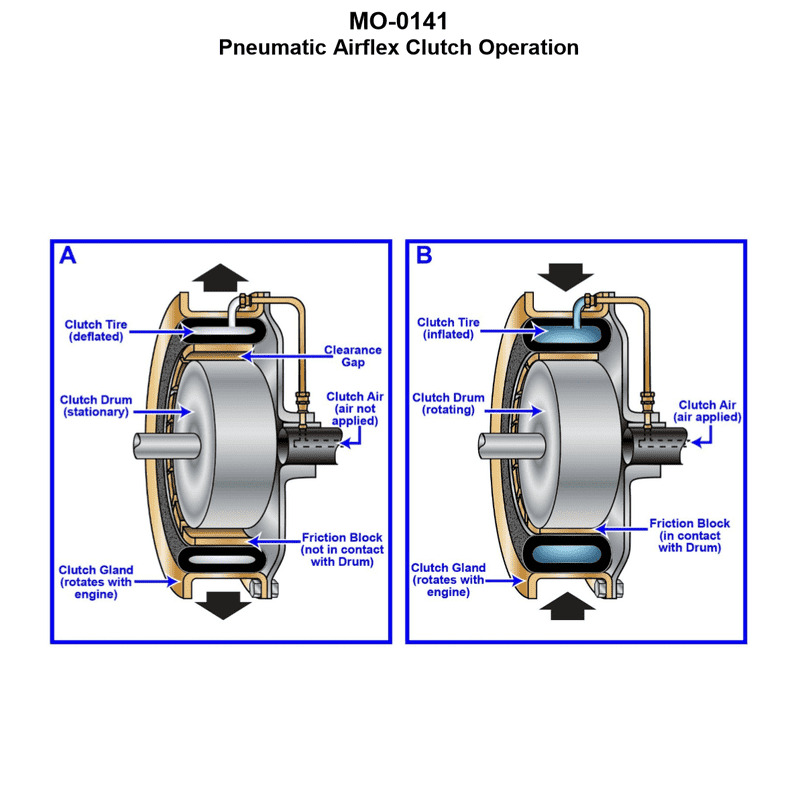

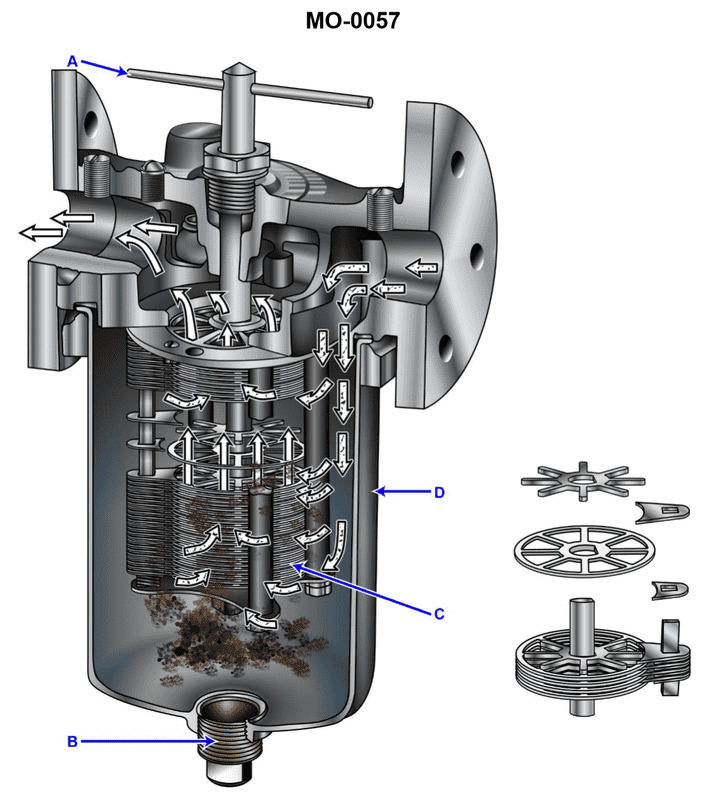

Question: A diesel generator set on your salvage tug has a simplex lube oil strainer of the type shown in the illustration, situated on the discharge side of the lube oil pump. At a specified engine rpm and lube oil temperature, you notice that the pressure drop becomes unacceptably high. When you rotate the cleaning handle you notice that it is extremely difficult to rotate. What should be done? Illustration MO-0057

A. After stopping the engine, the strainer element should be withdrawn and soaked in solvent to break up the heavy deposits on the disk stack (C).

B. The cleaning handle (A) should be forced to rotate, even if it requires an extender handle to produce greater rotating torque.

C. After stopping the engine, the drain plug (B) should be removed to drain the accumulated sludge from the strainer sump.

D. No special consideration need be taken as long as the cleaning handle (A) rotates, even if it rotates with great difficulty.

The Correct Answer is A **Explanation for Option A (Correct):** The problem describes a situation where the pressure drop across the lube oil strainer is unacceptably high, and the cleaning handle is extremely difficult to rotate. This specific type of simplex strainer (often a metal edge or plate-type strainer like the one typically implied by Illustration MO-0057) is cleaned by rotating the handle (A), which causes scrapers or combs to clean the disk stack (C). If the handle is extremely difficult to rotate, it indicates that the disk stack (C) is severely and densely clogged with hard, tenacious sludge, carbon, or heavy residues that the internal scrapers cannot easily dislodge or break up. Since the simple scraping action is failing, the only effective remedy is a thorough manual cleaning. To do this safely and effectively, the engine must be stopped, the element must be removed (withdrawn), and the severe deposits must be broken down by soaking the element in a suitable solvent before physical cleaning. This restores the required flow area and reduces the pressure drop to an acceptable level. **Explanation of Incorrect Options:** * **B) The cleaning handle (A) should be forced to rotate, even if it requires an extender handle to produce greater rotating torque.** Forcing the handle could damage the delicate internal scraping mechanism, warp the strainer disks, or potentially shear the shaft or handle mechanism. Strainer assemblies are precision components and should not be subjected to excessive, non-designed torque. Furthermore, even if forced, the severely impacted debris may only be partially scraped off, leading to rapid re-clogging and further damage. * **C) After stopping the engine, the drain plug (B) should be removed to drain the accumulated sludge from the strainer sump.** While draining the sump via plug (B) is a necessary routine maintenance step to remove accumulated sludge that has fallen off the disks, it addresses the sludge *after* it has been removed from the stack. The primary problem here is the *clogging* of the disk stack (C) which is causing the high differential pressure and preventing the handle from turning easily. Draining the sump will not clear the tenacious deposits stuck firmly between the strainer disks. * **D) No special consideration need be taken as long as the cleaning handle (A) rotates, even if it rotates with great difficulty.** The fact that the pressure drop is "unacceptably high" is itself a special consideration. High differential pressure compromises lubrication flow, potentially leading to lube starvation or bypass activation (if equipped), which can cause catastrophic engine damage. The difficulty in rotation signals a dangerous level of clogging that requires immediate attention, not neglect.

