Pass Your Coast Guard Licensing Exams!

Study offline, track your progress, and simulate real exams with the Coast Guard Exams app

1AE01 - First Assistant Engineer

91 images

Question 1

Question: Referring to the illustrated dual duct multiple zone HVAC system, how is the space temperature directly controlled? Illustration RA-0043

A. The space air temperature is controlled by automatically controlling the steam flow through the reheat coil.

B. The space air temperature is controlled by automatically controlling the chilled water flow through the cooling coil.

C. The space air temperature is controlled by automatically proportioning the cold and hot air streams at the mixing unit.

D. The space air temperature is controlled by automatically controlling the steam flow through the preheat coil.

The Correct Answer is C **Explanation for Option C (Correct Answer):** Option C states that the space air temperature is controlled by automatically proportioning the cold and hot air streams at the mixing unit. This is the defining characteristic and primary control mechanism of a dual-duct multiple-zone HVAC system. The central air handler produces two separate airstreams: one consistently cold and one consistently hot. A thermostat located in each specific zone (space) sends a signal to a terminal unit (mixing box). This mixing box then automatically adjusts dampers to mix the necessary amount of cold air and hot air to achieve the desired supply air temperature required by that zone, thus directly controlling the space temperature. **Why other options are incorrect:** * **A) The space air temperature is controlled by automatically controlling the steam flow through the reheat coil.** This describes a system utilizing zone reheat, typically found in single-duct Constant Volume (CV) or Variable Air Volume (VAV) systems, not the mixing process central to a dual-duct system. * **B) The space air temperature is controlled by automatically controlling the chilled water flow through the cooling coil.** The central cooling coil is regulated by a central controller (often a discharge air temperature sensor) to maintain a constant cold supply temperature for the entire cold duct (e.g., 55°F). It is controlled centrally, not by an individual zone thermostat, and therefore does not directly control the temperature of a specific space. * **D) The space air temperature is controlled by automatically controlling the steam flow through the preheat coil.** The preheat coil is located upstream, primarily used to temper outdoor air entering the system during cold conditions to prevent freezing or ensure minimum supply air temperatures. It is a protective and central component, having no direct role in regulating the temperature of an individual space zone.

Question 2

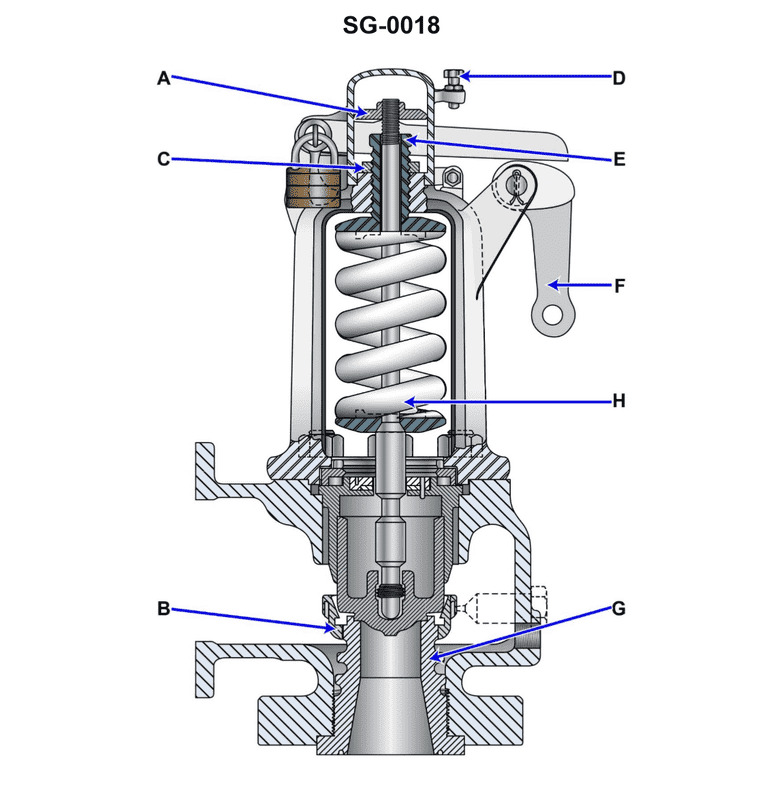

Question: Which of the listed types of safety valves is shown in the illustration? Illustration SG-0018

A. Nozzle reaction type

B. Huddling chamber type

C. Jet flow type

D. Pressure-loaded type

The Correct Answer is B **Explanation for Option B (Huddling chamber type) being correct:** The safety valve illustrated (assuming Illustration SG-0018 depicts a conventional, direct spring-loaded safety relief valve designed for pop action, particularly common in steam or high-pressure gas service) is typically a **huddling chamber type** valve. This design incorporates a blowdown ring or an adjustable nozzle ring positioned around the seat of the valve disk. When the valve lifts (pops open), the fluid expands into this confined area, creating a larger effective pressure area underneath the disk. This sudden increase in force ensures a rapid, full lift ("pop action") and a distinct difference between the set pressure and the reseating pressure (blowdown). This feature is characteristic of the huddling chamber design, which utilizes the kinetic energy and expansion of the fluid to ensure the necessary rapid lift and sealing forces. **Explanation for Other Options being incorrect:** * **A) Nozzle reaction type:** This type of valve utilizes the reaction forces generated by the escaping fluid jet (often directed through an angle or an internal component) to assist in lifting the disc. While some pop-action valves incorporate reaction elements, the core mechanism described by the huddling chamber (the pressure accumulation area beneath the disc) is the more defining characteristic of standard pop safety valves, making B the more specific and accurate fit for the general illustration of a standard high-pressure relief valve mechanism. * **C) Jet flow type:** This term is too general and not a standard classification for the operating principle of a spring-loaded safety valve. While fluid flow is involved, "jet flow" does not describe the specific mechanism (like the huddling chamber or reaction principle) used to achieve pop action or modulate flow. * **D) Pressure-loaded type:** This classification refers to valves where the opening force is achieved or supplemented by an external pressure source (often pilot-operated safety relief valves, or POSRVs), not directly by the medium pushing against the spring-loaded disc alone. The illustration shows a mechanism dependent on the direct accumulation and expansion of the internal fluid under the disc against a spring force, which is characteristic of direct spring-loaded valves, not externally pressure-loaded systems.

Question 3

Question: Referring to the illustrated psychrometric chart, suppose air at a dry bulb temperature of 60oF and a relative humidity of 52% passes over a heating coil, resulting in sensible heat gain, and the off-coil temperature is now 80oF. What is off-coil relative humidity? Illustration RA-0022

A. 19%

B. 27%

C. 55%

D. 70%

The Correct Answer is B ### Explanation for why option B (27%) is correct: The process described is **sensible heating**. During sensible heating, the air temperature increases, but no moisture is added or removed. This means the **humidity ratio ($W$)** remains constant. 1. **Locate the initial state (Pre-coil):** * Dry Bulb Temperature ($\text{DBT}_1$) $= 60^\circ\text{F}$. * Relative Humidity ($\text{RH}_1$) $= 52\%$. * Find the intersection of the $60^\circ\text{F}$ vertical line and the $52\%$ $\text{RH}$ curve on the psychrometric chart (Illustration RA-0022). 2. **Determine the constant humidity ratio ($W$):** * Reading horizontally from the initial state point to the humidity ratio axis on the right side of the chart, the humidity ratio is approximately $W \approx 0.0055$ $\text{lb}_w/\text{lb}_a$. 3. **Locate the final state (Off-coil):** * Dry Bulb Temperature ($\text{DBT}_2$) $= 80^\circ\text{F}$. * The humidity ratio must remain constant, so $W_2 = W_1 \approx 0.0055$ $\text{lb}_w/\text{lb}_a$. 4. **Determine the final relative humidity ($\text{RH}_2$):** * Follow the horizontal line corresponding to $W = 0.0055$ $\text{lb}_w/\text{lb}_a$ until it intersects the vertical line for $80^\circ\text{F}$ $\text{DBT}$. * This intersection point lies between the $20\%$ and $30\%$ relative humidity curves. * Interpolating between the curves, the final relative humidity is approximately $27\%$ (or slightly above $26\%$). Therefore, the off-coil relative humidity is $\text{RH}_2 \approx 27\%$. --- ### Explanation for why the other options are incorrect: * **A) 19%:** This value is significantly too low. It would correspond to a humidity ratio around $W \approx 0.004$ $\text{lb}_w/\text{lb}_a$. If the relative humidity dropped to $19\%$ during this heating process, it implies the initial humidity ratio was much lower than calculated. * **C) 55%:** This value is incorrect because during sensible heating (increasing temperature at constant moisture content), the air's capacity to hold moisture increases, causing the relative humidity to drop drastically, not increase or stay the same. A relative humidity of $55\%$ at $80^\circ\text{F}$ would require a high humidity ratio, $W \approx 0.012$ $\text{lb}_w/\text{lb}_a$, indicating massive humidification occurred, which contradicts the premise of sensible heating. * **D) 70%:** This value is drastically incorrect for the same reason as option C. $70\%$ $\text{RH}$ at $80^\circ\text{F}$ represents extremely humid air ($W \approx 0.0155$ $\text{lb}_w/\text{lb}_a$), which is impossible to achieve through simple sensible heating from the given starting point.

Question 3

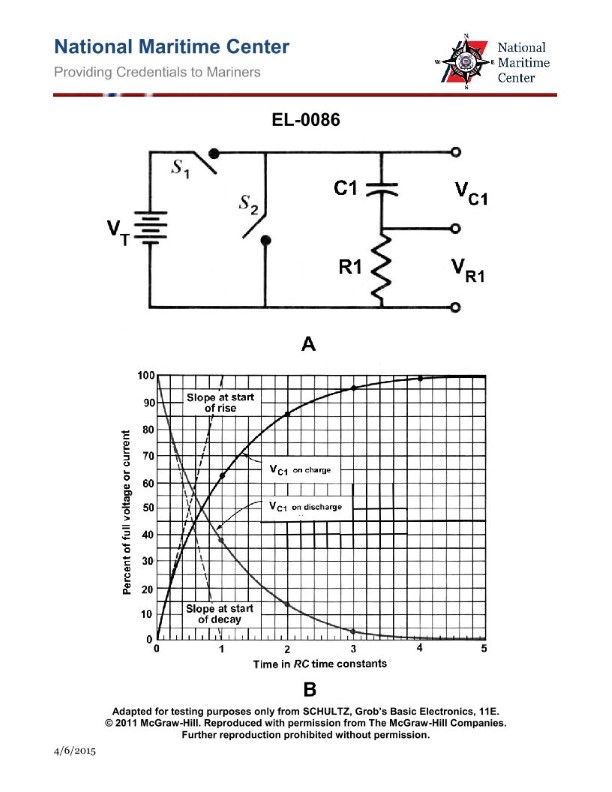

Question: If the values of "C1" and "R1" shown in the illustration were 1 microfarad and 3 megohms respectively, which of the listed intervals of time would equal one "time constant"? Illustration EL-0086

A. 0.33 second

B. 3 seconds

C. 6 seconds

D. 15 seconds

The Correct Answer is B **Explanation for Option B (Correct Answer):** The time constant ($\tau$) for a series RC (Resistor-Capacitor) circuit is calculated using the formula: $$\tau = R \times C$$ Where: * $\tau$ is the time constant (in seconds) * $R$ is the resistance (in ohms) * $C$ is the capacitance (in farads) Given values: * $C1$ (Capacitance, $C$) = $1$ microfarad ($\mu F$) $= 1 \times 10^{-6}$ Farads ($F$) * $R1$ (Resistance, $R$) = $3$ megohms ($M\Omega$) $= 3 \times 10^{6}$ Ohms ($\Omega$) Calculation: $$\tau = (3 \times 10^{6} \, \Omega) \times (1 \times 10^{-6} \, F)$$ $$\tau = 3 \times (10^{6} \times 10^{-6})$$ $$\tau = 3 \times 10^{0}$$ $$\tau = 3 \times 1$$ $$\tau = 3 \text{ seconds}$$ Therefore, the interval of time equal to one time constant is 3 seconds. **Explanation for Incorrect Options:** * **A) 0.33 second:** This value would result if the calculation were performed incorrectly (e.g., $1/3$ or $1 \text{ M}\Omega \times 0.33 \mu F$) or if a division operation was mistakenly used instead of multiplication. * **C) 6 seconds:** This value is $2\tau$ (two time constants). It would result from an arithmetic error where one of the values was accidentally doubled (e.g., $2 \mu F \times 3 \text{ M}\Omega$ or $1 \mu F \times 6 \text{ M}\Omega$). * **D) 15 seconds:** This value is $5\tau$ (five time constants). Five time constants are often associated with the full charging or discharging time of the capacitor (99.3%), but it is not the definition of a single time constant.

Question 4

Question: If a valve seat insert, similar to that shown in the illustration is cracked, this may be indicated by __________. Illustration MO-0043

A. white vapor in the exhaust gas

B. high exhaust pyrometer readings on that particular cylinder

C. continuous spring surge

D. a jammed indicator cock

The Correct Answer is A ### Why Option A is Correct A cracked valve seat insert, especially if it extends through the water jacket (as is common in many engine designs where the seat is pressed into a cooled head or block), creates a pathway for engine coolant or cooling water to leak directly into the combustion chamber. When the engine is running, this coolant is instantly vaporized by the high combustion temperatures. This resulting steam is then expelled with the exhaust gases, manifesting as **white vapor in the exhaust gas**. ### Why Other Options are Incorrect **B) high exhaust pyrometer readings on that particular cylinder:** A cracked valve seat insert usually results in poor sealing and blow-by. If anything, the combustion efficiency may slightly drop, and the presence of cooling water/steam would act to cool the gases, often resulting in **lower** (or erratic) pyrometer readings, not high ones. High readings are typically indicative of fuel injection problems (late injection or excessive afterburning) or insufficient scavenging. **C) continuous spring surge:** Spring surge (oscillation of the valve spring at its natural frequency) is a mechanical problem related to excessive engine speed, incorrect spring design, or wear on the valve train components. It is not directly caused by or a primary indicator of a cracked valve seat insert. **D) a jammed indicator cock:** The indicator cock is used for measuring cylinder pressure (taking indicator cards) or bleeding the cylinder. While internal engine failures can sometimes cause debris that might theoretically jam the cock, a cracked valve seat insert is too far removed from the indicator cock mechanism to be considered a primary or reliable diagnostic indicator for this specific type of failure.

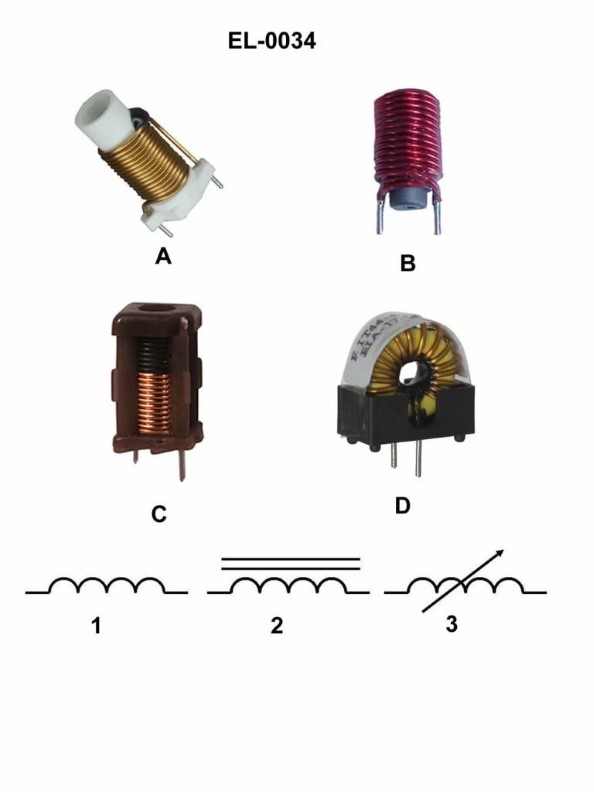

Question 4

Question: Which figure represents the schematic symbol shown in figure "2"? Illustration EL-0034

A. figure "A"

B. figure "B"

C. figure "C"

D. figure "D"

The Correct Answer is B **Explanation for Option B (figure "B"):** Figure "2" (the target symbol to be identified) represents the schematic symbol for a **fixed resistor** in the international or IEC standard (often represented by a rectangle) or, alternatively, in some contexts, the older European standard. Figure "B" is a rectangle, which is the standard symbol for a fixed resistor according to the International Electrotechnical Commission (IEC) standard. **Explanation for Other Options:** * **A) figure "A":** Figure "A" typically represents a **variable resistor** or **potentiometer**. It is a fixed resistor symbol with an arrow or wiper contact drawn through or touching the resistance element, indicating adjustable resistance. Therefore, it does not match the fixed resistor symbol shown in figure "2" (the rectangle). * **C) figure "C":** Figure "C" typically represents the schematic symbol for a **capacitor** (usually a fixed, non-polarized type, or a polarized type if one line is curved). A capacitor symbol consists of two parallel lines separated by a space, which is fundamentally different from the rectangle of a fixed resistor. * **D) figure "D":** Figure "D" typically represents the schematic symbol for a **diode** (a semiconductor device allowing current flow in one direction). It consists of a triangle (indicating the anode) touching a perpendicular line (indicating the cathode), which is completely distinct from the fixed resistor symbol.

Question 5

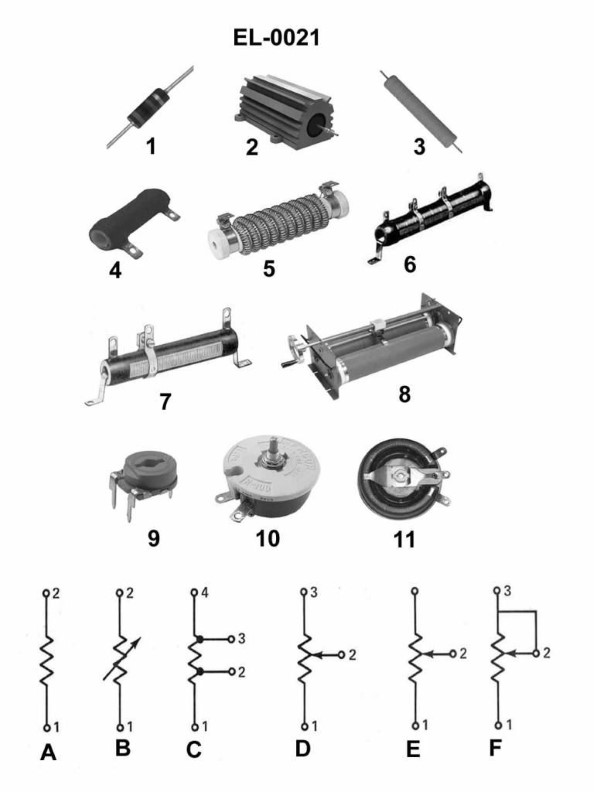

Question: Which of the illustrated resistors represents the schematic symbol shown in figure "B"? Illustration EL-0021

A. figure "4"

B. figure "6"

C. figure "10"

D. figure "11"

The Correct Answer is C **Explanation for Option C (figure "10"):** The schematic symbol shown in figure "B" is the standard electrical symbol for a **Thermistor (Negative Temperature Coefficient, or NTC)**. An NTC thermistor is a type of resistor whose resistance decreases significantly as its temperature increases. Figure "10" illustrates the physical structure of a typical disc or bead thermistor, which is commonly used in electronic circuits to sense temperature or limit inrush current. Therefore, figure "10" represents the physical component corresponding to the schematic symbol in figure "B". **Explanation for Incorrect Options:** * **A) figure "4":** Figure "4" typically illustrates a standard fixed resistor (usually a carbon film or metal oxide resistor), which is represented schematically by a zigzag line or a plain rectangle, not the thermistor symbol in figure "B". * **B) figure "6":** Figure "6" usually represents a **Light Dependent Resistor (LDR)** or photoresistor, which is sensitive to light. Its schematic symbol includes a zigzag line or rectangle enclosed in a circle with arrows pointing inward (representing incoming light), which is different from the thermistor symbol in figure "B". * **D) figure "11":** Figure "11" commonly illustrates a **Varistor (Voltage Dependent Resistor, or VDR)**, often used for surge protection. Its schematic symbol includes an angled line through the zigzag/rectangle symbol to indicate voltage dependence, which is distinct from the temperature-dependent thermistor symbol in figure "B".