Question 21

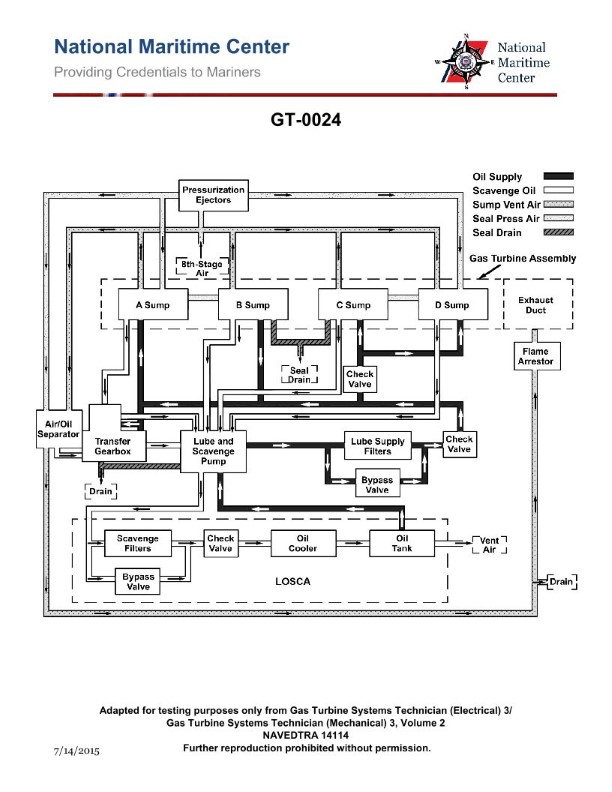

Question: What is the purpose of the air/oil separator shown in the illustration of the gas turbine lube oil system? Illustration GT-0024

A. Maintain oil pressure in the sumps

B. Minimize oil consumption by separating oily vapors being vented to the atmosphere

C. Reduce oil foaming

D. All of the above

The Correct Answer is B **Why option B is correct:** The air/oil separator (also commonly called a breather separator or demister) in a gas turbine lube oil system is designed to handle the air/vapor mixture that is vented from the bearing sumps (where the hot oil and rotating components create mist and vapor). This mixture contains fine droplets of lubricating oil carried by the vent air. The primary function of the separator is to strip or separate these oil droplets from the air stream before the air is discharged (vented) to the atmosphere. By capturing and returning this separated oil back to the system's main tank or sump, the separator effectively **minimizes oil consumption** that would otherwise be lost to the atmosphere as pollution (oily vapors). **Why the other options are incorrect:** * **A) Maintain oil pressure in the sumps:** The air/oil separator is installed on the *vent* line (the exhaust side of the sump pressure control system). While the overall lube oil system maintains proper air pressure (sump pressurization) to ensure proper bearing seals and oil flow, the *separator itself* is not the component responsible for regulating or maintaining the positive pressure inside the sump. Its function is purely separation and oil recovery from the vented air stream. * **C) Reduce oil foaming:** Oil foaming typically occurs within the main oil tank or sumps due to aeration, excessive agitation, or contamination (like water). While preventing the venting of large quantities of aerated oil might be a related issue, the air/oil separator's location and design purpose are specifically for recovering oil mist from the *vent air*, not for actively reducing foaming within the bulk oil reservoir. That function is usually handled by proper tank design, residence time, and anti-foaming additives. * **D) All of the above:** Since options A and C describe functions primarily handled by other components or system design parameters (sump pressurization valves, anti-foaming agents, or tank configuration), this option is incorrect.

Question 22

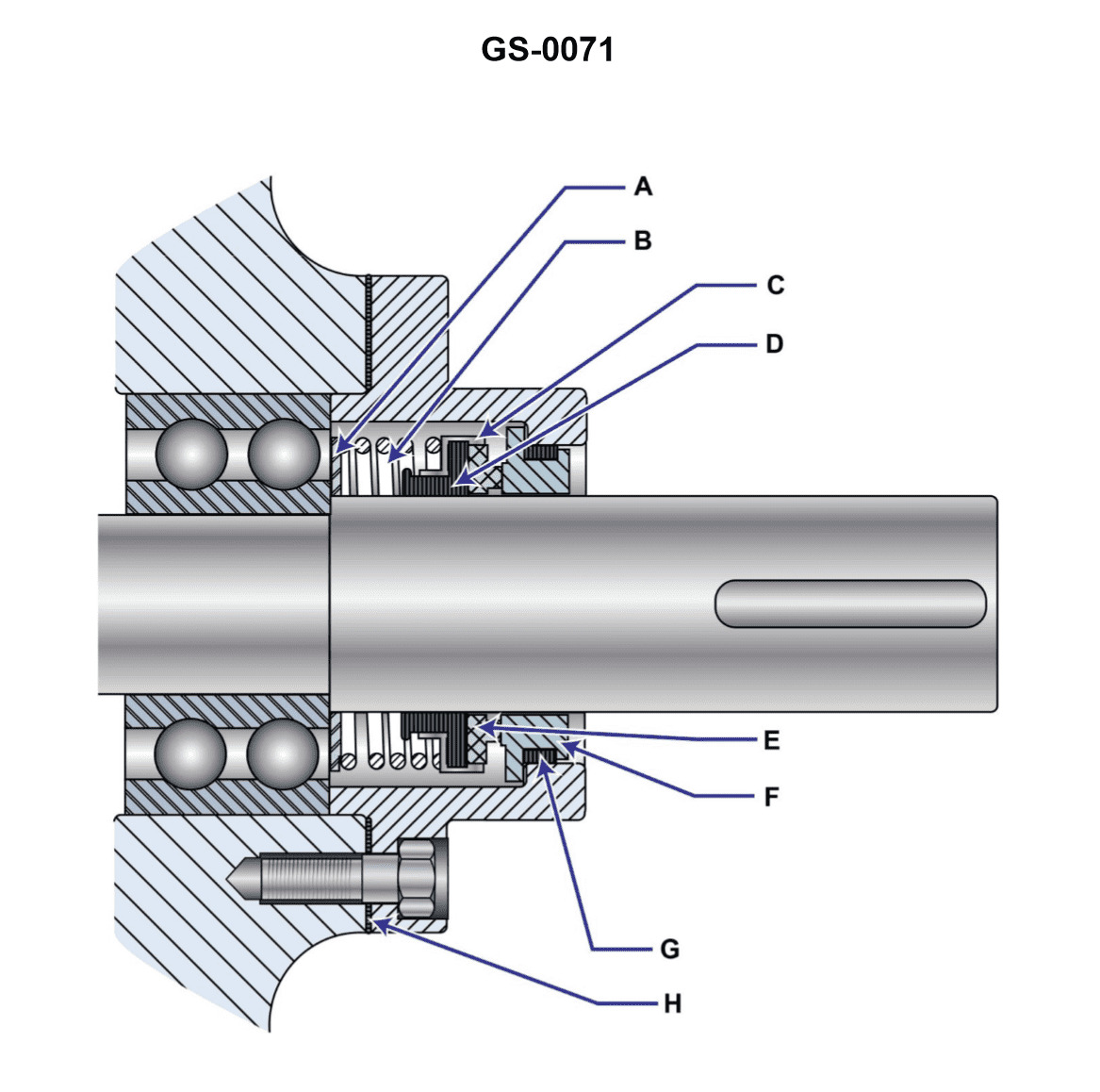

Question: Which of the devices listed is used to maintain a snug interface between the rotating and stationary seal members shown in the illustration? Illustration GS-0071

A. spring

B. notch and keyway

C. bellows

D. seal retaining ring

The Correct Answer is A **Explanation for Option A (spring):** In mechanical seals, the primary function of the seal is to prevent leakage along a rotating shaft. This requires maintaining continuous contact and a snug interface (often called face loading) between the stationary seal ring and the rotating seal ring. A **spring** (or multiple springs) is typically incorporated into the seal assembly specifically to provide the necessary axial force (load) to push the primary seal face against the mating ring, thereby maintaining the critical sealing interface even as the seal faces wear down or if there are minor thermal expansions/contractions or shaft movements. **Explanation of Incorrect Options:** * **B) notch and keyway:** A notch and keyway are used to ensure the non-rotating (or stationary) seal member does not rotate with the shaft, or to fix the rotating element to the shaft (anti-rotation). They ensure positional stability or torque transmission, but they do not provide the axial force needed to maintain a snug interface or compensate for wear. * **C) bellows:** A bellows (often made of elastomer or metal) is sometimes used as a secondary seal element or as a method of driving the primary seal face. While it can apply some force, its primary function in many seal designs is to act as a flexible, dynamic secondary seal and/or to transmit the spring force while accommodating axial movement, not to be the sole provider of the necessary consistent face loading force itself. Springs are the standard component for maintaining continuous axial pressure. * **D) seal retaining ring:** A seal retaining ring (or snap ring) is typically used to hold the seal components, such as the stationary element, within its housing or gland. It is a static component used for assembly retention and does not provide the dynamic axial force required to maintain the snug sealing interface.

Question 23

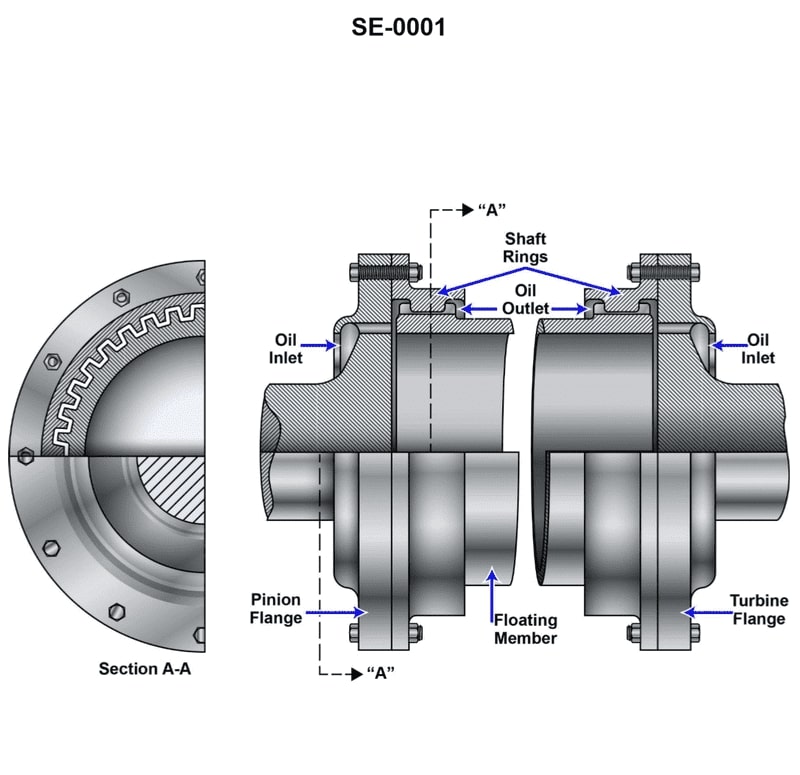

Question: Which of the coupling types listed is shown in the illustration? Illustration SE-0001

A. Solid

B. Pin

C. Gear

D. Claw

The Correct Answer is C **Explanation for Option C (Gear):** The illustration (SE-0001, assumed to depict a mechanical coupling) shows two hubs connected by an external component that facilitates torque transmission while accommodating misalignment. A gear coupling achieves this through two internal/external gear mesh sets (one on each shaft end) housed within a sleeve. This design allows for angular, parallel, and axial movement (float) while maintaining constant velocity, making "Gear" the correct classification for a coupling operating on this principle. **Why other options are incorrect:** * **A) Solid:** A solid coupling is a rigid connection that joins two shafts without any allowance for misalignment. It is typically a single, non-articulating block or sleeve, which contrasts with the multi-component, articulating nature required to accommodate misalignment typically shown in illustrations of flexible couplings. * **B) Pin:** Pin couplings (or flexible pin and bush couplings) transmit torque through metal pins inserted into flexible bushes or pads (often made of rubber or polyurethane) mounted on the opposing flange. They do not use meshing teeth or gears for connection. * **D) Claw:** Claw couplings (sometimes called Jaw or Oldham couplings) connect the shafts using interlocking jaws or lugs. While they are flexible and can handle misalignment, they rely on direct engagement of these projecting elements, which is mechanically distinct from the fine meshing teeth used in a gear coupling.

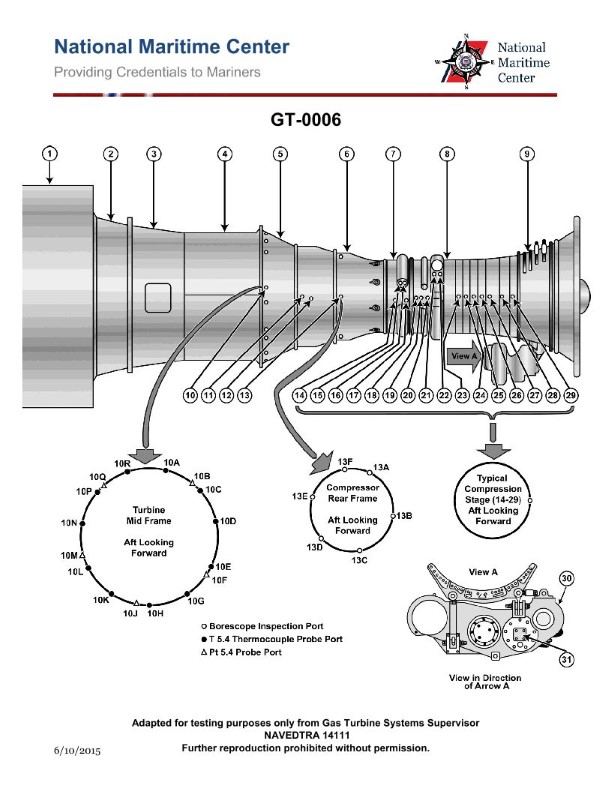

Question 23

Question: What type of engine starter motor is commonly found on the marine gas turbine shown in the illustration? Illustration GT-0006

A. AC synchronous motor

B. Hydraulic motor

C. DC series wound electric motor

D. AC induction motor

The Correct Answer is B **Explanation for Option B (Hydraulic motor):** Hydraulic starter motors are very commonly used for starting marine gas turbines (especially on larger commercial or naval applications) because they offer extremely high torque in a compact, lightweight package. Gas turbines require a high amount of power to rapidly spin the compressor and overcome inertia and windage losses until they reach the self-sustaining speed (light-off speed). Hydraulic systems utilize pressurized fluid (often supplied by an auxiliary power unit or an dedicated accumulator system) to drive the starter. This method provides reliable, high-power starting capabilities critical for the rapid starting requirements of a marine gas turbine. **Explanation for Incorrect Options:** **A) AC synchronous motor:** While AC motors are widely used in marine applications, synchronous motors are typically used where precise, constant speed is required (e.g., generators or propulsion motors). They are generally too large, heavy, and complex for the high-torque, intermittent duty cycle required of a gas turbine starter. **C) DC series wound electric motor:** DC series motors were historically the standard for smaller piston engines and some smaller turboprops due to their high starting torque. However, for the very large horsepower required to start a large modern marine gas turbine, a DC electric starter would need to be physically massive, drawing enormous current, and requiring a very large battery bank or complex high-voltage DC system, making them less practical and efficient than hydraulic or pneumatic starters. **D) AC induction motor:** Induction motors are rugged and common, but they typically have lower starting torque compared to hydraulic motors or DC series motors for a given size and weight. Furthermore, they would require a frequency converter (Variable Frequency Drive, VFD) to control the speed and torque profile necessary during the turbine start cycle, adding significant complexity and weight compared to a simple hydraulic system.