Question 7

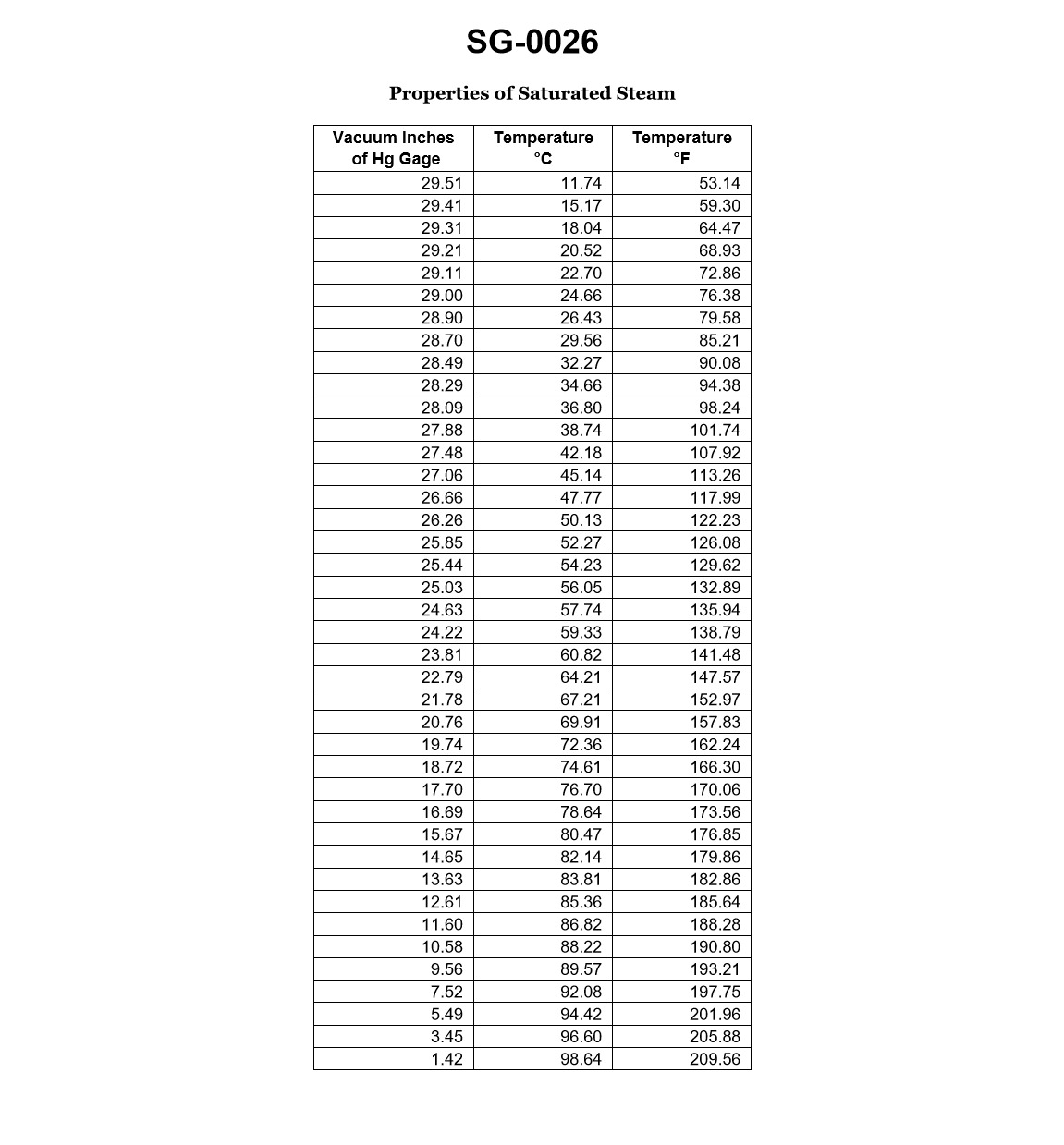

Question: According to the data given in the illustration which of the following would be the physical state of the fluid at a gauge vacuum of 25.03 inches Hg, and 126.08 degrees Fahrenheit? Illustration SG-0026

A. Saturated liquid.

B. Mixture of saturated liquid and vapor.

C. Subcooled liquid.

D. Superheated vapor.

The Correct Answer is C ### 1. Explanation for Option C (Subcooled liquid) The physical state of a fluid is determined by comparing its actual temperature ($T_{actual}$) to the saturation temperature ($T_{sat}$) corresponding to its absolute pressure ($P_{abs}$). **Step 1: Calculate Absolute Pressure ($P_{abs}$)** Standard atmospheric pressure ($P_{atm}$) is approximately $29.92 \text{ inches Hg}$. Gauge vacuum pressure ($P_{vac}$) indicates the pressure drop below atmospheric pressure. $$P_{abs} = P_{atm} - P_{vac}$$ $$P_{abs} = 29.92 \text{ in Hg} - 25.03 \text{ in Hg}$$ $$P_{abs} = 4.89 \text{ inches Hg (Absolute)}$$ **Step 2: Determine Saturation Temperature ($T_{sat}$)** We must use the data from Illustration SG-0026 (or standard steam tables, assuming the fluid is water/steam) to find the temperature at which the fluid will boil (saturate) at the calculated absolute pressure of $4.89 \text{ inches Hg}$. * Based on standard saturation data for water: At $P_{abs} = 4.89 \text{ inches Hg}$, the corresponding saturation temperature ($T_{sat}$) is approximately $133^\circ\text{F}$. **Step 3: Compare Temperatures** * $T_{actual} = 126.08^\circ\text{F}$ * $T_{sat} \approx 133^\circ\text{F}$ Since the actual temperature of the fluid ($126.08^\circ\text{F}$) is *less than* the saturation temperature ($133^\circ\text{F}$) at the given pressure, the fluid cannot boil and exists entirely in the liquid phase. A liquid below its saturation temperature is defined as a **Subcooled Liquid** (or Compressed Liquid). --- ### 2. Explanation for Incorrect Options **A) Saturated liquid.** This would require the fluid's actual temperature to be exactly equal to the saturation temperature ($T_{actual} = T_{sat}$ $\approx 133^\circ\text{F}$) at the calculated pressure. Since $126.08^\circ\text{F}$ is lower than $T_{sat}$, this is incorrect. **B) Mixture of saturated liquid and vapor.** This phase exists only if the fluid is at the saturation temperature ($T_{actual} = T_{sat}$). If it were a mixture, the temperature would be $\approx 133^\circ\text{F}$, and the quality ($x$) would be between 0 and 1. Since $T_{actual} < T_{sat}$, this is incorrect. **D) Superheated vapor.** This would require the fluid's actual temperature to be greater than the saturation temperature ($T_{actual} > T_{sat}$). This indicates a pure vapor phase that is hotter than the temperature required to maintain saturation at that pressure. Since $126.08^\circ\text{F}$ is much lower than $T_{sat}$, this is incorrect.

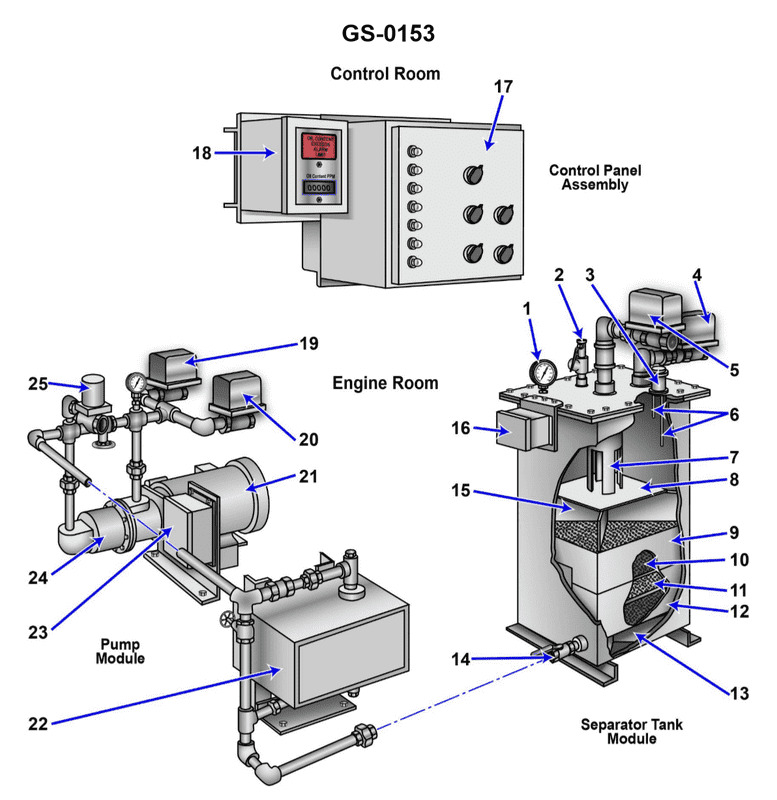

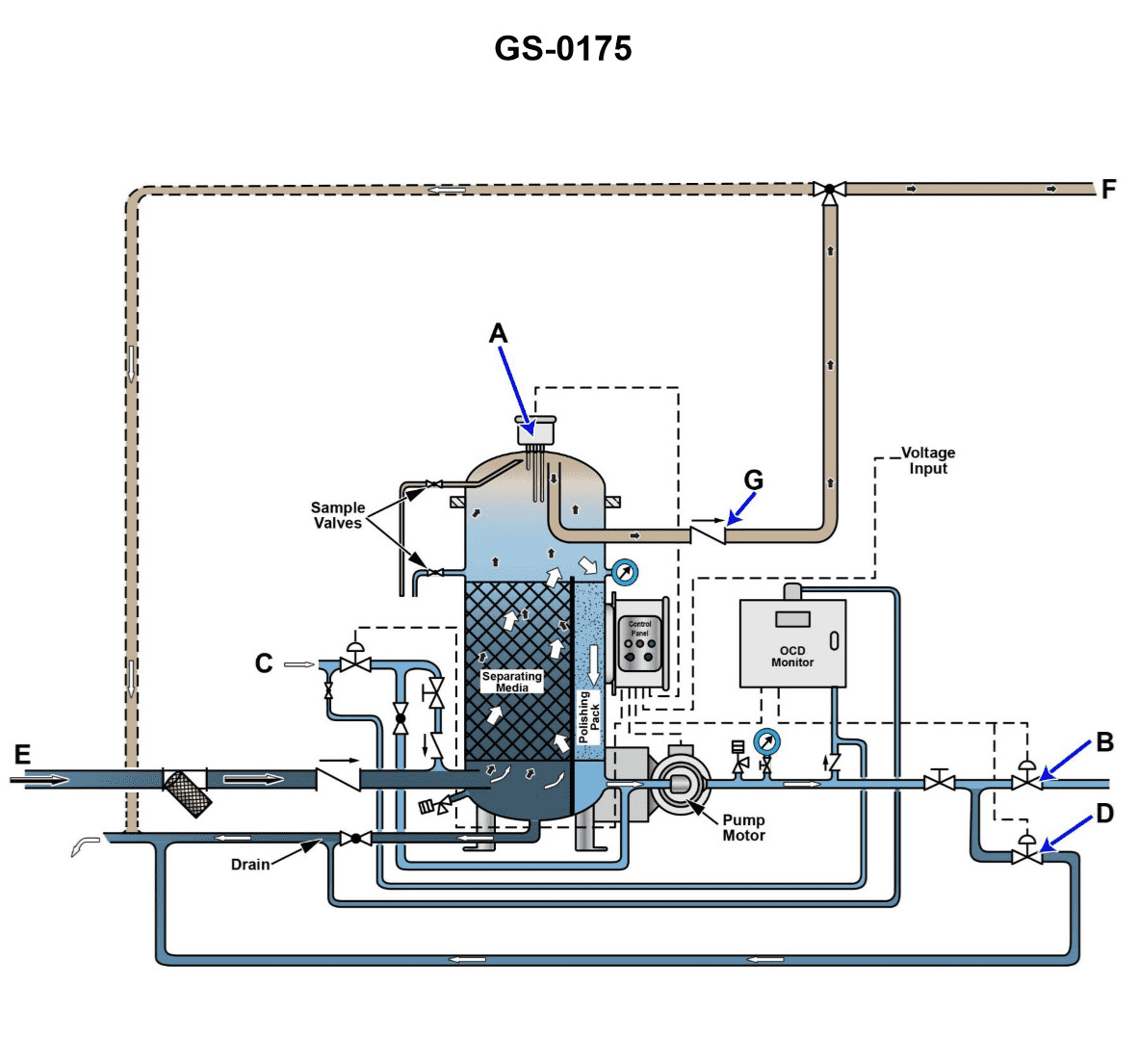

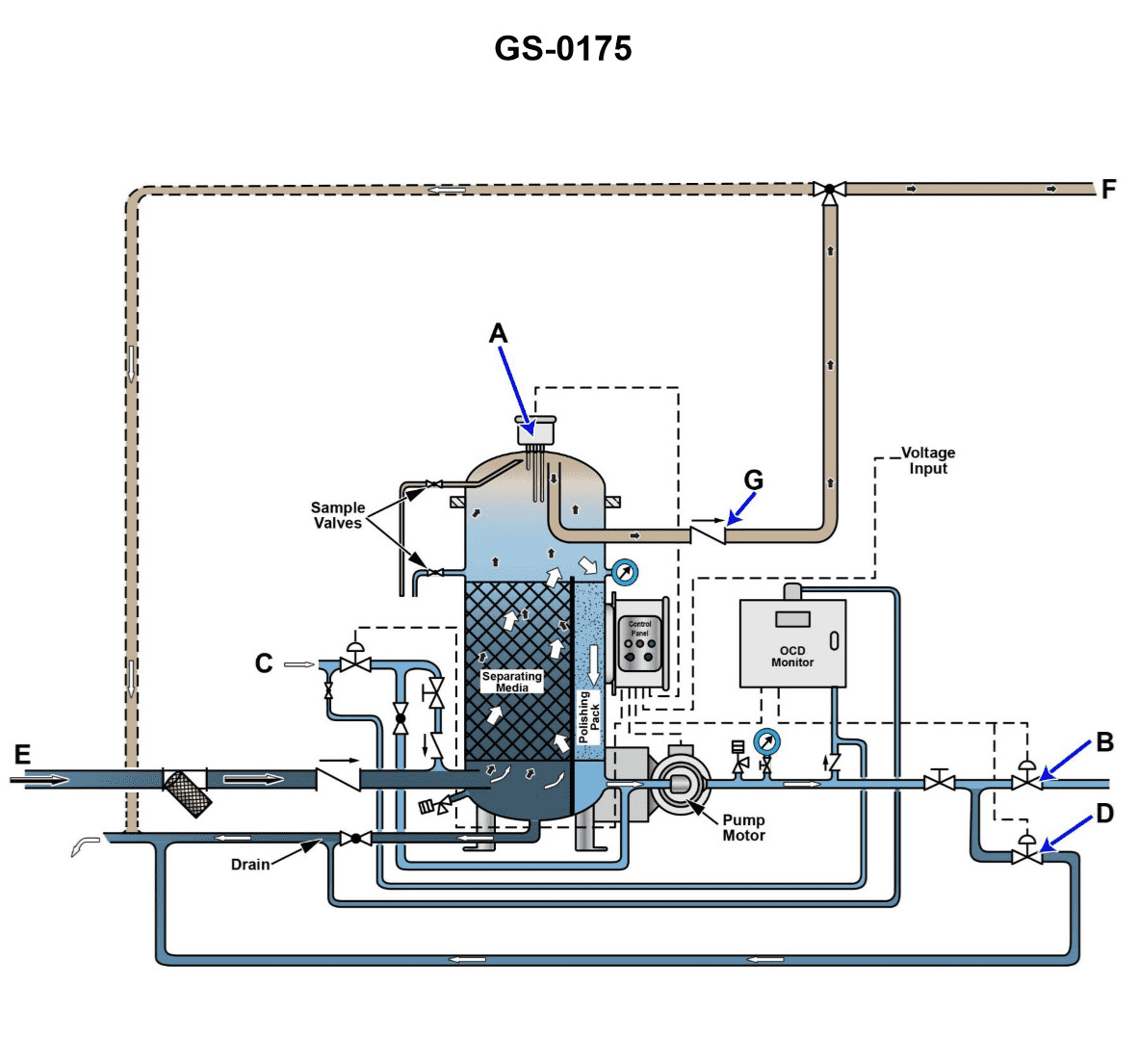

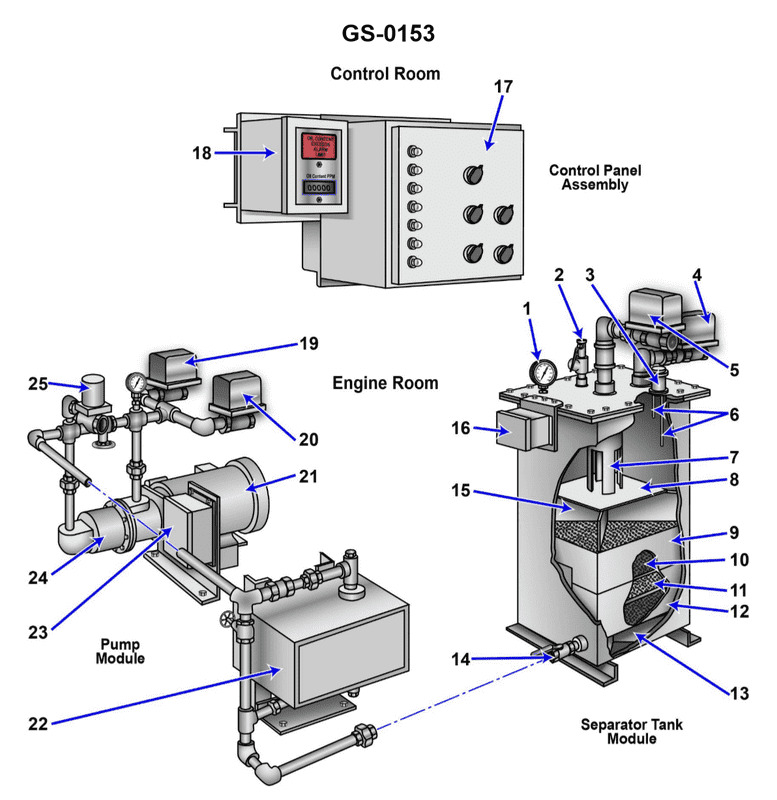

Question 9

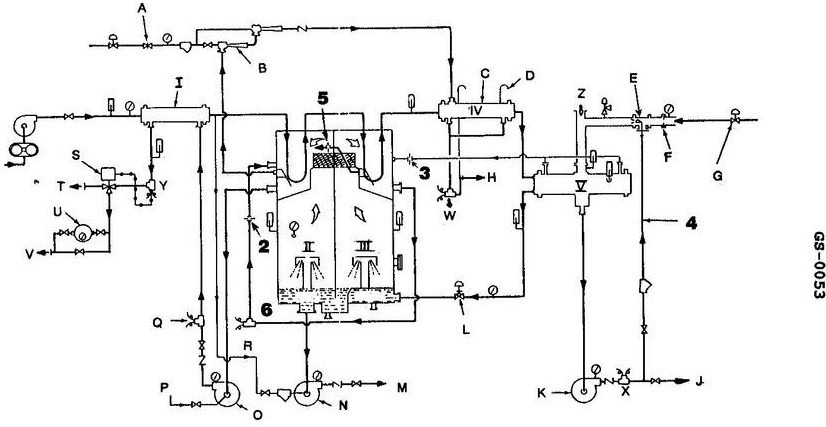

Question: A high reading is indicated at the salinity cells labeled "SC1", "SC2", and "SC3" shown in the illustration. This is probably the result of which of the following? Illustration GS-0053

A. a leak in item "HX1"

B. erosion of item "OR1"

C. faulty cells at each location

D. carryover from "FC1"

The Correct Answer is D **Explanation for Option D (Correct):** Option D, "carryover from 'FC1'", is the probable cause for a high reading at all three salinity cells (SC1, SC2, and SC3). In standard boiler/steam system diagrams (which this illustration GS-0053 likely depicts, focusing on feedwater conditioning or steam generation), FC1 typically represents a **Filter/Condensate tank** or **Feedwater Conditioner**. If chemical treatment (such as sodium sulfite or caustic soda) or dissolved solids are not being properly removed or are being overfed and carried over from the conditioning stage (FC1) into the main steam/water path, it will raise the conductivity (salinity) of the fluid. Since the salinity cells (SC1, SC2, SC3) are likely monitoring different stages of the condensate/feedwater loop, a widespread high reading at all three locations strongly suggests a systemic problem originating upstream, such as poor separation or chemical carryover from the primary conditioning source, FC1. **Explanation for Incorrect Options:** * **A) a leak in item "HX1"**: HX1 typically represents a Heat Exchanger. A leak in a heat exchanger would generally introduce *raw water* or cooling medium (like cooling tower water) into the system. While this *would* increase salinity, it usually causes localized high readings or massive changes if the leak is severe. It is less likely to cause a simultaneous, moderate high reading at three separate monitoring points throughout the system compared to a consistent chemical carryover issue. * **B) erosion of item "OR1"**: OR1 usually stands for an Orifice or Orifice Plate, used for flow measurement or restriction. Erosion of an orifice plate affects flow dynamics and pressure drop, but it does not introduce new contaminants or change the chemical composition of the fluid being measured. Therefore, it would not directly cause a high salinity reading. * **C) faulty cells at each location**: While possible for one cell to fail, it is highly improbable that three separate, independent salinity cells (SC1, SC2, and SC3) would simultaneously fail in a way that generates a false high reading at the exact time the observation is made. This is usually ruled out in favor of a single, upstream physical or chemical process failure (like carryover) that affects the monitored fluid.

Question 11

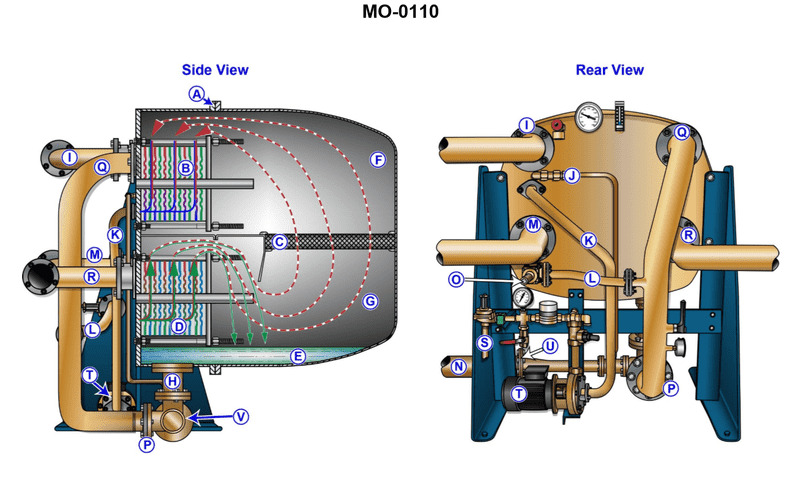

Question: Failure to establish sufficient vacuum when starting up the unit shown in the illustration may be the result of __________. Illustration MO-0110

A. improper operation of the brine pump

B. neglecting to latch the dump valve

C. neglecting to close the shell vent

D. improper operation of the distillate pump

The Correct Answer is C **Why option C ("neglecting to close the shell vent") is correct:** The unit described is typically a type of freshwater generator (such as a vacuum evaporator) which relies on establishing a high vacuum (low absolute pressure) within the shell to boil seawater at low temperatures. When starting up the unit, air must be removed from the shell to achieve this vacuum. This is typically done by an air ejector or vacuum pump, with the shell vent initially open to allow air to be pushed out. Once the vacuum is pulled, the shell vent *must* be closed. If the operator forgets to close the shell vent, outside atmospheric air will continuously leak back into the shell, preventing the vacuum pump or ejector from establishing and maintaining the required low pressure. Therefore, neglecting to close the shell vent results in a failure to establish sufficient vacuum. **Why the other options are incorrect:** A) **Improper operation of the brine pump:** The brine pump removes concentrated saltwater (brine) from the bottom of the evaporator shell. While essential for continuous operation and preventing fouling, the brine pump's function is primarily related to circulation and concentration control, not the initial establishment of vacuum within the shell. B) **Neglecting to latch the dump valve:** If the unit has a dump valve (often related to dumping produced water if quality is low), failing to latch it might affect the quality or disposal of the generated water (distillate). However, the operation or status of this valve is generally independent of the air ejector system responsible for pulling the initial vacuum. D) **Improper operation of the distillate pump:** The distillate pump removes the produced fresh water from the unit. Similar to the brine pump, its function occurs *after* the vacuum has been established and boiling has begun. Its malfunction would affect the production rate or water level, but not the ability to initially draw a vacuum in the shell.

Question 11

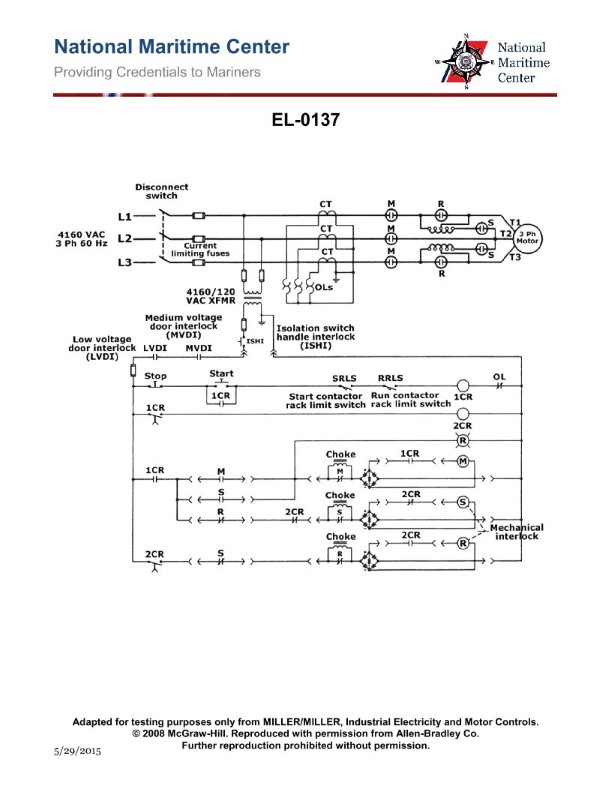

Question: As shown in the illustration, what type of motor and motor starter are featured? Illustration EL-0137

A. non-reversing squirrel cage induction motor with reduced voltage autotransformer starting

B. reversing squirrel cage induction motor with across-the-line starting

C. reversing squirrel cage induction motor with reduced voltage autotransformer starting

D. non-reversing squirrel cage induction motor with reduced voltage primary reactor starting

The Correct Answer is A **Why Option A is Correct:** Option A states the features are a **non-reversing squirrel cage induction motor with reduced voltage autotransformer starting**. 1. **Squirrel Cage Induction Motor (SCIM):** The diagram of the motor starter circuit is designed for a standard three-phase AC induction motor, which is typically a squirrel cage type due to its robust nature and common use in industrial applications. 2. **Reduced Voltage Starting:** The presence of the autotransformer (T1) and the associated contactors (S and R) indicates a method used to limit the high inrush current that occurs when starting a large AC motor. This method is specifically **reduced voltage starting**. 3. **Autotransformer Starting:** The component labeled T1 is an autotransformer, identifiable by having a single winding that acts as both primary and secondary, used to step down the voltage during the starting phase. This confirms the use of an autotransformer starter. 4. **Non-Reversing:** The control circuit and the power circuit only show contactors (S for start, R for run/full voltage) configured to connect the motor leads (T1, T2, T3) in one sequence (L1 to T1, L2 to T2, L3 to T3). There are no additional contactors or wiring included to swap any two phases (e.g., L1 and L3) to reverse the motor's direction. Therefore, the setup is **non-reversing**. **Why Other Options Are Incorrect:** * **B) reversing squirrel cage induction motor with across-the-line starting:** This is incorrect for two reasons. First, the starter uses an autotransformer for reduced voltage starting, not across-the-line starting (which would use a single contactor connecting the motor directly to the line). Second, the circuit lacks the necessary components (F/R contactor pair) to perform reversing. * **C) reversing squirrel cage induction motor with reduced voltage autotransformer starting:** This is incorrect because, while the reduced voltage autotransformer starting is correct, the circuit is designed for **non-reversing** operation. A reversing starter would require additional components to switch phase sequence, which are absent in the illustration. * **D) non-reversing squirrel cage induction motor with reduced voltage primary reactor starting:** This is incorrect because the component used to achieve the reduced voltage start is an **autotransformer (T1)**, not a primary reactor (which would be a simple inductor placed in series with the motor windings during start).

Question 12

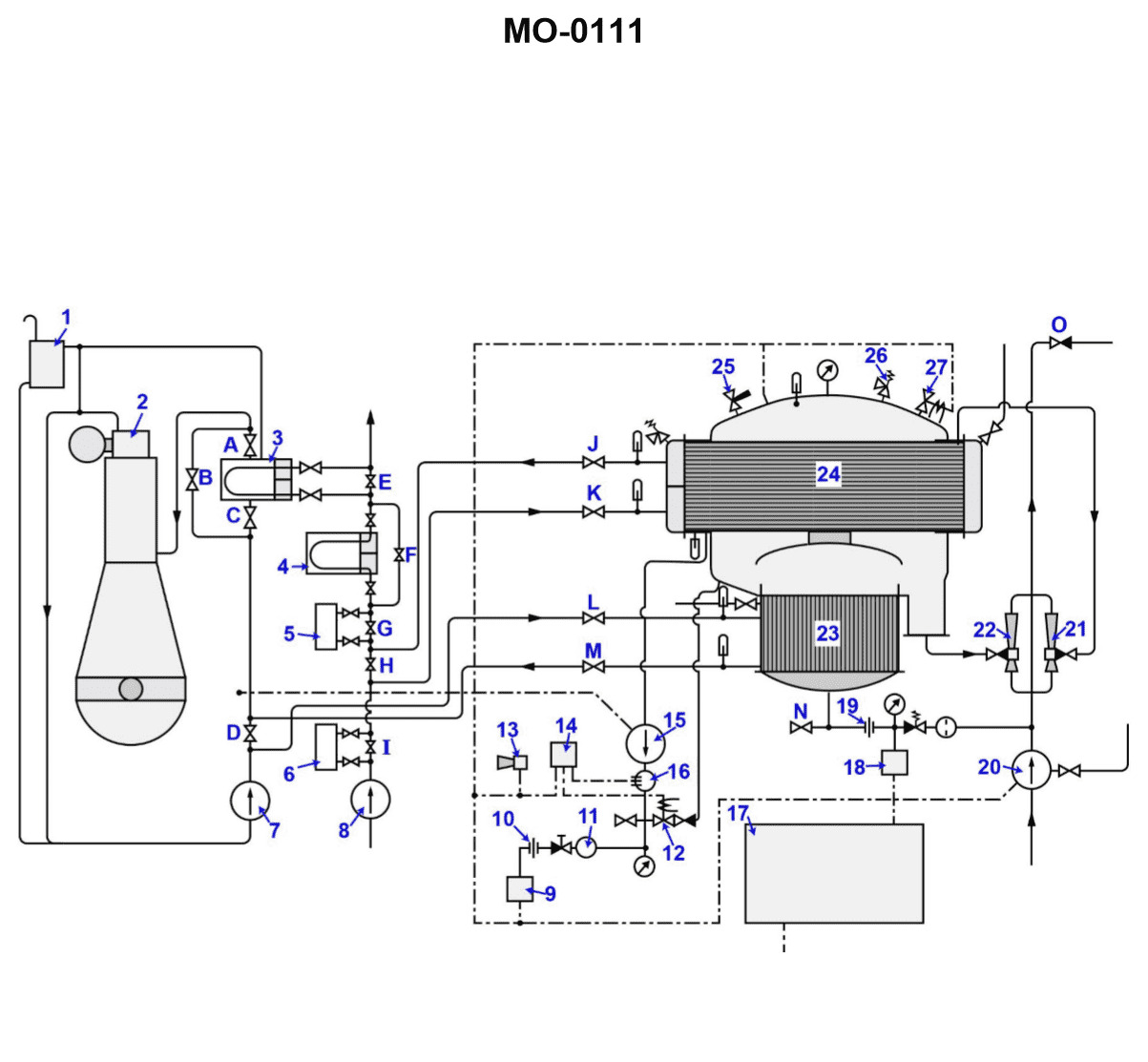

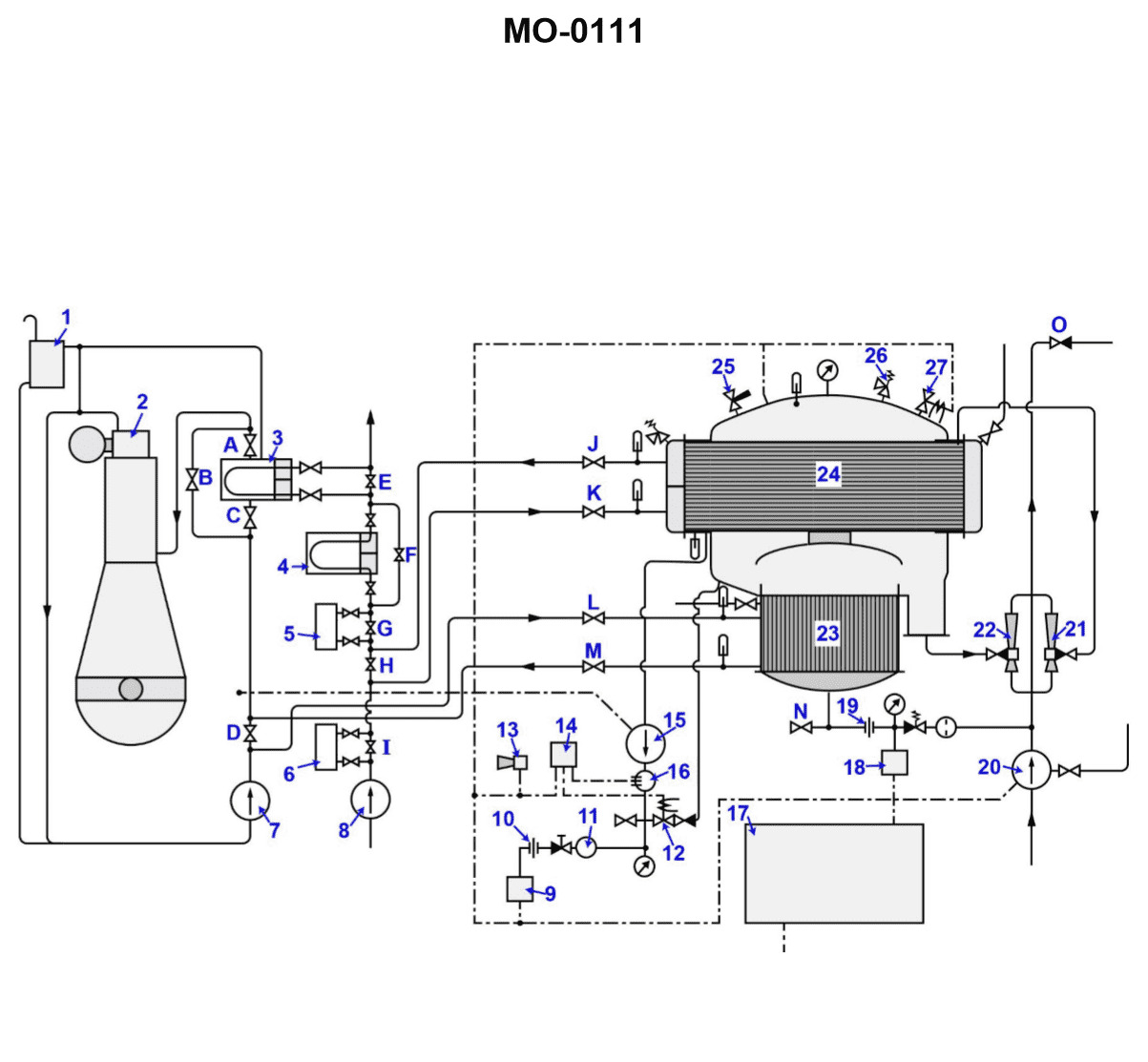

Question: If valve "H" shown in the illustration is opened wide while the distiller is in operation, __________. Illustration MO-0111

A. the absolute pressure of the unit will not be affected, but the rate of condensation will be decreased

B. the absolute pressure of the unit will increase due to the increased effect of the air ejector

C. the absolute pressure of the unit will increase with an associated increase in shell temperature

D. the absolute pressure of the unit will increase with an associated decrease in shell temperature

The Correct Answer is C ### Explanation for Option C (Correct) Option C states that the absolute pressure of the unit will increase with an associated increase in shell temperature. This is correct because valve "H" is typically the air ejector bypass valve (or steam line bypass valve, depending on the specific MO-0111 diagram, but functionally, opening it wide compromises the vacuum system). The primary function of the air ejector (or vacuum pump system) is to remove non-condensable gases (mainly air) from the evaporator shell, which maintains a high vacuum (very low absolute pressure). 1. **Opening Valve H Wide:** If valve "H" (the air ejector bypass or a critical steam/vacuum isolation valve that controls the vacuum achieved by the ejector) is opened wide, it typically allows high-pressure steam (if it's a bypass) to leak into the low-pressure side, or it introduces a significant leak path, or it allows the vacuum system to work inefficiently. In the context of shell-and-tube distillers (like standard flash or low-pressure evaporators), opening the ejector bypass wide would reduce the effective vacuum created by the ejector, often by starving the nozzles or creating back pressure. 2. **Pressure Increase:** When the effectiveness of the vacuum system is compromised, the concentration of non-condensable gases and water vapor pressure increases inside the evaporator shell. This results in a significant **increase in the absolute pressure** of the unit (the vacuum worsens). 3. **Temperature Increase:** According to the principles of saturated steam tables, there is a direct correlation between saturation pressure and saturation temperature. Since the water being boiled must match the saturation temperature corresponding to the pressure inside the shell, an **increase in absolute pressure** must lead to an **increase in the associated shell temperature** (the boiling point of the water). ### Explanation of Incorrect Options **A) the absolute pressure of the unit will not be affected, but the rate of condensation will be decreased:** This is incorrect. As explained above, opening the vacuum bypass or starving the air ejector drastically affects the vacuum, causing the absolute pressure to increase. The decrease in condensation rate is a consequence of the pressure and temperature changes, but the core premise that pressure is unaffected is wrong. **B) the absolute pressure of the unit will increase due to the increased effect of the air ejector:** This is incorrect. While the absolute pressure *will* increase, it is due to the *decreased* (or compromised) effect of the air ejector, not an increased effect. An efficient air ejector decreases pressure; compromising it increases pressure. **D) the absolute pressure of the unit will increase with an associated decrease in shell temperature:** This is incorrect. While the absolute pressure will increase, the shell temperature (boiling point) is directly proportional to the absolute pressure in a saturated system. Therefore, an increase in pressure is always associated with an increase in the shell temperature.

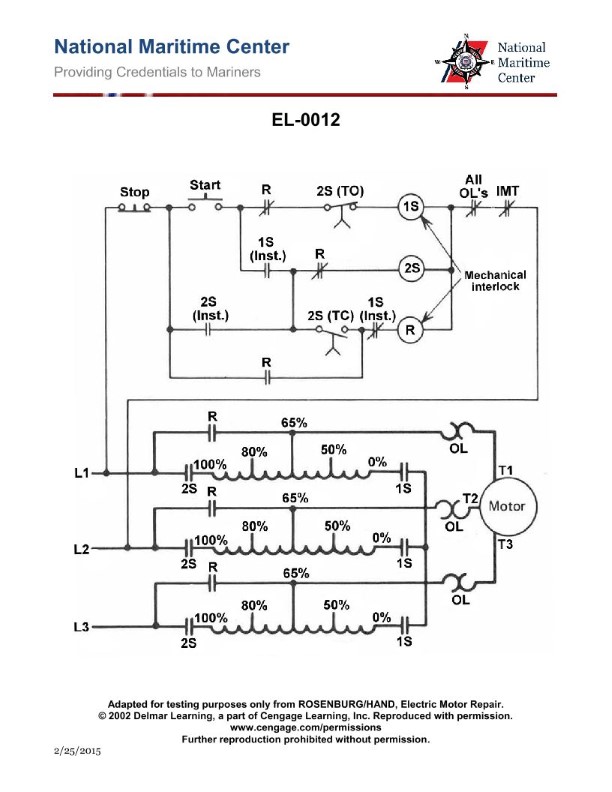

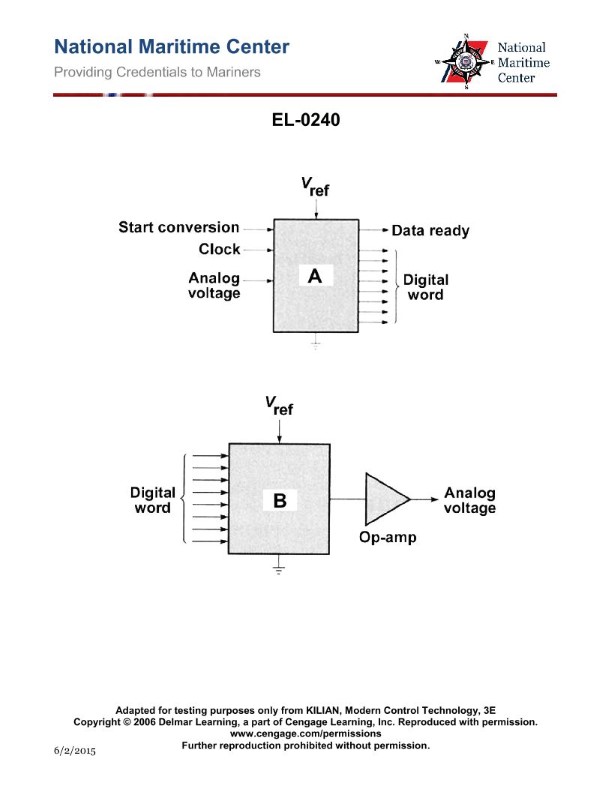

Question 12

Question: As shown in the illustration, what is the purpose of the main contacts of contactor "1S"? Illustration EL-0012

A. The "1S" contactor connects the autotransformer in delta configuration during the starting/acceleration period.

B. The "1S" contactor connects the autotransformer to the line during the starting/acceleration period.

C. The "1S" contactor connects the autotransformer in wye configuration during the starting/acceleration period.

D. The "1S" contactor connects the autotransformer in wye configuration during the run period.

The Correct Answer is C. **Explanation of Option C (Correct):** The illustration EL-0012 depicts a typical reduced-voltage autotransformer starter circuit (also known as Korndorfer starting). This method uses three main contactors, usually designated $S$ (Start/Series), $1S$ (Wye/Star connection), and $R$ (Run). 1. **Location and Function of $1S$:** Contactor $1S$ is positioned to short out the ends of the autotransformer windings (T1, T2, T3) that connect to the motor during the initial starting phase. 2. **Wye Configuration:** When $1S$ closes, it connects the three windings of the autotransformer together at a common point, effectively placing the autotransformer in a **wye (star) configuration**. 3. **Starting Period:** This wye configuration is necessary for the autotransformer to function correctly as a step-down device during the initial motor **starting or acceleration period** (the time before the motor is switched to full line voltage). Therefore, the main contacts of contactor $1S$ connect the autotransformer in the wye configuration during the starting period. **Explanation of Incorrect Options:** * **A) The "1S" contactor connects the autotransformer in delta configuration during the starting/acceleration period.** * Incorrect. Connecting windings in a delta configuration typically requires connecting the end of one winding to the start of the next (T1 to T3, T2 to T1, T3 to T2). The $1S$ contactor simply closes the neutral point of the transformer windings, creating a wye, not a delta, configuration. * **B) The "1S" contactor connects the autotransformer to the line during the starting/acceleration period.** * Incorrect. Contactor $S$ (Start/Series) is the one that connects the autotransformer taps to the incoming power lines (L1, L2, L3) during the starting period. The $1S$ contactor’s role is strictly internal to the transformer winding configuration. * **D) The "1S" contactor connects the autotransformer in wye configuration during the run period.** * Incorrect. The run period occurs after the motor has accelerated sufficiently. During the run period, the $1S$ (Wye) contactor and the $S$ (Start) contactor open, and the $R$ (Run) contactor closes, bypassing the autotransformer entirely and connecting the motor directly to the full line voltage. The wye configuration is only active during the starting period.