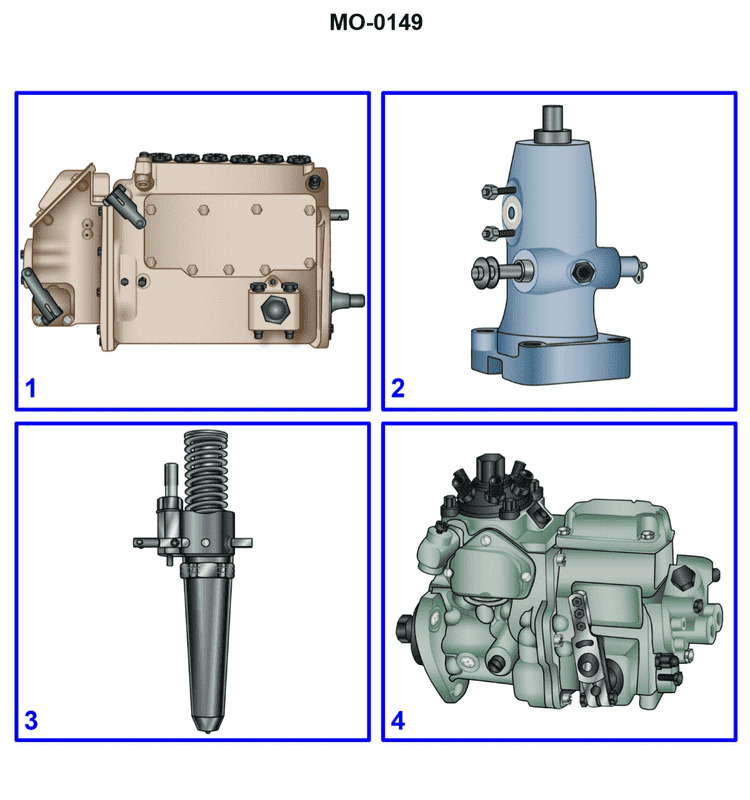

Question 24

Question: The harbor tug to which you are assigned has a diesel engine fitted with a rotary plunger distributor type pump. Which figure of the illustration represents the most likely type of fuel injection equipment used? Illustration MO-0149

A. 1

B. 2

C. 3

D. 4

The Correct Answer is D **Explanation for Option D (4) being correct:** Option D, representing Figure 4, illustrates a **Distributor Pump** (specifically, a Rotary Plunger Distributor pump, like a Bosch VE type). The question explicitly states that the diesel engine is fitted with a **rotary plunger distributor type pump**. Figure 4 is the visual representation of this type of pump, which uses a single metering/pumping plunger and distributes high-pressure fuel sequentially to all cylinders via a rotary motion. This matches the description given in the prompt exactly. **Explanation for why the other options are incorrect:** * **Option A (1):** Figure 1 typically illustrates an **Individual Pump** or **Unit Injector System (UIS)**, where the pump and injector are combined into a single unit actuated by the camshaft (often found in newer high-speed engines). This is not a centralized rotary plunger distributor pump. * **Option B (2):** Figure 2 typically illustrates a **Jerk Pump** or **Inline Pump** system. In this system, there is a separate pumping element (plunger and barrel) for each cylinder, all contained within one housing and actuated by a common camshaft. This is a common type of pump for marine and older heavy-duty applications, but it is not a *rotary plunger distributor* pump. * **Option C (3):** Figure 3 typically illustrates a **Common Rail (CR)** system. This system uses a high-pressure pump to continuously pressurize a common rail (accumulator), and solenoid or piezo injectors are used to deliver fuel based on an electronic control unit (ECU). While advanced harbor tugs might use this, the pump itself is a high-pressure continuous pump, not the specific mechanical *rotary plunger distributor* type described.

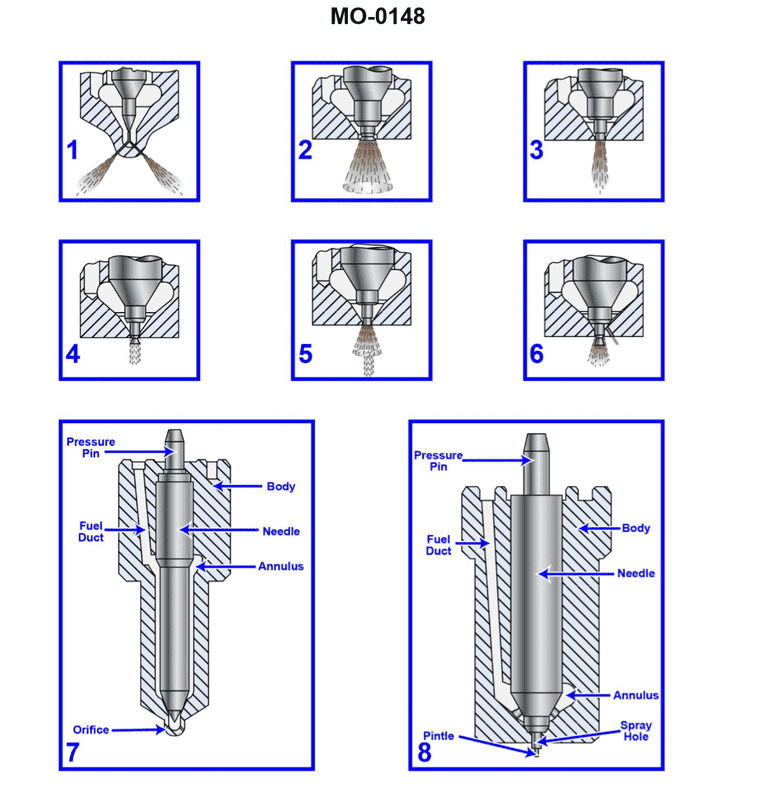

Question 25

Question: The harbor tug to which you are assigned has main engines fitted with open type combustion chambers featuring direct injection. Of the listed figures below found in the illustration, which figure represents the most likely type of injector nozzle type? Illustration MO-0148

A. 1

B. 2

C. 3

D. 4

The Correct Answer is A. **Explanation for Option A (1 being correct):** Figure 1 represents a **multi-hole nozzle** (typically featuring 4 to 12 holes). This type of nozzle is the standard choice for **open type combustion chambers featuring direct injection** in medium and high-speed diesel engines, such as those typically found in harbor tugs. The design allows the fuel spray to be precisely distributed across the large volume of the open combustion chamber, ensuring efficient mixing of fuel and air (turbulence) to achieve complete combustion and high power output. **Explanation for why other options are incorrect:** * **Option B (2):** Figure 2 represents a **pintle nozzle**. Pintle nozzles are generally used in smaller, high-speed engines utilizing **pre-combustion chambers** or **swirl chambers** (indirect injection systems). They are not typically used for direct injection into large, open combustion chambers of medium-speed marine engines due to their limited spray coverage. * **Option C (3):** Figure 3 represents a **long stem pintle nozzle** or an early variation of a single-hole nozzle designed for specific chamber types, sometimes used in pre-chamber designs. Like the standard pintle nozzle, it lacks the multi-spray pattern necessary for the efficient filling and combustion in a large, open, direct-injection chamber. * **Option D (4):** Figure 4 represents a **single-hole nozzle** (or possibly a throttling pintle nozzle variant). Single-hole nozzles create a highly concentrated, narrow spray pattern, which is unsuitable for achieving uniform mixing across the wide volume of an open combustion chamber. This leads to poor combustion efficiency and localized high temperatures.