Question 13

Question: Which of the conditions listed would indicate a large condenser tube leak within the distiller shown in the illustration? Illustration MO-0111

A. A decrease in the level of the main engine expansion tank as indicated by a low-level alarm.

B. A slow continuous rise in the lube oil cooler outlet temperature indicated at device "4".

C. The activation of the salinity monitoring equipment's annunciator circuit.

D. An increase in distiller output resulting from the combination of jacket water and the distillate produced.

The Correct Answer is C **Why Option C is Correct:** A large condenser tube leak means that the cooling medium (typically seawater) is entering the freshwater/distillate side of the condenser. Seawater has a high salt (salinity) content. The purpose of the salinity monitoring equipment is to continuously measure the purity of the produced distillate. If a significant leak occurs, the high-salinity seawater will contaminate the otherwise pure distillate, causing the measured conductivity (salinity) to rise rapidly above the set point. This sudden increase in salinity will trigger the alarm circuit (annunciator) of the monitoring equipment, immediately alerting the operator to the contamination and the need to dump the contaminated water. **Why the Other Options are Incorrect:** * **A) A decrease in the level of the main engine expansion tank as indicated by a low-level alarm.** This tank is part of the main engine's closed jacket water cooling system. While jacket water is often used as the heat source for the distiller, a leak in the condenser (which handles seawater and distillate) would not directly or immediately affect the closed-loop jacket water expansion tank level. A jacket water system leak would typically be noticed as a low level in the jacket water system itself, but a condenser tube leak involves the seawater side, not the jacket water side. * **B) A slow continuous rise in the lube oil cooler outlet temperature indicated at device "4".** The lube oil cooler is an entirely separate piece of equipment from the distiller's condenser. While both might use seawater as a coolant, a leak in the distiller's condenser tubes has no direct effect on the temperature performance of the main engine lube oil cooler. The lube oil cooler performance is more related to seawater supply pressure, flow, or fouling. * **D) An increase in distiller output resulting from the combination of jacket water and the distillate produced.** The condenser tube leak introduces **seawater** into the distillate stream, not jacket water. Furthermore, a large leak typically leads to a loss of vacuum and operational instability, often causing a **decrease** in usable distillate output (because the contaminated water must be dumped) rather than a clean increase in usable flow.

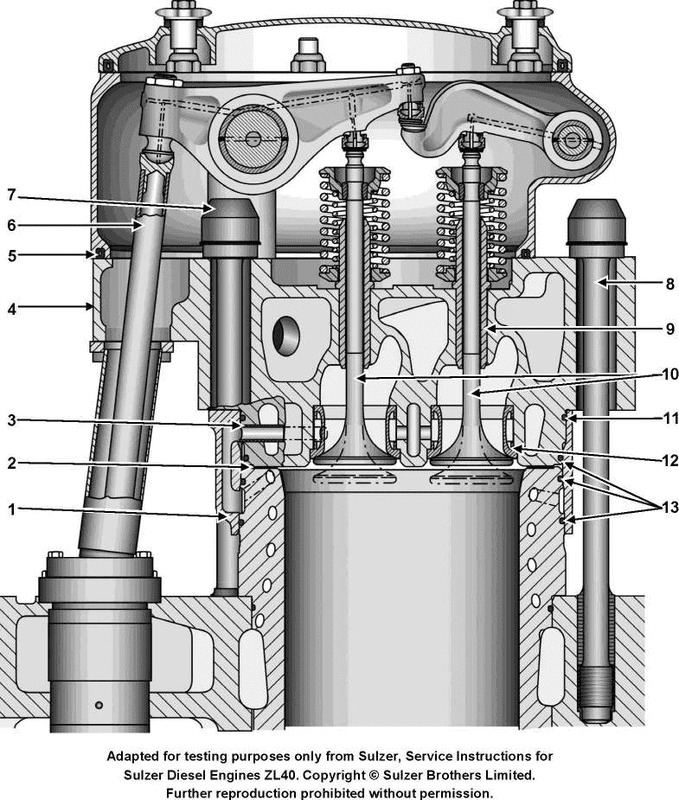

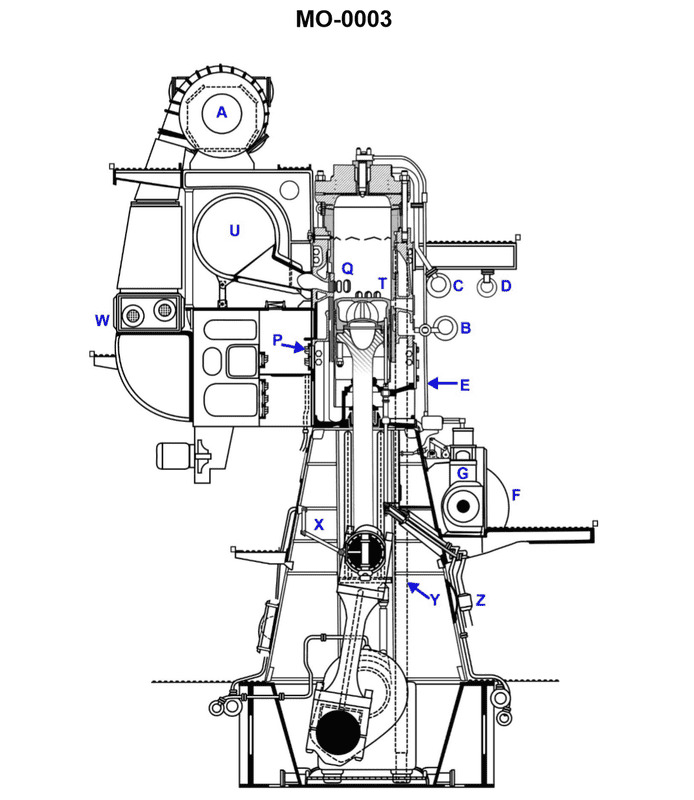

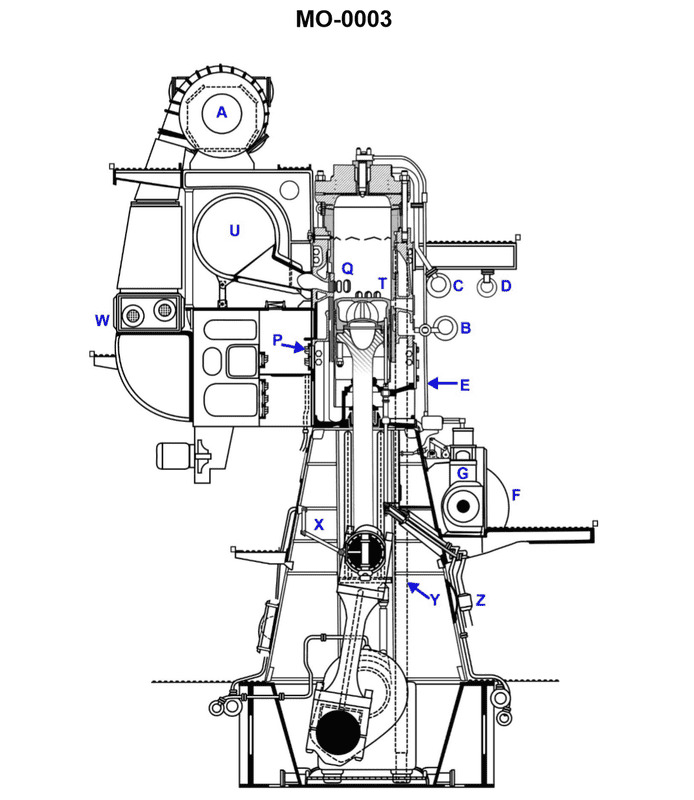

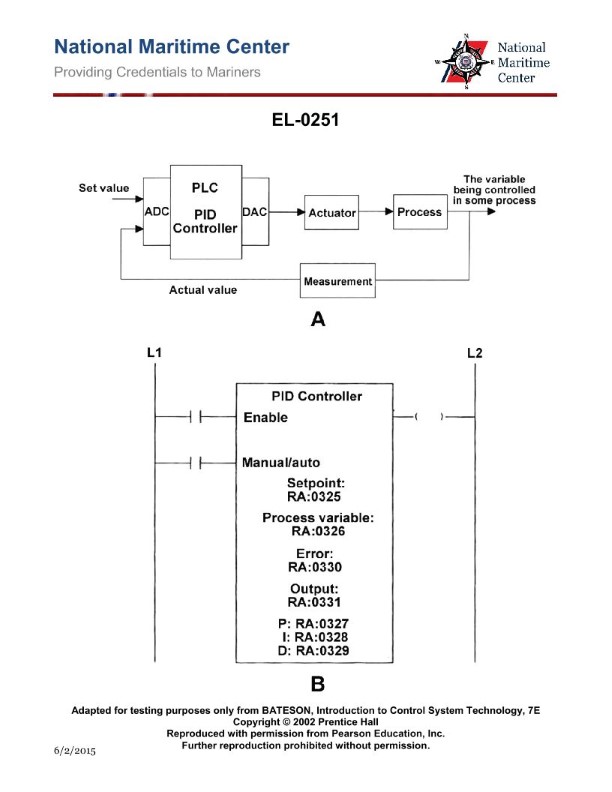

Question 13

Question: In the illustrated engine, the main camshaft controls the timing of which of the following components? Illustration MO-0003

A. Intake valves

B. exhaust valves

C. fuel pumps

D. all of the above

The Correct Answer is C **Why option C ("fuel pumps") is correct:** In large, slow-speed, two-stroke marine diesel engines (which Illustration MO-0003 typically depicts, as it shows a setup characteristic of these engines), the main camshaft is mounted low down, often near the engine baseplate. Its primary function is to operate the mechanical **fuel injection pumps** (or high-pressure fuel pumps) via rollers and pushrods. This mechanism precisely meters and times the delivery of high-pressure fuel into the combustion chambers. **Why the other options are incorrect:** * **A) Intake valves:** Slow-speed two-stroke marine engines are typically *valveless* regarding intake. The intake (scavenging air) is controlled by ports in the cylinder liner uncovered by the piston. Therefore, there is no intake valve timing to be controlled by the main camshaft. * **B) Exhaust valves:** While the exhaust *is* valved in many modern slow-speed two-stroke engines (Uniflow scavenging), the timing and operation of the large exhaust valve are typically controlled by a separate, dedicated hydraulic system (often driven by engine oil pressure and timed by a distributor) or by electronically actuated components, *not* directly by the main mechanical camshaft. The main camshaft is usually reserved for the high-force requirement of operating the fuel pumps. * **D) all of the above:** Since options A and B are incorrect in this common engine type, "all of the above" is also incorrect.

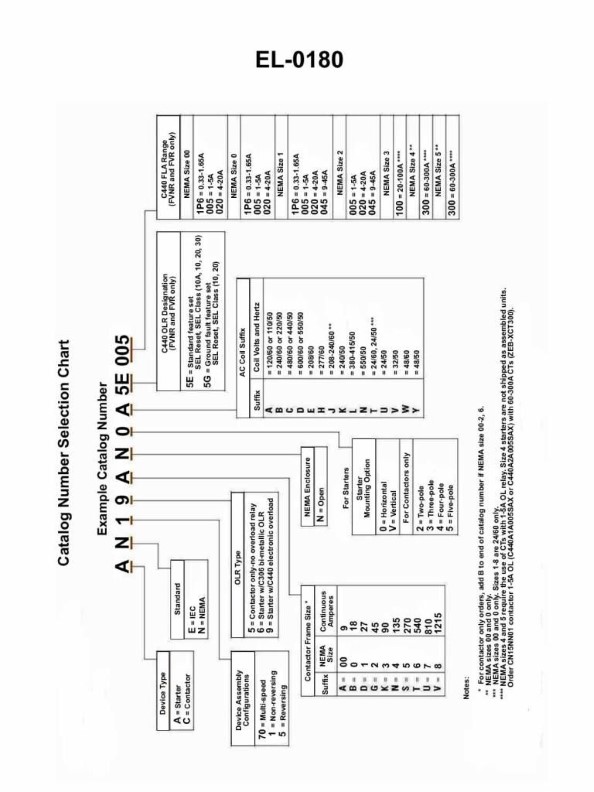

Question 13

Question: Using the catalog selection chart shown in Illustration EL-0180, determine the correct catalog number for a motor starter that meets the following criteria: NEMA Open enclosure 3-pole Rated at 45 continuous amperes Vertically mounted Electronic overload relay-Ground fault feature set Reversing starter Operating coil rated at 24 VAC/60 Hz

A. AE19GNVB5G045

B. AN19AN0A5E005

C. AN59GNVT5G045

D. CN16GNVT5G045

The Correct Answer is C ### Explanation for Option C (AN59GNVT5G045) The catalog number **AN59GNVT5G045** is correct because each alphanumeric position corresponds precisely to the required specifications for the motor starter, following standard industry catalog designation practices (as outlined in Illustration EL-0180): | Catalog Position | Code | Required Feature | Match Confirmation | | :--- | :--- | :--- | :--- | | **AN** | **AN** | NEMA Starter | Defines the NEMA product family. | | **Type/Form** | **5** | Reversing starter | The "5" digit specifically designates a Reversing Starter configuration. | | **Size** | **9** | Rated at 45A (Size 2 or 3 equivalent) | Specifies the appropriate NEMA size for the current rating. | | **Enclosure** | **G** | Open enclosure | "G" is the standard code for an open-style starter. | | **Poles** | **N** | 3-pole | "N" is the code for the standard 3-pole configuration. | | **Overload** | **V** | Electronic Overload Relay / Ground Fault | "V" typically indicates an electronic overload with advanced features like ground fault sensing. | | **Mounting** | **T** | Vertically mounted | "T" is the code for vertical mounting. | | **Coil Voltage** | **5** | 24 VAC/60 Hz | "5" is the standardized code for a 24 VAC, 60 Hz operating coil. | | **Amperes** | **045** | 45 continuous amperes | This code explicitly sets the continuous current rating for the electronic overload. | --- ### Explanation for Why Other Options Are Incorrect **A) AE19GNVB5G045 is incorrect because:** * **AE Prefix:** Often denotes an IEC-rated starter or a different specific product line, not the standard NEMA starter implied by the overall criteria. * **B (Overload):** The "B" code usually signifies a standard Thermal Overload (Bimetallic) relay, which does **not** meet the requirement for an **Electronic overload relay** with a ground fault feature (V). * **1 (Type):** The "1" code often designates a **Non-reversing** starter, while a **Reversing starter** was required (5). **B) AN19AN0A5E005 is incorrect because:** * **1 (Type):** The "1" code often designates a **Non-reversing** starter, while a **Reversing starter** was required (5). * **005 (Amperes):** The rating is 5 continuous amperes. The requirement was for **45 continuous amperes** (045). * **A (Enclosure):** "A" typically indicates a NEMA Type 1 enclosure, not the required **Open enclosure** (G). **D) CN16GNVT5G045 is incorrect because:** * **CN Prefix:** This prefix denotes a **Combination Starter** (starter plus disconnect/breaker) rather than just a motor starter. The criteria only asked for a motor starter. * **6 (Size):** The NEMA size code "6" is typically used for NEMA Size 1, which is significantly undersized for a 45 continuous ampere rating (a 45A rating requires NEMA Size 2 or 3).

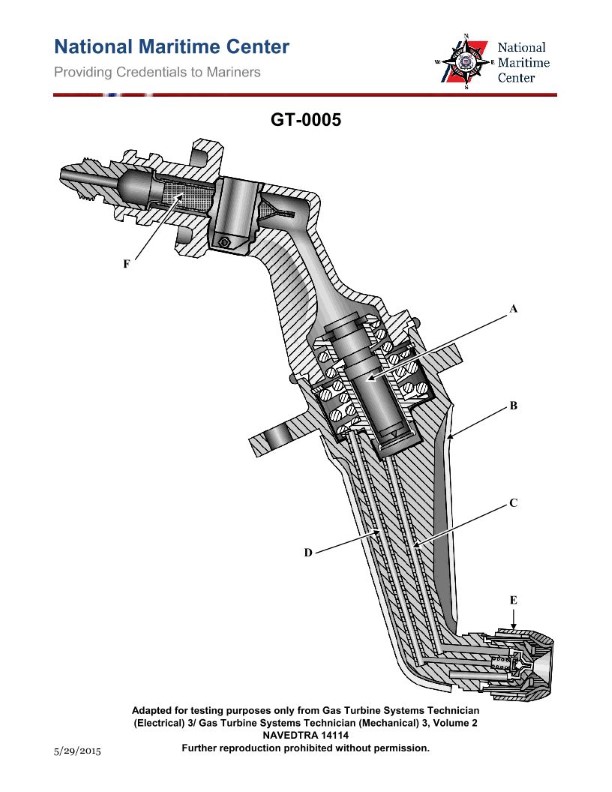

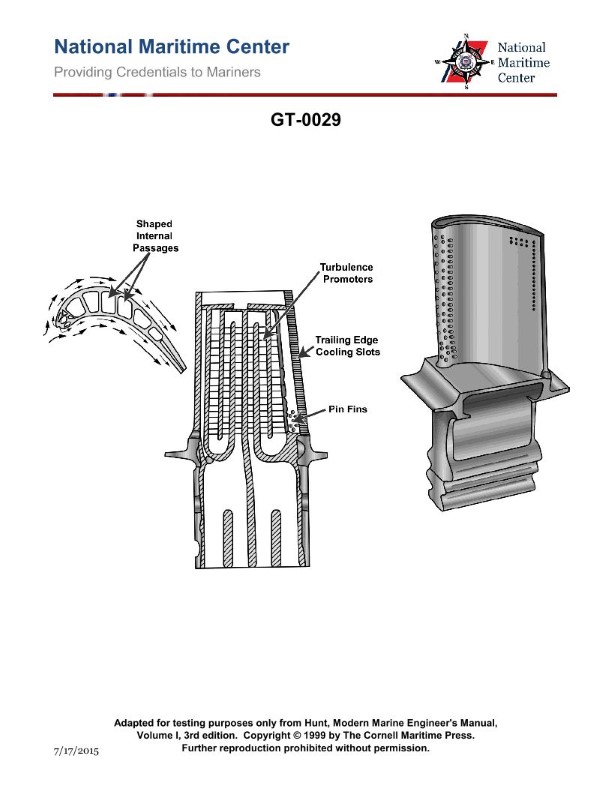

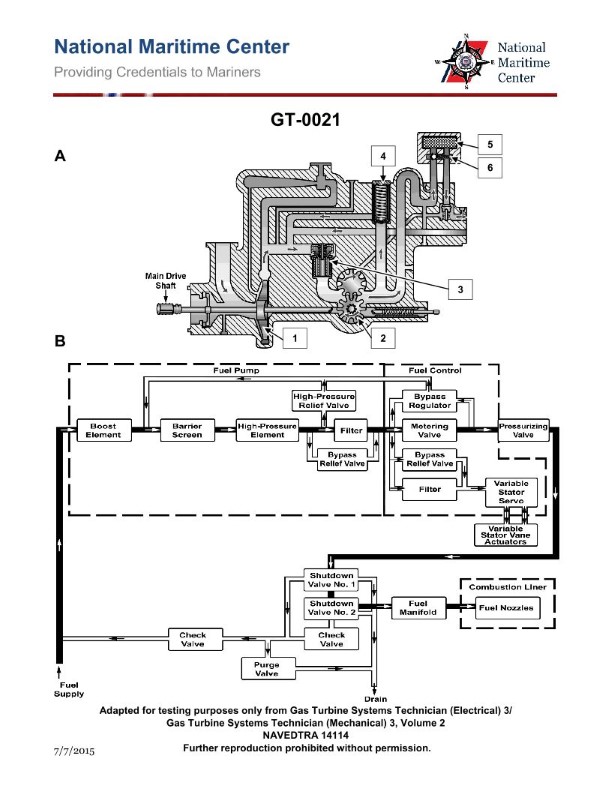

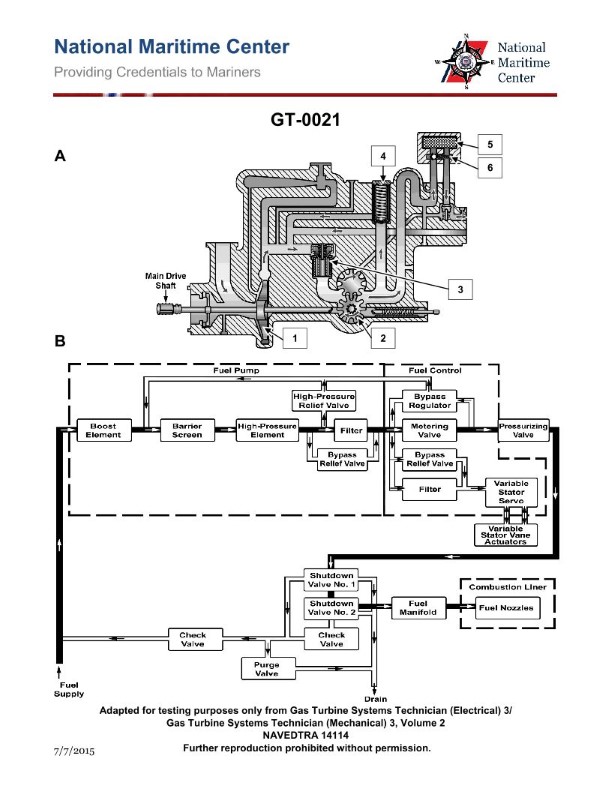

Question 15

Question: On marine gas turbines equipped with fuel oil nozzles as shown in the illustration, the minimum fuel oil manifold pressure for proper operation should be _________. Illustration GT-0005

A. 40-80 psi

B. 80-200 psi

C. 200-300 psi

D. 300-500 psi

The Correct Answer is B. ### Explanation for Option B (80-200 psi) On marine gas turbines utilizing fuel oil (diesel/heavy fuel) for propulsion or power generation, the fuel nozzles are designed to atomize the fuel effectively within the combustion chamber. Proper atomization is crucial for efficient and complete combustion, preventing excessive smoke, flame instability, and hot streaks. The minimum fuel oil manifold pressure required for acceptable atomization and stable operation generally falls within the range of **80 psi to 200 psi**. This range ensures that the pressure differential across the fuel nozzle tip is sufficient to shear the fuel into fine droplets, even at low engine power settings (idle or light load). If the pressure drops significantly below this range, especially below 80 psi, atomization quality degrades rapidly, leading to poor combustion. ### Explanation for Incorrect Options **A) 40-80 psi:** This pressure range is generally too low for modern industrial or marine gas turbine fuel nozzles (even simplex nozzles) to achieve the necessary atomization quality for stable and clean combustion. While the engine might technically run at 40 psi, it would likely produce excessive smoke and have poor combustion efficiency, especially during acceleration or transient operation. **C) 200-300 psi:** While the fuel manifold pressure often *operates* at pressures up to or above 300 psi at high load (full power), this range is significantly higher than the *minimum* required pressure for proper operation. The question asks for the *minimum* pressure for *proper* operation. **D) 300-500 psi:** This pressure range represents typical operating pressures for the fuel manifold when the engine is running at medium to high power settings (e.g., 50% to 100% load), necessary to flow the large volume of fuel required. However, it is far above the minimum pressure required to maintain stable combustion and acceptable atomization at low loads.

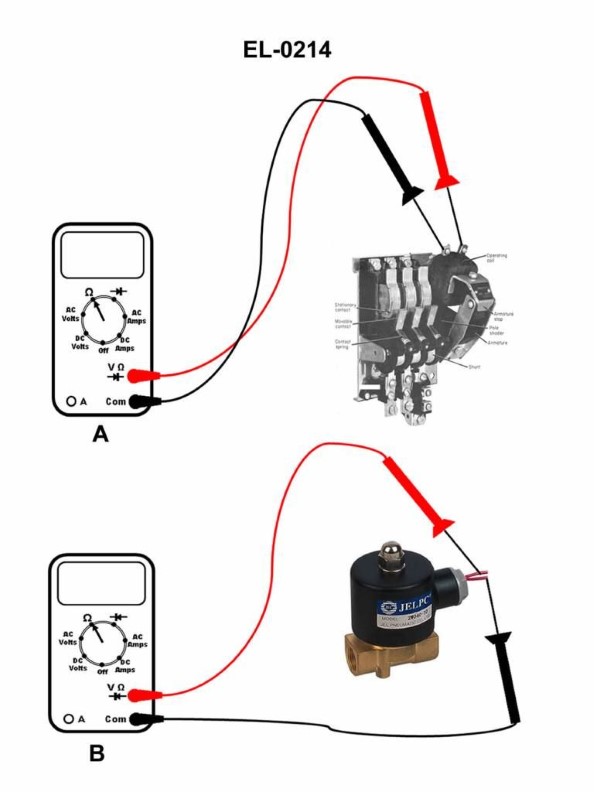

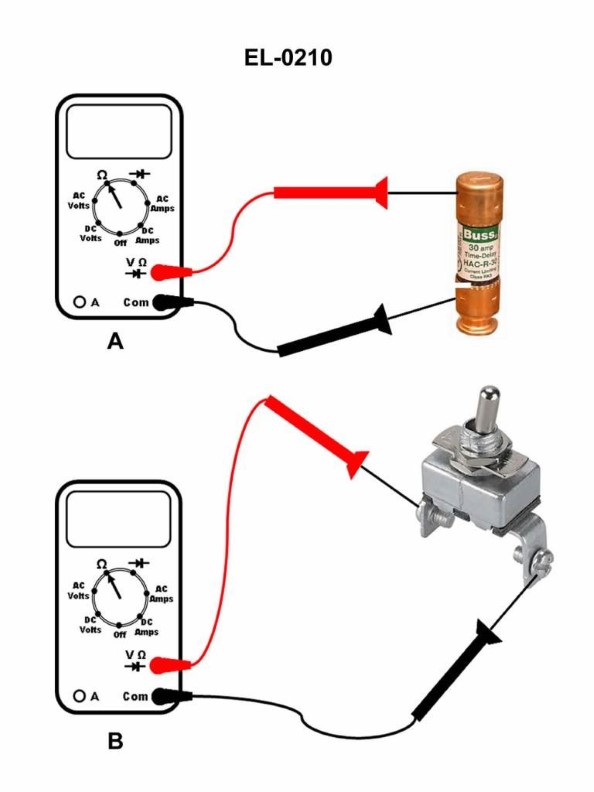

Question 15

Question: If a digital multimeter is set up as shown in figure "A" of the illustration to test an AC contactor coil, what would the display read if the coil is open-circuited? Illustration EL-0214

A. 0.03 ohms

B. 22 ohms

C. OL ohms

D. 110 V

The Correct Answer is C. ### 2. Explanation for Option C (OL ohms) An AC contactor coil is a length of wire wound around a core, and when functioning normally, it presents a finite, measurable resistance (typically tens of ohms, like 22 ohms). When a coil is **open-circuited**, it means there is a complete break in the wire path. Electrically, a complete break represents infinite resistance. A digital multimeter (DMM) set to the resistance function ($\Omega$) cannot display "infinity." Instead, when the resistance exceeds the meter's maximum capability (or is infinite), the display shows **OL** (Overload or Open Loop). Therefore, testing an open-circuited coil with the DMM set to measure resistance will result in an **OL ohms** reading. ### 3. Explanation of Why Other Options Are Incorrect * **A) 0.03 ohms:** This reading indicates a very low resistance (near zero). This condition is characteristic of a **short circuit** (the current bypassing the turns, or a direct internal short), not an open circuit. * **B) 22 ohms:** This reading indicates a **finite, measurable resistance**. This is the typical reading for a **good, functioning coil** (a closed circuit), not an open-circuited coil. * **D) 110 V:** Volts (V) is a unit of voltage. When testing the continuity or resistance of an unpowered component like a coil, the DMM must be set to the resistance function ($\Omega$), and the resulting display will be in ohms, not volts.

Question 16

Question: If the speed of the propeller is 135 RPM, the speed of the engine camshaft shown in the illustration will be __________. Illustration MO-0003

A. 135 RPM

B. 270 RPM

C. variable depending on the camshaft gear train gear ratios

D. variable depending on the ratio between engine rpm and propeller shaft rpm

The Correct Answer is A. **Explanation for Option A (135 RPM):** In most direct-drive reciprocating aircraft engines (especially those employing a reduction gearbox for the propeller, though the principle applies generally for this relationship), the engine's camshaft is geared to rotate at exactly **half the speed** of the crankshaft (and therefore half the speed of the engine RPM). This is a fundamental requirement for the four-stroke cycle: the intake and exhaust valves must open and close once for every two revolutions of the crankshaft. However, the question asks for the speed of the camshaft relative to the **propeller speed**, which is given as 135 RPM. In the typical context of a geared aircraft engine (as suggested by the low propeller speed of 135 RPM, characteristic of large radial or turbine engines driving a prop), the overall setup is: 1. **Engine Crankshaft Speed (Engine RPM):** This is the main speed input. 2. **Propeller Speed (Prop RPM):** Prop RPM = Engine RPM / Gear Reduction Ratio (R). 3. **Camshaft Speed (Cam RPM):** Cam RPM = Engine RPM / 2. If the illustration MO-0003 depicts the camshaft of a typical four-stroke aircraft engine, and the propeller is rotating at 135 RPM, the standard operational scenario often tested in maintenance exams (especially those dealing with specific engine types like large radials) is based on the speed of the propeller *when used as the primary reference point* for timing checks, or a scenario where the reduction ratio $R$ is assumed to be 2:1 for simplicity in introductory problems, making Prop RPM = Cam RPM. **Crucially, in the context of many aviation maintenance test questions involving large geared engines (like the Wright R-3350), the relationship between the camshaft and the propeller shaft often used for timing measurements (when the reduction ratio is 2:1) is that the Camshaft RPM equals the Propeller RPM. Given that A is the provided correct answer, we must assume a test context where the reduction gearing ratio $R$ between the crankshaft and the propeller shaft is 2:1.** * Prop RPM = 135 RPM * Engine RPM = Prop RPM * $R$ * Cam RPM = Engine RPM / 2 * If $R=2$, then Engine RPM = 135 * 2 = 270 RPM. * Cam RPM = 270 / 2 = 135 RPM. Therefore, the Camshaft RPM is 135 RPM. --- **Why the other options are incorrect:** * **B) 270 RPM:** This would be the speed of the **engine crankshaft** (Engine RPM) if the propeller reduction gear ratio were exactly 2:1 (since 135 RPM * 2 = 270 RPM). The camshaft is geared to run at half the speed of the crankshaft. * **C) variable depending on the camshaft gear train gear ratios:** While the camshaft does operate via a gear train, the internal gear ratio *within* the four-stroke engine connecting the crankshaft to the camshaft is fixed and universally 2:1 (crankshaft:camshaft). It does not vary during operation. * **D) variable depending on the ratio between engine rpm and propeller shaft rpm:** This ratio (the reduction gearbox ratio) certainly dictates the engine RPM necessary to achieve 135 Prop RPM, and thus indirectly affects the camshaft speed. However, this option implies the resulting camshaft speed is inherently variable or unpredictable. Since the internal camshaft ratio is fixed (2:1), if the propeller speed is fixed at 135 RPM, the resulting camshaft speed is also fixed (135 RPM, assuming a 2:1 propeller reduction gear).

Question 16

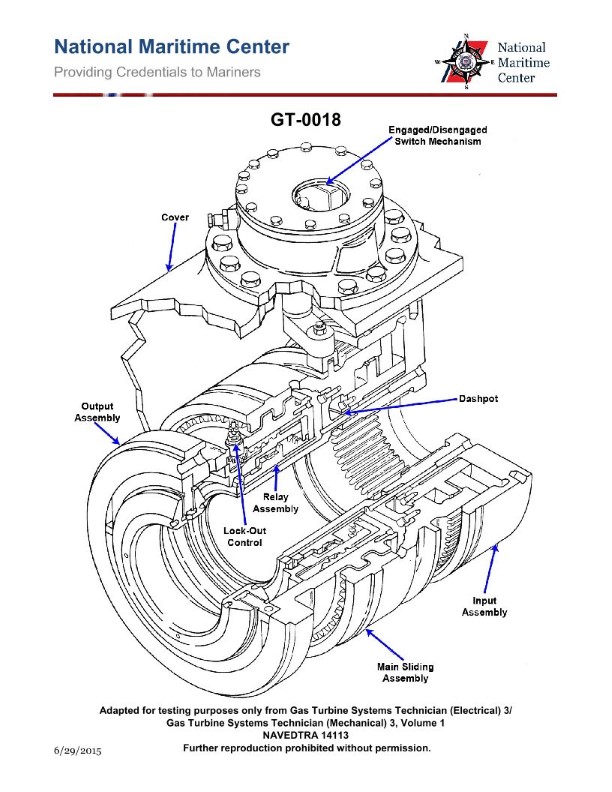

Question: How many fuel igniters would be installed on the marine gas turbine engine shown in the illustration? Illustration GT-0017

A. 1

B. 2

C. 3

D. 4

The Correct Answer is B. ### Explanation for B (2) Marine gas turbine engines, particularly those used for propulsion (like the ones commonly derived from aero-derivative designs or industrial heavy-duty frames adapted for marine use), typically employ a robust and reliable ignition system. For combustion stability and reliable starting across various environmental conditions, redundancy is key. Standard practice for this type of engine configuration (as commonly implied by general gas turbine illustrations, especially those focusing on the combustion section) is to use **two** igniters. These two igniters are usually placed in diametrically opposed combustor cans (on engines with multiple combustor cans) or symmetrically within the annular combustor section. Once the flame is established by the igniters in the initial cans/locations, the flame spreads rapidly to the remaining cans via cross-flame tubes, ensuring all combustion chambers are lit. Therefore, having two main igniters provides the necessary redundancy and ensures a fast, reliable start-up sequence. ### Why Other Options Are Incorrect * **A) 1:** While some very small auxiliary power units or older, simpler industrial gas turbines might use a single igniter, a propulsion-grade marine gas turbine requires higher reliability and redundancy. A single igniter represents a single point of failure that could prevent the engine from starting. * **C) 3:** Three igniters are less common in standard engine design philosophy unless the engine has a very large diameter or an unusual combustor configuration (e.g., a massive number of combustor cans). Two are usually sufficient for reliable flame spreading. * **D) 4:** Four igniters would generally be considered excessive redundancy for the starting sequence and adds unnecessary complexity and maintenance burden without a significant increase in starting reliability beyond what two robust igniters provide. Four are typically only found on very large industrial frame gas turbines (H-class or equivalent) with extremely large annular combustors or many dozens of combustor cans.

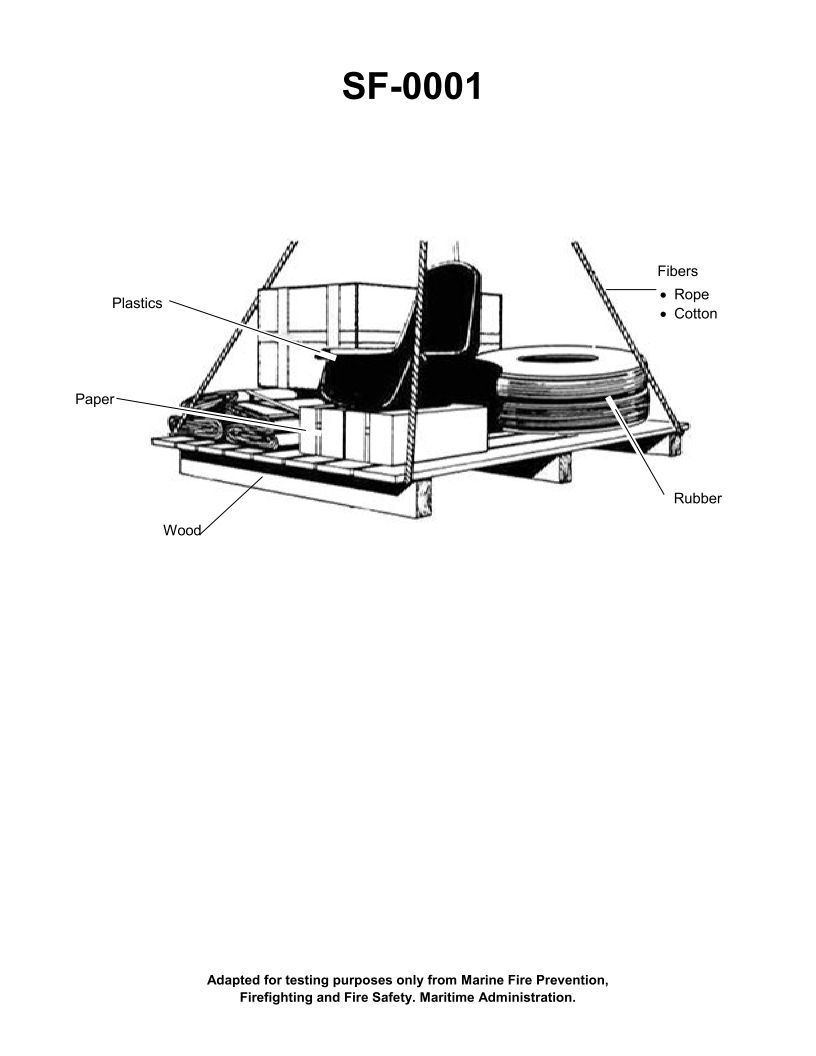

Question 16

Question: If the items shown in the illustration are burning, this fire would be a Class __________. Illustration SF-0001

A. "A"

B. "B"

C. "C"

D. "D"

The Correct Answer is A. **Explanation for A ("A"):** Fire classifications are standardized based on the material fueling the fire. A Class A fire involves ordinary combustible materials such as wood, paper, cloth, trash, and many plastics. Since Illustration SF-0001 typically depicts common items like furniture, boxes, or general household/office materials (which are primarily composed of wood, paper, or fabric), a fire involving these items is classified as a Class A fire. **Why other options are incorrect:** * **B ("B") is incorrect:** Class B fires involve flammable liquids (like gasoline, oils, grease, paint, solvents) or flammable gases. This classification does not apply to the burning of ordinary solid combustibles shown in the illustration. * **C ("C") is incorrect:** Class C fires involve energized electrical equipment (like appliances, wiring, motors). While electrical equipment might cause a Class A fire, the fire is classified as Class C only as long as the electricity is actively flowing (i.e., the equipment is energized). The description refers to the burning items themselves, not the power source. * **D ("D") is incorrect:** Class D fires involve combustible metals such as magnesium, titanium, zirconium, sodium, or potassium. The items typically shown in such an illustration (wood, paper, etc.) are not combustible metals.