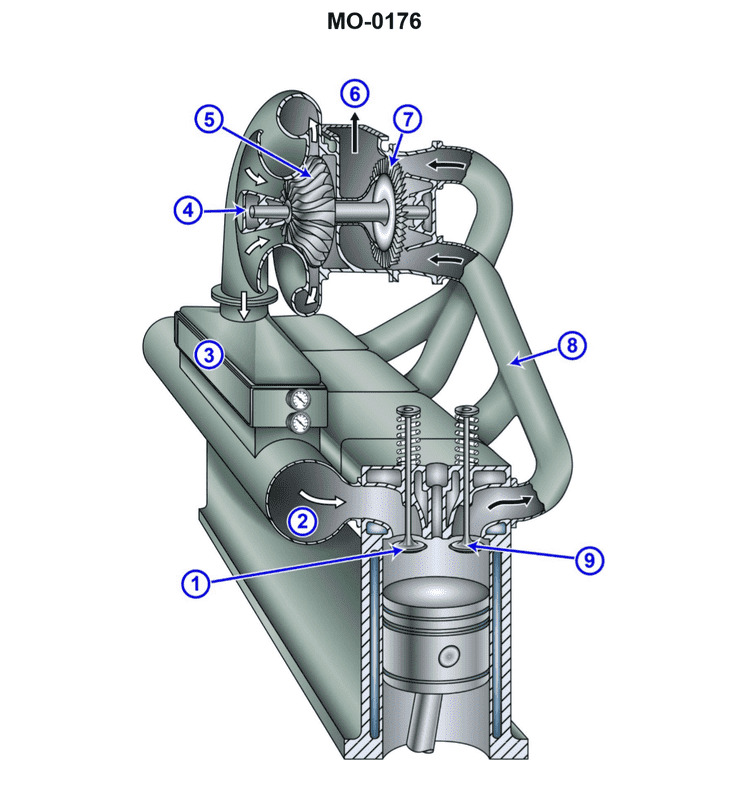

Question 26

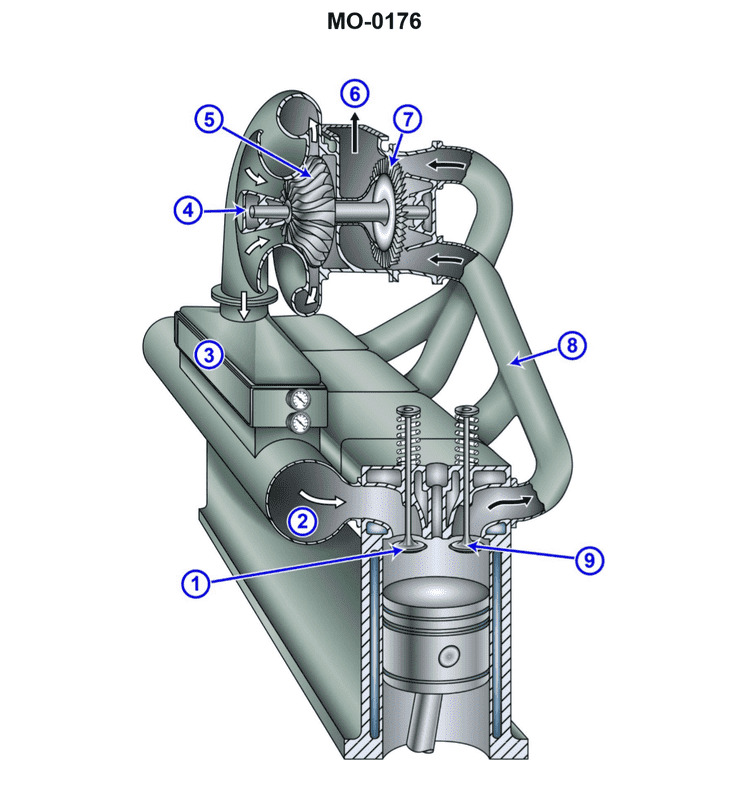

Question: The river push boat to which you are assigned has diesel generators fitted with intake and exhaust systems as shown in the illustration. What does the component labeled "3" represent? Illustration MO-0176

A. Wet muffler

B. Charge air cooler

C. Charge air manifold

D. Exhaust manifold

The Correct Answer is B **Explanation for Option B (Charge air cooler):** The component labeled "3" is situated directly after the turbocharger compressor (which would be labeled "2" if the turbocharger itself is labeled "1") and before the engine intake manifold (charge air manifold, labeled "4"). Its primary function in this position is to cool the compressed air coming from the turbocharger before it enters the engine cylinders. Compressing air heats it significantly; cooling this air increases its density, allowing more oxygen into the cylinder, which leads to greater engine power and efficiency while reducing the thermal stress on the engine components. This device is universally known as a charge air cooler (also often called an intercooler or aftercooler). **Explanation for Incorrect Options:** * **A) Wet muffler:** A muffler is part of the exhaust system, designed to reduce noise. A wet muffler uses water injection for cooling and noise suppression, but it would be located at the end of the exhaust line (past component 5, the turbocharger turbine housing), not in the air intake path. * **C) Charge air manifold:** The charge air manifold (or intake manifold) is the chamber or set of runners that distributes the cooled, compressed air from component 3 into the individual engine cylinder intake ports. Component 3 is positioned *before* the manifold (which is typically labeled 4 in standard diagrams). * **D) Exhaust manifold:** The exhaust manifold is located on the exhaust side of the engine, collecting hot exhaust gases from the cylinders and directing them into the turbocharger turbine. It is entirely separate from the intake air path where component 3 is located.

Question 27

Question: The river push boat to which you are assigned has diesel generators fitted with intake and exhaust systems as shown in the illustration. What does the component labeled "2" represent? Illustration MO-0176

A. Wet muffler

B. Exhaust manifold

C. Charge air manifold

D. Charge air cooler

The Correct Answer is C **Explanation for Option C (Charge air manifold):** The Charge Air Manifold (also known as the intake manifold or plenum) is the component responsible for collecting the high-pressure, cooled air delivered by the turbocharger/charge air cooler system and distributing it evenly to the intake ports of the individual cylinders. Since the illustration refers to a diesel generator with intake and exhaust systems, and component "2" is positioned after the cooling stage (usually labeled as a charge air cooler, D), its function must be to deliver the boosted air to the engine cylinders. Therefore, component "2" represents the Charge Air Manifold. **Why the other options are incorrect:** * **A) Wet muffler:** A muffler is part of the **exhaust system** and is used to dampen engine noise. Component "2" is positioned within the intake (air) system flow, making this incorrect. * **B) Exhaust manifold:** The Exhaust Manifold collects spent gases **after** combustion and directs them to the turbocharger turbine or directly out of the engine. Component "2" is involved with the air entering the engine, making this incorrect. * **D) Charge air cooler:** The Charge Air Cooler (CAC) removes heat from the air compressed by the turbocharger, increasing the density of the air charge. While air passes through the CAC *before* the manifold, the manifold (C) is the distribution component itself. If "2" is the final distribution point just prior to the cylinder head, it is the manifold, not the cooler.