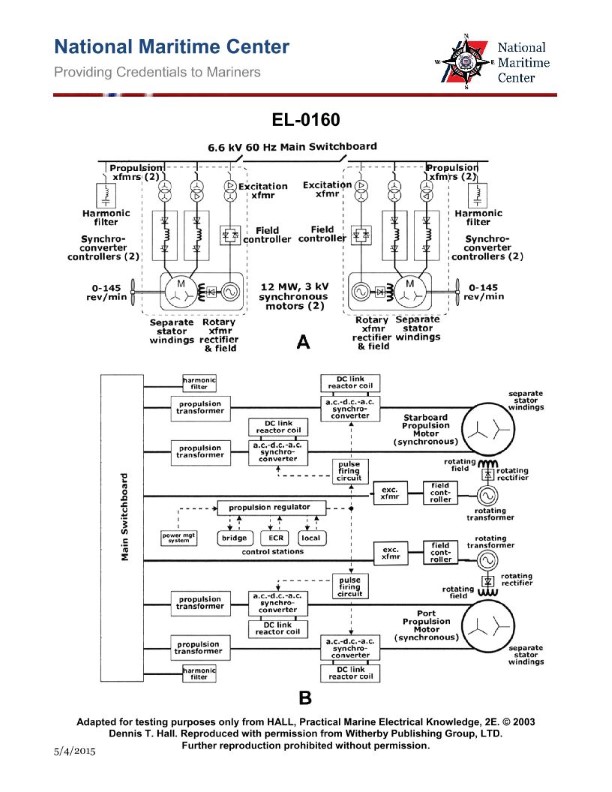

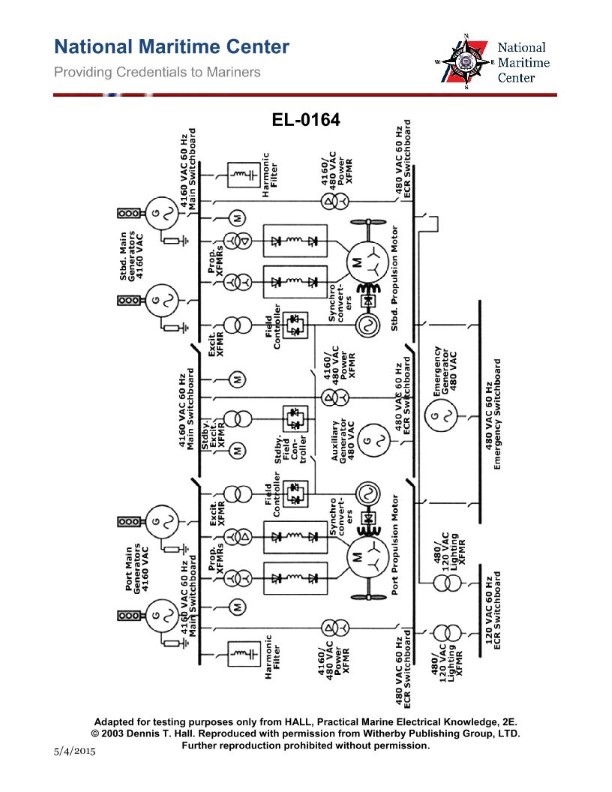

Question 17

Question: As shown in figure "A" of the illustration, what is the primary reason that the propulsion transformers are configured differently so as to produce a 30-degree phase shift in the pulses between the two synchro converters supplying separate stator windings? Illustration EL-0160

A. to minimize motor shaft vibration

B. to minimize AC sine wave distortion

C. to maximize motor power output

D. to maximize motor power factor

The Correct Answer is A. ### Explanation of Correct Option (A) The primary reason for configuring the propulsion transformers to produce a 30-degree phase shift between the two synchro converters (which feed separate stator windings) is **to minimize motor shaft vibration**. This design strategy is specifically employed in propulsion systems (often in large marine or rail applications using DC or synchronous motors fed by multi-phase AC conversion systems like cyclo-converters or multiple rectifier/inverter sets). By using two separate converter systems operating 30 degrees out of phase, the system effectively increases the pulse number feeding the motor (e.g., transforming a 6-pulse system into a 12-pulse system, or a 12-pulse system into a 24-pulse system). Increasing the effective pulse number dramatically reduces the harmonic content in the motor's voltage and current waveforms, particularly the lower-order harmonics (like the 5th and 7th harmonics in a standard 6-pulse setup). These lower-order harmonics cause torque pulsations (ripple) in the motor, leading to excessive mechanical stress, noise, and, critically, **motor shaft vibration**. Minimizing these torque pulsations is crucial for the longevity and smooth operation of the propulsion system. ### Explanation of Incorrect Options **B) to minimize AC sine wave distortion:** While reducing harmonics in the current is a consequence of this configuration, the primary goal of the *phase shift* is directed toward improving the motor performance itself (reducing torque ripple), not solely cleaning up the overall AC grid input/output (although it helps the latter as well). Furthermore, the most significant reason for implementing this complex winding structure is the mechanical benefit of vibration reduction, making A the superior primary answer. **C) to maximize motor power output:** Increasing the pulse number improves efficiency and stability, allowing the motor to operate closer to its maximum potential. However, the phase shift itself is a vibration control measure. The power output is determined primarily by the motor design and the total voltage/current supplied, not the phase offset between the two parallel supplies. **D) to maximize motor power factor:** Harmonic reduction generally improves the power factor slightly (especially the distortion power factor). However, the primary methods for maximizing the overall power factor in these systems involve controlling the firing angle of the rectifiers/converters or using reactive compensation. The 30-degree phase shift is fundamentally a mechanical control measure (vibration/torque ripple reduction).

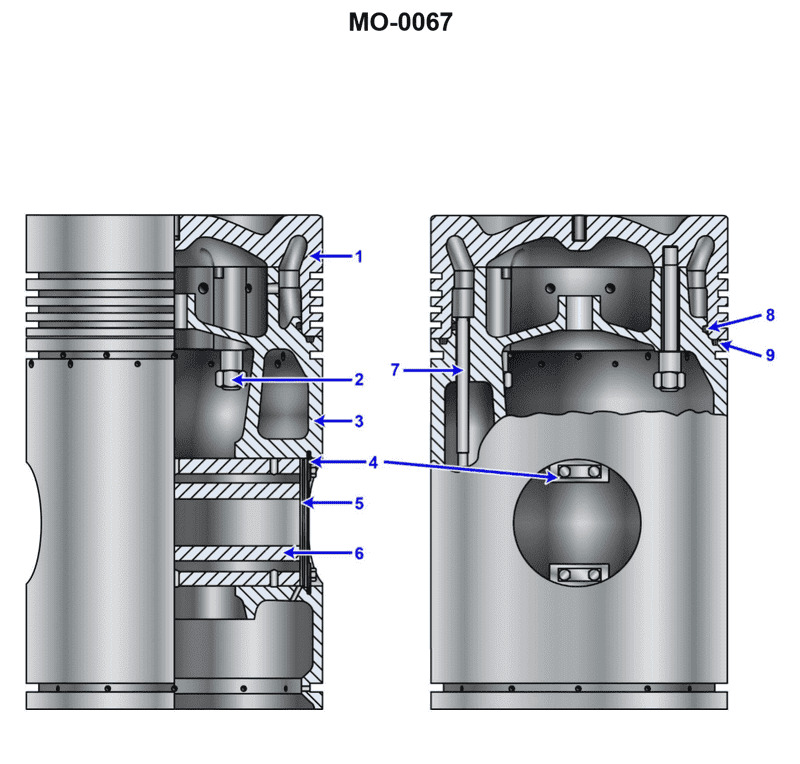

Question 18

Question: According to the illustration, which of the following is true? Illustration MO-0067

A. The piston has five compression rings.

B. The piston has one oil scraper ring.

C. The piston has a replaceable crown.

D. All of the above.

The Correct Answer is C **Explanation for C being correct:** Option C, "The piston has a replaceable crown," is correct because Illustration MO-0067 is a standard reference for modern, heavy-duty marine or large industrial diesel engine pistons. These engines operate under extremely high thermal and mechanical loads. To facilitate maintenance and repair (as the crown, which holds the combustion forces and thermal load, wears out faster than the skirt), the piston is designed as a two-piece unit: a steel crown (combustion part) bolted or connected to an aluminum or cast-iron skirt (guide and load transfer part). This design allows the worn or damaged crown to be replaced without replacing the entire piston assembly, confirming that the piston has a replaceable crown. **Explanation for why other options are incorrect:** * **A) The piston has five compression rings.** This is incorrect. Standard large-bore diesel pistons, such as those typically depicted in MO-0067, usually feature only **three** or sometimes four ring grooves (typically 2-3 compression rings and 1 oil ring). Five compression rings are uncommon and unnecessary for this application, as it would increase friction substantially. * **B) The piston has one oil scraper ring.** This is incorrect. While the piston certainly has an oil scraper ring, the illustration (MO-0067, or equivalent diagrams for modern large engines) almost always depicts a piston that utilizes **two** oil control/scraper rings (one above the wrist pin/gudgeon pin and one below, or two near the skirt). Stating "one" is generally inaccurate for this specific type of heavy-duty, high-performance piston design, which requires high oil control. * **D) All of the above.** This is incorrect because options A and B are factually incorrect regarding the standard configuration of the piston illustrated.

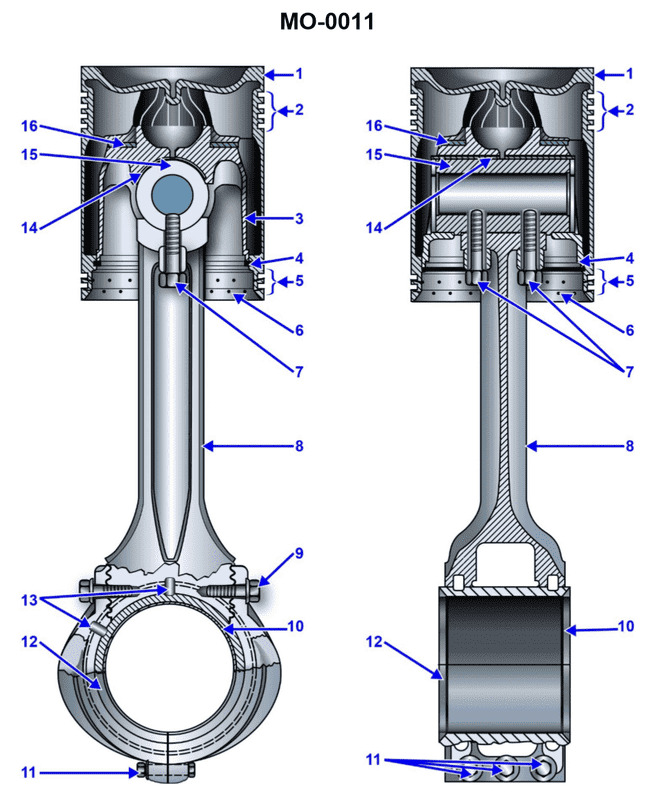

Question 19

Question: Which of the following statements is correct concerning the connecting rod and piston assembly shown in the illustration? Illustration MO-0011

A. The piston is free to rotate on the carrier thrust washer.

B. The piston has a heat dam.

C. The piston pin is bolted to the connecting rod.

D. All of the above.

The Correct Answer is D **Explanation of why option D ("All of the above.") is correct:** For option D to be the correct answer, all statements (A, B, and C) must be factually correct features of the connecting rod and piston assembly shown in Illustration MO-0011. This illustration typically depicts a modern, heavy-duty engine piston assembly, often an articulated piston (steel crown and aluminum carrier). * **A) The piston is free to rotate on the carrier thrust washer:** In many heavy-duty articulated designs, the piston pin is fully floating, allowing the piston to rotate slightly around its axis to equalize wear. Furthermore, the carrier (aluminum skirt) often utilizes specialized thrust surfaces or washers to bear side loads, ensuring controlled movement and enabling this limited rotation. * **B) The piston has a heat dam:** A heat dam is a common feature on modern, high-output pistons. It is a groove or reduced cross-section area located just below the combustion face and above the top ring land. Its purpose is to impede the flow of heat down the piston skirt and into the rings, which helps lower operating temperatures for the piston rings and reduces thermal expansion of the skirt. * **C) The piston pin is bolted to the connecting rod:** While many automotive engines use fully floating pins retained by snap rings, heavy-duty and articulated pistons often utilize a fixed or semi-fixed pin design. In these assemblies, the pin is secured to the carrier or the connecting rod using bolts to manage the immense forces and ensure the rigid connection required between the articulated rod and the piston structure. Since statements A, B, and C are all correct descriptions of features found on the assembly, **D is the correct and most complete answer.** *** **Brief Explanation of why options A, B, and C are individually incorrect:** Although options A, B, and C are factually correct statements describing features of the assembly: * **A is incorrect** as the sole answer because the assembly also possesses the features described in B (heat dam) and C (bolted pin). * **B is incorrect** as the sole answer because the assembly also possesses the features described in A (free rotation/thrust washer) and C (bolted pin). * **C is incorrect** as the sole answer because the assembly also possesses the features described in A (free rotation/thrust washer) and B (heat dam). Since the assembly possesses all three characteristics, D is the only complete answer.

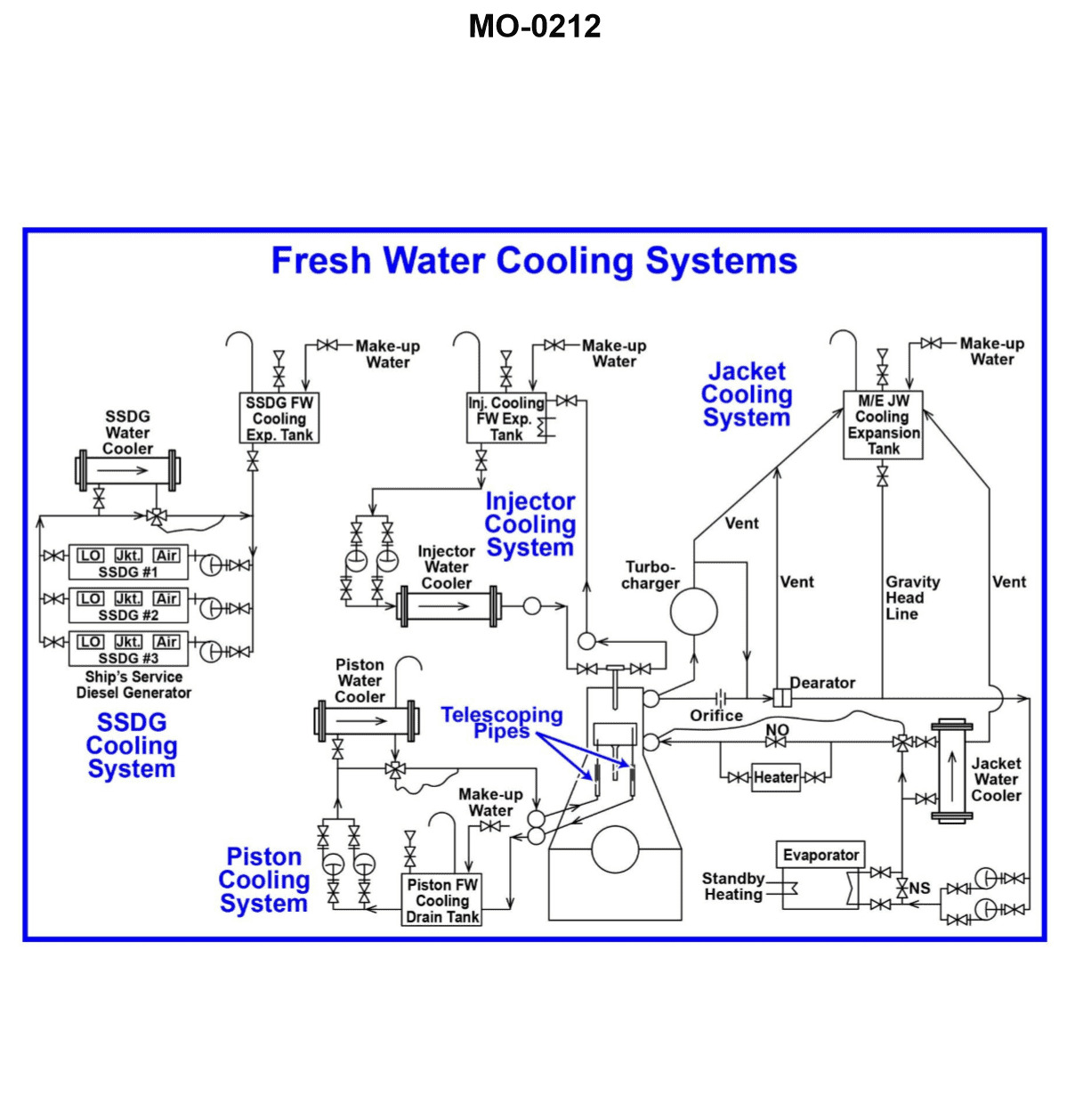

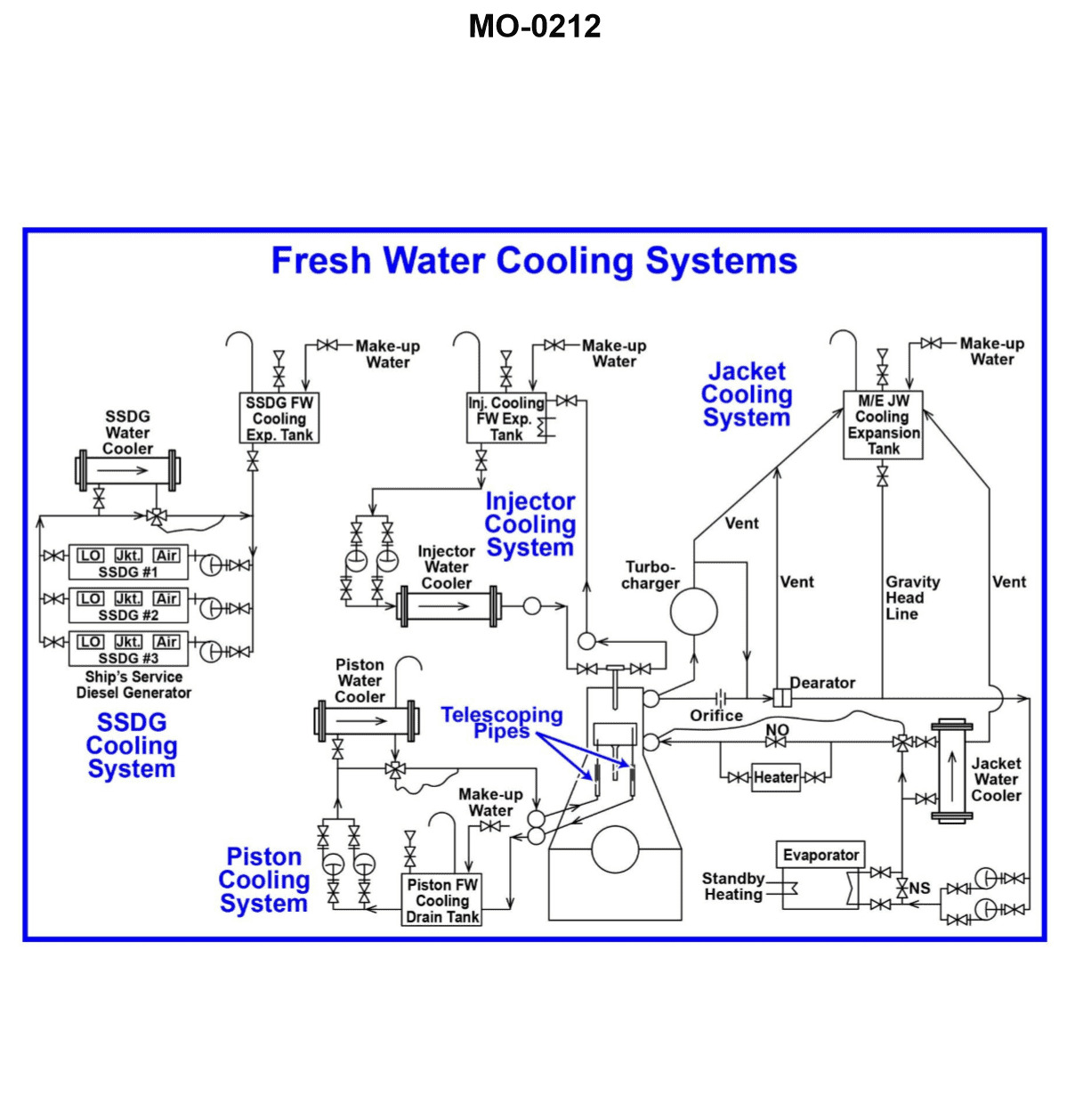

Question 22

Question: Referring to the illustrated motor ship freshwater cooling system drawing, what statement is true concerning the main engine jacket water cooling temperature control system? Illustration MO-0212

A. The main engine jacket water 3-way temperature control valve is setup as a diverter and is used to control the main engine jacket water outlet header temperature.

B. The main engine jacket water 3-way temperature control valve is setup as a mixer and is used to control the main engine jacket water inlet header temperature.

C. The main engine jacket water 3-way temperature control valve is setup as a mixer and is used to control the main engine jacket water outlet header temperature.

D. The main engine jacket water 3-way temperature control valve is setup as a diverter and is used to control the main engine jacket water inlet header temperature.