Question 27

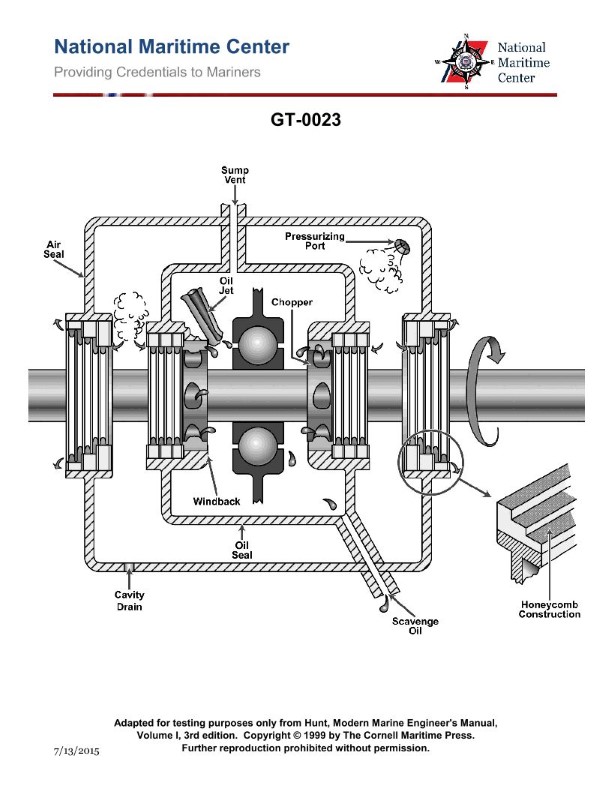

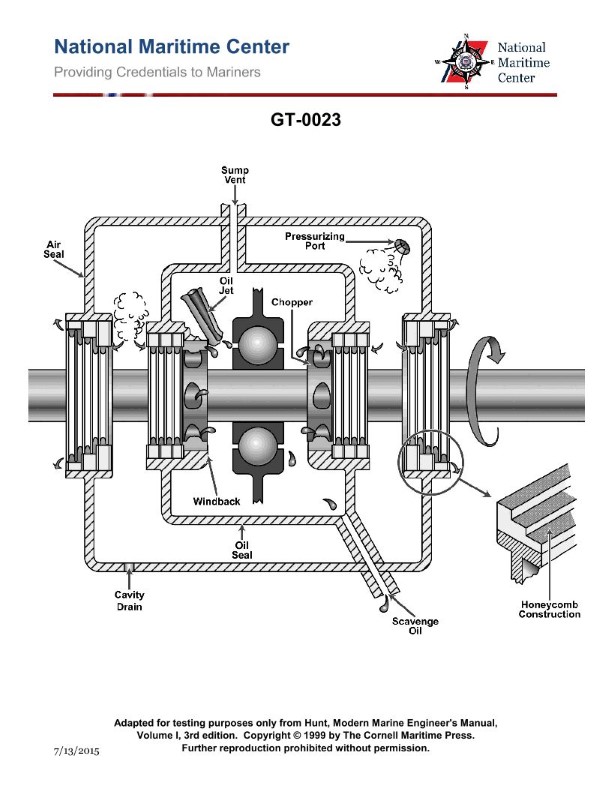

Question: As shown in the illustration, what is the purpose of pressurizing the main bearing lube oil sumps on a typical marine gas turbine? Illustration GT-0023

A. Provides uniform lube oil distribution around the bearing.

B. Minimizes oil leakage from the rotor shaft.

C. Increases lube oil penetration.

D. Assists in cooling the lube oil.

The Correct Answer is B **Explanation for B (Minimizes oil leakage from the rotor shaft.):** On marine gas turbines, the main bearing lube oil sumps (or compartments/cavities) are pressurized with air (often called "buffer air" or "sealing air"). This pressurized air acts as a barrier or seal. The main purpose of this pressurized air is to prevent the lubricating oil, which is actively sprayed or flowing inside the sump, from escaping past the labyrinth seals or oil slingers along the high-speed rotor shaft, especially into the adjacent high-temperature compressor or turbine sections. By maintaining a pressure differential where the air pressure is higher than the oil pressure in the sealing area, oil is forced back into the sump, thus minimizing leakage and conserving the oil. **Why the other options are incorrect:** * **A) Provides uniform lube oil distribution around the bearing:** Lube oil distribution is achieved through oil jets, spray nozzles, and oil flow paths, not by pressurizing the air space within the sump cavity itself. * **C) Increases lube oil penetration:** The lubrication itself is driven by the pressure of the oil supply pump and the design of the oil passages, not by the air pressure maintained in the surrounding sump cavity. * **D) Assists in cooling the lube oil:** Cooling is primarily achieved by passing the returned lube oil through heat exchangers (coolers). While the air circulation might offer some minor secondary cooling effect, the primary function of pressurization is sealing, not thermal regulation.

Question 28

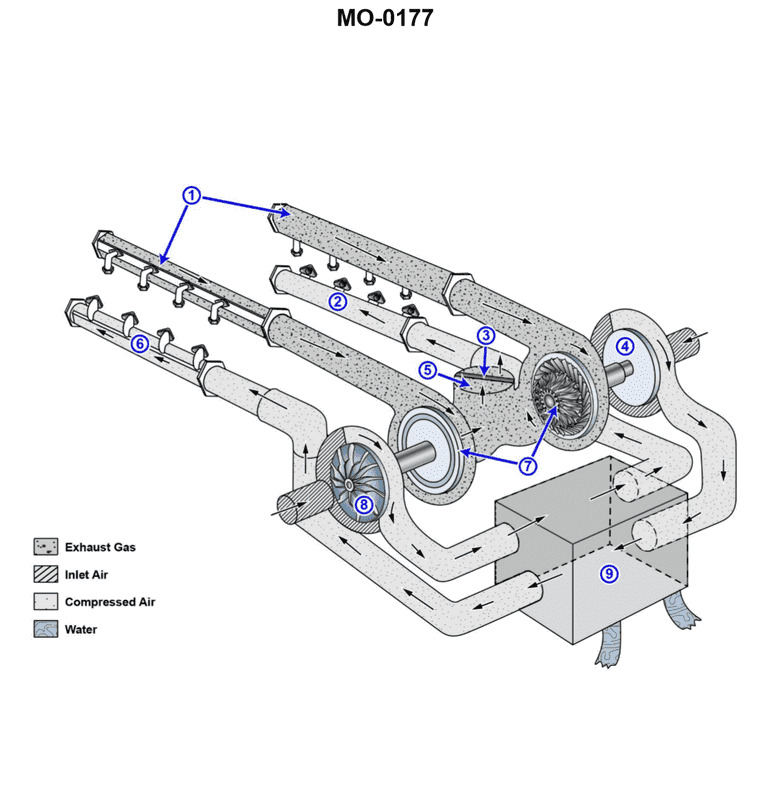

Question: The tractor tug to which you are assigned has main engines fitted with intake and exhaust systems as shown in the illustration. What statement best describes the configuration of the multiple turbochargers? Illustration MO-0177

A. Two (2) turbochargers are used and configured in series for a two-staging effect to boost charge air pressure.

B. Four (4) turbochargers are used, two for each cylinder bank, to reduce exhaust back pressure.

C. Four (4) turbochargers are used and configured in series for a four-staging effect to boost charge air pressure.

D. Two (2) turbochargers are used, one for each cylinder bank, to reduce exhaust back pressure.

The Correct Answer is D **Explanation for why Option D is correct:** Large marine diesel engines, especially V-type engines found in tugs and similar vessels, are typically equipped with multiple turbochargers. The most common configuration involves using one turbocharger for each cylinder bank (or side) of the engine. This configuration (Two turbochargers used, one for each cylinder bank) achieves several goals: 1. **Efficient Exhaust Gas Collection:** It simplifies the routing and reduces the length of the exhaust manifolds leading to the turbine inlet for each bank. 2. **Optimized Pulsation:** It allows the turbocharger to efficiently utilize the exhaust pressure pulses generated by the firing order of that specific bank of cylinders. 3. **Reduced Exhaust Back Pressure:** By utilizing appropriately sized turbochargers—one per bank—the design ensures that the exhaust gas flow is handled efficiently, minimizing back pressure against the pistons during the exhaust stroke, which improves engine efficiency and performance. **Explanation for why other options are incorrect:** * **A) Two (2) turbochargers are used and configured in series for a two-staging effect to boost charge air pressure.** While two-stage (series) turbocharging is used on some high-performance modern engines, it is not the primary or defining feature of a typical twin-turbo V-engine setup shown in standard illustrations. Usually, the two turbochargers operate in parallel, not series, with one serving each bank. * **B) Four (4) turbochargers are used, two for each cylinder bank, to reduce exhaust back pressure.** Using four turbochargers (two per bank) is possible in very high-output or specialized engines (e.g., sequential twin-turbo setups), but it is a complex and less common configuration for the baseline illustration of a typical marine diesel. The standard configuration for a V-engine with twin turbos uses only two total (one per bank). * **C) Four (4) turbochargers are used and configured in series for a four-staging effect to boost charge air pressure.** Four-stage turbocharging is excessively complex, rarely (if ever) seen, and would provide marginal benefit compared to the immense cost and design difficulty. If four turbochargers were present, they would likely be configured in a parallel arrangement for maximum flow, not series.

Question 28

Question: The lube oil system shown in the illustration, is designed to lubricate the main bearings by what principle? Illustration GT-0023

A. Spray lubrication with dry sumps

B. Splash lubrication

C. Totally submerged oil bath

D. Self-contained partial oil bath

The Correct Answer is A **Explanation for Option A (Spray lubrication with dry sumps) being correct:** The illustration GT-0023 typically depicts the lubrication system of a modern gas turbine (GT) engine. In high-speed, high-performance engines like gas turbines or jet engines, the main bearings are usually located near the compressor and turbine disks, operating at extreme speeds and temperatures. To effectively cool and lubricate these bearings while preventing oil foaming and windage losses: 1. **Spray Lubrication:** Pressurized oil jets (nozzles) are used to directly spray a precisely metered amount of cool, filtered oil onto the bearing races and roller elements. This ensures maximum cooling and effective lubrication penetration. 2. **Dry Sumps:** Instead of allowing the oil to pool (wet sump), the used oil is immediately scavenged (pumped out) from the bearing cavity (sump) by dedicated scavenge pumps, returning it to an external oil tank. This "dry sump" configuration prevents foaming, reduces the amount of oil exposed to hot air, and allows the engine to operate in any orientation (crucial for aerospace or marine GTs). Therefore, the combination of direct spray lubrication and immediate scavenging (dry sump) accurately describes the principle shown for the main bearings of a gas turbine. **Explanation for why other options are incorrect:** * **B) Splash lubrication:** This method relies on moving parts (like connecting rods) dipping into a pool of oil and splashing it around. This is too unreliable, inefficient for cooling, and inadequate for the high-speed main bearings found in advanced engines like gas turbines. * **C) Totally submerged oil bath:** While some low-speed industrial gearboxes might use this, submerging the main bearings of a high-speed gas turbine in an oil bath would create excessive churning (windage) and heat, leading to rapid oil degradation and mechanical failure. Modern GT bearings cannot be fully submerged. * **D) Self-contained partial oil bath:** This implies a wet sump where the bearing housing contains its own supply, often only partially submerging the lower part of the bearing. While better than a full bath, it lacks the precision cooling and immediate scavenging required for high-performance GT bearings, which mandate a pressurized spray and dry sump system.

Question 29

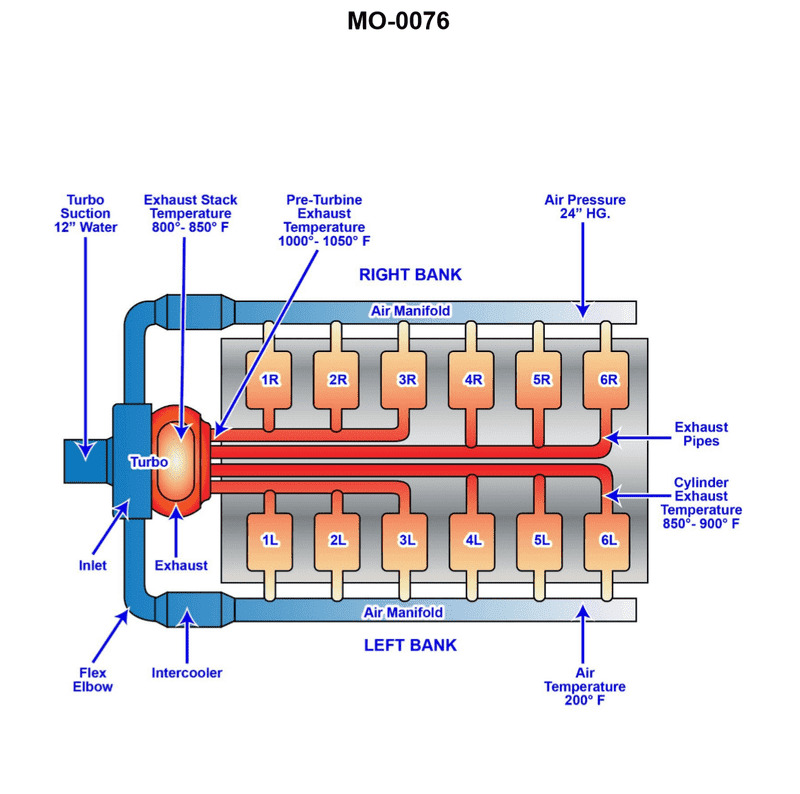

Question: The harbor tug to which you are assigned has main engines fitted with intake and exhaust systems as shown in the illustration. What type of turbo-charging configuration is used? Illustration MO-0076

A. 2-stage turbocharging.

B. Boost-controlled turbocharging.

C. Constant pressure turbocharging.

D. Pulse turbocharging.

The Correct Answer is D **Explanation for Option D (Pulse turbocharging):** Pulse turbocharging (also known as pressure-wave turbocharging or partial-admission turbocharging) is characterized by the use of an exhaust manifold system designed to maintain and utilize the kinetic energy and pressure pulses generated when the exhaust valves open. In a typical pulse system, the exhaust from a small number of cylinders (often two or three) is grouped into separate, small-volume manifolds (or "pipes") that lead directly to the turbine inlet. These inlets are often separated by partitions (pulse-converting nozzles) in the turbine housing (making it a twin or triple-entry turbine). If Illustration MO-0076 depicts short, distinct exhaust pipes leading from cylinder groups directly to a divided turbine inlet, it indicates that the system is engineered to capture and exploit the high-energy pressure pulses. This design provides better turbocharger response at lower engine loads compared to constant pressure systems, making it a very common configuration for medium and high-speed four-stroke diesel engines, such as those found in harbor tugs. **Why the other options are incorrect:** * **A) 2-stage turbocharging:** This configuration involves the air being compressed sequentially by two separate turbochargers (a high-pressure stage and a low-pressure stage) to achieve extremely high boost pressures. While highly efficient, this description relates to the overall compression process, not the specific design of the exhaust manifold/turbine entry illustrated by the choice between pulse and constant pressure systems. The illustration must show the specific manifold arrangement (separated pipes vs. large common manifold) to distinguish the configuration. * **B) Boost-controlled turbocharging:** This term refers to a control mechanism (like a wastegate or variable turbine geometry) used to limit or regulate the maximum boost pressure, especially at high engine speeds. It is a control feature, not the fundamental classification of the manifold and turbine inlet design (pulse vs. constant pressure). * **C) Constant pressure turbocharging:** This system uses a large-volume exhaust manifold (plenum) that collects the exhaust gases from all cylinders, damping out the individual pressure pulses before the gas reaches a single-entry turbine. The gas enters the turbine at a relatively steady (constant) pressure, utilizing thermal energy more efficiently but suffering from slower response at low loads. If the illustration shows short, separated pipes (as required for D), then it cannot be a constant pressure system.