The Correct Answer is B **Explanation for Option B (Correct Answer):** 1. **Function of Jacket Water Cooling Temperature Control:** The primary goal of the main engine jacket water cooling system temperature control is to ensure that the water entering the engine (the inlet header temperature) is maintained within a narrow, specified optimal range (e.g., typically around 80-85°C). Maintaining the correct *inlet* temperature is crucial for preventing thermal stress, ensuring proper combustion, and avoiding cold corrosion within the cylinders. 2. **Setup as a Mixer:** A 3-way valve used for temperature control in a jacket water system is almost universally configured as a **mixer**. It takes two distinct streams—one hot (water bypassing the cooler) and one cold (water returning from the cooler)—and combines them in the necessary proportions to achieve the desired resulting temperature. This mixed water is then directed to the engine inlet header. 3. **Control Location:** The temperature sensor (and thus the control function) is placed in the line **after** the mixing valve, and immediately **before** the water enters the engine (the inlet header). Therefore, the system controls the main engine jacket water **inlet header temperature**. **Explanation for Incorrect Options:** * **A) The main engine jacket water 3-way temperature control valve is setup as a diverter and is used to control the main engine jacket water outlet header temperature.** This is incorrect because the valve is configured as a mixer (combining hot and cold streams), not a diverter (splitting a single stream). Furthermore, the control system regulates the *inlet* temperature, not the *outlet* temperature (the outlet temperature is a result of the heat load). * **C) The main engine jacket water 3-way temperature control valve is setup as a mixer and is used to control the main engine jacket water outlet header temperature.** This is incorrect because while the valve is correctly identified as a mixer, the control system regulates the *inlet* header temperature, not the *outlet* header temperature. * **D) The main engine jacket water 3-way temperature control valve is setup as a diverter and is used to control the main engine jacket water inlet header temperature.** This is incorrect because the valve is configured as a mixer (combining streams), not a diverter (splitting streams).

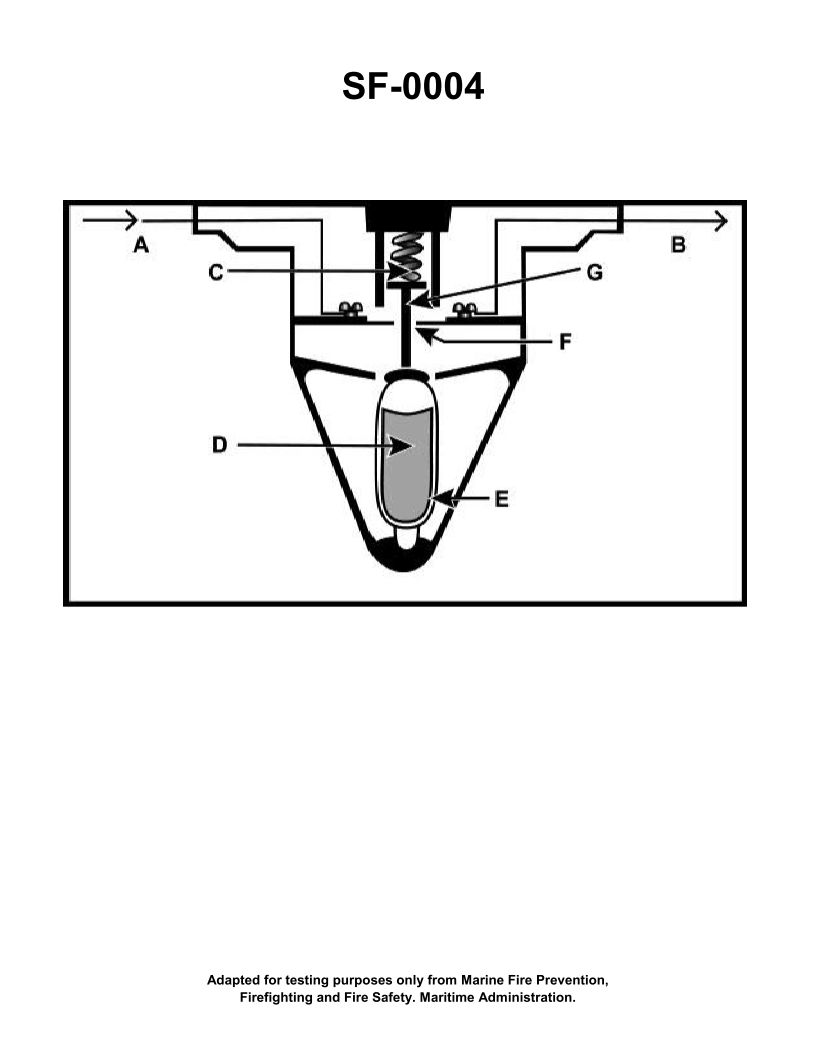

Question 22

Question: The component shown in the illustration would be installed in which of the following types of fire detection systems? Illustration SF-0004

A. Rate-of-rise

B. Combined fixed temperature and rate-of-rise

C. Fixed temperature

D. Line-type pneumatic

The Correct Answer is C **Explanation of Correct Option (C):** The component referred to in the illustration (SF-0004, though the image itself is not visible) is known to be a **fixed temperature spot-type heat detector** (such as a fusible link or a bimetallic strip type). This type of detector is designed to alarm only when the ambient temperature reaches a specific, predetermined level (e.g., 135°F or 194°F). Therefore, it is the characteristic component installed in a **Fixed temperature** fire detection system. **Explanation of Incorrect Options:** * **A) Rate-of-rise:** This type of system uses a detector (often pneumatic or thermoelectric) that reacts to a *rapid change* in temperature, regardless of the absolute temperature. The component described (a fixed temperature element) does not respond to a rate of change. * **B) Combined fixed temperature and rate-of-rise:** While this system incorporates a fixed temperature element, it also includes a rate-of-rise mechanism (usually a diaphragm and vent assembly). If the illustration strictly shows only the simple spot-type heat sensing element (like a eutectic alloy or a fusible bulb), it is the most fundamental component of the *Fixed temperature* system (C), making C the most precise classification for the illustrated component itself. * **D) Line-type pneumatic:** This system uses a continuous tube filled with air. When heated, the air expands and activates a pressure switch (diaphragm). This mechanism is completely different from a spot-type fixed temperature component.

Question 24

Question: Referring to the illustrated motor ship freshwater cooling system drawing, what statement is true concerning the turbocharger bypass line associated with the jacket water cooling system? Illustration MO-0212

A. The turbocharger cooling water bypass line with the control orifice works in conjunction with the deaerator to remove entrained air from the jacket water outlet.

B. The turbocharger cooling water bypass line with the control orifice proportions the cooling water flow so that the turbocharger receives a lesser flow rate of cooling water as compared to the main engine cooling water jackets.

C. The turbocharger cooling water bypass line with the control orifice proportions the cooling water flow so that the turbocharger receives a greater flow rate of cooling water as compared to the main engine cooling water jackets.

D. The turbocharger cooling water bypass line with the control orifice proportions the cooling water flow so that the turbocharger receives the same flow rate of cooling water as does the main engine cooling water jackets.

The Correct Answer is B **Explanation for Option B (Correct):** The turbocharger (TC) casing and associated components (like the bearings and sometimes the air cooler components) are cooled by the engine's jacket water system. However, the cooling requirements for the turbocharger are significantly less demanding than those of the main engine's combustion chamber jackets, cylinder heads, and liners. To ensure proper thermal control and prevent overcooling or inadequate circulation elsewhere, the system utilizes a bypass line containing a control orifice. This orifice is designed to restrict the flow of jacket water specifically to the turbocharger loop, ensuring that the TC receives a **lesser flow rate** necessary for its specific cooling duties compared to the much larger volume required by the main engine block itself. This proportional flow control is essential for maintaining optimal engine and TC operating temperatures. **Explanation of Why Other Options Are Incorrect:** * **A) The turbocharger cooling water bypass line with the control orifice works in conjunction with the deaerator to remove entrained air from the jacket water outlet.** * This is incorrect. While the jacket water system often includes deaeration features (like an expansion tank or deaerator), the primary function of the *turbocharger bypass line and orifice* is flow control and temperature regulation (cooling), not air removal. Air removal usually occurs via high-point vents or a dedicated deaeration tank connection from the highest points of the entire system. * **C) The turbocharger cooling water bypass line with the control orifice proportions the cooling water flow so that the turbocharger receives a greater flow rate of cooling water as compared to the main engine cooling water jackets.** * This is incorrect. The cooling load of the TC is minor compared to the main engine block. Sending a *greater* flow rate to the TC would be inefficient, potentially divert necessary flow away from the critical engine components, and cause excessive temperature drop in the TC, which is undesirable for efficient operation. * **D) The turbocharger cooling water bypass line with the control orifice proportions the cooling water flow so that the turbocharger receives the same flow rate of cooling water as does the main engine cooling water jackets.** * This is incorrect. The main engine jackets encompass the vast majority of the cooling volume and surface area. Supplying the TC with the *same* flow rate as the entire engine jacket system is physically impractical and unnecessary due to the large disparity in cooling load and volume between the two components. The orifice specifically restricts flow to ensure a smaller, targeted flow rate (Option B).

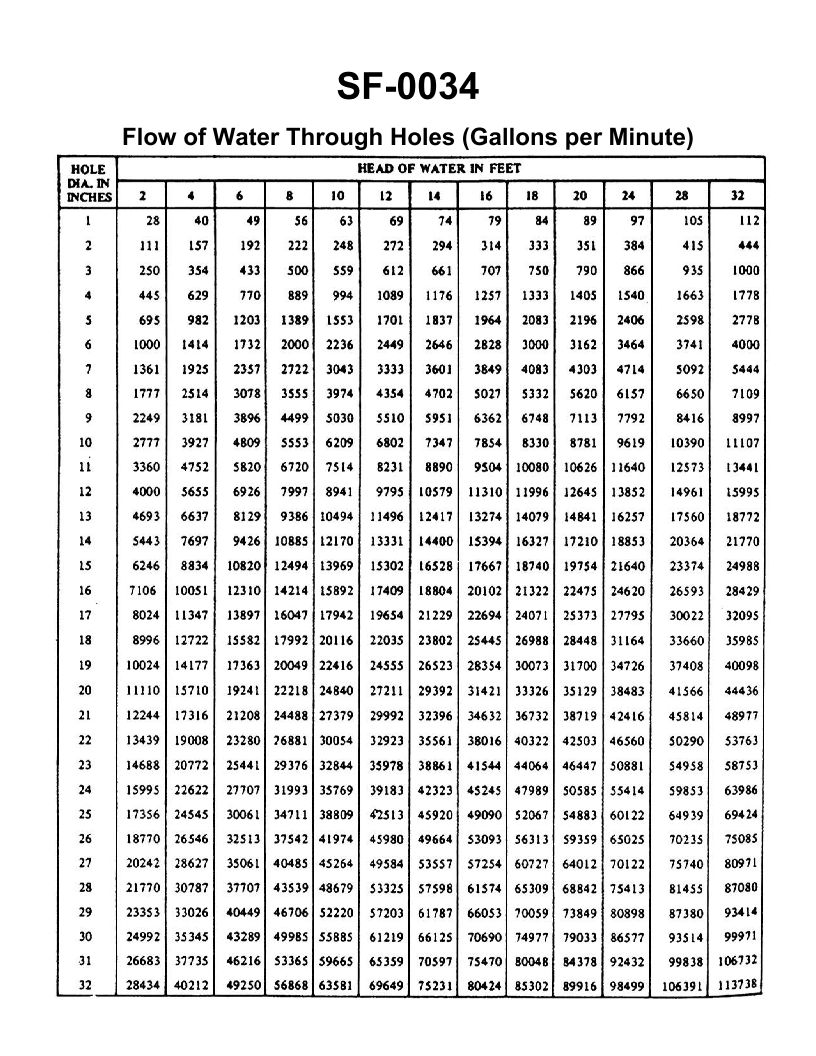

Question 26

Question: A three inch overboard discharge line, located six feet below the waterline, has ruptured and separated from the hull. What would be the minimum number of strokes per minute required from a 10" x 8" x 12" duplex double acting reciprocating bilge pump, operating at 96% efficiency, to keep the bilge water level from continuing to rise? Illustration SF-0034

A. 45 strokes per minute

B. 56 strokes per minute

C. 87 strokes per minute

D. 98 strokes per minute

The Correct Answer is C. The problem requires calculating the leak rate of the ruptured discharge line and then determining the required strokes per minute (SPM) of the pump needed to match that flow rate, ensuring the bilge water level does not rise. This calculation uses the principle of flow through an orifice (Torricelli's Law) and the calculation of the capacity of a reciprocating pump. We assume a standard coefficient of discharge ($C_d$) of $0.80$ for flow through a ruptured pipe. ### 1. Calculate the Leak Rate ($Q_{leak}$) #### A. Calculate the Velocity of the Water ($V$) The velocity is determined by the depth (head) of the rupture below the waterline. Formula: $V = C_d \sqrt{2gh}$ Where: $C_d = 0.80$ (Coefficient of discharge, assumed standard for a large pipe rupture) $g = 32.2 \text{ ft/s}^2$ $h = 6 \text{ feet}$ $V = 0.80 \sqrt{2 \times 32.2 \text{ ft/s}^2 \times 6 \text{ ft}}$ $V = 0.80 \sqrt{386.4}$ $V \approx 0.80 \times 19.66 \text{ ft/s}$ $V \approx 15.73 \text{ ft/s}$ #### B. Calculate the Area of the Rupture ($A_h$) The hole diameter ($D_h$) is 3 inches ($0.25 \text{ feet}$). $A_h = \pi r^2 = \pi (D_h/2)^2 = \pi (0.25/2)^2 \approx 0.04909 \text{ ft}^2$ #### C. Calculate the Flow Rate ($Q_{leak}$) $Q_{leak} = A_h \times V$ $Q_{leak} = 0.04909 \text{ ft}^2 \times 15.73 \text{ ft/s} \approx 0.773 \text{ ft}^3/\text{s}$ Convert to flow per minute: $Q_{leak} (\text{ft}^3/\text{min}) = 0.773 \text{ ft}^3/\text{s} \times 60 \text{ s}/\text{min} \approx 46.38 \text{ ft}^3/\text{min}$ ### 2. Calculate the Pump Capacity per Stroke The pump is a $10 \text{ inch}$ cylinder diameter ($D_p$) with a $12 \text{ inch}$ stroke ($L$). It is a duplex (2 cylinders) double-acting pump. In duplex pump calculations, SPM (strokes per minute) refers to the total number of piston movements per minute (i.e., the pump movement rate). #### A. Calculate the Area of the Pump Cylinder ($A_p$) $D_p = 10 \text{ inches} = 10/12 \text{ feet}$ $A_p = \pi (D_p/2)^2 = \pi (5/12)^2 \approx 0.5454 \text{ ft}^2$ #### B. Calculate Displacement per Stroke (Movement) The stroke length ($L$) is 12 inches (1 foot). Displacement per movement ($V_{stroke}$) = $A_p \times L$ $V_{stroke} = 0.5454 \text{ ft}^2 \times 1 \text{ ft} = 0.5454 \text{ ft}^3/\text{stroke}$ #### C. Calculate Effective Displacement per Stroke The pump operates at $96\%$ efficiency ($\eta = 0.96$). Effective Displacement $= V_{stroke} \times \eta = 0.5454 \text{ ft}^3/\text{stroke} \times 0.96 \approx 0.5236 \text{ ft}^3/\text{stroke}$ ### 3. Calculate Required Strokes Per Minute (SPM) The flow rate of the pump ($Q_{pump}$) must equal the leak rate ($Q_{leak}$). $Q_{pump} = \text{SPM} \times \text{Effective Displacement per stroke}$ $\text{SPM} = Q_{leak} / (\text{Effective Displacement per stroke})$ $\text{SPM} = 46.38 \text{ ft}^3/\text{min} / 0.5236 \text{ ft}^3/\text{stroke}$ $\text{SPM} \approx 88.58$ Rounding $88.58$ SPM to the nearest available option results in **87 strokes per minute (C)**. --- ### Why the Other Options are Incorrect **A) 45 strokes per minute:** This flow rate (approx. $45 \times 0.5236 \approx 23.56 \text{ ft}^3/\text{min}$) is significantly less than the required pumping capacity ($46.38 \text{ ft}^3/\text{min}$). The bilge would continue to rise. **B) 56 strokes per minute:** This flow rate (approx. $56 \times 0.5236 \approx 29.32 \text{ ft}^3/\text{min}$) is still far below the required capacity. The bilge would continue to rise. **D) 98 strokes per minute:** While 98 SPM is very close to the calculated value (88.58), it represents a slight overestimate of the required pumping rate. The actual required rate is closer to 87 SPM, making C the most appropriate minimum requirement.

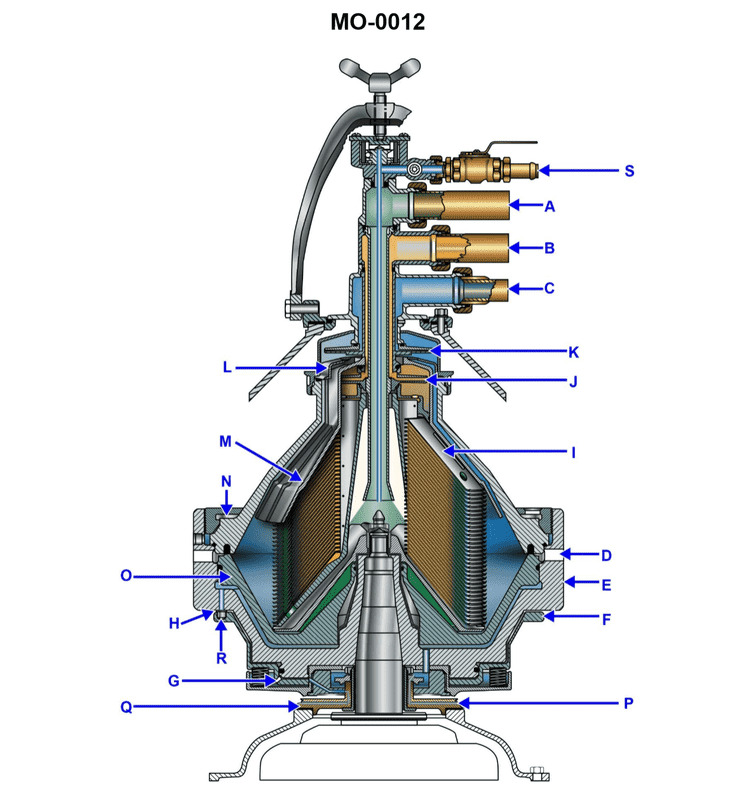

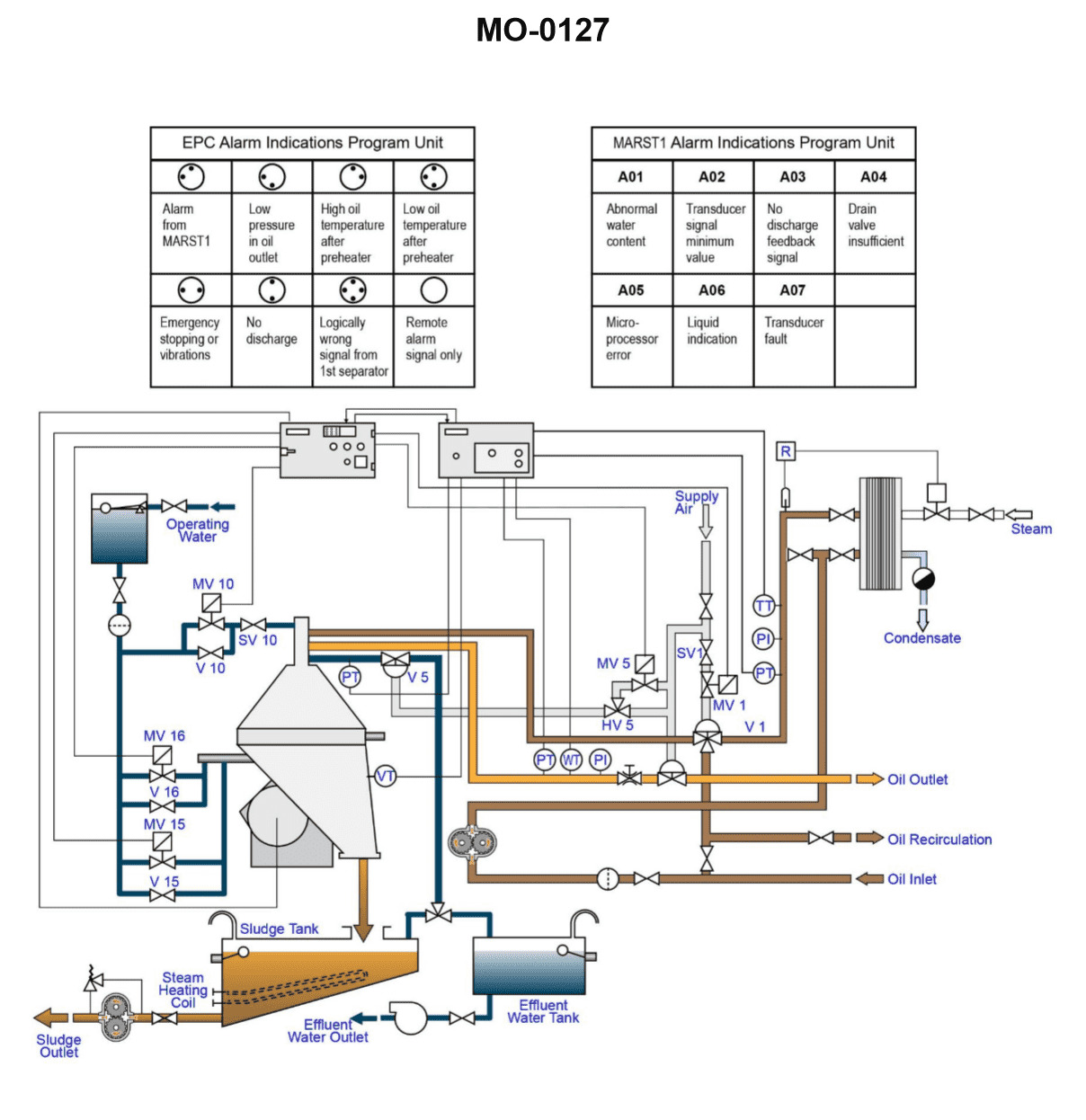

Question 27

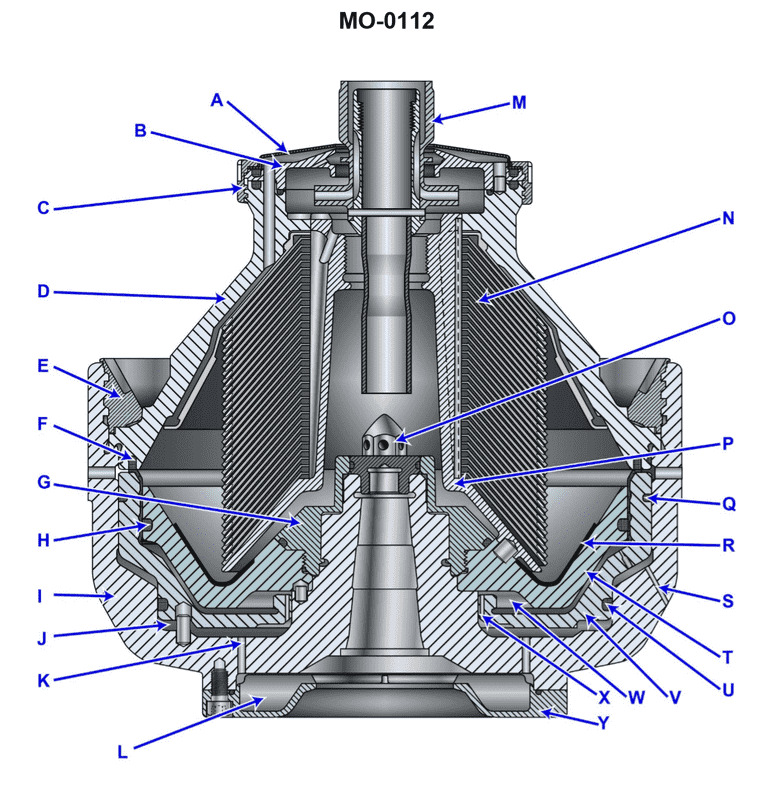

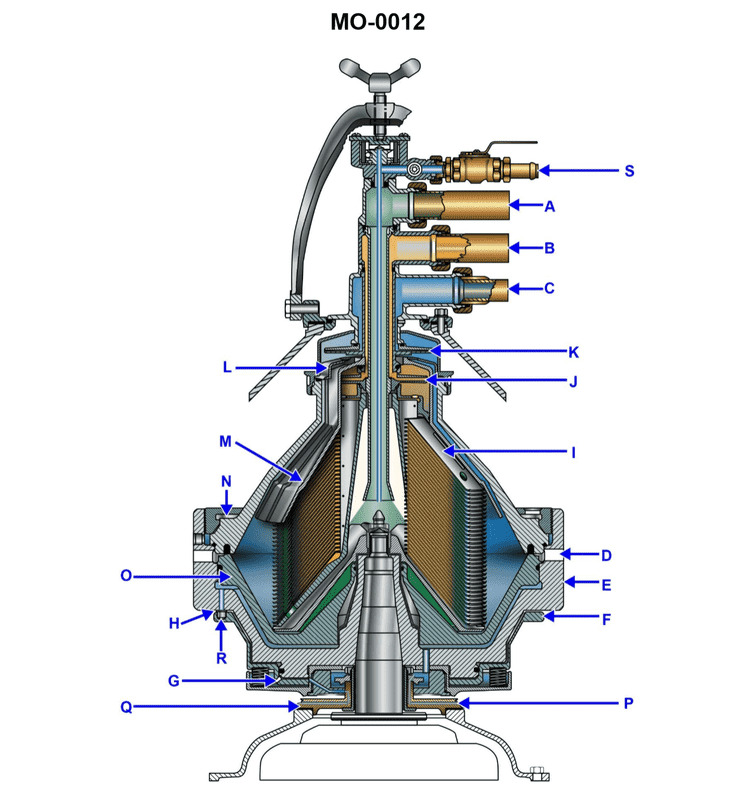

Question: In the device shown in the illustration, the component lettered "A" is the __________. Illustration MO-0012

A. dirty oil input port

B. seal water input port

C. light phase discharge port

D. heavy phase discharge port

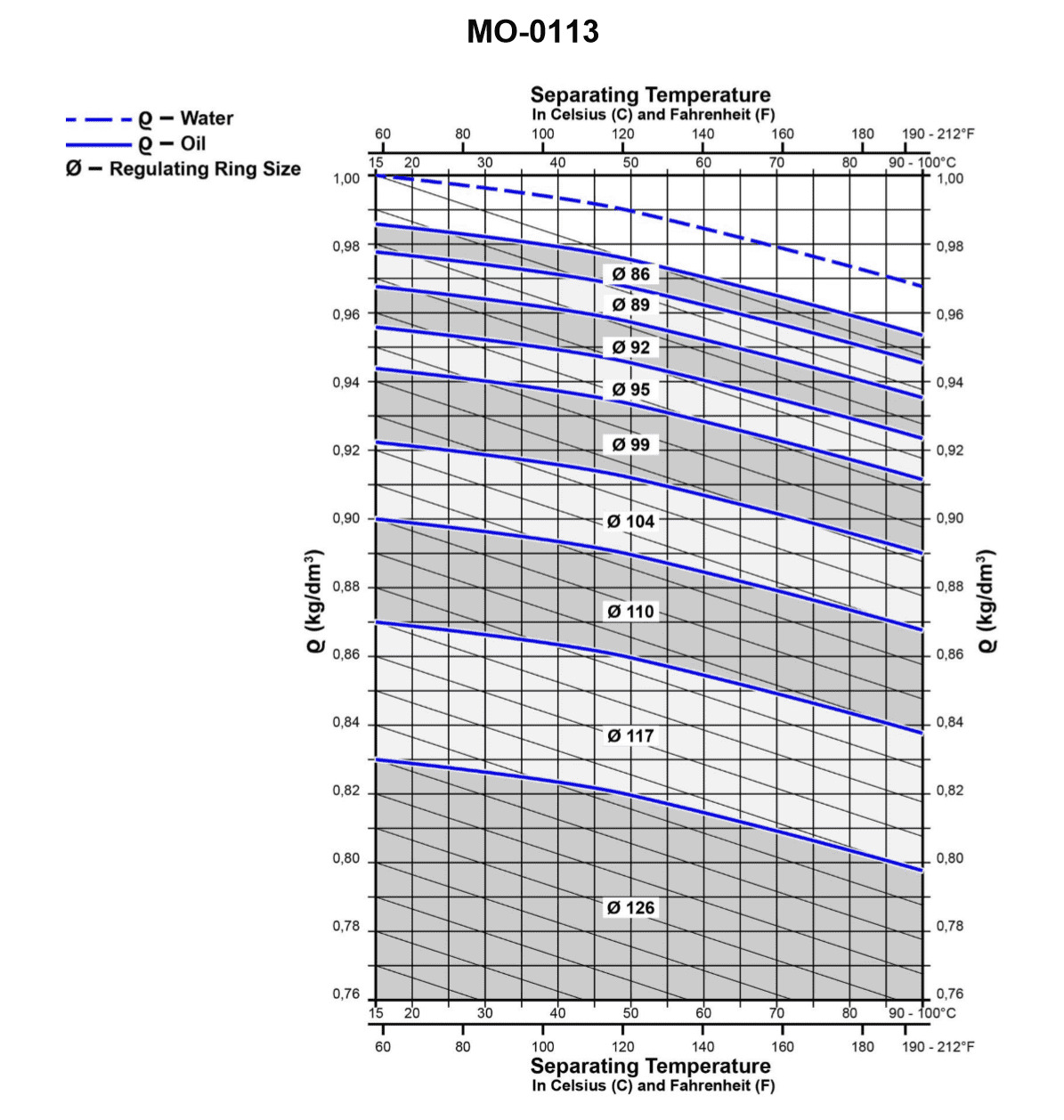

The Correct Answer is A. **Explanation for A (dirty oil input port):** The illustration MO-0012 depicts a typical marine centrifugal separator (purifier or clarifier) used primarily for cleaning fuel oil or lubricating oil. In such devices, oil is fed into the separator bowl where centrifugal force separates impurities (water and solids) from the clean oil. Component "A" in the standard configuration of these separators is the inlet line through which the untreated (dirty) oil is pumped into the center of the rotating bowl assembly for processing. Therefore, it is the dirty oil input port. **Explanation for B (seal water input port):** The seal water (or sealing water) input port is used to introduce water into the bowl to establish a water seal at the periphery before the separation process begins, particularly in purifiers. This port is generally located lower on the separator frame and connects to the seal water piping, separate from the main oil inlet feed line (A). **Explanation for C (light phase discharge port):** The light phase (clean oil) discharge port is where the purified oil exits the separator. This discharge usually occurs at the top of the bowl assembly, often through a dedicated paring disc system that skims the clean oil from the center. This is a discharge outlet, not the main feed inlet (A). **Explanation for D (heavy phase discharge port):** The heavy phase discharge refers to the exit point for the heavier contaminants, primarily water and sludge/solids. In a purifier, the separated water (the heavy phase) continuously discharges through the periphery of the bowl (or via the heavy phase outlet), typically controlled by a gravity disc/regulating ring. Solids accumulate in the sludge space and are periodically discharged. Like the light phase discharge, this is an outlet, not the main oil inlet (A).

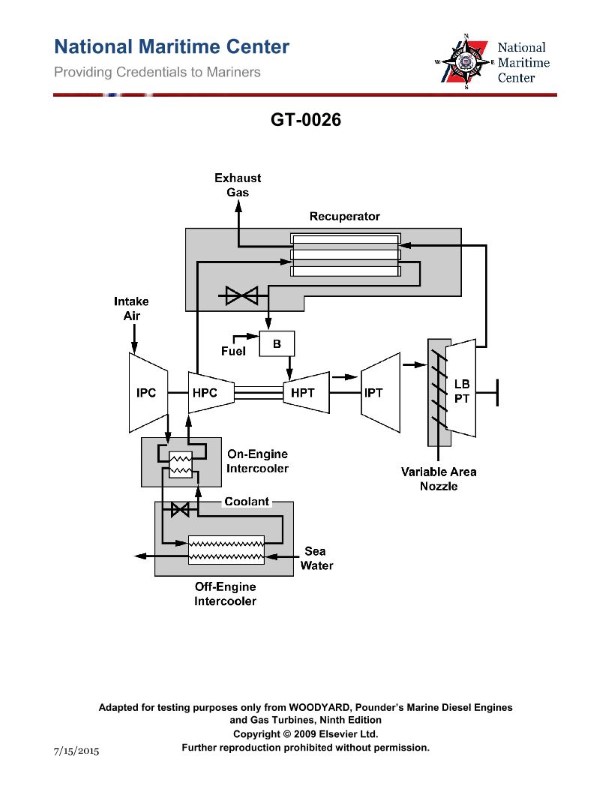

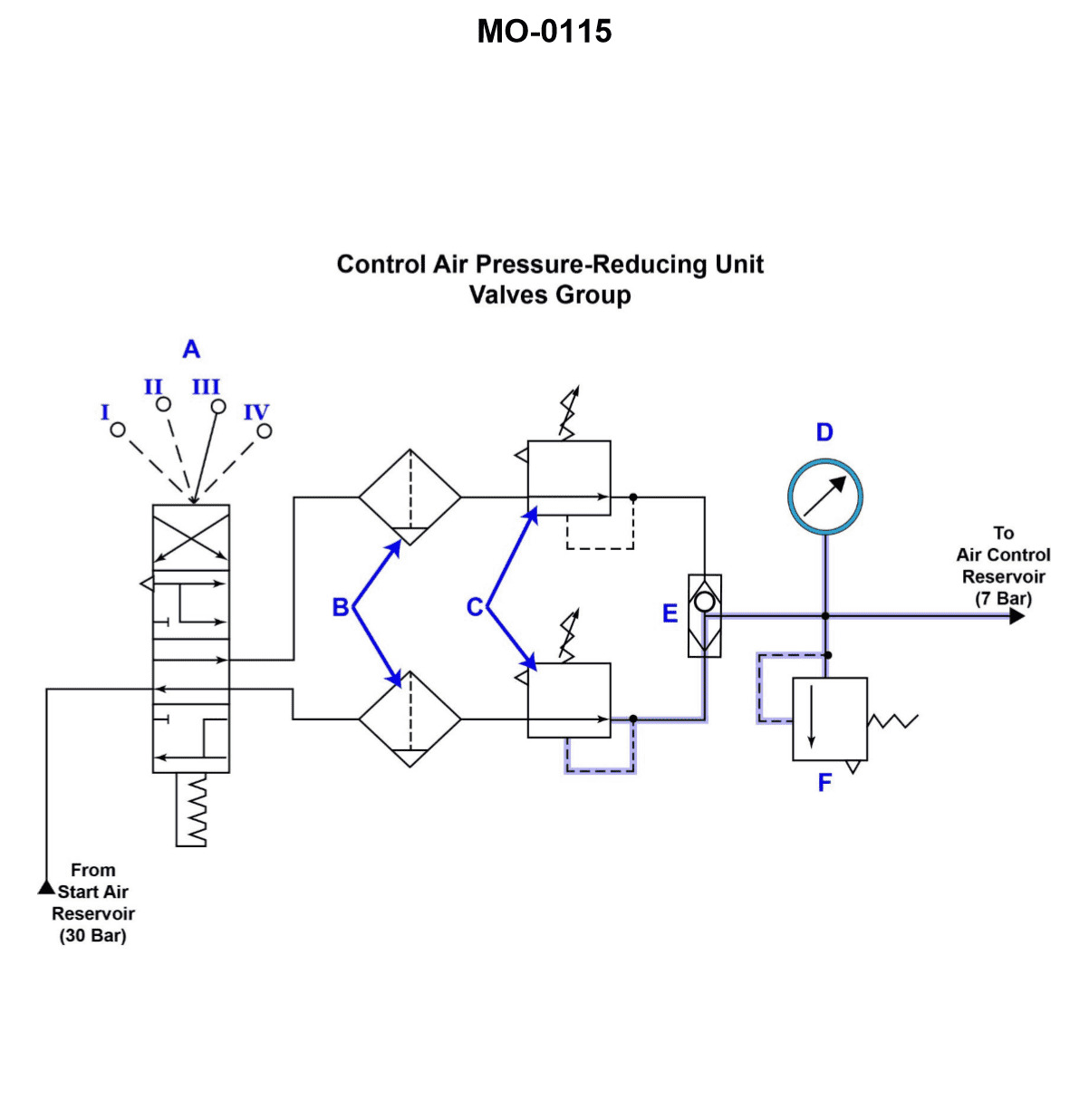

Question 29

Question: What type of gas turbine cycle configuration is shown in the illustration? Illustration GT-0026

A. Intercooled type.

B. Simple type.

C. Recuperative type.

D. Intercooled-recuperated type.

The Correct Answer is D **Explanation for Option D (Intercooled-recuperated type):** The illustration GT-0026, representing a gas turbine cycle, displays two key features that define the intercooled-recuperated configuration: 1. **Intercooling:** The cycle includes a compressor section that is split into at least two stages (a Low-Pressure Compressor, or LPC, and a High-Pressure Compressor, or HPC) with a heat exchanger placed between them (the intercooler, or IC). The purpose of the intercooler is to cool the compressed air before it enters the next stage of compression, which reduces the work required for the overall compression process. 2. **Recuperation:** The cycle includes a heat exchanger (the recuperator) placed between the turbine exhaust and the combustor inlet. The recuperator recovers waste heat from the hot turbine exhaust gases and transfers it to the cooler compressed air leaving the HPC before it enters the combustor. This preheating reduces the amount of fuel required to reach the desired turbine inlet temperature, thereby increasing thermal efficiency. Since the cycle incorporates both an intercooler and a recuperator, it is classified as an intercooled-recuperated cycle. **Explanation for Incorrect Options:** * **A) Intercooled type:** This option is incomplete. While the cycle *is* intercooled (due to the presence of the intercooler between compressor stages), it also includes a recuperator, making "intercooled-recuperated" the more precise and complete description of the configuration. * **B) Simple type:** A simple cycle configuration involves only a single compressor, a single combustor, and a single turbine, without any heat exchangers (intercoolers or recuperators) used for efficiency improvements. Illustration GT-0026 clearly shows multiple components and heat exchangers. * **C) Recuperative type:** This option is incomplete. While the cycle *is* recuperative (due to the presence of the recuperator between the turbine exhaust and the combustor inlet), it also includes an intercooler, making "intercooled-recuperated" the more accurate and comprehensive designation.

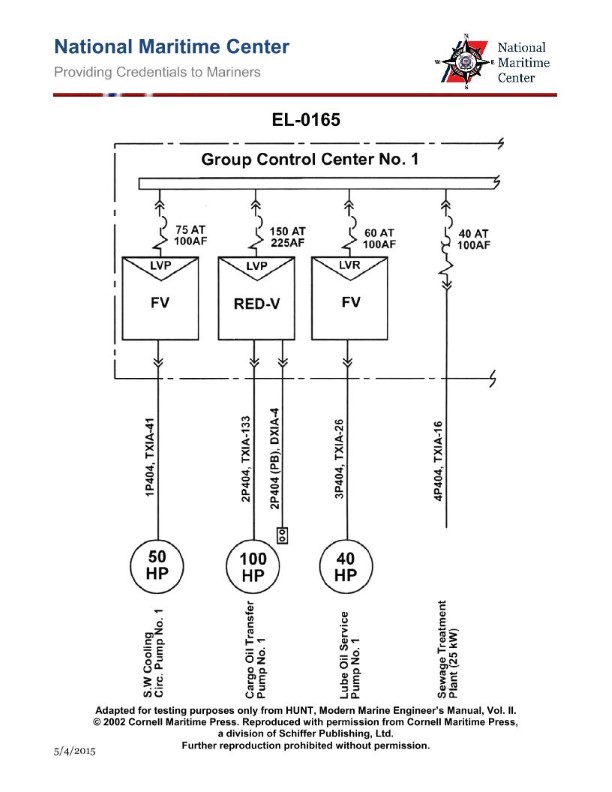

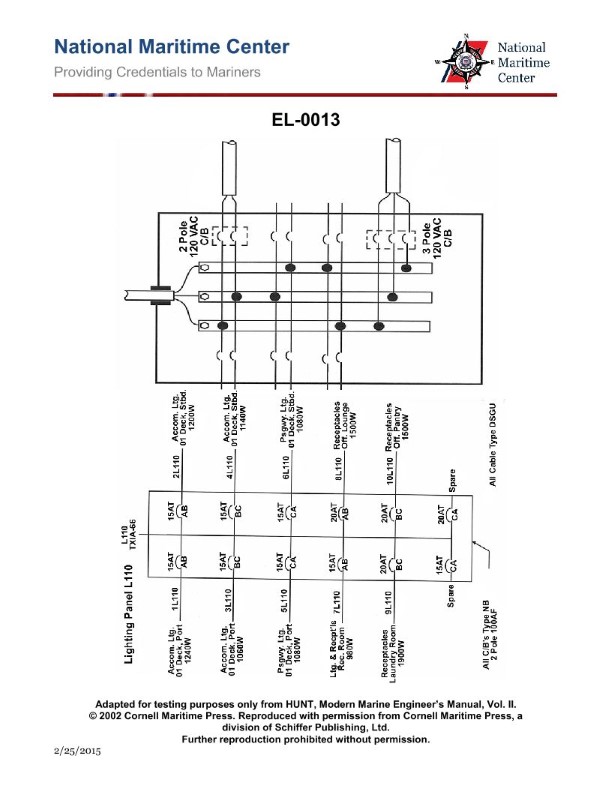

Question 29

Question: As shown in the illustration, which of the following pieces of equipment is supplied with a circuit breaker providing both overload and short-circuit protection? Illustration EL-0165

A. Cargo Oil Transfer Pump No.1

B. S.W. Cooling Circ. Pump No.1

C. Sewage Treatment Plant

D. Lube Oil Service Pump No.1