Question 30

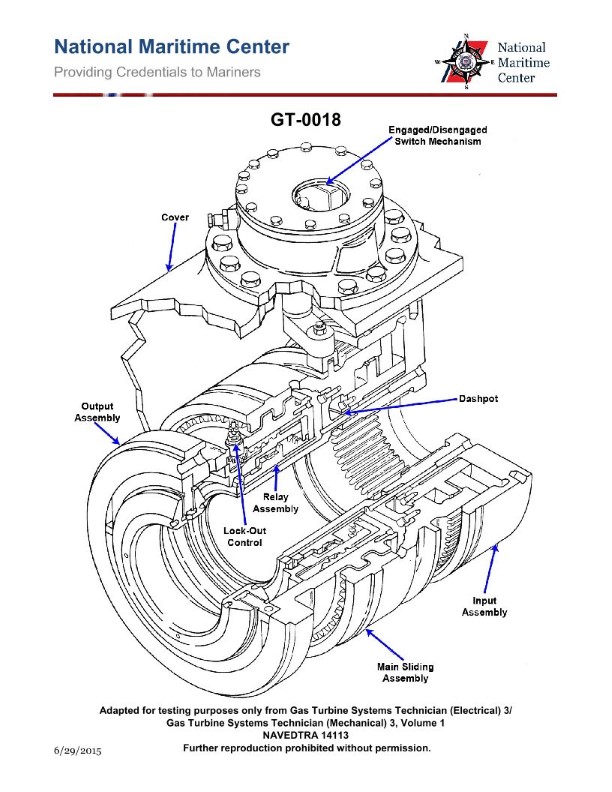

Question: How is the clutch shown in the attached illustration engaged? Illustration GT-0018

A. Clutch is engaged manually prior to start up.

B. Pneumatic pressure from the compressor engages the clutch.

C. Clutch engages automatically when input shaft flange is rotating faster than the output assembly.

D. Clutch engages automatically once the output assembly begins rotating.

The Correct Answer is C ### Why Option C is Correct: The illustration GT-0018 (typical for certain types of automatic transmissions or specialized clutches, particularly those using fluid coupling and friction plates, or an overrunning clutch design) generally depicts a mechanism that relies on a speed differential to achieve engagement. This describes a **synchronizer** or **freewheel/overrunning clutch** function where the clutch elements are designed to couple the input shaft to the output assembly only when the input is trying to drive the output (i.e., when the input shaft flange is rotating faster than the output assembly). When the input speed exceeds the output speed, internal mechanisms (like friction cones or centrifugal weights in some designs) are activated, causing the clutch plates or dog teeth to engage and transmit torque. ### Why Other Options Are Incorrect: * **A) Clutch is engaged manually prior to start up:** This mechanism is clearly part of an automatic or semi-automatic system (like a torque converter or specialized gearbox), not a traditional manual clutch where the operator uses a pedal or lever to set the initial engagement before the engine is even running. * **B) Pneumatic pressure from the compressor engages the clutch:** While pneumatic or hydraulic pressure is used in many heavy-duty automatic clutches, the primary engaging condition described by the mechanism (especially if it’s a synchronizer or fluid coupling) is the rotational speed differential, not merely the presence of pressure. Pressure typically acts as the *actuator* for engagement, but the *condition* that triggers the engagement is the speed difference (as described in C). * **D) Clutch engages automatically once the output assembly begins rotating:** This is backward. The goal of the clutch is usually to *cause* the output assembly to rotate by connecting it to the rotating input (engine/motor). If the clutch only engaged after the output was already moving, it wouldn't be able to initiate motion effectively or would allow the input to spin freely until the output accidentally achieved speed. The critical factor is the relationship between the *input* speed and the *output* speed.

Question 31

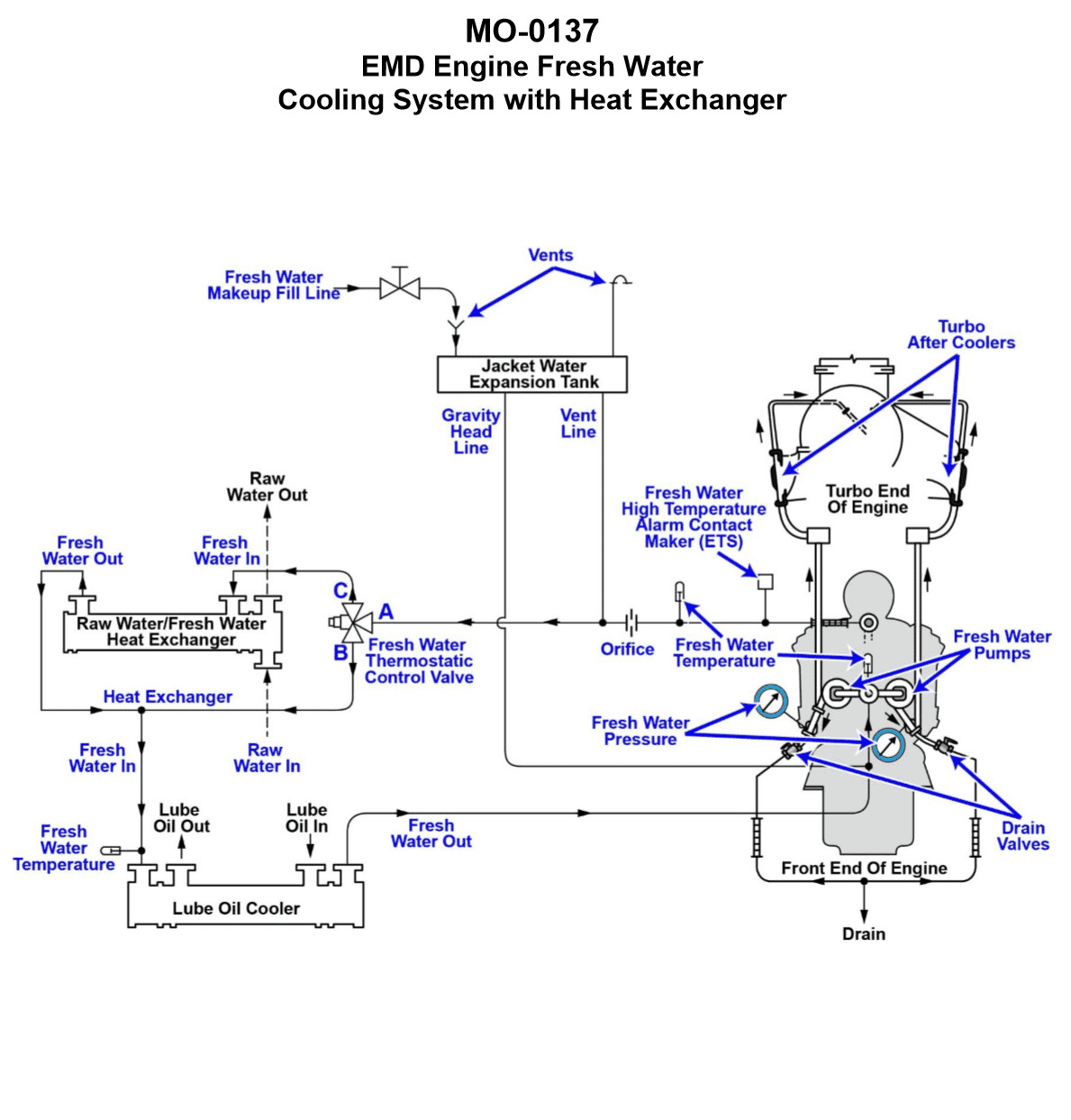

Question: The freshwater cooling systems serving the main engines of your towing vessel are of the type shown in the illustration. What statement accurately describes the characteristics of the freshwater cooling circuit? Illustration MO-0137

A. The freshwater circuit is a pressurized system using a stationary/marine type 3-way thermostatic control valve for temperature control.